fuel pump issue !!

Discussion

Rob, isnt that the problem with the old valve in that is had a weighted ball inside and when the fuel left the tank causing vacuum the valve opened to let air in which allowed the ball moved up the tube, could it be that if the ball blocks the top part of the tube or valve and once there the vacuum would hold it in place like a suction cup and stop air from being pulled in, then the only place air gets pulled in slowly is through the filler cap until eventually the pressure regulates and the ball drops again.

This is what was happening with mine, that is why the fuel would come gushing out until the vaccuum was created, then it would trickle at a slow rate which was governed by how much air the filler cap was letting in, i assume the problem with the stock valve was that the ball inside must have been too light? it would be nice to see a diagram of how one of these things actually work, i think the stock one was literally a ball in a tube.

This is what was happening with mine, that is why the fuel would come gushing out until the vaccuum was created, then it would trickle at a slow rate which was governed by how much air the filler cap was letting in, i assume the problem with the stock valve was that the ball inside must have been too light? it would be nice to see a diagram of how one of these things actually work, i think the stock one was literally a ball in a tube.

To answer the last point first. I think the current part on my car is jamming in a vacuum position and not moving. I can leave the car for a long time in the winter after using it and then when I release the cap the vacuum is there - it doesn`t self release over time without taking off the filler cap.

I agree that if fuel did get down into the tube with a roll over valve it might get sucked back into the tank or it might not. Air could just bubble through the column of fuel. The combined function valve is a Newton VRJ6-6 which has 7/16" UNF (JIC6) male connections both ends. As it has a ball it needs to be mounted vertically and with the connection to the tank at the bottom. I guess you could fit pigtail connections to plumb it into the current tubing.

I agree that if fuel did get down into the tube with a roll over valve it might get sucked back into the tank or it might not. Air could just bubble through the column of fuel. The combined function valve is a Newton VRJ6-6 which has 7/16" UNF (JIC6) male connections both ends. As it has a ball it needs to be mounted vertically and with the connection to the tank at the bottom. I guess you could fit pigtail connections to plumb it into the current tubing.

Edited by BobE on Thursday 14th April 14:58

Edited by BobE on Thursday 14th April 14:58

R0162 said:

Is this the final verdict then with the tank connection pointing down? are you 100% on this?

Depends on what unit you`ve got. If its a roll over valve with a ball system the unit must be vertical with the connection to the tank at the bottom. If its a breather only unit using spring loaded valves then the unit doesn`t need to be vertical but the `tank arrow` should point to the tank connection - so in Simons installation the valve would be upside down relative to the Newton logo.See also my next post.....

I think I`ve decided what to do - fit both. The cost of the two units - a breather and a roll over unit plus a bit of tube and some reducing fittings is less than the combined unit plus pigtail converters. There is hopefully enough space as well in the side pod. I did a test with some plastic tubing of the correct approximate diameter bent into a `U` shape and water, and yes you can suck the liquid back up until the remaining liquid surface lines up with the top of the bend inner surface and then you suck - or blow air through the liquid. I just need to optimise the tube lengths/installation to reduce as far as possible any pressurisation problems. (If air is coming in through a petrol column it`s also likely to vaporise some of the liquid so I think that the risk of pressurising the tank isn`t high). I`ll mount the rollover unit below the breather unit - ie first in line for any petrol as that`s what it`s therefore for. (The way I think the breather valve works on it`s own may stop some petrol flow depending on the exact setting of over pressurisation valve which Demon-tweeks catalogue reckons is 0.725psi and which is therefore something like 27" head of petrol so it might be a bit marginal depending upon the exact calibration and certainly if dynamic forces are involved as well).

A final thought....If it`s a vent/breather valve fitted as standard then it`s very likely that there will always be a vacuum in the tank if the filler cap is correctly fitted and sealed. All the units I`ve found have a 5 millibar vacuum break level before the vent valve opens to allow air into the tank. So you drive the car - use fuel, the tank also heats up because of it`s location maybe/maybe not expelling some air/vapour. You then park up everything cools down and when you check the cap there`s a vacuum. Could just be normal operation.... Does anyone NEVER get a vacuum in their tank after a drive and has a correctly adjusted filler cap and no leaks in the system, (ie no smells of petrol)?

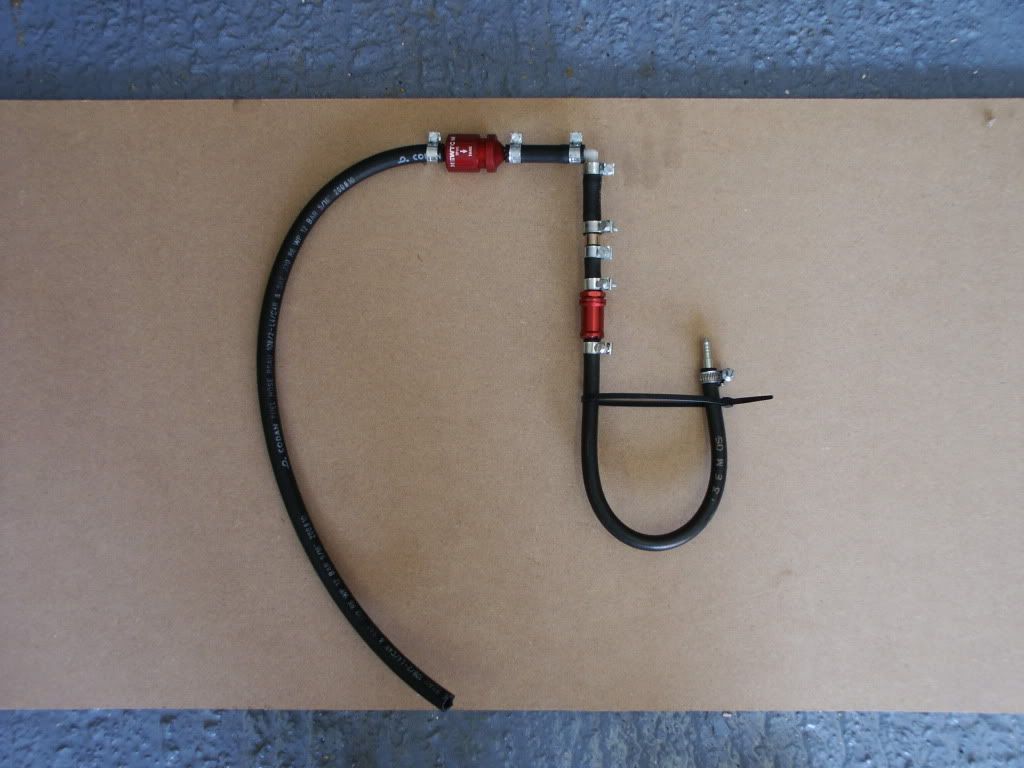

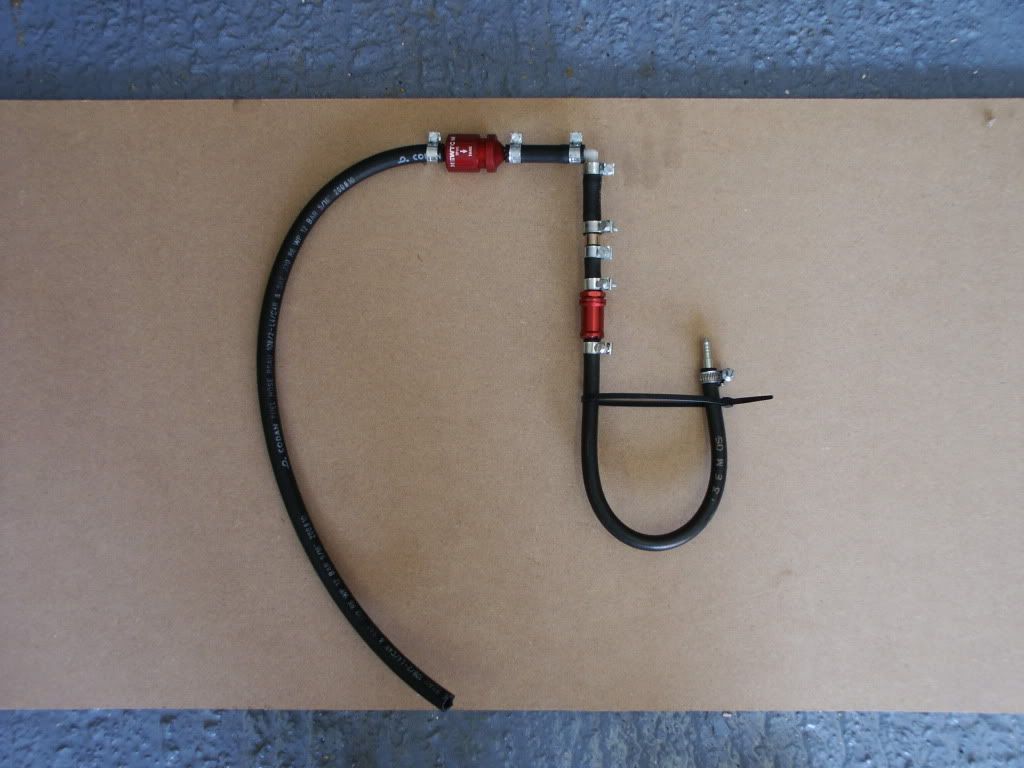

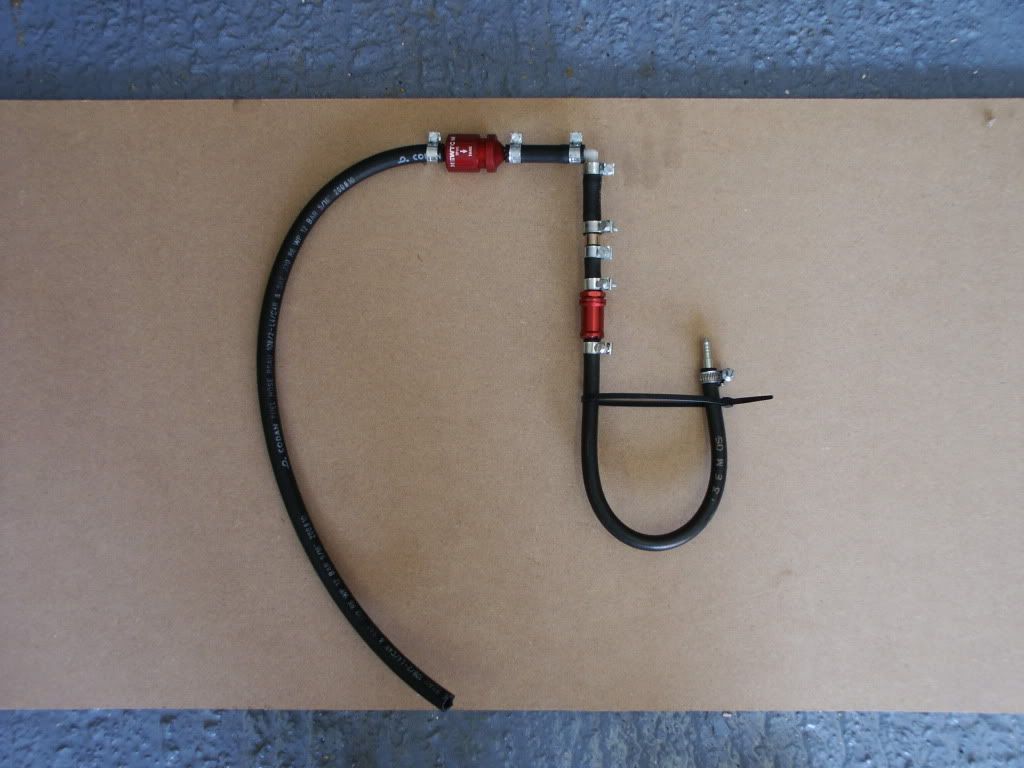

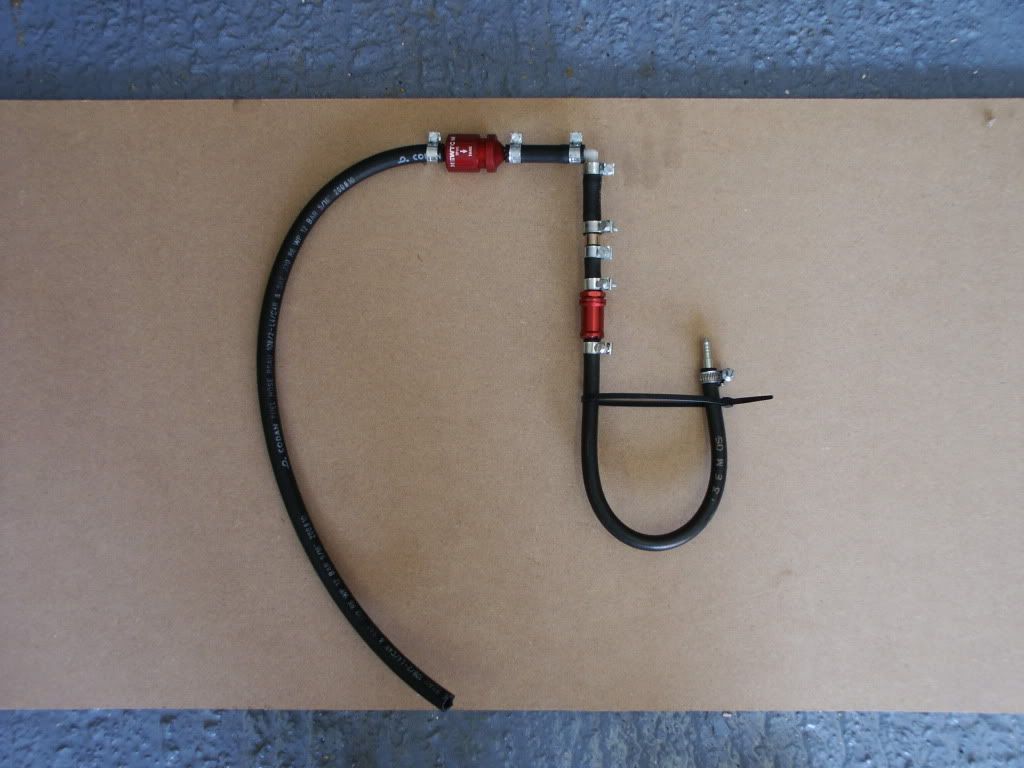

I`ve now replaced the fuel tank breather system on my car - I strongly suspected the valve was malfunctioning. Occasionaly the garage would smell of petrol and then at other times there would be a significant vacuum in the tank - to the point it sometimes made it slightly difficult to remove the filler cap. (When I dismantled the Ford valve system fitted there was some evidence of malfunction - although all breather systems will mean a slight vacuum can be drawn in the tank as fuel is used). The current Ford part is both a roll over valve - to prevent fuel loss if the car rolls over - and a breather system to allow air into the tank as fuel is used and allow over pressure to be released, for instance due to the tank heating up. I wanted both functions but decided not to use another Ford part - which to give an economical solution meant two seperate valves. The assembly with the new parts is as shown here:

The connection at the top right is a 6mm/6mm connector to the tube that comes from the tank filler connection. There is then a loop of tube to a roll over valve that must be mounted vertically and in a particular orientation with the connection to the tank at the bottom. Then another short length of tube to a 6mm/8mm converter connector and then again a short run of tube to a 90 degree acetal plastic elbow. This then links to a breather valve that `points` back to the tank. (This valve doesn`t need to be mounted vertically). There is then a length of tube that will exit the car at sill level. The assembly is slightly complicated by the use of both 6mm and 8mm connections/tubing. The whole assembly is then foam wrapped to prevent rattles:

Then it is fitted to the car and held in place with strategically placed cable ties ensuring the roll over valve is vertical. The breather outlet tube is taken over the side pod air inlets:

Finally the tube exits through a slightly larger hole in the aluminium floor, (8mm I/D versus 6mm I/D tubing). This hole size increase takes a few seconds if you`ve got a conical sheel metal `drill bit`, There is a final piece of foam to stop the tube knocking against the car body and I`ve put small cable tie wraps either side of the aluminium floor to hold the tube in place.

Job done! The various panels to gain access to the valve area are easier to remove if you take off the nearside rear wheel. I`ll let you know how I get on with this mod.

The connection at the top right is a 6mm/6mm connector to the tube that comes from the tank filler connection. There is then a loop of tube to a roll over valve that must be mounted vertically and in a particular orientation with the connection to the tank at the bottom. Then another short length of tube to a 6mm/8mm converter connector and then again a short run of tube to a 90 degree acetal plastic elbow. This then links to a breather valve that `points` back to the tank. (This valve doesn`t need to be mounted vertically). There is then a length of tube that will exit the car at sill level. The assembly is slightly complicated by the use of both 6mm and 8mm connections/tubing. The whole assembly is then foam wrapped to prevent rattles:

Then it is fitted to the car and held in place with strategically placed cable ties ensuring the roll over valve is vertical. The breather outlet tube is taken over the side pod air inlets:

Finally the tube exits through a slightly larger hole in the aluminium floor, (8mm I/D versus 6mm I/D tubing). This hole size increase takes a few seconds if you`ve got a conical sheel metal `drill bit`, There is a final piece of foam to stop the tube knocking against the car body and I`ve put small cable tie wraps either side of the aluminium floor to hold the tube in place.

Job done! The various panels to gain access to the valve area are easier to remove if you take off the nearside rear wheel. I`ll let you know how I get on with this mod.

The honest answer is I don`t know for certain. My pump is always noisy but it`s worst when I first start the engine and then it gradually reduces but I`m always aware of it when the car is ticking over etc. I guess if you did draw a high vacuum in the tank because the valve had jammed shut and then you used a lot of fuel the pump might start to cavitate which could increase noise and wear. I would also think you`d perhaps notice some fuel starvation issues as well. Don`t know for sure...

BobE said:

The honest answer is I don`t know for certain. My pump is always noisy but it`s worst when I first start the engine and then it gradually reduces but I`m always aware of it when the car is ticking over etc. I guess if you did draw a high vacuum in the tank because the valve had jammed shut and then you used a lot of fuel the pump might start to cavitate which could increase noise and wear. I would also think you`d perhaps notice some fuel starvation issues as well. Don`t know for sure...

Pump noise does not change when I remove breather pipe and is clear when I blow through it.Bondy

BobE said:

I`ve now replaced the fuel tank breather system on my car - I strongly suspected the valve was malfunctioning. Occasionaly the garage would smell of petrol and then at other times there would be a significant vacuum in the tank - to the point it sometimes made it slightly difficult to remove the filler cap. (When I dismantled the Ford valve system fitted there was some evidence of malfunction - although all breather systems will mean a slight vacuum can be drawn in the tank as fuel is used). The current Ford part is both a roll over valve - to prevent fuel loss if the car rolls over - and a breather system to allow air into the tank as fuel is used and allow over pressure to be released, for instance due to the tank heating up. I wanted both functions but decided not to use another Ford part - which to give an economical solution meant two seperate valves. The assembly with the new parts is as shown here:

The connection at the top right is a 6mm/6mm connector to the tube that comes from the tank filler connection. There is then a loop of tube to a roll over valve that must be mounted vertically and in a particular orientation with the connection to the tank at the bottom. Then another short length of tube to a 6mm/8mm converter connector and then again a short run of tube to a 90 degree acetal plastic elbow. This then links to a breather valve that `points` back to the tank. (This valve doesn`t need to be mounted vertically). There is then a length of tube that will exit the car at sill level. The assembly is slightly complicated by the use of both 6mm and 8mm connections/tubing. The whole assembly is then foam wrapped to prevent rattles:

Then it is fitted to the car and held in place with strategically placed cable ties ensuring the roll over valve is vertical. The breather outlet tube is taken over the side pod air inlets:

Finally the tube exits through a slightly larger hole in the aluminium floor, (8mm I/D versus 6mm I/D tubing). This hole size increase takes a few seconds if you`ve got a conical sheel metal `drill bit`, There is a final piece of foam to stop the tube knocking against the car body and I`ve put small cable tie wraps either side of the aluminium floor to hold the tube in place.

Job done! The various panels to gain access to the valve area are easier to remove if you take off the nearside rear wheel. I`ll let you know how I get on with this mod.

I don't mean to be cheeky but from my research (manufacturers websites not DT site) you seem to have installed two devices (one Newton and one Mocal? right?)that both do breather (air in/vapour out) and fuel escape prevention?? The only difference I can see is that the Mocal needs vertical mounting whereas the Newton is not bothered?

The connection at the top right is a 6mm/6mm connector to the tube that comes from the tank filler connection. There is then a loop of tube to a roll over valve that must be mounted vertically and in a particular orientation with the connection to the tank at the bottom. Then another short length of tube to a 6mm/8mm converter connector and then again a short run of tube to a 90 degree acetal plastic elbow. This then links to a breather valve that `points` back to the tank. (This valve doesn`t need to be mounted vertically). There is then a length of tube that will exit the car at sill level. The assembly is slightly complicated by the use of both 6mm and 8mm connections/tubing. The whole assembly is then foam wrapped to prevent rattles:

Then it is fitted to the car and held in place with strategically placed cable ties ensuring the roll over valve is vertical. The breather outlet tube is taken over the side pod air inlets:

Finally the tube exits through a slightly larger hole in the aluminium floor, (8mm I/D versus 6mm I/D tubing). This hole size increase takes a few seconds if you`ve got a conical sheel metal `drill bit`, There is a final piece of foam to stop the tube knocking against the car body and I`ve put small cable tie wraps either side of the aluminium floor to hold the tube in place.

Job done! The various panels to gain access to the valve area are easier to remove if you take off the nearside rear wheel. I`ll let you know how I get on with this mod.

Wow this thread was not bedtime reading material, perhaps taking things a bit to far here guys? id like to add my less anal take on things  don't take it personally though!

don't take it personally though!

If my valve ever fails I'll remove it, if the car rolls over chances are it'll be totalled and I won't care if fuel leaks, its not like the movies where the car would go kaboom! if I was trapped in the car following a rollover I'd most likely be dead from the accident. pumps generally make noise so at least I know it's working, they all seem to do it in nobles.

Bed time... Yes I've had a terrible day

Graham

don't take it personally though!

don't take it personally though!If my valve ever fails I'll remove it, if the car rolls over chances are it'll be totalled and I won't care if fuel leaks, its not like the movies where the car would go kaboom! if I was trapped in the car following a rollover I'd most likely be dead from the accident. pumps generally make noise so at least I know it's working, they all seem to do it in nobles.

Bed time... Yes I've had a terrible day

Graham

Rob_W said:

I don't mean to be cheeky but from my research (manufacturers websites not DT site) you seem to have installed two devices (one Newton and one Mocal? right?)that both do breather (air in/vapour out) and fuel escape prevention?? The only difference I can see is that the Mocal needs vertical mounting whereas the Newton is not bothered?

No that`s not the case. The roll over device, which could be Mocal or Newton as they look the same, is not a breather. Inside the unit there are two balls - one plastic and one steel. Normally they are both held down by gravity away from a seat. If petrol enters the unit from the bottom the plastic ball floats up and blocks the outlet by coming into contact with the seat. If the car rolls over the steel ball lies on top of the plastic one holding it against the seat. In normal use air and fuel vapour are free to move in and out of the unit. The second breather valve has two sensitive valves normally held closed by spring pressure. If a vacuum is drawn in the tank they open to let air in - if the tank pressurises they again open to allow vapour out. The opening pressures for each function are slightly different hence the need to orientate the valve correctly. The valve setting is such that any significant weight of fuel could cause the valves to open and let fuel come out. The current Ford part fitted to Nobles does both functions. There is a heavy ball that falls down on a seat the block off fuel if the car turns over and there is a double valve arrangement with a rolling diaphram to give the breather function - mounted in a seperate chamber above the ball system.hollowpockets said:

Wow this thread was not bedtime reading material, perhaps taking things a bit to far here guys? id like to add my less anal take on things  don't take it personally though!

don't take it personally though!

If my valve ever fails I'll remove it, if the car rolls over chances are it'll be totalled and I won't care if fuel leaks, its not like the movies where the car would go kaboom! if I was trapped in the car following a rollover I'd most likely be dead from the accident. pumps generally make noise so at least I know it's working, they all seem to do it in nobles.

Bed time... Yes I've had a terrible day

Graham

I rolled a car on track once and ended upside down (pictures in magazines somewere it was a cossie) a little fuel leaked out but not loads... I can tell you if it had been gushing out it would have ignited and I would be dead now. don't take it personally though!

don't take it personally though!If my valve ever fails I'll remove it, if the car rolls over chances are it'll be totalled and I won't care if fuel leaks, its not like the movies where the car would go kaboom! if I was trapped in the car following a rollover I'd most likely be dead from the accident. pumps generally make noise so at least I know it's working, they all seem to do it in nobles.

Bed time... Yes I've had a terrible day

Graham

Gassing Station | Noble | Top of Page | What's New | My Stuff