E30 M52-swapped Trackday Car

Discussion

So, now it's time for the Fabia daily to get some attention.

It's been loosing a bit of coolant over the past couple of months. No biggie - down to a tiny leak in the radiator. But as it was due a full service and cambelt change in a few weeks anyway, got it booked in. Not a small bill - cambelt, water pump, routine service + radiator and anti-freeze - but fingers crossed it'll do me another few years yet

The local VAG specialist does all the work on the flying banana - because I can't afford to have it off the road for very long, should I manage to screw something up or have to wait for parts. Small price to pay in the long run

It's been loosing a bit of coolant over the past couple of months. No biggie - down to a tiny leak in the radiator. But as it was due a full service and cambelt change in a few weeks anyway, got it booked in. Not a small bill - cambelt, water pump, routine service + radiator and anti-freeze - but fingers crossed it'll do me another few years yet

The local VAG specialist does all the work on the flying banana - because I can't afford to have it off the road for very long, should I manage to screw something up or have to wait for parts. Small price to pay in the long run

Hi Lewis, I've been following the thread for a while now, glad to see it looks like you're finally ironing out all the niggles with the car. It's a shame I couldn't make it to Blyton, ruddy house seems to eat up more than its fair share of time and money!!

Hopefully we can catch up soon as I'd like to see the car in the flesh. I'll keep an eye out for any mention of upcoming track days and maybe see you there.

Al.

Hopefully we can catch up soon as I'd like to see the car in the flesh. I'll keep an eye out for any mention of upcoming track days and maybe see you there.

Al.

Hi Steve. This is what you need to be looking for

The '067' on the end denotes it as a 3-turn rack. I think most racks are Part no. 32136755068 which is a 3.2 or 3.4 turn rack, I forget.

Weight wise - my thoughts will be invalidated somewhat by the E36 5-stud setup I have up front. This puts the pivot point for the track rod end closer to the stub axle than on an E30 strut, which in turns lessens feedback and increases weight slightly compared with fitting the rack to a regular E30. Still, it feels good to me Certainly turns half a lock of 'oppo' on the E30 rack into a more manageable 'dab of oppo'. Don't find myself wanting more feedback and the weight is nice.

Certainly turns half a lock of 'oppo' on the E30 rack into a more manageable 'dab of oppo'. Don't find myself wanting more feedback and the weight is nice.

Well impressed by the way that RX8 of your's and Matt's hung on in the corners Al! Flat and properly planted. Struggled to stay put in the slidey leather passenger seat though! Shame you couldn't make it, it was a good day all round, save for Rick's engine failure - even then, he was still smiling.

I'm sure we'll get a chance to catch up soon. Will almost certainly be at Frank's next Blyton day and hope to get another day or two in between.

The '067' on the end denotes it as a 3-turn rack. I think most racks are Part no. 32136755068 which is a 3.2 or 3.4 turn rack, I forget.

Weight wise - my thoughts will be invalidated somewhat by the E36 5-stud setup I have up front. This puts the pivot point for the track rod end closer to the stub axle than on an E30 strut, which in turns lessens feedback and increases weight slightly compared with fitting the rack to a regular E30. Still, it feels good to me

Certainly turns half a lock of 'oppo' on the E30 rack into a more manageable 'dab of oppo'. Don't find myself wanting more feedback and the weight is nice.

Certainly turns half a lock of 'oppo' on the E30 rack into a more manageable 'dab of oppo'. Don't find myself wanting more feedback and the weight is nice. Well impressed by the way that RX8 of your's and Matt's hung on in the corners Al! Flat and properly planted. Struggled to stay put in the slidey leather passenger seat though! Shame you couldn't make it, it was a good day all round, save for Rick's engine failure - even then, he was still smiling.

I'm sure we'll get a chance to catch up soon. Will almost certainly be at Frank's next Blyton day and hope to get another day or two in between.

Some updates on work done this summer. Not a lot, all considered! No trackdays and a 2nd house tying up funds. But now that's gone, I've been cracking on. First up was fitting the Mishimoto S50 rad I treated myself to on my birthday...

...starting with a spanking expansion bottle from BMW. Prices are starting to take the pee a bit though, this was best part of £80 with the level sensor blanking cap and the mounting bracket!

The fan fitting using some little ally brackets I knocked up. It's so much nicer having a garage and proper work bench at home now, it means the various bits and pieces I can throw together are much tidier.

Ignore the croc clips, they were just test wires to make sure I knew which way to wire it up to get it spinning the correct way!

