Front Crank Oil Seal Replacement AJP

Discussion

Have been getting on with some winter jobs, like replacing the heater pipes. While doing this I saw a glistening oil drop under the front crank seal🙁. I knew there was a leak, but thought (hoped) it could be from the crankcase breather.

Anyway, the car is currently up on QuickJacks in my garage. What are my options? Is it possible to disconnect a few things (exhaust, coolant hoses etc), put a trolley jack underneath and lift the front of the engine so the crank pulley clears the crossmember? I don't really want to try and take the engine completely out, I don't think my garage roof will have enough height. Or do I just reassemble the car and book it in to have fixed?

I've posted this on FB, but am aware some of the community aren't on there. Thanks!

Anyway, the car is currently up on QuickJacks in my garage. What are my options? Is it possible to disconnect a few things (exhaust, coolant hoses etc), put a trolley jack underneath and lift the front of the engine so the crank pulley clears the crossmember? I don't really want to try and take the engine completely out, I don't think my garage roof will have enough height. Or do I just reassemble the car and book it in to have fixed?

I've posted this on FB, but am aware some of the community aren't on there. Thanks!

You might be able to do it in place by removing coolant pipes for access. The pulley can be removed by taking out the 4 cap head screws and the crank end bolt. Then the drive sleeve can be prized out (watch out for the woodruff key), and finally the seal housing can be removed. Although I believe the last bit might be engine year specific.

Your main problem as you know will be access, but if you can get the pulley clear then I think you should manage the rest by moving the engine around a bit. Might need to remove the front engine mounts to drop the front or move it side to side.

.

.

.

.

Your main problem as you know will be access, but if you can get the pulley clear then I think you should manage the rest by moving the engine around a bit. Might need to remove the front engine mounts to drop the front or move it side to side.

In case anyone does a search on this in the future, it looks like I have done it! Obviously this is just my experience, but it might be useful.

With a bit of guidance from a fellow on the Cerbera FB page, a new seal has been fitted by just lifting the engine by about a cm. There was enough space through the chassis without removing anything else apart from the bracket that holds to windscreen washer fluid (I had to saw those bolts, clearly not been off in 27 years!).

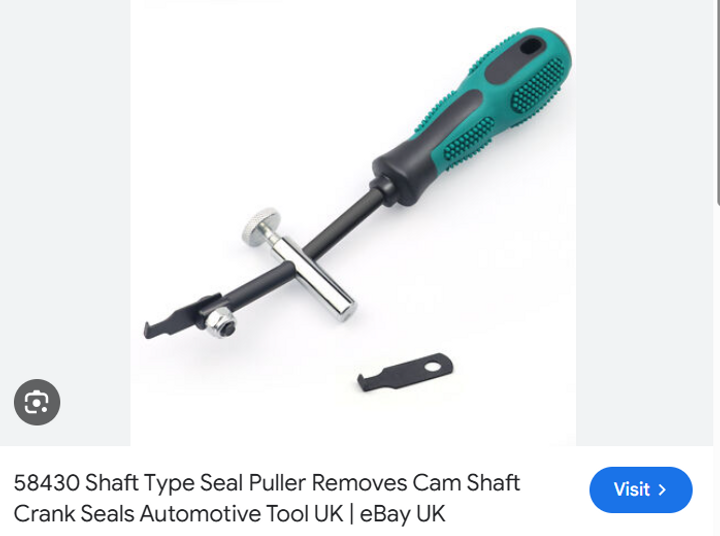

I needed a 32mm deep impact socket (deep socket only needed to provide clearance for the impact wrench), a powerful impact wrench with a short body and a seal removal tool like this:

I already had one of these pullers, using the jaws facing outwards to remove the aircon pulley and inwards to remove the hub:

https://www.sealey.co.uk/reversible-twin-leg-pulle...

Undoing the engine mounts and lifting the engine by a cm was enough to remove the pulley between the chassis and the engine. Seal removal was easy with the tool and after thoroughly cleaning everything I had to use a large socket and a short length of pipe to ensure the new seal went in squarely. It was then a case of reassembly, torquing the main bolt to 80 lbft and the smaller pulley bolts (5mm allen fitting) to 15 lbft with a bit of threadlock on each.

With a bit of guidance from a fellow on the Cerbera FB page, a new seal has been fitted by just lifting the engine by about a cm. There was enough space through the chassis without removing anything else apart from the bracket that holds to windscreen washer fluid (I had to saw those bolts, clearly not been off in 27 years!).

I needed a 32mm deep impact socket (deep socket only needed to provide clearance for the impact wrench), a powerful impact wrench with a short body and a seal removal tool like this:

I already had one of these pullers, using the jaws facing outwards to remove the aircon pulley and inwards to remove the hub:

https://www.sealey.co.uk/reversible-twin-leg-pulle...

Undoing the engine mounts and lifting the engine by a cm was enough to remove the pulley between the chassis and the engine. Seal removal was easy with the tool and after thoroughly cleaning everything I had to use a large socket and a short length of pipe to ensure the new seal went in squarely. It was then a case of reassembly, torquing the main bolt to 80 lbft and the smaller pulley bolts (5mm allen fitting) to 15 lbft with a bit of threadlock on each.

Message Board | Cerbera | Top of Page | What's New | My Stuff

.I think this makes it a bit more difficult to replace even when I have access! Will make some calls.....

.I think this makes it a bit more difficult to replace even when I have access! Will make some calls.....