325TI - Project Mpact

Discussion

Bookmarked also.

I love M3 transplants into the compacts. BMW made one E36 M3 Compact and it looked fantastic, haven't seen any E46 ones but it'll look fantastic with the M3 front end on it and probably be a ton of fun.

Just please don't put CSL reps on it or dark headlights, both are overdone and s t.

t.

I love M3 transplants into the compacts. BMW made one E36 M3 Compact and it looked fantastic, haven't seen any E46 ones but it'll look fantastic with the M3 front end on it and probably be a ton of fun.

Just please don't put CSL reps on it or dark headlights, both are overdone and s

t.

t.J4CKO said:

Love the idea, but it seems a bit mad (unless I have missed something) hacking up an E46 M3 that is worth a few quid, dodgy respray or not to use the running gear in a Compact which isnt worth much ?

Think of it another way. Customer walks into his unit. "show me some of your work" guide him round the bmw show him all the bespoke work that's going into it. It may not be worth "much" as a m3 compact but business wise I'd say it'll be worth it's weight in goldLooking forward to plenty more updates on this. These compacts are growing on me lately

Ste372 said:

J4CKO said:

Love the idea, but it seems a bit mad (unless I have missed something) hacking up an E46 M3 that is worth a few quid, dodgy respray or not to use the running gear in a Compact which isnt worth much ?

Think of it another way. Customer walks into his unit. "show me some of your work" guide him round the bmw show him all the bespoke work that's going into it. It may not be worth "much" as a m3 compact but business wise I'd say it'll be worth it's weight in goldLooking forward to plenty more updates on this. These compacts are growing on me lately

This Project should be well documented and put on his Business Website. It´ll definitely bring in a lot of customers.

Also don´t forget: There are a lot of M3s many are in better condition than his donor car but there aren´t many M3 Compact and I just assume that most of them will be worse than his.

J4CKO said:

Love the idea, but it seems a bit mad (unless I have missed something) hacking up an E46 M3 that is worth a few quid, dodgy respray or not to use the running gear in a Compact which isnt worth much ?

Not all projects are based on financial sense! That said a the last M3 powered compact I saw sold for £10k

Count me in the looking forward to updates group, I'd love an estoril blue 6 cylinder compact but have only ever seen a handful of horrendously overpriced 318Tis.

5harp3y said:

Bookmarked, looks like a fun project!

lovely looking welds too! fancy making a Z3 2.8 exhaust???

I can, when the compact is back on it's wheels and clear of the ramp. I'm trying to find a supplier of quality silencers at the moment, I've used magnaflow ones in the past but the welds on them aren't the prettiest. lovely looking welds too! fancy making a Z3 2.8 exhaust???

F1GTRUeno said:

Bookmarked also.

I love M3 transplants into the compacts. BMW made one E36 M3 Compact and it looked fantastic, haven't seen any E46 ones but it'll look fantastic with the M3 front end on it and probably be a ton of fun.

Just please don't put CSL reps on it or dark headlights, both are overdone and s t.

t.

Too late, back in 2010 with the purchase of VMR VB3's I love M3 transplants into the compacts. BMW made one E36 M3 Compact and it looked fantastic, haven't seen any E46 ones but it'll look fantastic with the M3 front end on it and probably be a ton of fun.

Just please don't put CSL reps on it or dark headlights, both are overdone and s

t.

t.

J4CKO said:

Love the idea, but it seems a bit mad (unless I have missed something) hacking up an E46 M3 that is worth a few quid, dodgy respray or not to use the running gear in a Compact which isnt worth much ?

I was waiting for someone to say this! I can see what you're saying, and to be honest you are not the only one who has that opinion.I had been looking into the conversion for a few years, the price of the S54 engines alone are £2000-3000+, plus looms, gearbox, prop, subframe, diff, clocks etc. I then went on to Copart Auctions and bidding on written off cars, these were selling in excess of £7000 for a heavy side impact car with around 80,000 miles on them (most of the cars were then collected and taken to poland).

Which got me thinking, If i could find an undamaged road legal car and use it for 6 months to make sure everything worked i could then take off what i needed, break the car for parts and sell the body shell.

Then the perfect opportunity came up on Ebay for the Grey M3, it was on a long auction and i nearly forgot about it. Last minute i put a bid in and the M3 was mine for less than the price of a written off M3 on Copart Auctions.

Yes, i could of kept the M3 on the road and spent £5000-6000+ on making a nice example of it, but after all that it would be exactly the same as every other M3 on the road. The M3 would be worth more money to someone else if it was a nice example, but i'm not willing to spend an extra £5000-6000 on top of the price i payed for the car to make it worth more to someone else.

I'm the second owner of the 325TI. If i can buy a cheap M3, break it to make money back and build a Compact to a high standard with M3 performance for half the cost of a tidy M3 and it be the only BMW Compact like it, i'd choose to do that.

Next on the 'things to do list' was to fully cover the car and protect it for the up coming work. With grinding, wire wheels and anything abrasive the dust and metal filings get everywhere and there a nightmare to get out. With the 'Prevention is better than cure' attitude i spent the next 3 hours covering the car and taping up every loose edge.

On to cleaning and de-greasing the underside of the car, removing 13 years of muck and grime was a messy job....best part of two days work using water based de-greasers as there nicer to work with.

And........this is what happens when the under trays are not reinstalled after the brake lines were fitted by a 'Specialist' two years previous.

Corrosion, everywhere. At this point i stopped and thought, 'should i really carry on with this'.

And........this is what happens when the under trays are not reinstalled after the brake lines were fitted by a 'Specialist' two years previous.

Corrosion, everywhere. At this point i stopped and thought, 'should i really carry on with this'.

After a few days of thinking i decided to get stuck in. With the rest of the workshop covered in dust sheets and a curtain pulled across i made a mess.... lots of mess.

Each mount that was corroded i carefully drilled all the factory spot welds and removed, this included the front and rear Fuel Tank mounts on both sides, Brake Line mounts and one of the brackets that the Fuel Tank sits up against . Carefully, with a grinder and wire wheel attachment any loose paint and rust was removed front the underside of the car.

When all the dust and crap had settled i went back, had a clean and tidy and then inspected it. All in all it wasn't that bad, there was some slight pitting but nothing to the extent where it had to be cut out and and new panels welding in (which is what i expected).

All the mounts went into the Blast Cabinet and were thoroughly cleaned up. Using POR15, the three Part process of De-grease, Metal Prep and then Rust Proventive paint was applied. Each part that would be puddle welded back on was sprayed in a weld through primer.

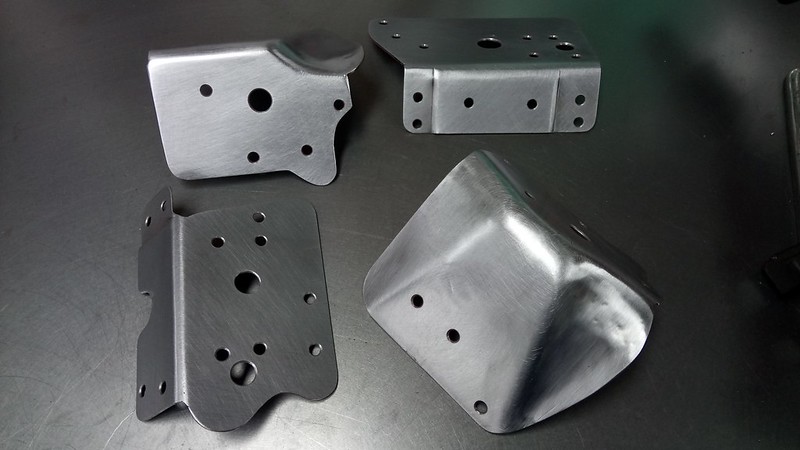

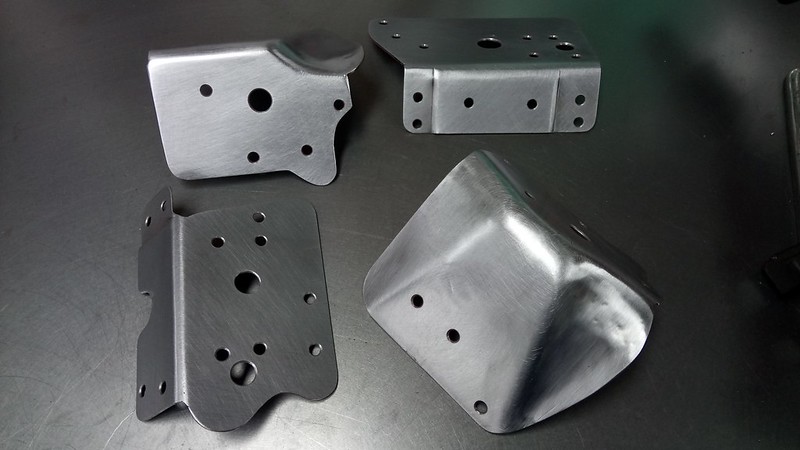

The front Fuel Tank mounts were too far gone, easiest way was to make some new ones.

Each mount that was corroded i carefully drilled all the factory spot welds and removed, this included the front and rear Fuel Tank mounts on both sides, Brake Line mounts and one of the brackets that the Fuel Tank sits up against . Carefully, with a grinder and wire wheel attachment any loose paint and rust was removed front the underside of the car.

When all the dust and crap had settled i went back, had a clean and tidy and then inspected it. All in all it wasn't that bad, there was some slight pitting but nothing to the extent where it had to be cut out and and new panels welding in (which is what i expected).

All the mounts went into the Blast Cabinet and were thoroughly cleaned up. Using POR15, the three Part process of De-grease, Metal Prep and then Rust Proventive paint was applied. Each part that would be puddle welded back on was sprayed in a weld through primer.

The front Fuel Tank mounts were too far gone, easiest way was to make some new ones.

Future Proofing.

With E46's (mainly M3's) the boot floor is a well known weak spot. Where the Subframe bolts locate into the boot floor/carrier panel this can flex over time causing stress fractures. If it is left and ignored over time the spot welds can fail separating panels, this will gradually get worse and spread across the boot floor panel and can then separate the boot floor from the chassis legs and wheel arch tubs. This can result in either the entire boot floor becoming detached or the stress fractures around where the Subframe mounts ripping out the floor.

A well known way of slowing this down is to Stop Drill a Fracture at each end, grind out the crack and Re-weld. Any spot welds that have failed can be carefully drilled out and Re-welded. After that, 'Reinforcement plates' can be welded on. THESE WILL NOT STOP IT HAPPENING AGAIN on there own, these plates simply spread the load over a larger area. BMW structural foam can then be pumped into the internal cavities .

With the 325TI i could not find a single crack anywhere, although there was a couple of spot welds that looked a bit iffy which were drilled and re-welded.

I Decided to make my own 'Reinforcement Plates', these were out of 2mm mild steel. I formed them over a Anvil and various formers rather than hammering them into the car to get the shape.

Each hole in the plate locates on top of an existing spot weld on the car, this allows not only the plate to be puddle welded onto one layer/skin of the floor but also picks up on the internal layer/mount too.

With E46's (mainly M3's) the boot floor is a well known weak spot. Where the Subframe bolts locate into the boot floor/carrier panel this can flex over time causing stress fractures. If it is left and ignored over time the spot welds can fail separating panels, this will gradually get worse and spread across the boot floor panel and can then separate the boot floor from the chassis legs and wheel arch tubs. This can result in either the entire boot floor becoming detached or the stress fractures around where the Subframe mounts ripping out the floor.

A well known way of slowing this down is to Stop Drill a Fracture at each end, grind out the crack and Re-weld. Any spot welds that have failed can be carefully drilled out and Re-welded. After that, 'Reinforcement plates' can be welded on. THESE WILL NOT STOP IT HAPPENING AGAIN on there own, these plates simply spread the load over a larger area. BMW structural foam can then be pumped into the internal cavities .

With the 325TI i could not find a single crack anywhere, although there was a couple of spot welds that looked a bit iffy which were drilled and re-welded.

I Decided to make my own 'Reinforcement Plates', these were out of 2mm mild steel. I formed them over a Anvil and various formers rather than hammering them into the car to get the shape.

Each hole in the plate locates on top of an existing spot weld on the car, this allows not only the plate to be puddle welded onto one layer/skin of the floor but also picks up on the internal layer/mount too.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff