My MK1 3.2 TT Turbo

Discussion

SteveS Cup said:

Performance thumbs up! But I can't stand mk1 TT's with those new style audi grill body kits... doesn't suit the lines of the mk1 tt at all.

The MK2 front bumper is fully functional and allows more air in through the front to help the charge cooler and i have rads in each of the side scoops, 1 for oil and 1 for water.Steve

I have a water to air heat exchanger.

A lot of peeps seem to fit an FMIC or air to air but for me the CC is the best setup for me.

Here is some more of my build..

Here is the difference the port matching has made to the exhaust manifold..

As bought..

You can see from the lighter coloured metal on some of the ports, what needs to come off, so the ports match up..

As bought..

After port matching, the manifold will be painted soon..

The Head cover has been acid dipped and cleaned. Its not 100% perfect as its pitted and will be painted..

The block has now been honed and has been crosshatched at 40 degrees..

Pistons started to be built up..

Piston rings being fitted and tolerances checked and modified to give best fit..

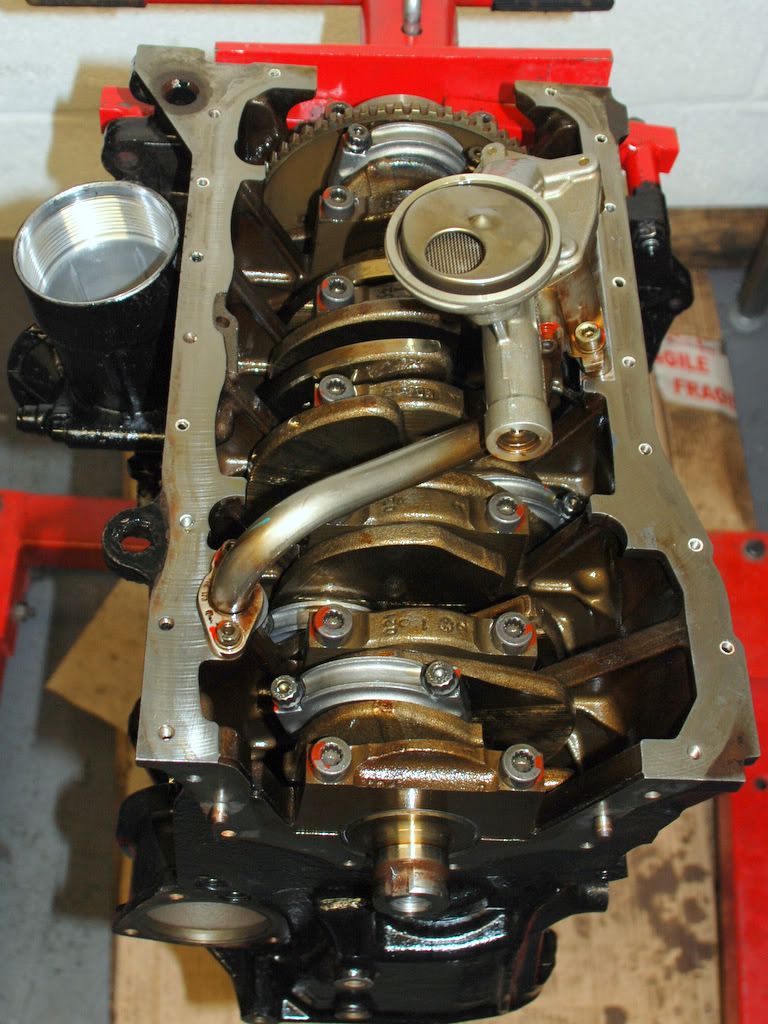

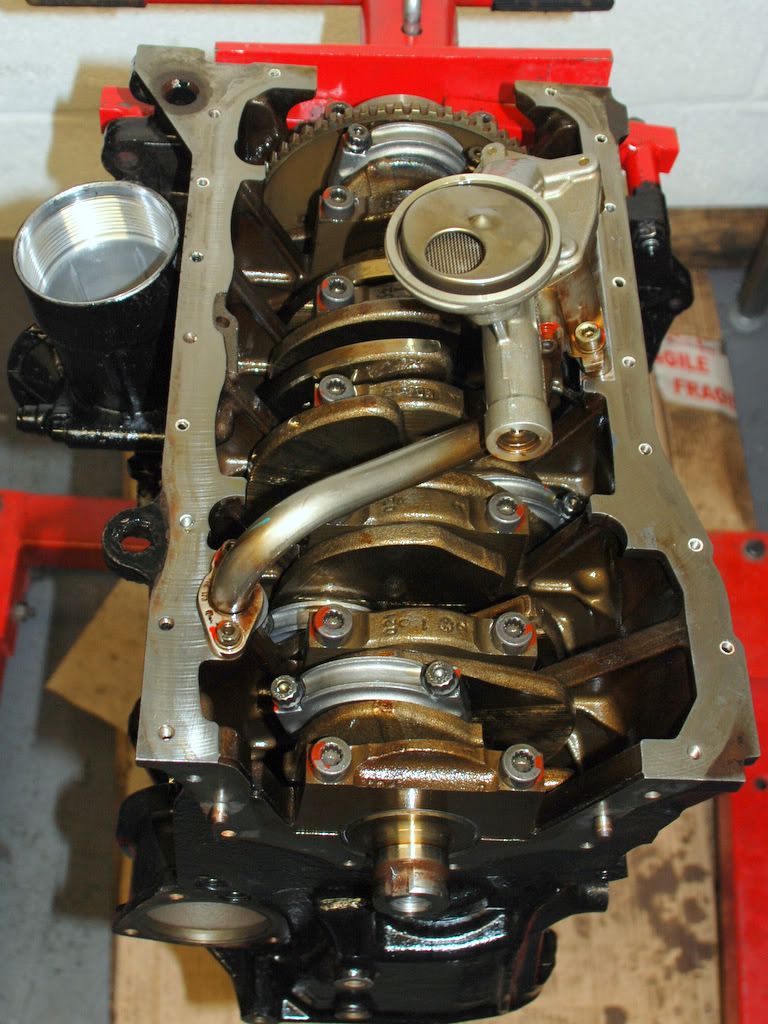

The crank has had new sputtered and coated bearings fitted. Oil pickup and mech pump stripped down and no wear found so it will be reused..

All the bolts have been torqued down and marked..

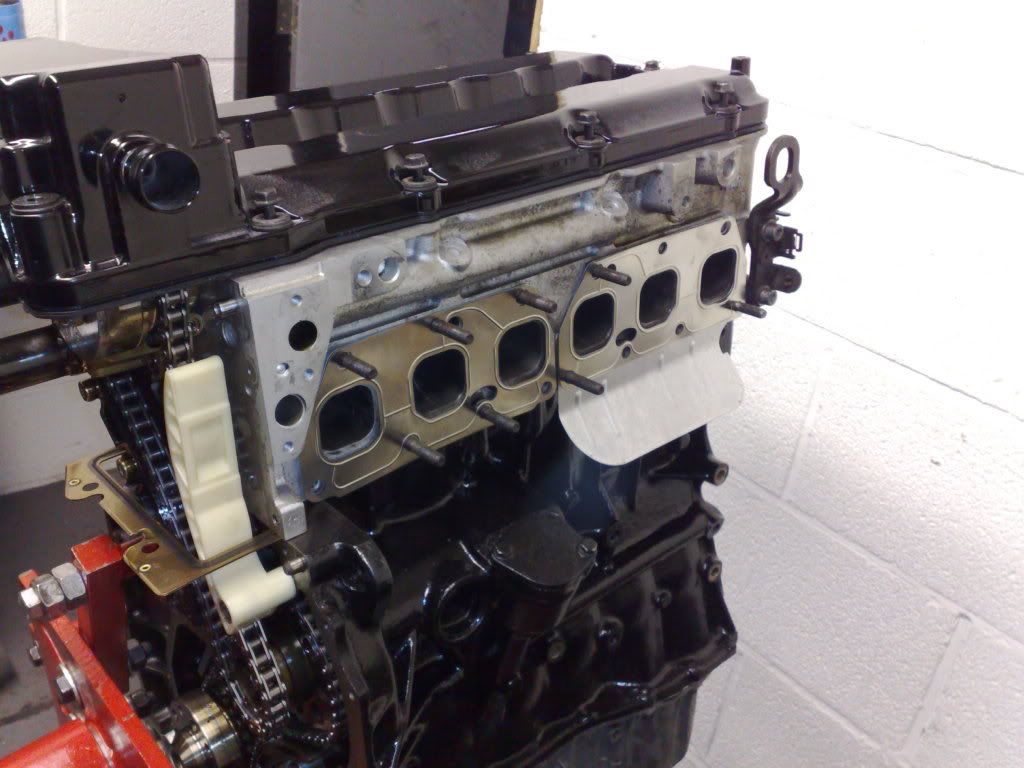

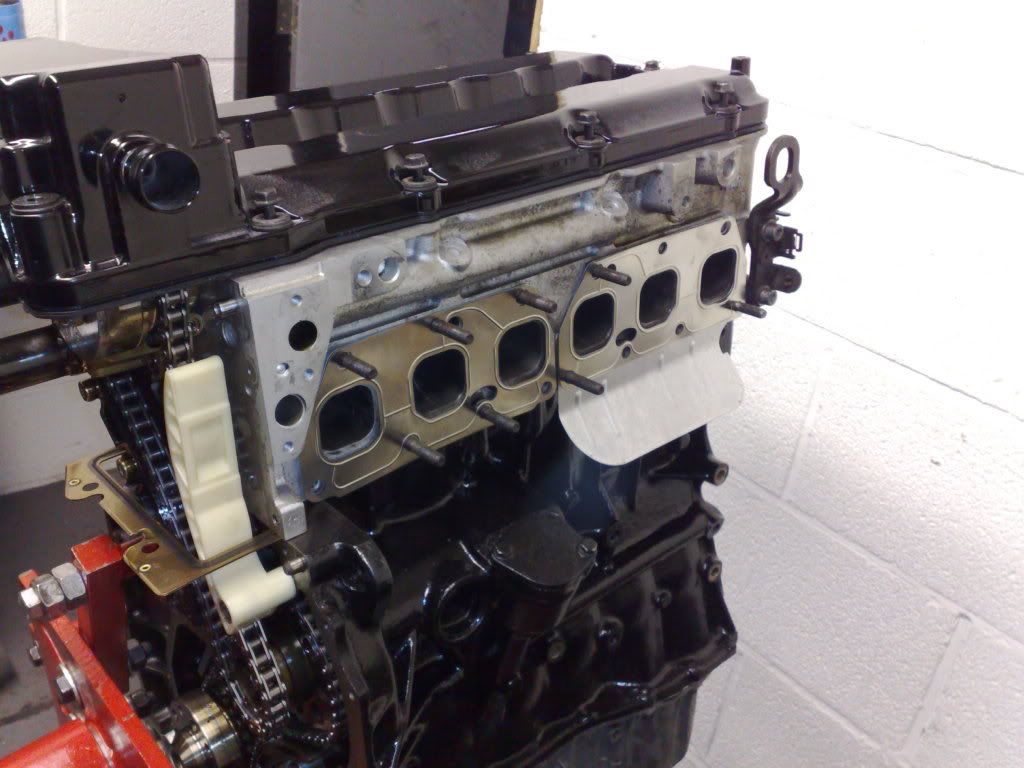

Top view of the head with the wossers fitted and the cross hatching on show, nice black painted block..

Get your sunglasses on for a look into the shinny stuff..

Well some bits have come back into the indie this week from ceramic coating.

Here is the Turbo Hot Side and the Exhaust Manifold with a spattering of that ceramic stuff..

A look at the other side of the Exhaust Manifold..

Two strangers about to hook up for a long term partnership..

Here's the happy couple..

Oil Pump Intermediate shaft..New Cam chain and tensioner fitted..

Ah!! the sumps been fitted, nearly missed that one..Head bolts and Gasket ready to be fitted..

Here are just some of the hoses that are waiting to be fitted..

These are the most expensive fast road Friction clutch plates, Steels and Viton Basket Seals in the world, well, feels like it..

This is where the new engine mounts will be going..

Oh dear, that clamp looks as though its causing some pain.

A couple of the new engine seals fitted..

and more..

I was shown the old water pump and its plastic, thought they were metal on the V6..however a new shinny metal one is being fitted. Its not an Audi part but a VW..

Here are some of the aeroquip hoses that are going to be used..

To eliminate spiking and achieve better control over boost, we will be fitting one of these HKS boost controllers..

This is a water way manifold from the A6 which routes the pipework better than TT OEM which may be used to improve the water cooling on cylinders 4,5 and 6..

Now a few pics of the block and shinny painted stuff for your amusement..

Well, the next update is in and things are progressing smoothly and a little progress has been made..

The steels for the clutch pack have been prepared for the rebuild..

The Friction plates are being soaked before going into the clutch pack..

The clutch pack starting to be rebuilt..

Clutch pack assembly nearly finished or the icing on the cake is nearly done..

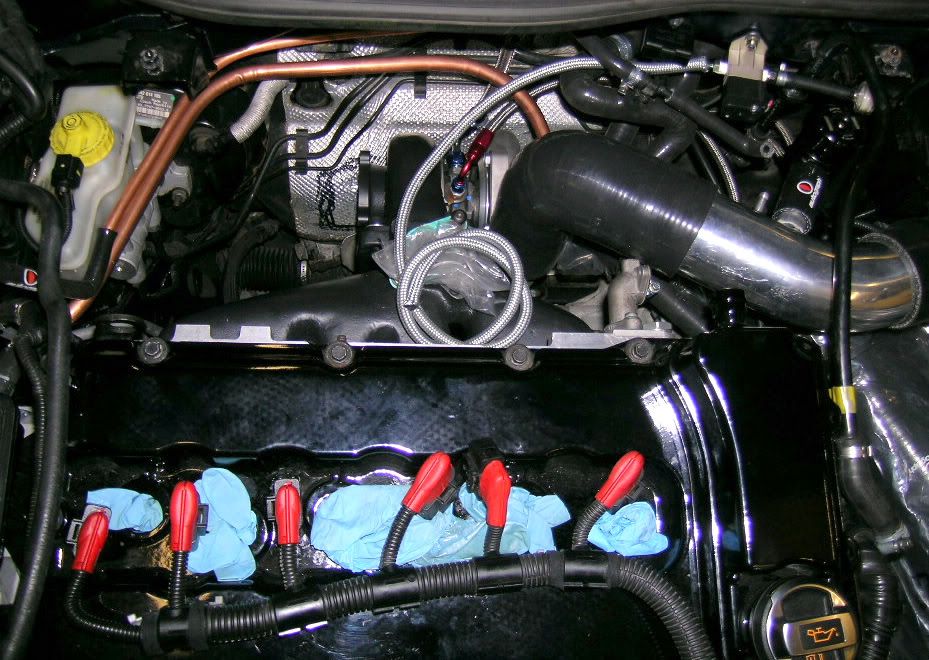

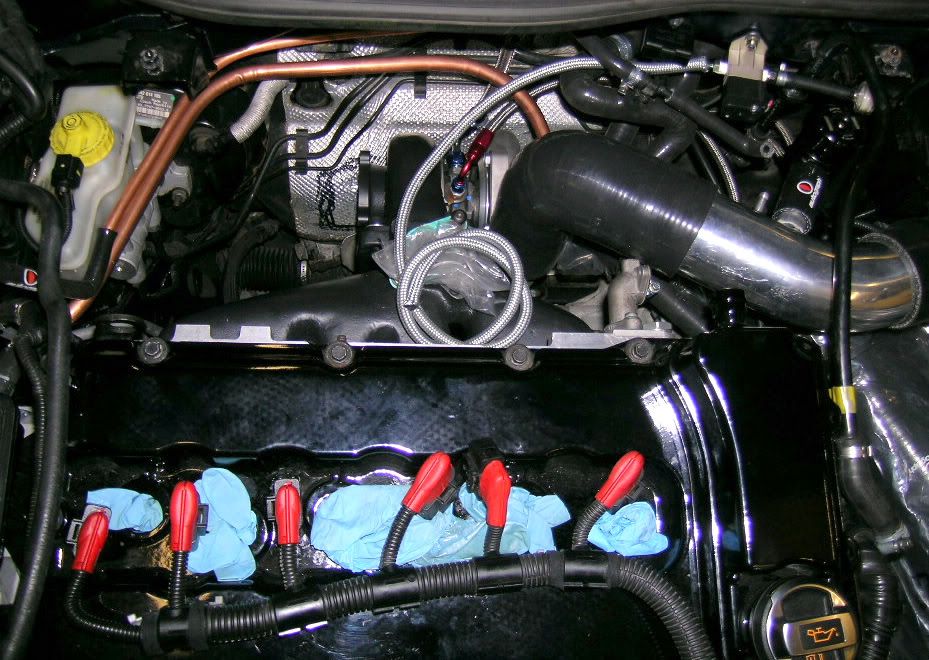

New Genesis 500 injectors being prepared to be fitted to the fuel rail..

Oil feed line and New RS4 Maf fitted..

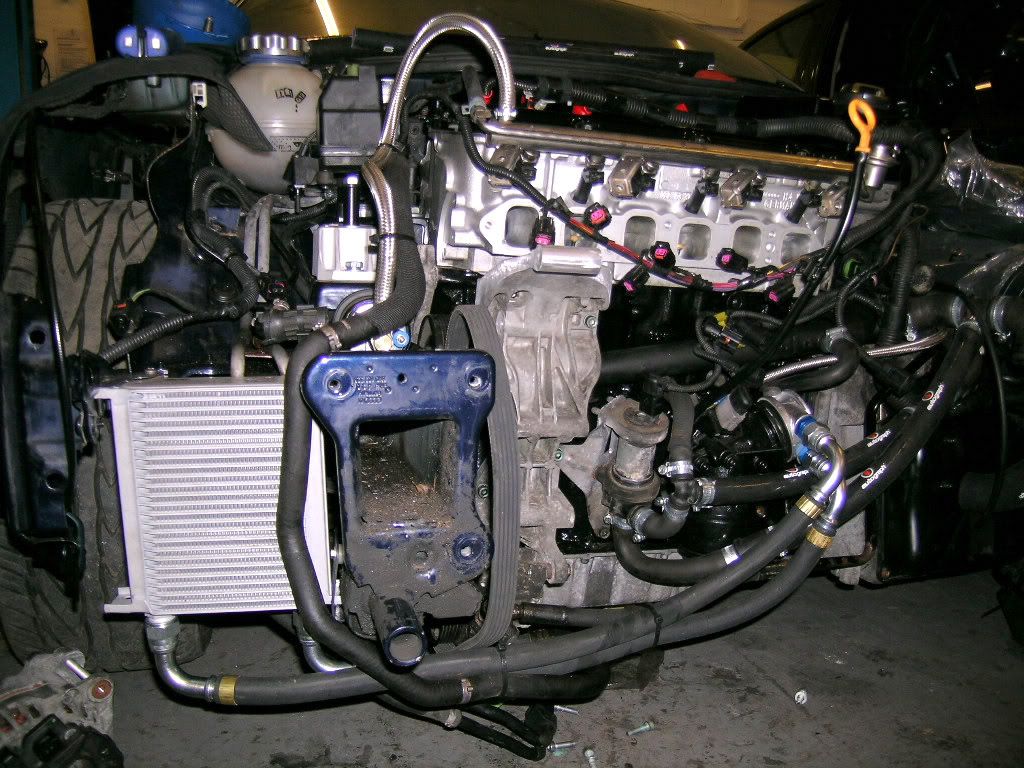

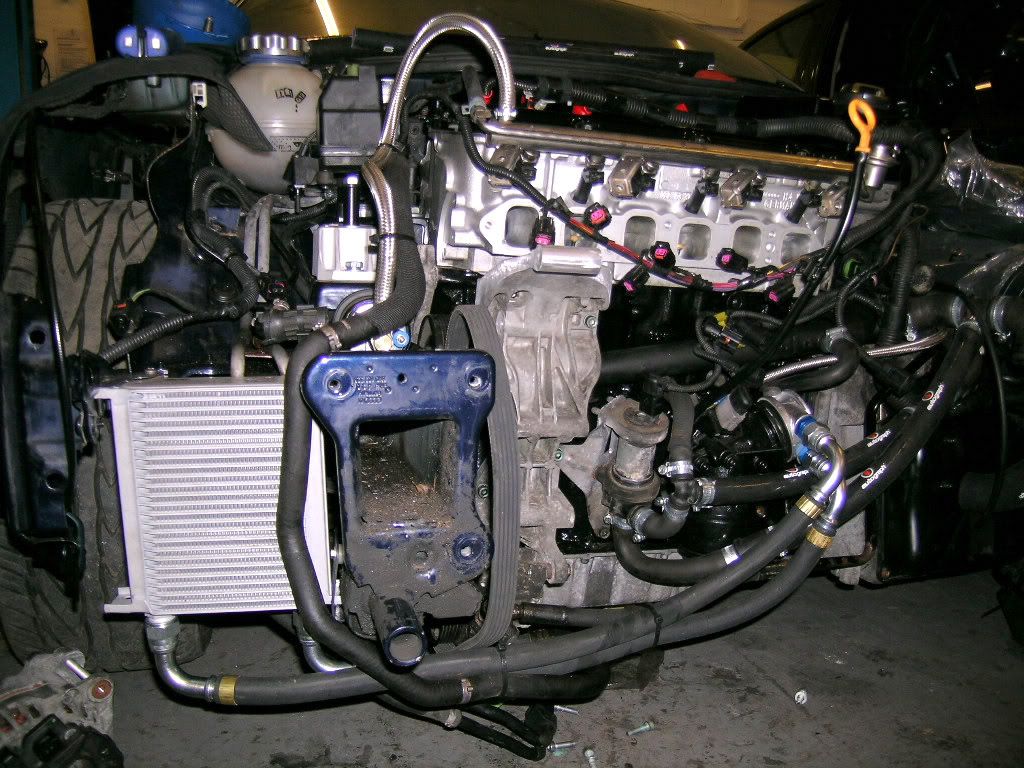

Manifold, Turbo, oil lines and MAF fitted..

Work has pushed on a little more over the past few days and there is a further update to see..

The end float is being checked on the input shaft and is within tolerance..

The end float is now checked on the new clutch pack to determine the circlip size required..

Here is a picture of the new clutch pack and circlip fitted..

This is the cover of the mechatronic unit, pretty rusty, this will have to be wire brushed and painted a little later..

The cover is whipped off and here we have every DSG owners nightmare..the inner workings of the mechatronic unit..

Steve

A lot of peeps seem to fit an FMIC or air to air but for me the CC is the best setup for me.

Here is some more of my build..

Here is the difference the port matching has made to the exhaust manifold..

As bought..

You can see from the lighter coloured metal on some of the ports, what needs to come off, so the ports match up..

As bought..

After port matching, the manifold will be painted soon..

The Head cover has been acid dipped and cleaned. Its not 100% perfect as its pitted and will be painted..

The block has now been honed and has been crosshatched at 40 degrees..

Pistons started to be built up..

Piston rings being fitted and tolerances checked and modified to give best fit..

The crank has had new sputtered and coated bearings fitted. Oil pickup and mech pump stripped down and no wear found so it will be reused..

All the bolts have been torqued down and marked..

Top view of the head with the wossers fitted and the cross hatching on show, nice black painted block..

Get your sunglasses on for a look into the shinny stuff..

Well some bits have come back into the indie this week from ceramic coating.

Here is the Turbo Hot Side and the Exhaust Manifold with a spattering of that ceramic stuff..

A look at the other side of the Exhaust Manifold..

Two strangers about to hook up for a long term partnership..

Here's the happy couple..

Oil Pump Intermediate shaft..New Cam chain and tensioner fitted..

Ah!! the sumps been fitted, nearly missed that one..Head bolts and Gasket ready to be fitted..

Here are just some of the hoses that are waiting to be fitted..

These are the most expensive fast road Friction clutch plates, Steels and Viton Basket Seals in the world, well, feels like it..

This is where the new engine mounts will be going..

Oh dear, that clamp looks as though its causing some pain.

A couple of the new engine seals fitted..

and more..

I was shown the old water pump and its plastic, thought they were metal on the V6..however a new shinny metal one is being fitted. Its not an Audi part but a VW..

Here are some of the aeroquip hoses that are going to be used..

To eliminate spiking and achieve better control over boost, we will be fitting one of these HKS boost controllers..

This is a water way manifold from the A6 which routes the pipework better than TT OEM which may be used to improve the water cooling on cylinders 4,5 and 6..

Now a few pics of the block and shinny painted stuff for your amusement..

Well, the next update is in and things are progressing smoothly and a little progress has been made..

The steels for the clutch pack have been prepared for the rebuild..

The Friction plates are being soaked before going into the clutch pack..

The clutch pack starting to be rebuilt..

Clutch pack assembly nearly finished or the icing on the cake is nearly done..

New Genesis 500 injectors being prepared to be fitted to the fuel rail..

Oil feed line and New RS4 Maf fitted..

Manifold, Turbo, oil lines and MAF fitted..

Work has pushed on a little more over the past few days and there is a further update to see..

The end float is being checked on the input shaft and is within tolerance..

The end float is now checked on the new clutch pack to determine the circlip size required..

Here is a picture of the new clutch pack and circlip fitted..

This is the cover of the mechatronic unit, pretty rusty, this will have to be wire brushed and painted a little later..

The cover is whipped off and here we have every DSG owners nightmare..the inner workings of the mechatronic unit..

Steve

V6RUL said:

SteveS Cup said:

Performance thumbs up! But I can't stand mk1 TT's with those new style audi grill body kits... doesn't suit the lines of the mk1 tt at all.

The MK2 front bumper is fully functional and allows more air in through the front to help the charge cooler and i have rads in each of the side scoops, 1 for oil and 1 for water.Steve

RobCrezz said:

V6RUL said:

The MK2 front bumper is fully functional and allows more air in through the front to help the charge cooler and i have rads in each of the side scoops, 1 for oil and 1 for water.

Steve

By charge cooler do you mean air to air front mount intercooler or a water to air?Steve

Sea-Doo said:

RobCrezz said:

V6RUL said:

The MK2 front bumper is fully functional and allows more air in through the front to help the charge cooler and i have rads in each of the side scoops, 1 for oil and 1 for water.

Steve

By charge cooler do you mean air to air front mount intercooler or a water to air?Steve

Steve

A direct follow on from the previous post..

Obviously the box has been drained of oil and here is the old filter..

In she goes, a new oil filter to keep that red stuff clean..

Here is the old drive shaft seal and a new one just about to be fitted..

The transfer box is now fitted to the DSG..

The DSG is now built up and ready for a little clean before fitting..

The engine is ready for install and is put on its new wheels, ha ha

The car is ready to receive the engine and box now which should be coming together on Monday..

Well, she has finally been installed, its all a bit tight and im glad i went for the ceramic coating to keep the heat within the exhaust system. Just hope the bonnet closes with that red thing sticking up so high..

It was decided to cusom fit the down pipe once the engine goes in as its something that has to be bespoke to the fit so as to avoid any impact issues. Some of the flexi hoses look close to the engine on the near side but these havn't been fitted correctly and will deffo be looking better once the plumbing gets a bit further on,

The plumbing is starting now and i believe there are 32 new Samco pipes to fit so she will be looking nice with new arteries fitted. Wheels and arches look a little futuristic with a view of the rubber through them.

A hair line crack was found at the front of the gearbox as seen in the pic it has been magnesium welded. The crack was only a surface defect but its been welded up just to be on the safe side. It didn't show up untill the gearbox was cleaned, unfortunately it has slowed the build down by 2 days, but hey ho, thats life.

Got a few picks and a small update from the garage.

Here is the the throttle body with the welded bead as shown to stop the hose from blowing off once fitted..

Heres the Down Pipe spot welded for best fit, it will be tig welded up and sent for ceramic coating with the external wastegate body..

OEM there is nothing located in the N/S front scoop so this is where this little baby will be going. Its an additional oil cooler with a built in thermostat in the take off adapter that will switch at approx 85C to give some additional cooling.

Here is a pic of the turbo inlet and outlet pipework..

Here is a pic of the water/air charge cooler, in the wrap to keep it from getting scratched, and its position. The air filter has also been put in place..

An overview of roughly where most of the bits are going to be landed..

The next update is in, there are no radical big changes to see as the work has been fiddly..

Ali pipes have been cut, welded,cut and welded to allow for the best fitment.

Hoses have been tried and modded to allow for best fitment as well.

It all takes time, but it is time to put the jigsaw together.

The secondary oil cooler has been mounted and the feed and return pipework has been installed to the sandwich plate..

Wiring looms have been modified where required to remove unwanted wiring and generally ran in to their locations..

Some more wiring..

Some new copper water pipes have been installed..

Here is the motorsport uprated in line fuel pump..

Here is the boost contol electronics ready to go in..

The boost control equipment installed in the engine bay..

The DP was all welded up last week and sent off to Scotland for coating but due to transport problems it never arrived to the coaters. It will now be returned to the indie who will fit it with a blanket wrap for now, but it will be sent for recoating in the new year when time allows. We cannot afford any more delays as im back in the UK within 10 or 11 days and i want the car back for a few weeks to run it in.

Its getting close to the end now and this may be the penultimate update..

The boost controller has been fitted here..

A slight modification to the exhaust has seen the cats and res section removed..

The chargecooler pump needed a mounting bracket fabricating..

Here is the chargecooler pump fitted in place of where the A/C was, good use of space..

Wastegate is plumbed in, DP wrapped in a temporary coating, charge cooler resevoir installed..

Taken this morning..after 4 months of being in bits..

Click to view the vid..

Its a race to get it put back together for running in.

Right, all the major components have been fitted and the car has been running for nearly two weeks on running in maps.

Here are a few pics from the last few days and it's just a case of getting the trim and bling finished off...

As you can see she looks almost finished, just a bit of fettling.

I will be putting some miles on her over the next few days and i am to Santa Pod for a big TT meet.

[QUOTE="Toffs"]Great work, the engine bay is even more cramped than the Mk4 FI's ![/QUOTE]

As you can see, the TT is built up and is approx 99% complete.

The car has been made ready for Santa Pod. Although not going down the Strip.

The TT has never done over 50 miles in one hit and unbeknown to all, there was an electrical issue that was causing the TT to cut out now and then.

I've struggled for the past few days putting 500+ miles on her so this running in map, 0.4 Bar boost and oil and filter can now be tweaked or changed and the boost upped to 0.8 Bar, for the next phase of the running in phase.

I've dropped her off today for the work to be done and the electrical issue to be resolved. Hopefully I will be back in her on Thursday to get some more miles on her and to take her to 5K rpm instead of 4K max.

As a guide on the performance so far..

I set the Liquid adaption to 119% as 100% is for an OEM MAF and the RS4 is 19% bigger.

6th gear at 4k rpm on 0.4 bar boost realised 300lb/ft torque

Went out for a little run out today and i ended up going past one of those places that are just to hard to keep on driving by.

The place in question is Pipewerx.. :P

I just need to say that i had a temporary system fitted by Autograph, but this was not the finished article, but it was functional.

Let me just say, 9 hours of standing on my feet and watching Geoff and Jay work their magic.

Enjoy and look out for the twist..

Put up on the ramp for the guys to have a look at whats on..

Then it was whipped off..

Here is the old girl..

and the temporary downpipe..

A little fabrication later..and

and the downpipe, unfortunately the flange wasn't on in this pic..

but it is on this pic..

OOO what about tips...let me see..eeney meeney miney mo..

little bit of snake action..

and from the back..valance courtesy of Syd..cheers mate..

This is a turbo back system in 3" and some component parts are 316SS for extra strength.

Steve

Obviously the box has been drained of oil and here is the old filter..

In she goes, a new oil filter to keep that red stuff clean..

Here is the old drive shaft seal and a new one just about to be fitted..

The transfer box is now fitted to the DSG..

The DSG is now built up and ready for a little clean before fitting..

The engine is ready for install and is put on its new wheels, ha ha

The car is ready to receive the engine and box now which should be coming together on Monday..

Well, she has finally been installed, its all a bit tight and im glad i went for the ceramic coating to keep the heat within the exhaust system. Just hope the bonnet closes with that red thing sticking up so high..

It was decided to cusom fit the down pipe once the engine goes in as its something that has to be bespoke to the fit so as to avoid any impact issues. Some of the flexi hoses look close to the engine on the near side but these havn't been fitted correctly and will deffo be looking better once the plumbing gets a bit further on,

The plumbing is starting now and i believe there are 32 new Samco pipes to fit so she will be looking nice with new arteries fitted. Wheels and arches look a little futuristic with a view of the rubber through them.

A hair line crack was found at the front of the gearbox as seen in the pic it has been magnesium welded. The crack was only a surface defect but its been welded up just to be on the safe side. It didn't show up untill the gearbox was cleaned, unfortunately it has slowed the build down by 2 days, but hey ho, thats life.

Got a few picks and a small update from the garage.

Here is the the throttle body with the welded bead as shown to stop the hose from blowing off once fitted..

Heres the Down Pipe spot welded for best fit, it will be tig welded up and sent for ceramic coating with the external wastegate body..

OEM there is nothing located in the N/S front scoop so this is where this little baby will be going. Its an additional oil cooler with a built in thermostat in the take off adapter that will switch at approx 85C to give some additional cooling.

Here is a pic of the turbo inlet and outlet pipework..

Here is a pic of the water/air charge cooler, in the wrap to keep it from getting scratched, and its position. The air filter has also been put in place..

An overview of roughly where most of the bits are going to be landed..

The next update is in, there are no radical big changes to see as the work has been fiddly..

Ali pipes have been cut, welded,cut and welded to allow for the best fitment.

Hoses have been tried and modded to allow for best fitment as well.

It all takes time, but it is time to put the jigsaw together.

The secondary oil cooler has been mounted and the feed and return pipework has been installed to the sandwich plate..

Wiring looms have been modified where required to remove unwanted wiring and generally ran in to their locations..

Some more wiring..

Some new copper water pipes have been installed..

Here is the motorsport uprated in line fuel pump..

Here is the boost contol electronics ready to go in..

The boost control equipment installed in the engine bay..

The DP was all welded up last week and sent off to Scotland for coating but due to transport problems it never arrived to the coaters. It will now be returned to the indie who will fit it with a blanket wrap for now, but it will be sent for recoating in the new year when time allows. We cannot afford any more delays as im back in the UK within 10 or 11 days and i want the car back for a few weeks to run it in.

Its getting close to the end now and this may be the penultimate update..

The boost controller has been fitted here..

A slight modification to the exhaust has seen the cats and res section removed..

The chargecooler pump needed a mounting bracket fabricating..

Here is the chargecooler pump fitted in place of where the A/C was, good use of space..

Wastegate is plumbed in, DP wrapped in a temporary coating, charge cooler resevoir installed..

Taken this morning..after 4 months of being in bits..

Click to view the vid..

Its a race to get it put back together for running in.

Right, all the major components have been fitted and the car has been running for nearly two weeks on running in maps.

Here are a few pics from the last few days and it's just a case of getting the trim and bling finished off...

As you can see she looks almost finished, just a bit of fettling.

I will be putting some miles on her over the next few days and i am to Santa Pod for a big TT meet.

[QUOTE="Toffs"]Great work, the engine bay is even more cramped than the Mk4 FI's ![/QUOTE]

As you can see, the TT is built up and is approx 99% complete.

The car has been made ready for Santa Pod. Although not going down the Strip.

The TT has never done over 50 miles in one hit and unbeknown to all, there was an electrical issue that was causing the TT to cut out now and then.

I've struggled for the past few days putting 500+ miles on her so this running in map, 0.4 Bar boost and oil and filter can now be tweaked or changed and the boost upped to 0.8 Bar, for the next phase of the running in phase.

I've dropped her off today for the work to be done and the electrical issue to be resolved. Hopefully I will be back in her on Thursday to get some more miles on her and to take her to 5K rpm instead of 4K max.

As a guide on the performance so far..

I set the Liquid adaption to 119% as 100% is for an OEM MAF and the RS4 is 19% bigger.

6th gear at 4k rpm on 0.4 bar boost realised 300lb/ft torque

Went out for a little run out today and i ended up going past one of those places that are just to hard to keep on driving by.

The place in question is Pipewerx.. :P

I just need to say that i had a temporary system fitted by Autograph, but this was not the finished article, but it was functional.

Let me just say, 9 hours of standing on my feet and watching Geoff and Jay work their magic.

Enjoy and look out for the twist..

Put up on the ramp for the guys to have a look at whats on..

Then it was whipped off..

Here is the old girl..

and the temporary downpipe..

A little fabrication later..and

and the downpipe, unfortunately the flange wasn't on in this pic..

but it is on this pic..

OOO what about tips...let me see..eeney meeney miney mo..

little bit of snake action..

and from the back..valance courtesy of Syd..cheers mate..

This is a turbo back system in 3" and some component parts are 316SS for extra strength.

Steve

Autograph Cars in Burnley are doing the build and will be looking after her from now on.

Went out for a little run with a fellow TT owner in the car and i came back with a big smile on my face and Syd needing new undies..

537 bhp

430 lb/ft

The boost is still 0.8 and in 4th gear i went to 6300 rpm.

There are niggles that are getting ironed out on a daily basis and the TT is improving every day.

The DSG still has some way to adapt correctly but its getting there and the engine is running well.

Im sure there are peeps in the States running in the 700s with the DSG but the important thing is to fit a high performance clutch and some decent software for the box.

Steve

Went out for a little run with a fellow TT owner in the car and i came back with a big smile on my face and Syd needing new undies..

537 bhp

430 lb/ft

The boost is still 0.8 and in 4th gear i went to 6300 rpm.

There are niggles that are getting ironed out on a daily basis and the TT is improving every day.

The DSG still has some way to adapt correctly but its getting there and the engine is running well.

Im sure there are peeps in the States running in the 700s with the DSG but the important thing is to fit a high performance clutch and some decent software for the box.

Steve

V6RUL said:

Autograph Cars in Burnley are doing the build and will be looking after her from now on.

Went out for a little run with a fellow TT owner in the car and i came back with a big smile on my face and Syd needing new undies..

537 bhp

430 lb/ft

The boost is still 0.8 and in 4th gear i went to 6300 rpm.

There are niggles that are getting ironed out on a daily basis and the TT is improving every day.

The DSG still has some way to adapt correctly but its getting there and the engine is running well.

Im sure there are peeps in the States running in the 700s with the DSG but the important thing is to fit a high performance clutch and some decent software for the box.

Steve

, and how does this amazing gadget work?Went out for a little run with a fellow TT owner in the car and i came back with a big smile on my face and Syd needing new undies..

537 bhp

430 lb/ft

The boost is still 0.8 and in 4th gear i went to 6300 rpm.

There are niggles that are getting ironed out on a daily basis and the TT is improving every day.

The DSG still has some way to adapt correctly but its getting there and the engine is running well.

Im sure there are peeps in the States running in the 700s with the DSG but the important thing is to fit a high performance clutch and some decent software for the box.

Steve

Thanks in anticipation.

This is called a Liquid Gauge and connects to the OBD 2 port that a lot of modern cars have as a diagnostic port.

It logs the car in real time and converts the data into bhp and torque figures.

It monitors a whole host of other info ie water temp, oil temp, egts, g/s, spped, rpm, ignition advanc, fault codes, TB reset and other stuff. Its is one of the best additions i have on the car.

Steve

It logs the car in real time and converts the data into bhp and torque figures.

It monitors a whole host of other info ie water temp, oil temp, egts, g/s, spped, rpm, ignition advanc, fault codes, TB reset and other stuff. Its is one of the best additions i have on the car.

Steve

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff