Vauxhall 1.2 16v engine keeps spitting out cam followers

Discussion

Looking for some advice please. I bought a Corsa C with a 1.2 16v engine with 70,000 miles and FSH.

Shortly after buying it, I discovered that the exhaust followers on cyl 3 and 4 had detatched from their proper position - i.e. the 'cup' was no longer located on the hydraulic lifter. The car was running rough with a lot of top-end noice. I took the cam out, inspected it (it's worn, but not excessively so) and refitted the followers.

All was fine for a few hundred miles, then yesterday one of the followers on cylinder 1 islodged itself and the OBD flagged a fault code P0301 'misfire in cylinder 1'.

Today I took the cam out again - and re-fitted the follower...... but what could be causing it? It's now happened on 3 different cylinders.

The only other 'sympton' is on cold startup, the top end rattles like a bag of bolts for 3 or 4 seconds while the lifters fill with oil - but that's fairly normal, right?

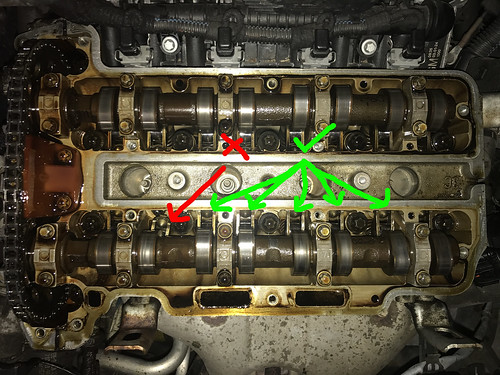

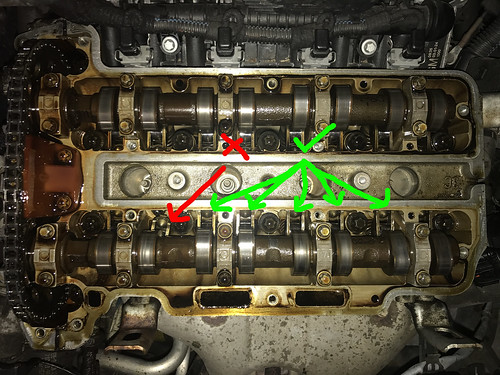

Here's a couple of pictures -

1. with the cam still in situ : Untitled by Wobble Chernobyl, on Flickr

Untitled by Wobble Chernobyl, on Flickr

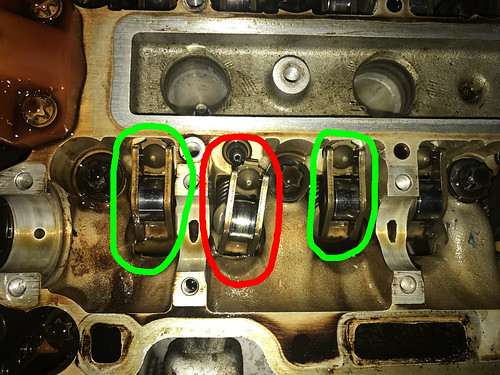

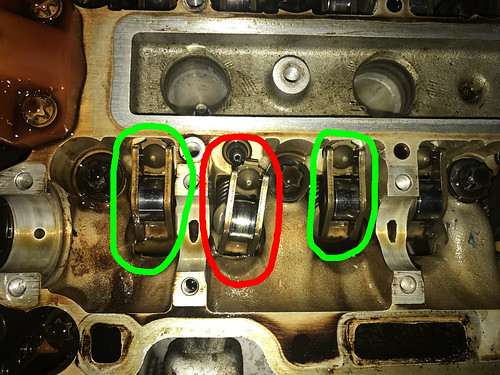

2. with the cam removed : Untitled by Wobble Chernobyl, on Flickr

Untitled by Wobble Chernobyl, on Flickr

Shortly after buying it, I discovered that the exhaust followers on cyl 3 and 4 had detatched from their proper position - i.e. the 'cup' was no longer located on the hydraulic lifter. The car was running rough with a lot of top-end noice. I took the cam out, inspected it (it's worn, but not excessively so) and refitted the followers.

All was fine for a few hundred miles, then yesterday one of the followers on cylinder 1 islodged itself and the OBD flagged a fault code P0301 'misfire in cylinder 1'.

Today I took the cam out again - and re-fitted the follower...... but what could be causing it? It's now happened on 3 different cylinders.

The only other 'sympton' is on cold startup, the top end rattles like a bag of bolts for 3 or 4 seconds while the lifters fill with oil - but that's fairly normal, right?

Here's a couple of pictures -

1. with the cam still in situ :

Untitled by Wobble Chernobyl, on Flickr

Untitled by Wobble Chernobyl, on Flickr2. with the cam removed :

Untitled by Wobble Chernobyl, on Flickr

Untitled by Wobble Chernobyl, on FlickrIt's possible the head was reconditioned previously and for example the exhaust valves are not std, too short, insufficient preload on the lifters. Or it could be lack of oil pressure but normally the spring inside the lifter keeps that pumped up. Valve springs weak or broken and over revving to the point of valve bounce are other causes.

Mignon said:

It's possible the head was reconditioned previously and for example the exhaust valves are not std, too short, insufficient preload on the lifters. Or it could be lack of oil pressure but normally the spring inside the lifter keeps that pumped up. Valve springs weak or broken and over revving to the point of valve bounce are other causes.

I don't *think* the head has been rebuilt, on the basis that I have a pretty full set of history/invoices etc and there's nothing to suggest that. But of course you never know.... I might try some replacement lifters on the Exhaust side and see if that does the trick, £6 each it's not the end of the world if it doesn't fix it.

Wobble2Chernobyl said:

The only other 'sympton' is on cold startup, the top end rattles like a bag of bolts for 3 or 4 seconds while the lifters fill with oil - but that's fairly normal, right?

I've never owned that engine, but I wouldn't expect it to rattle as you describe. Does that engine need the preload to be set correctly? It might just be a trick of the photos but to me it doesn't look like the rollers on the cam followers actually stick up above the side rails of the followers and clearly the cam lobes are too wide to fit down between those. The cam lobes should only contact the rollers obviously and not the side rails they rotate between. Is it possible those rollers are worn away? However I don't see lobe contact marks on the side rails. Odd.

Anyway a normal compression for a hydraulic tappet is about 3mm so I'd check that the cam compresses them at least that much when you fit it.

Anyway a normal compression for a hydraulic tappet is about 3mm so I'd check that the cam compresses them at least that much when you fit it.

Mignon said:

It might just be a trick of the photos but to me it doesn't look like the rollers on the cam followers actually stick up above the side rails of the followers and clearly the cam lobes are too wide to fit down between those. The cam lobes should only contact the rollers obviously and not the side rails they rotate between. Is it possible those rollers are worn away? However I don't see lobe contact marks on the side rails. Odd.

Anyway a normal compression for a hydraulic tappet is about 3mm so I'd check that the cam compresses them at least that much when you fit it.

I think it's the angle the photo was taken at - in reality the rollers sit well above the side rails.Anyway a normal compression for a hydraulic tappet is about 3mm so I'd check that the cam compresses them at least that much when you fit it.

Your second comment is interesting though... on some of the valves, there is no compression when refitting the cam - on those where the cam lobe is pointing away from the roller, there is a small gap between the cam and the roller, meaning the rocker is slightly loose (not enough to dislodge by hand - but perhaps on startup it could be enough for the cam to knock it off before the lifters re-fill with oil?

Should the lifters be pushing against the rocker, even when the engine is not running? Do they have springs inside them?

The more I think about it, the more it sounds like this is the problem.....

Some of those followers are looking pretty second hand so perhaps consider replacing those also.

With the follower on the back of the cam lobe the lifter should be under some compression. I don't know how much for that engine so you need to research that. If there is a clearance, as you suggest, then you could have the same effect as valve bounce.

Steve

With the follower on the back of the cam lobe the lifter should be under some compression. I don't know how much for that engine so you need to research that. If there is a clearance, as you suggest, then you could have the same effect as valve bounce.

Steve

Steve_D said:

Some of those followers are looking pretty second hand so perhaps consider replacing those also.

With the follower on the back of the cam lobe the lifter should be under some compression. I don't know how much for that engine so you need to research that. If there is a clearance, as you suggest, then you could have the same effect as valve bounce.

Steve

But the whole point of hydraulic lifters is to remove any clearance once filled with oil ? Can't remember the ones I changed having any 'Spring' in them, they just pumped up, removed any clearance then the nrv holds it full of oil and just at contact with the cam rather than pressing on it while the valve is closed.With the follower on the back of the cam lobe the lifter should be under some compression. I don't know how much for that engine so you need to research that. If there is a clearance, as you suggest, then you could have the same effect as valve bounce.

Steve

Edit

Humm, looks like some do.

Edited by Gary C on Monday 28th August 11:11

Did you notice any movement in the cam caps before you removed the cam?

The screws clamping the cam caps in position are very lightly torqued and these are often cited as the route-cause of snapped cams and other issues with this engine's top end.

My guess is that the cam cap screws have worked loose allowing the tappet to extend beyond it's normal range and cause the top-end noise you describe in your post. Eventually the tappet guide is working free of the tip of the valve because it's all getting a bit loose in that area.

After locking up the engine with a lock-set I would incrementally back off all the cam cap screws in a spiral pattern and then clean the hole and screw thoroughly with brake cleaner. Use a drinking straw to blow the holes clear of any brake cleaner if you don't have an airline (just don't breathe in).

Then apply a dab of Loctite 243 to each screw and sequentially re-torque them in to manufacturer's spec.

Hope this helps

The screws clamping the cam caps in position are very lightly torqued and these are often cited as the route-cause of snapped cams and other issues with this engine's top end.

My guess is that the cam cap screws have worked loose allowing the tappet to extend beyond it's normal range and cause the top-end noise you describe in your post. Eventually the tappet guide is working free of the tip of the valve because it's all getting a bit loose in that area.

After locking up the engine with a lock-set I would incrementally back off all the cam cap screws in a spiral pattern and then clean the hole and screw thoroughly with brake cleaner. Use a drinking straw to blow the holes clear of any brake cleaner if you don't have an airline (just don't breathe in).

Then apply a dab of Loctite 243 to each screw and sequentially re-torque them in to manufacturer's spec.

Hope this helps

HRCM said:

Did you notice any movement in the cam caps before you removed the cam?

The screws clamping the cam caps in position are very lightly torqued and these are often cited as the route-cause of snapped cams and other issues with this engine's top end.

My guess is that the cam cap screws have worked loose allowing the tappet to extend beyond it's normal range and cause the top-end noise you describe in your post. Eventually the tappet guide is working free of the tip of the valve because it's all getting a bit loose in that area.

After locking up the engine with a lock-set I would incrementally back off all the cam cap screws in a spiral pattern and then clean the hole and screw thoroughly with brake cleaner. Use a drinking straw to blow the holes clear of any brake cleaner if you don't have an airline (just don't breathe in).

Then apply a dab of Loctite 243 to each screw and sequentially re-torque them in to manufacturer's spec.

Hope this helps

Hey, thanks for a great bit of advice. Yes, originally the cam caps were a little loose - but after re-fitting the followers and cams, I torqued the followers up quite tight... but the followers still came loose again :-/ The screws clamping the cam caps in position are very lightly torqued and these are often cited as the route-cause of snapped cams and other issues with this engine's top end.

My guess is that the cam cap screws have worked loose allowing the tappet to extend beyond it's normal range and cause the top-end noise you describe in your post. Eventually the tappet guide is working free of the tip of the valve because it's all getting a bit loose in that area.

After locking up the engine with a lock-set I would incrementally back off all the cam cap screws in a spiral pattern and then clean the hole and screw thoroughly with brake cleaner. Use a drinking straw to blow the holes clear of any brake cleaner if you don't have an airline (just don't breathe in).

Then apply a dab of Loctite 243 to each screw and sequentially re-torque them in to manufacturer's spec.

Hope this helps

Mr2Mike said:

Are all the rollers on the followers free to rotate? Some of the cam lobes are quite marked, and you wouldn't normally expect to get any significant wear with roller followers. If a roller is seized it might be possible that the cam lobe is dragging the whole follower off the tappet

Hmm, I *think* the rollers were rotating freely - but you've got me doubting myself. One to check I think :-) thanks

I don't know how the oiling system works on that engine but if it's only happening on the exhaust side I'd be tempted to check there isn't a blocked oil feed to the lifters on that side. Maybe just pull the cams and lifters so the valves are all shut and see if oil appears in the lifter bores when you crank it.

Wobble2Chernobyl said:

Hmm, I *think* the rollers were rotating freely - but you've got me doubting myself. One to check I think :-)

thanks

Wouldn't it produce very obvious wear patterns on the roller if one was seized? I think insufficient preload allowing the followers to rattle loose engine off is a more likely explanation.thanks

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff