Johns cerbera rebuild and upgrade

Discussion

I just stumbled across this whilst looking whistfully at the Cerbera forum, I miss mine...

Looks like a fantastic machine you're making there, congratulations. What is the foam you're using for your fibreglass plug? I need to make up some wide arches myself and was looking into options.

Looks like a fantastic machine you're making there, congratulations. What is the foam you're using for your fibreglass plug? I need to make up some wide arches myself and was looking into options.

first door sill out of the mould well pleased great surface.

https://photos.app.goo.gl/sIENMepNwvrEuNN62

john

https://photos.app.goo.gl/sIENMepNwvrEuNN62

john

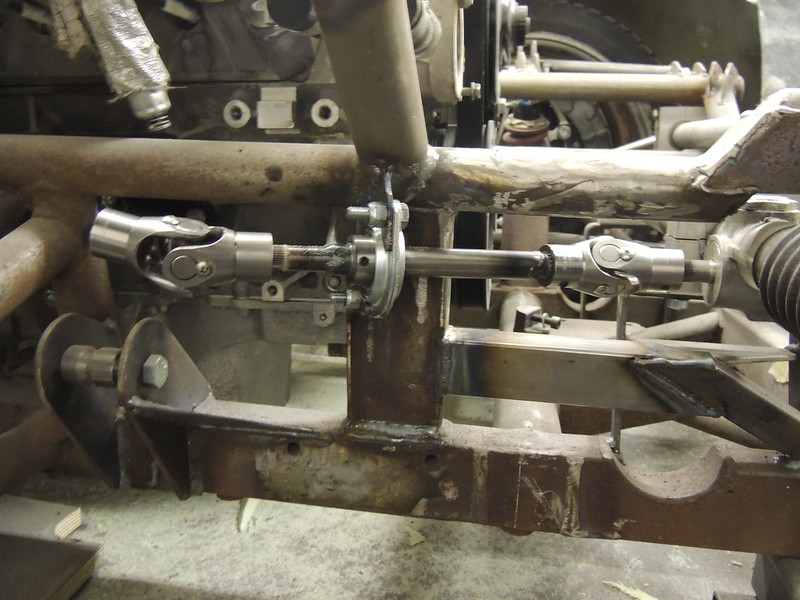

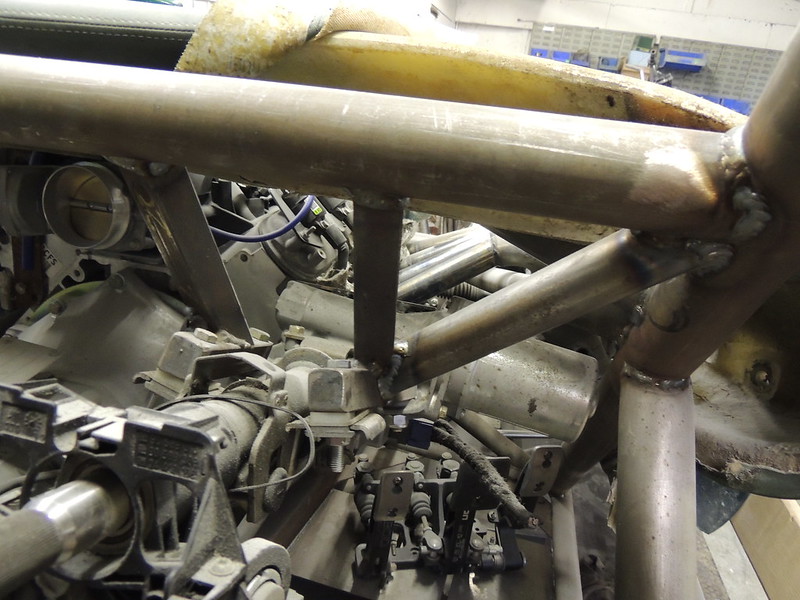

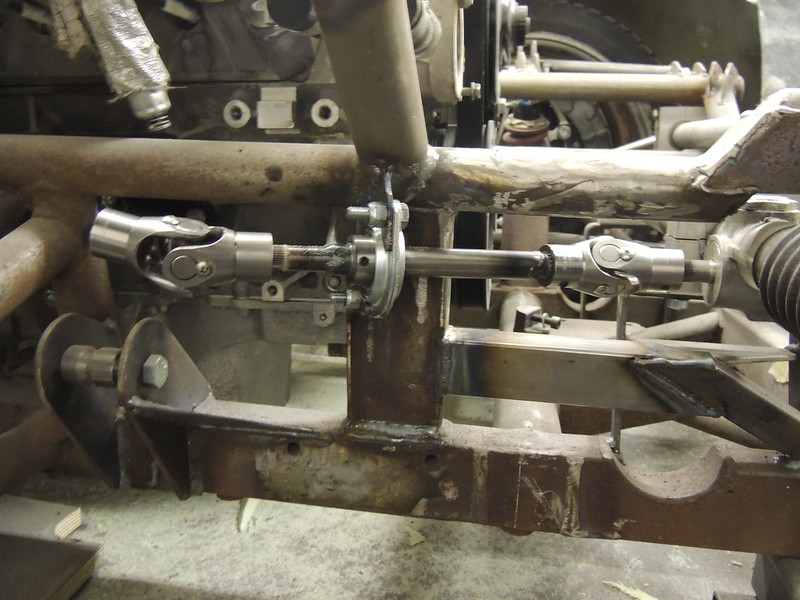

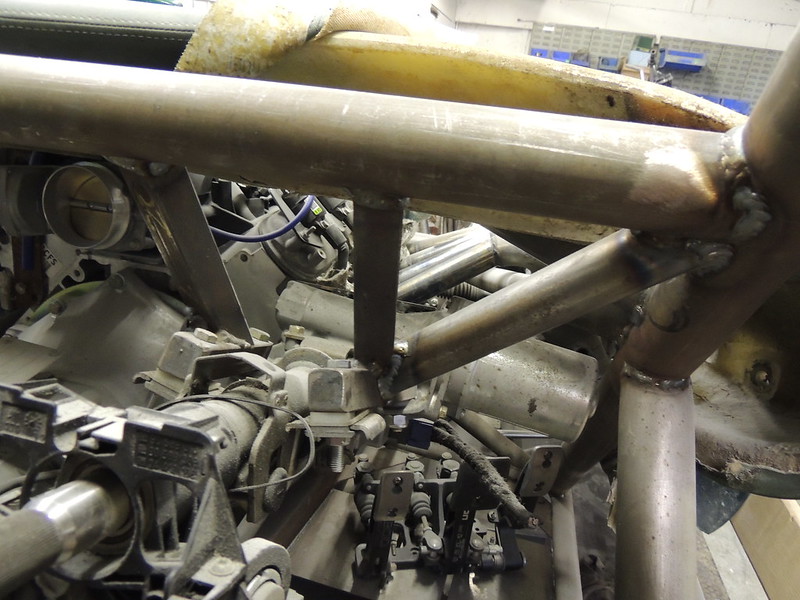

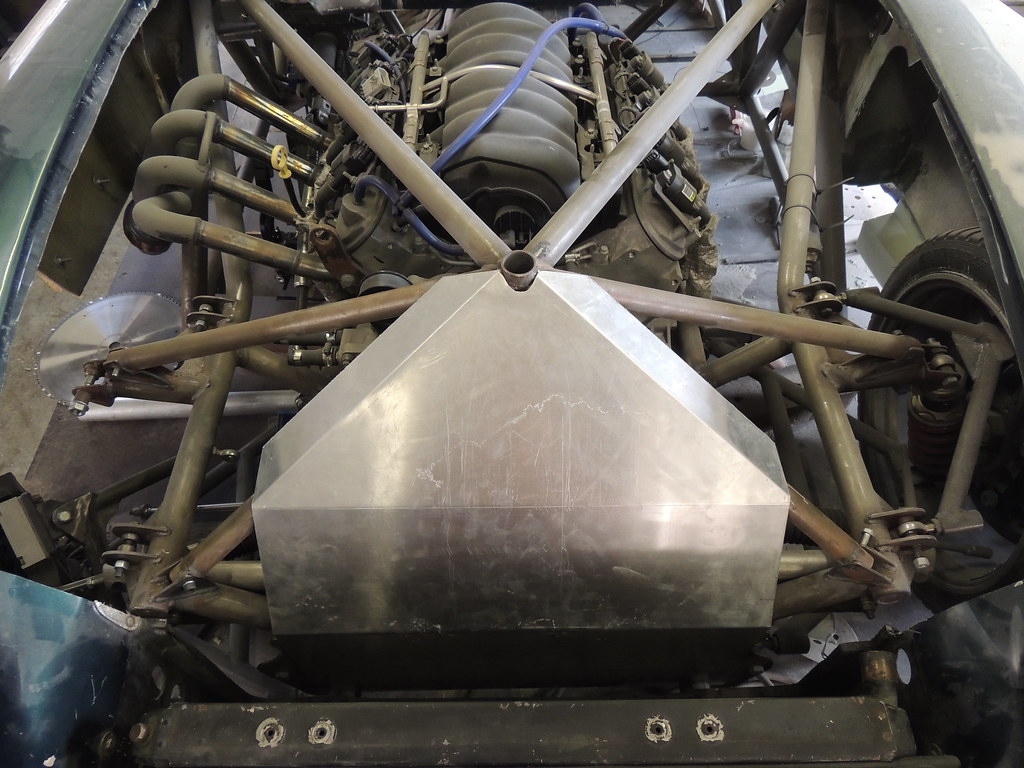

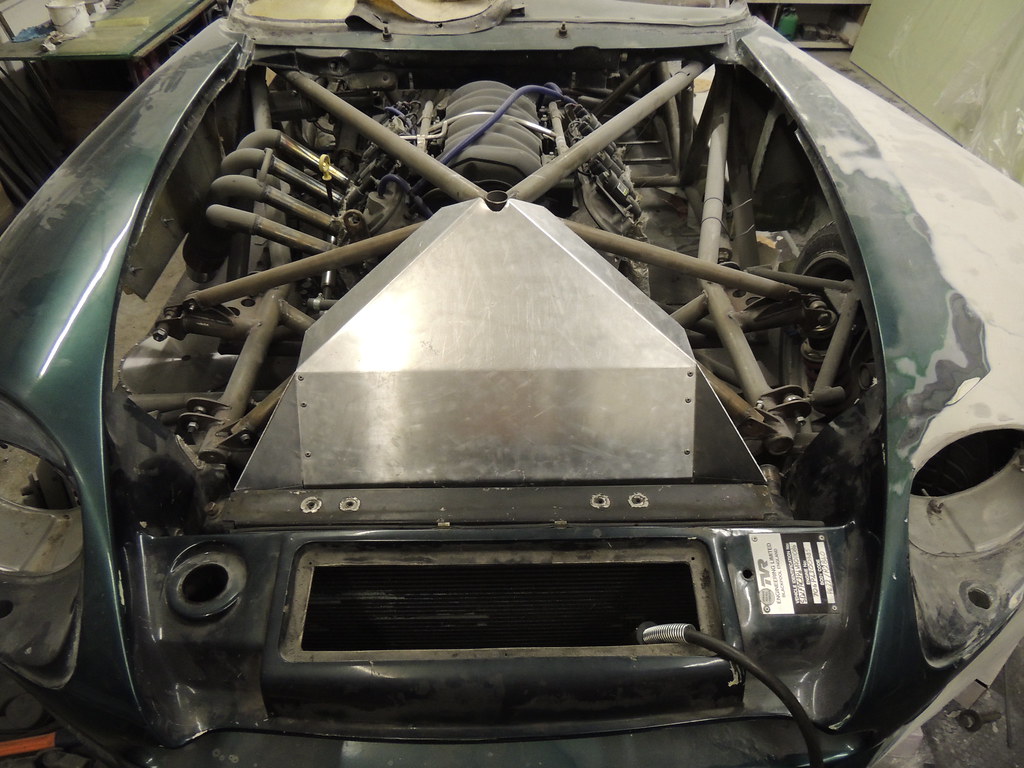

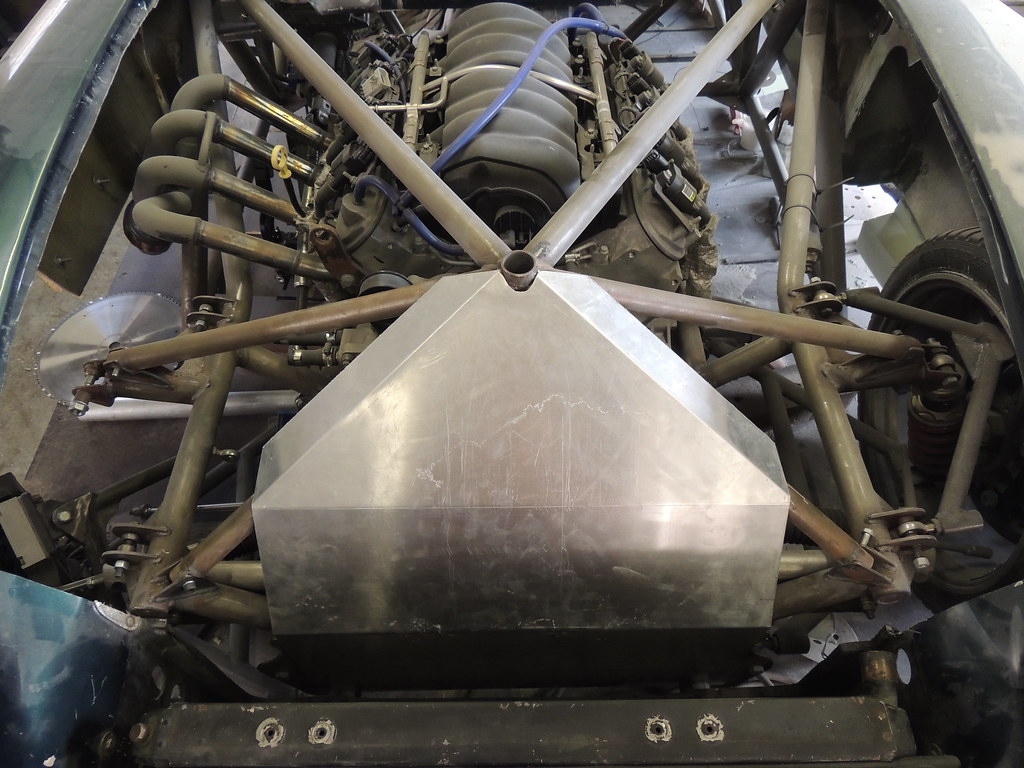

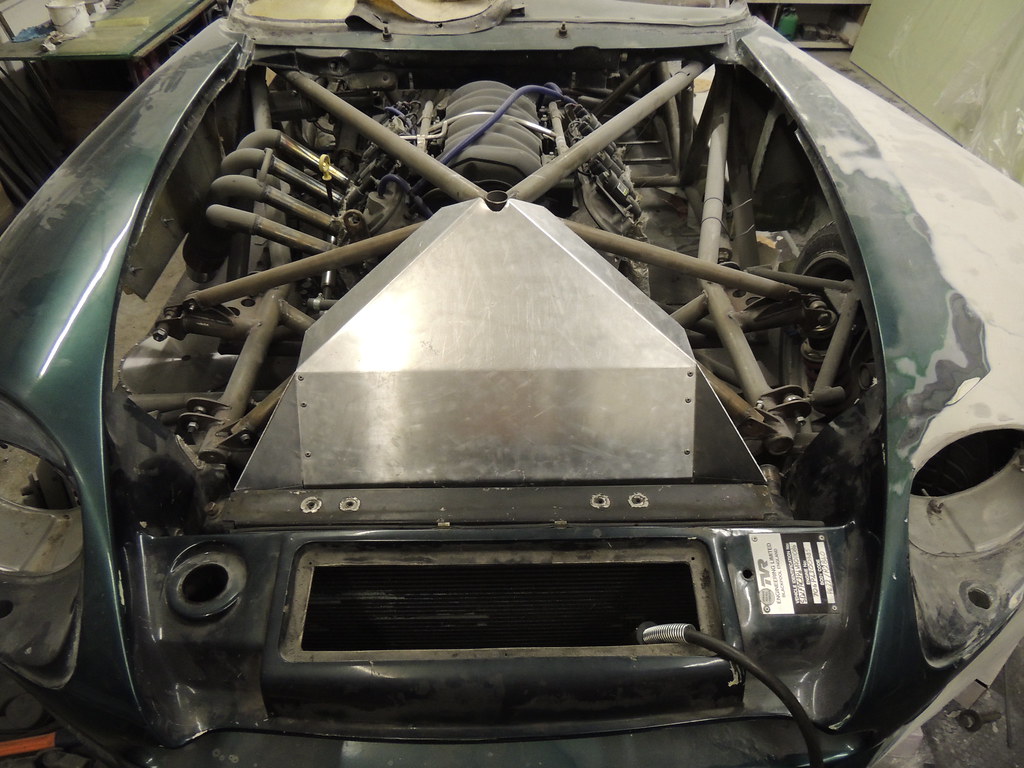

long time since i posted been busy restoring two wedges plus power steering to a griff etc. etc. but now having a concerted effort on the cerb finally finished the power steering column and the mounting for the power unit and lots of work to the n/s plugs for the new wings also laid up the bonnet with the cooling duct for the rad pics on that to follow but pics should give you a flavour of the work.

john

DSCN2872 by Brundall Motorsport, on Flickr

DSCN2872 by Brundall Motorsport, on Flickr

DSCN3096 by Brundall Motorsport, on Flickr

DSCN3096 by Brundall Motorsport, on Flickr

DSCN3095 by Brundall Motorsport, on Flickr

DSCN3095 by Brundall Motorsport, on Flickr

DSCN3094 by Brundall Motorsport, on Flickr

DSCN3094 by Brundall Motorsport, on Flickr

DSCN3093 by Brundall Motorsport, on Flickr

DSCN3093 by Brundall Motorsport, on Flickr

DSCN3091 by Brundall Motorsport, on Flickr

DSCN3091 by Brundall Motorsport, on Flickr

DSCN3098 by Brundall Motorsport, on Flickr

DSCN3098 by Brundall Motorsport, on Flickr

DSCN3099 by Brundall Motorsport, on Flickr

DSCN3099 by Brundall Motorsport, on Flickr

DSCN3100 by Brundall Motorsport, on Flickr

DSCN3100 by Brundall Motorsport, on Flickr

DSCN3102 by Brundall Motorsport, on Flickr

DSCN3102 by Brundall Motorsport, on Flickr

john

DSCN2872 by Brundall Motorsport, on Flickr

DSCN2872 by Brundall Motorsport, on Flickr DSCN3096 by Brundall Motorsport, on Flickr

DSCN3096 by Brundall Motorsport, on Flickr DSCN3095 by Brundall Motorsport, on Flickr

DSCN3095 by Brundall Motorsport, on Flickr DSCN3094 by Brundall Motorsport, on Flickr

DSCN3094 by Brundall Motorsport, on Flickr DSCN3093 by Brundall Motorsport, on Flickr

DSCN3093 by Brundall Motorsport, on Flickr DSCN3091 by Brundall Motorsport, on Flickr

DSCN3091 by Brundall Motorsport, on Flickr DSCN3098 by Brundall Motorsport, on Flickr

DSCN3098 by Brundall Motorsport, on Flickr DSCN3099 by Brundall Motorsport, on Flickr

DSCN3099 by Brundall Motorsport, on Flickr DSCN3100 by Brundall Motorsport, on Flickr

DSCN3100 by Brundall Motorsport, on Flickr DSCN3102 by Brundall Motorsport, on Flickr

DSCN3102 by Brundall Motorsport, on Flickrengine transmission etc. is all sorted its a chevvy ls3 producing 503 bhp and 475 ftlbs as far as i can remember all run in and mapped on emeralds engine dyno, i think pics etc. are back somwhere in the thread, driving onto a 56 magnum 6 speed box 8 1/4 diff, hollow gun barrel lathe turned drive shafts and mosler uprights hubs and brakes, bbs wheels.

john

john

Demondad said:

A fascinating engineering project for us Cerbie pervs. It would make a brilliant TV show.

Not even just Cerbie pervs - I have to confess I'm not a massive Cerb fan (for me the Tuscan is, and will always remain, the pinnacle of automotive design, although admittedly I'm biased...), but I stumbled across this thread some time ago (>1yr) and am delighted to see that the project is still making progress.John, I have the utmost admiration for your skills, and can't wait to see the end result. The bodywork alone is an absolute work of art

This may be a naive question, but out of interest, how do you match up the offside and the nearside given that the contours appear to be hand-sculpted? Do you take measurements at datum points on either side, or is it just a case of judging everything by eye (I suspect not, but would love to know how it's done!?)?

This may be a naive question, but out of interest, how do you match up the offside and the nearside given that the contours appear to be hand-sculpted? Do you take measurements at datum points on either side, or is it just a case of judging everything by eye (I suspect not, but would love to know how it's done!?)?rob it starts off being done by eye to get a basic shape certainly when on the first stage building up the foam prior to filling and fairing, then we scribe vertical lines at precise distances along the (in this case wing) using a laser level nowadays used to use a plumb bob and use the shadow cast by a lamp, then make a template of that section and form the opposite wing to that shape at that station not easy but with practise not so bad.we will be performing this very soon so will take loads of pics and post on here.

john

john

Hello, please excuse my ignorance

To me it looks like you are using car body filler on top of the foam and then you rub both sides down to the perfect shape as you have explained above, I am absolutely clueless as to what happens next.....Do you later make a mould from what you have shaped and then use that mould to make fibreglass panels or whatever, then later rip all your hard work off the vehicle to replace it with those panels

Not that I will ever be attempting this type of work but I am intrigued to know

To me it looks like you are using car body filler on top of the foam and then you rub both sides down to the perfect shape as you have explained above, I am absolutely clueless as to what happens next.....Do you later make a mould from what you have shaped and then use that mould to make fibreglass panels or whatever, then later rip all your hard work off the vehicle to replace it with those panels

Not that I will ever be attempting this type of work but I am intrigued to know

more work done finishing touches to thew plugs plus have nearly finished the air duct to carry the air from the rad out the bonnet outlet developing takes a lot of cardboard cutting etc. before the ally is finally cut but all worked out well.

john

DSCN3104 by Brundall Motorsport, on Flickr

DSCN3104 by Brundall Motorsport, on Flickr

DSCN3105 by Brundall Motorsport, on Flickr

DSCN3105 by Brundall Motorsport, on Flickr

DSCN3106 by Brundall Motorsport, on Flickr

DSCN3106 by Brundall Motorsport, on Flickr

DSCN3107 by Brundall Motorsport, on Flickr

DSCN3107 by Brundall Motorsport, on Flickr

DSCN3108 by Brundall Motorsport, on Flickr

DSCN3108 by Brundall Motorsport, on Flickr

DSCN3112 by Brundall Motorsport, on Flickr

DSCN3112 by Brundall Motorsport, on Flickr

DSCN3113 by Brundall Motorsport, on Flickr

DSCN3113 by Brundall Motorsport, on Flickr

DSCN3114 by Brundall Motorsport, on Flickr

DSCN3114 by Brundall Motorsport, on Flickr

DSCN3115 by Brundall Motorsport, on Flickr

DSCN3115 by Brundall Motorsport, on Flickr

john

DSCN3104 by Brundall Motorsport, on Flickr

DSCN3104 by Brundall Motorsport, on Flickr DSCN3105 by Brundall Motorsport, on Flickr

DSCN3105 by Brundall Motorsport, on Flickr DSCN3106 by Brundall Motorsport, on Flickr

DSCN3106 by Brundall Motorsport, on Flickr DSCN3107 by Brundall Motorsport, on Flickr

DSCN3107 by Brundall Motorsport, on Flickr DSCN3108 by Brundall Motorsport, on Flickr

DSCN3108 by Brundall Motorsport, on Flickr DSCN3112 by Brundall Motorsport, on Flickr

DSCN3112 by Brundall Motorsport, on Flickr DSCN3113 by Brundall Motorsport, on Flickr

DSCN3113 by Brundall Motorsport, on Flickr DSCN3114 by Brundall Motorsport, on Flickr

DSCN3114 by Brundall Motorsport, on Flickr DSCN3115 by Brundall Motorsport, on Flickr

DSCN3115 by Brundall Motorsport, on FlickrEdited by Engineer1949 on Monday 17th December 20:09

Gassing Station | Cerbera | Top of Page | What's New | My Stuff