All assembled and running - the return hose routing isn't ideal, but it'll pass for the trackday on the 9th Oct, I can sort it out properly later. Really need to get rid of the factory M40 airbox bracket too, it's really getting in the way! I've been avoiding doing that because I know it will mean paint

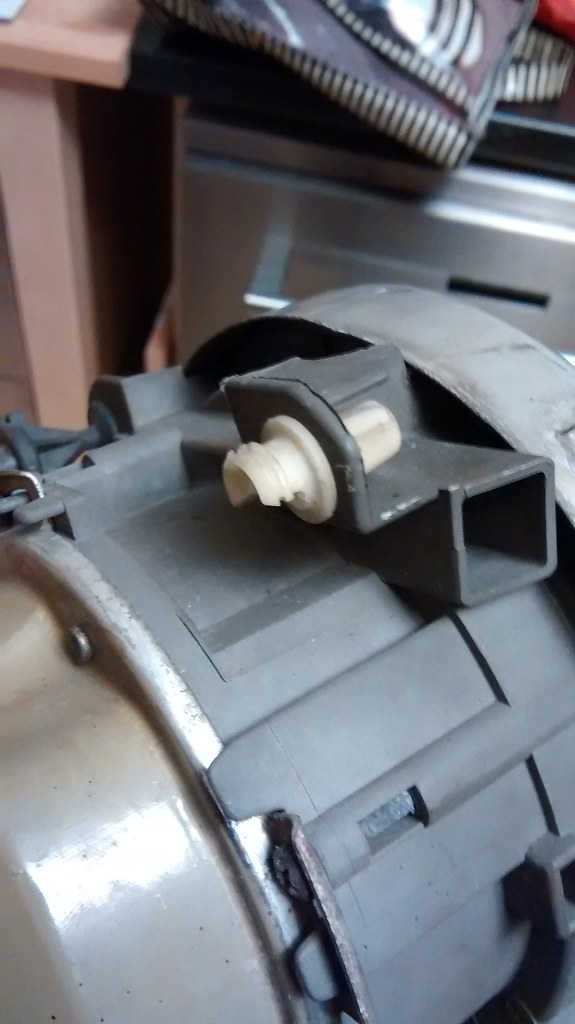

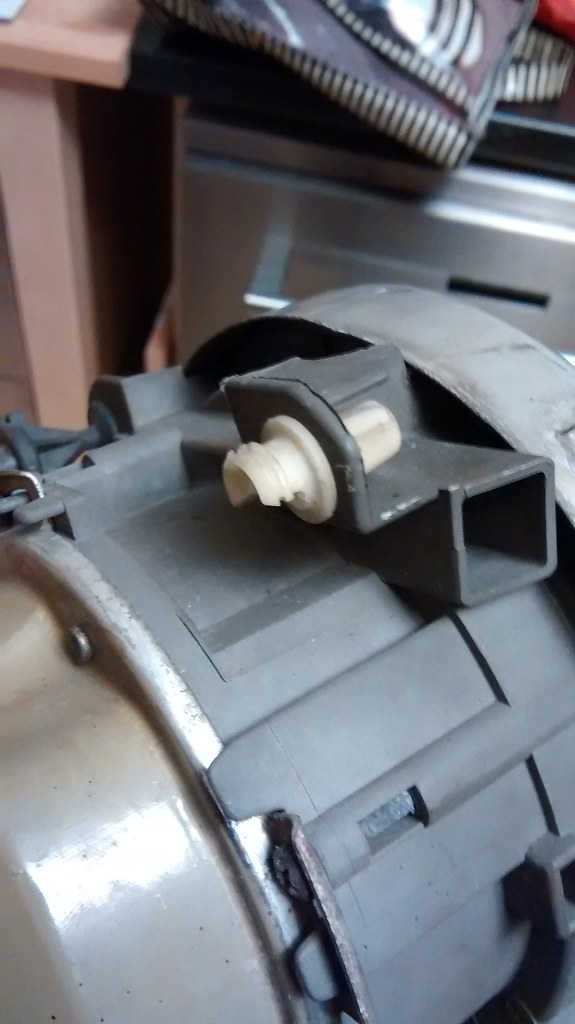

I also fixed these cracked headlight adjust bushes! Been giving me minor MOT issues for the past two years, was about time I fixed it properly. Flew through this time, with no advisories

Then this week, I got this delivered! A running, albeit roughly, M54B30 engine complete with all ancillaries for, well...rather less than the £300-£400 people are asking on Ebay for an M54B30 set of crank, rods and pistons. Hopefully I'll be able to recoup almost all of the engine purchase price by selling on the ancillaries, intake manifold, exhaust manifold, head, block, sump etc on Ebay.

So the plan is, take my time and put together an M52B30. Next stage of the learning process I guess...build an engine. How hard can it be? :?

...starting with a spanking expansion bottle from BMW. Prices are starting to take the pee a bit though, this was best part of £80 with the level sensor blanking cap and the mounting bracket!

The fan fitting using some little ally brackets I knocked up. It's so much nicer having a garage and proper work bench at home now, it means the various bits and pieces I can throw together are much tidier.

Ignore the croc clips, they were just test wires to make sure I knew which way to wire it up to get it spinning the correct way!

All assembled and running - the return hose routing isn't ideal, but it'll pass for the trackday on the 9th Oct, I can sort it out properly later. Really need to get rid of the factory M40 airbox bracket too, it's really getting in the way! I've been avoiding doing that because I know it will mean paint

I also fixed these cracked headlight adjust bushes! Been giving me minor MOT issues for the past two years, was about time I fixed it properly. Flew through this time, with no advisories

Then this week, I got this delivered! A running, albeit roughly, M54B30 engine complete with all ancillaries for, well...rather less than the £300-£400 people are asking on Ebay for an M54B30 set of crank, rods and pistons. Hopefully I'll be able to recoup almost all of the engine purchase price by selling on the ancillaries, intake manifold, exhaust manifold, head, block, sump etc on Ebay.

So the plan is, take my time and put together an M52B30. Next stage of the learning process I guess...build an engine. How hard can it be? :?

I can foresee a road trip coming up, I do have an engine stand somewhere that's not being used at this moment in time Motorhole

Given the car's no slouch even now, this will put it into M3 territory? It's certainly going to be a handful!

Would suggest you go for a underdrive pulley set on it too.

Given the car's no slouch even now, this will put it into M3 territory? It's certainly going to be a handful!

Would suggest you go for a underdrive pulley set on it too.

Sf_Manta said:

I can foresee a road trip coming up, I do have an engine stand somewhere that's not being used at this moment in time Motorhole

Given the car's no slouch even now, this will put it into M3 territory? It's certainly going to be a handful!

Would suggest you go for a underdrive pulley set on it too.

Well if all goes well at Blyton on Friday, I may sign myself up for the BMW Car Club Trackday at Oulton Park on 6th November. If that happens, you're welcome to tag along.

Given the car's no slouch even now, this will put it into M3 territory? It's certainly going to be a handful!

Would suggest you go for a underdrive pulley set on it too.

Have already stripped the loom and most of the ancillaries off the M54B30 now, can't take it much further until I get a stand. Was going to go out and buy one, they arn't too expensive

Besides, there's no rush for this. I just want to get the lump cleared out the garage and get all the bits I want from it packaged and boxed up. I also have an M50 filter housing knocking about for fitting a sandwich plate for an oil cooler too.

Besides, there's no rush for this. I just want to get the lump cleared out the garage and get all the bits I want from it packaged and boxed up. I also have an M50 filter housing knocking about for fitting a sandwich plate for an oil cooler too. An under drive pulley set - well I really only need one for the PAS pump, as alternator aside, that's the only other thing being run off the aux belt. But not a bad idea

You will easily recoup the cost on the complete engine, keeping the bits you need. I used a non-running head gasket failure M54B30 for the internal parts, and sold the rest/ancillaries for more than double what I paid for the engine in the first place.... which basically paid for the rings, bearings and other bits.

Well, all went well at Blyton. Drove over the night before without issue, good night's sleep in (complete fluke this!) the honeymoon suite at the Beckett Arms and then to the track!

Took Mrs Motorhole with me this time, so she got her first experience in the passenger seat. Her cousin and her partner turned up later in the morning too so with them, and the beautiful weather, none of the non-petrolheads got bored whilst I lapped to my heart's content. I did 8 sessions in all...I think...and the car proved reliable once more, then got me home too without any issues.

Still gets a bit warm when given the beans, but I have a few ideas to improve that in the meantime - I'm planning an oil cooler for the M54B30 - the lack thereof now perhaps being one of the issues. But it never stopped me having a great day!

I've started stripping the M54B30 and have already sold a couple of bits. Looks like the intake boots/vacuum hoses have seen better days and the water pump bearings are a bit rattly. Plugs are all sooted up too. But provided rich and rough is the extent of the issues, hopefully the crank/conrods/pistons will be good. Picked up a Clarke engine stand locally for £34 too, so once I've cracked the crank bolt, up it'll go and the real work will commence.

Regarding chassis developments - I'm looking to get a set of custom tubular wishbones made up. Non-adjustable and that will take OEM ball-joints. These will be shaped to my own spec to address some of the caster/camber issues inherent with the E36 M3 5-stud conversion whilst reducing unsprung weight. Why go to so much bother? Well, I like the performance of the brakes (strong and consistent) - and the affordable associated OEM consumables. I like the availability of E36 parts compared to E30. The bigger wheel bearings are more durable. And the expense of a pair of custom arms - though not insignificant - is still going to be rather less than a big brake kit and different wheels!

Next will be a set of coilovers more suited to track work than the Koni stuff I currently have. I'll also make sure to get the 'M' spec stuff with the roll bar pickups on the strut for better roll resistance. I think GAZ seem to fit the bill for me with regards to budget and ability to customise. Besides, I doubt my driving ability would do justice to the money spent on Ohlins, Nitrons or AST! And by that time, hopefully the M54B30 will be in and running...

Took Mrs Motorhole with me this time, so she got her first experience in the passenger seat. Her cousin and her partner turned up later in the morning too so with them, and the beautiful weather, none of the non-petrolheads got bored whilst I lapped to my heart's content. I did 8 sessions in all...I think...and the car proved reliable once more, then got me home too without any issues.

Still gets a bit warm when given the beans, but I have a few ideas to improve that in the meantime - I'm planning an oil cooler for the M54B30 - the lack thereof now perhaps being one of the issues. But it never stopped me having a great day!

I've started stripping the M54B30 and have already sold a couple of bits. Looks like the intake boots/vacuum hoses have seen better days and the water pump bearings are a bit rattly. Plugs are all sooted up too. But provided rich and rough is the extent of the issues, hopefully the crank/conrods/pistons will be good. Picked up a Clarke engine stand locally for £34 too, so once I've cracked the crank bolt, up it'll go and the real work will commence.

Regarding chassis developments - I'm looking to get a set of custom tubular wishbones made up. Non-adjustable and that will take OEM ball-joints. These will be shaped to my own spec to address some of the caster/camber issues inherent with the E36 M3 5-stud conversion whilst reducing unsprung weight. Why go to so much bother? Well, I like the performance of the brakes (strong and consistent) - and the affordable associated OEM consumables. I like the availability of E36 parts compared to E30. The bigger wheel bearings are more durable. And the expense of a pair of custom arms - though not insignificant - is still going to be rather less than a big brake kit and different wheels!

Next will be a set of coilovers more suited to track work than the Koni stuff I currently have. I'll also make sure to get the 'M' spec stuff with the roll bar pickups on the strut for better roll resistance. I think GAZ seem to fit the bill for me with regards to budget and ability to customise. Besides, I doubt my driving ability would do justice to the money spent on Ohlins, Nitrons or AST! And by that time, hopefully the M54B30 will be in and running...

Havn't updated this for a while, but progress has been slow yet omnipresent.

Car hasn't been out since October, for no other reason than I've been a bit busy. Though this week I'm going to change the brake fluid and see what I can do with rad airflow before my next track day on 18th March.

The M52B30 build - well I have some photos of this, though it's more of an M52 stripdown at the moment! I've sold off most of the M54 engine now, so at it stands, the crank, rods, pistons and intake cam have cost me about £30. Still got the block, head and a few other bits - sensors etc - for sale so I will do better than break even eventually.

Then for £200, I bought an M52B25 nikasil lined block and a separate steel-lined block to build it all into.

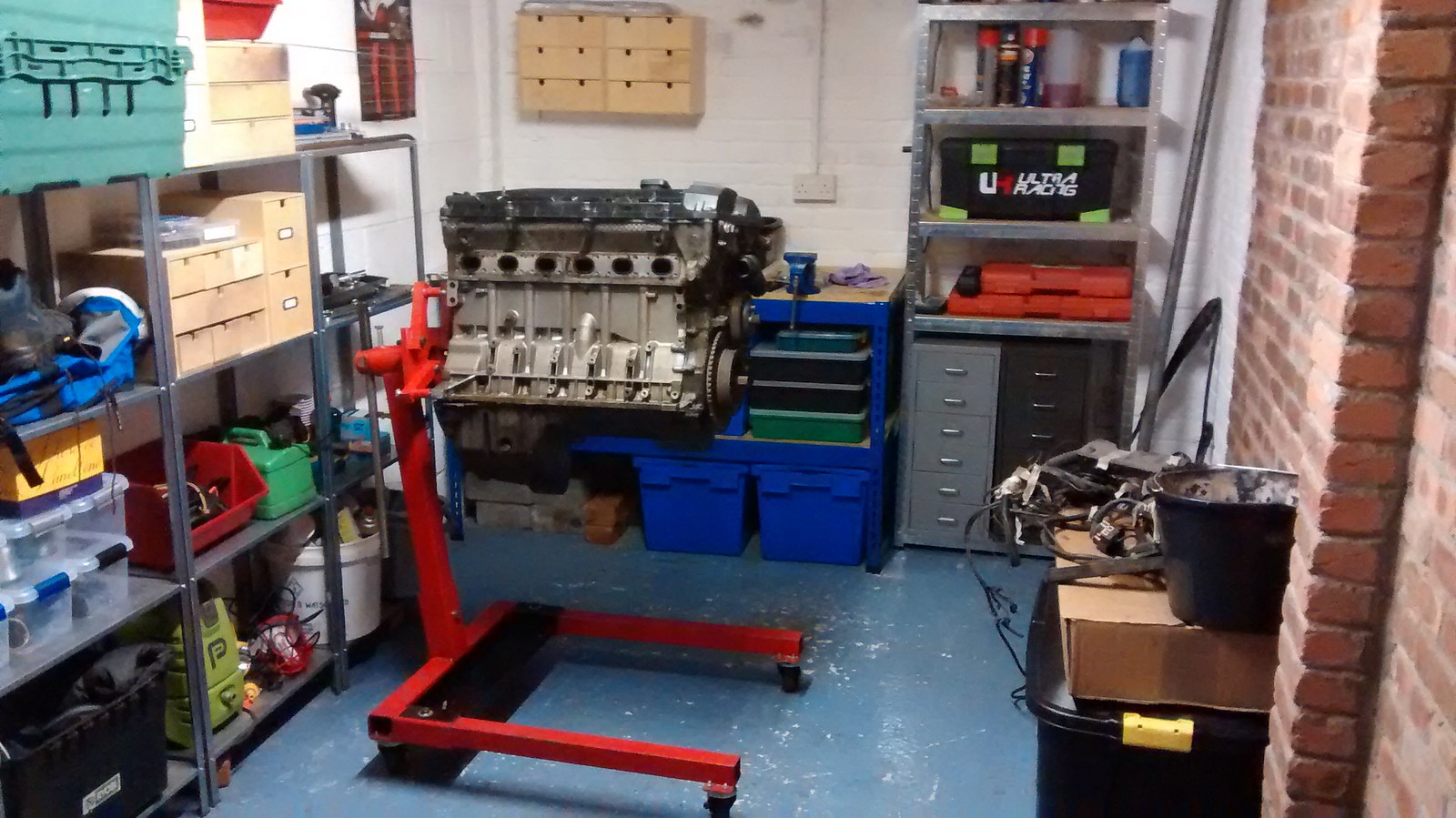

M52 engine on the stand

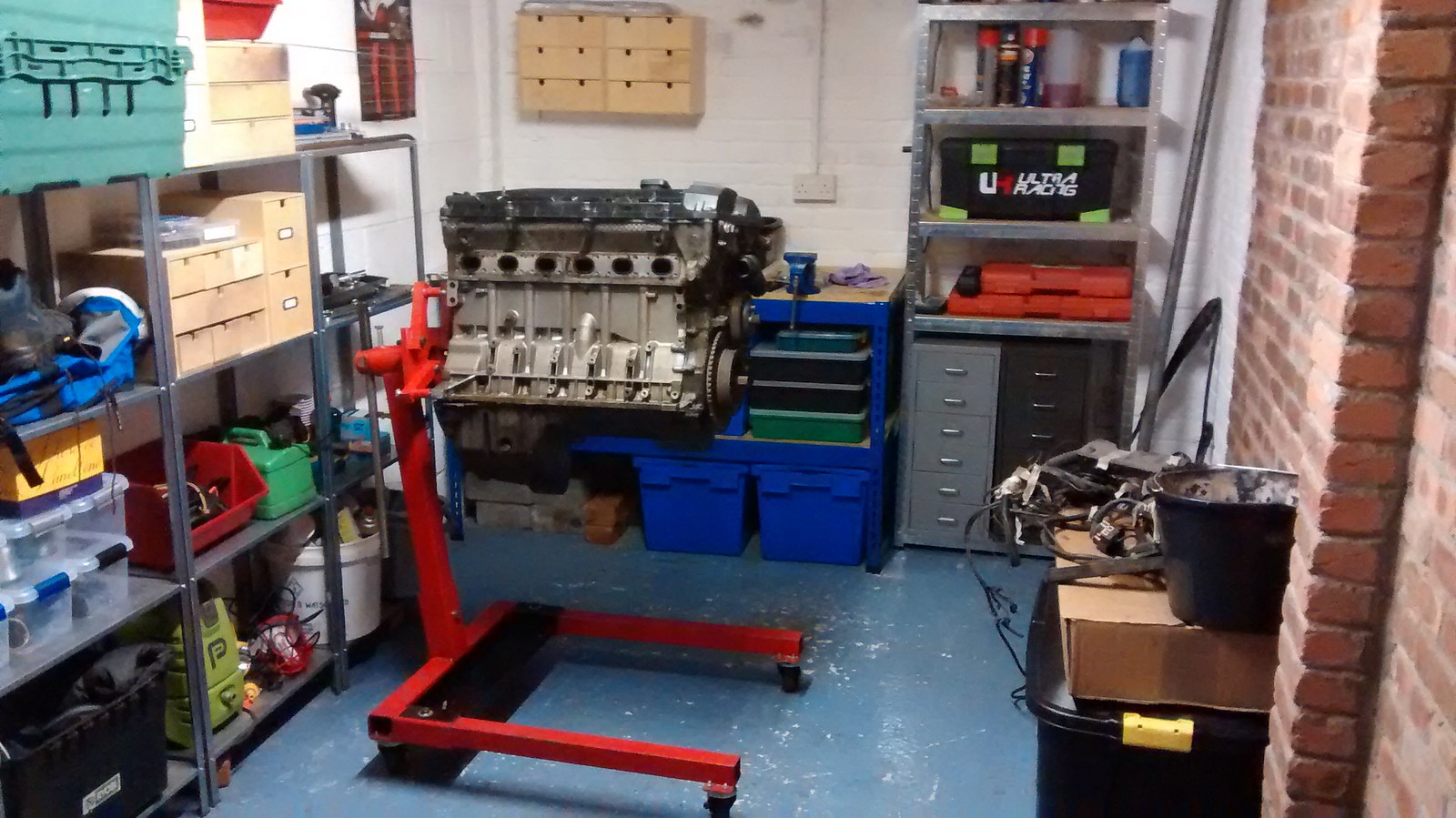

M52 steel-lined block under the bench

I then set about removing the loom and attached parts then collecting bits and tidying/cleaning the garage for preparation.

Including this little bad boy so I can fit an oil cooler! I currently have a 16-row cooler and thermostat on the way.

And pretty much since then, I've been dismantling, cleaning and stowing! I figured that if I have all the bits ready to go, the build itself should be fairly hassle free and the 'clean' engine will be open for the minimum amount of time. A 4-day weekend should be enough time for a first time to put an engine together right!? :roll:

One question if anyone can help though - basically am I best using assembly grease on cam/crank journals or just using whatever mineral oil I'll be using to break the engine in with? Speaking of which - any recommendations on that front?

So far the M52 cylinder head is pretty much dismantled with everything cleaned up save for the exhaust lifters ( ). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

Car hasn't been out since October, for no other reason than I've been a bit busy. Though this week I'm going to change the brake fluid and see what I can do with rad airflow before my next track day on 18th March.

The M52B30 build - well I have some photos of this, though it's more of an M52 stripdown at the moment! I've sold off most of the M54 engine now, so at it stands, the crank, rods, pistons and intake cam have cost me about £30. Still got the block, head and a few other bits - sensors etc - for sale so I will do better than break even eventually.

Then for £200, I bought an M52B25 nikasil lined block and a separate steel-lined block to build it all into.

M52 engine on the stand

M52 steel-lined block under the bench

I then set about removing the loom and attached parts then collecting bits and tidying/cleaning the garage for preparation.

Including this little bad boy so I can fit an oil cooler! I currently have a 16-row cooler and thermostat on the way.

And pretty much since then, I've been dismantling, cleaning and stowing! I figured that if I have all the bits ready to go, the build itself should be fairly hassle free and the 'clean' engine will be open for the minimum amount of time. A 4-day weekend should be enough time for a first time to put an engine together right!? :roll:

One question if anyone can help though - basically am I best using assembly grease on cam/crank journals or just using whatever mineral oil I'll be using to break the engine in with? Speaking of which - any recommendations on that front?

So far the M52 cylinder head is pretty much dismantled with everything cleaned up save for the exhaust lifters (

). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

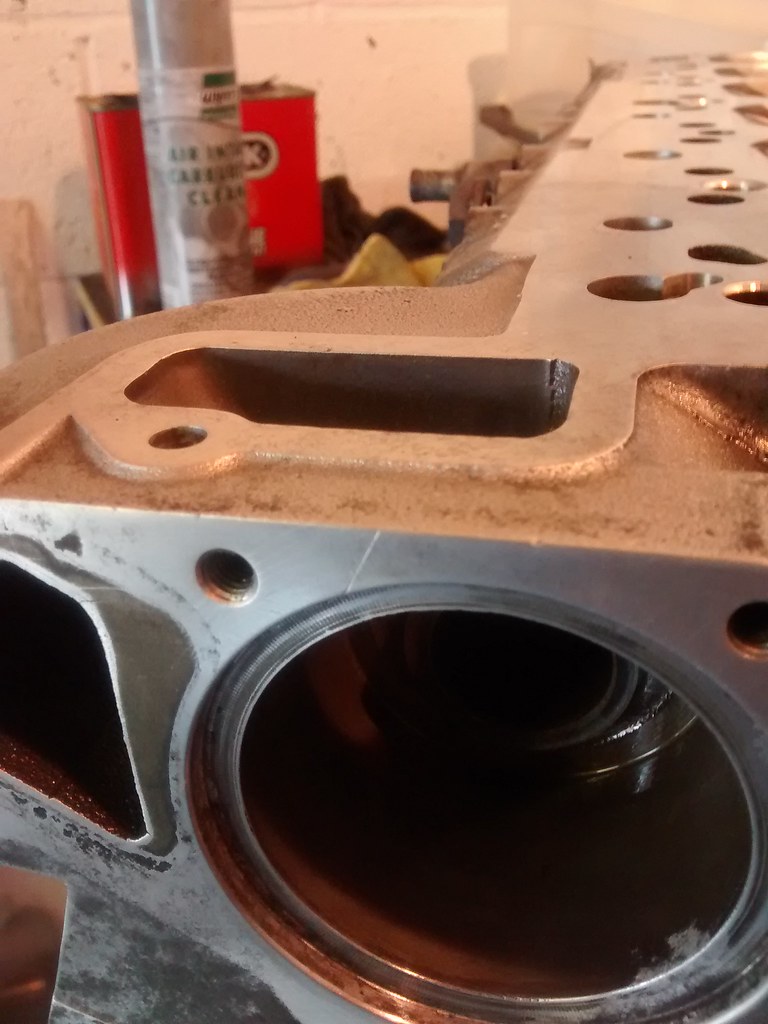

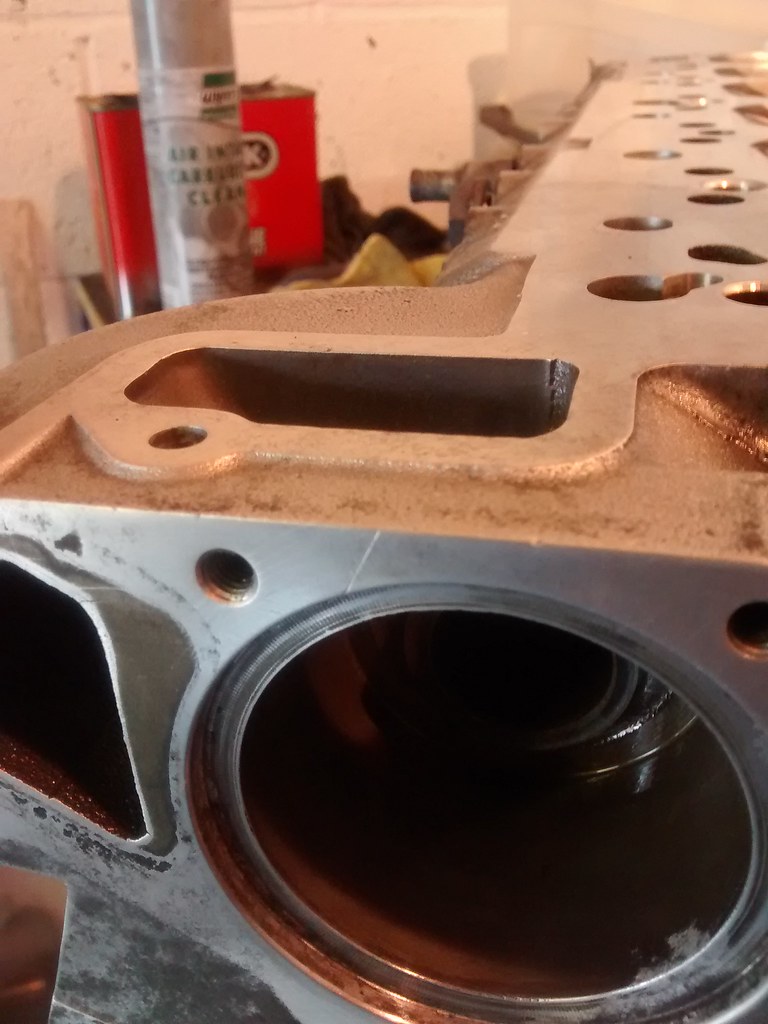

So yesterday I got on with cleaning up the cylinder head. Lots of labour and now I have a stiff right arm from...er...all the reciprocating hand actions. Still...although it's not perfect, I'm fairly happy with the results.

It started looking something like this.

Started with a good soaking in Gunk natural green then a thorough going over with a pressure washer. Then I went to work on the various gasket surfaces, ports etc.

Head gasket surface - began (very, very carefully!) with a sharp Stanley knife blade. Then lots and lots of work with an ultra-fine sanding sponge and wd40 - same in the chambers, taking care to avoid the valve seats. Using a straight edge and feeler gauges, the head comes out nice and flat.

Other gasket surfaces got the same sponge and wd40 treatment. Then to make sure I got all the residual crap out of the head, it got another good soaking in Gunk green and another blast with the pressure washer, taking care to clear out all the galleries and ports. Let it drain, some heat gun action then some oil on parts liable to corrode, job done!

One slight issue - there appears to be a scratch on the gasket surface for the thermostat housing. It's just about deep enough to catch a nail in - is this likely to cause an issue as is? If so, what's the best course of action?

Today, it's back to the car for trackday prep as I'm at Blyton on Friday. After that I need to think about getting all the pistons cleaned up so I can drop them off with the block and M54 intake cam at the machine shop and while all that's being done, I'll get on with putting stem seals, valve, springs etc back into the head

It started looking something like this.

Started with a good soaking in Gunk natural green then a thorough going over with a pressure washer. Then I went to work on the various gasket surfaces, ports etc.

Head gasket surface - began (very, very carefully!) with a sharp Stanley knife blade. Then lots and lots of work with an ultra-fine sanding sponge and wd40 - same in the chambers, taking care to avoid the valve seats. Using a straight edge and feeler gauges, the head comes out nice and flat.

Other gasket surfaces got the same sponge and wd40 treatment. Then to make sure I got all the residual crap out of the head, it got another good soaking in Gunk green and another blast with the pressure washer, taking care to clear out all the galleries and ports. Let it drain, some heat gun action then some oil on parts liable to corrode, job done!

One slight issue - there appears to be a scratch on the gasket surface for the thermostat housing. It's just about deep enough to catch a nail in - is this likely to cause an issue as is? If so, what's the best course of action?

Today, it's back to the car for trackday prep as I'm at Blyton on Friday. After that I need to think about getting all the pistons cleaned up so I can drop them off with the block and M54 intake cam at the machine shop and while all that's being done, I'll get on with putting stem seals, valve, springs etc back into the head

Good day at Blyton park on Friday. Did more track miles in one day than I've done yet - 8 sessions, perhaps 110-120 miles? Plus the 240 miles return trip in the car too with all my cr*p loaded into the boot  Car didn't miss a beat. I havn't made any progress on sorting earlier minor cooling niggles, but it seemed that with a 6-degree ambient temperature, I had no problems at all. It's proving pretty good on consumables too - still plenty of tread left on the tyres, still plenty of meat left on the pads that have been there since the car first hit the road. The only work I've done on the actual car since October is change the brake fluid.

Car didn't miss a beat. I havn't made any progress on sorting earlier minor cooling niggles, but it seemed that with a 6-degree ambient temperature, I had no problems at all. It's proving pretty good on consumables too - still plenty of tread left on the tyres, still plenty of meat left on the pads that have been there since the car first hit the road. The only work I've done on the actual car since October is change the brake fluid.

On the downside - could still be doing with track tyres and it still rolls far too much But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.

But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.

Some photos and video from the day Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.

Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.

https://www.youtube.com/watch?v=-cDMLzUF9a0

https://www.youtube.com/watch?v=hHDhYsdJ924

Car didn't miss a beat. I havn't made any progress on sorting earlier minor cooling niggles, but it seemed that with a 6-degree ambient temperature, I had no problems at all. It's proving pretty good on consumables too - still plenty of tread left on the tyres, still plenty of meat left on the pads that have been there since the car first hit the road. The only work I've done on the actual car since October is change the brake fluid.

Car didn't miss a beat. I havn't made any progress on sorting earlier minor cooling niggles, but it seemed that with a 6-degree ambient temperature, I had no problems at all. It's proving pretty good on consumables too - still plenty of tread left on the tyres, still plenty of meat left on the pads that have been there since the car first hit the road. The only work I've done on the actual car since October is change the brake fluid.On the downside - could still be doing with track tyres and it still rolls far too much

But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.

But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.Some photos and video from the day

Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.

Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.https://www.youtube.com/watch?v=-cDMLzUF9a0

https://www.youtube.com/watch?v=hHDhYsdJ924

Car looks great and certainly seems to go well enough!

Beware going to stiff on the ARB's. Especially on a car that needs to cope with all weather conditions. I bit of body roll is just what you want in the wet, where the weight transfer, onto the outside tyres, will help with grip levels. Definitely helps on lighter cars such as ours.

Beware going to stiff on the ARB's. Especially on a car that needs to cope with all weather conditions. I bit of body roll is just what you want in the wet, where the weight transfer, onto the outside tyres, will help with grip levels. Definitely helps on lighter cars such as ours.

Cheers Mark. Yeah, I plan to purchase stiffer springs with inverted monotube dampers valved to match. Will leave the ARBs as they are for now. The rear is probably fairly ineffectual right now anyway as the OEM drop links are a bit long for a lowered car. I havn't gotten round to putting the shorter Z3 links on yet.

But I might have a look around and see how much of a skim I can get away with without having to do that...

But I might have a look around and see how much of a skim I can get away with without having to do that...

shalmaneser said:

Are you not going to skim that head? Seems a shame not to since it's all in bits, plus you gain a tiny bit more compression too which is a good thing!

I wasn't going to bother seeing as it all came out flat and true - and I didn't want to get into machining piston crowns  But I might have a look around and see how much of a skim I can get away with without having to do that...

But I might have a look around and see how much of a skim I can get away with without having to do that...Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff