Con-Rods in charged engines

Discussion

Ok, My interpretation of things was that Revs kill rods. In simple terms.

So, when building a turbo/supercharged engine and having the rev limit the same as a standard car, what are the reasons needed for stronger rods?

Obviously the bearing material would need to change, but would a compressive load on the road from extra boost and power create the same kind of problems as too many revs?

Anyone had a rod fail due to too much power as opposed to too many revs?

Dave!

So, when building a turbo/supercharged engine and having the rev limit the same as a standard car, what are the reasons needed for stronger rods?

Obviously the bearing material would need to change, but would a compressive load on the road from extra boost and power create the same kind of problems as too many revs?

Anyone had a rod fail due to too much power as opposed to too many revs?

Dave!

I've wondered about this as well. My take is that so long as the boosted cylinder pressure isn't raised by much I reckon factory rods will be fine. Peak cylinder pressure lasts for a nanosecond and then the rod's on the downstroke and rotating the crank anyway. There will be pressure pushing the piston downwards for longer but it's lower then the atmo high pressure spike. Most people will usually lower the compression ratio or just use low boost if engine internals aren't changed. Plenty of people turbocharge stock engines without any rod issues.

Boosted LS1 said:

I've wondered about this as well. My take is that so long as the boosted cylinder pressure isn't raised by much I reckon factory rods will be fine. Peak cylinder pressure lasts for a nanosecond and then the rod's on the downstroke and rotating the crank anyway. There will be pressure pushing the piston downwards for longer but it's lower then the atmo high pressure spike. Most people will usually lower the compression ratio or just use low boost if engine internals aren't changed. Plenty of people turbocharge stock engines without any rod issues.

This was pretty much my thinking. But I couldn't think of a technical reason as to why you would need vastly upgraded rods to cope with more power. Only revs.I will be lowering the compression but 8 rods is a large expense so I want to know i'm putting the money into the right areas.

From doing some reading i'll be putting around 1.5 bar of boost into the engine (Based on another similarly tuned engine) but how that relates to the peak cylinder pressure I don't know how to work it out.

Dave!

Howitzer said:

Boosted LS1 said:

I've wondered about this as well. My take is that so long as the boosted cylinder pressure isn't raised by much I reckon factory rods will be fine. Peak cylinder pressure lasts for a nanosecond and then the rod's on the downstroke and rotating the crank anyway. There will be pressure pushing the piston downwards for longer but it's lower then the atmo high pressure spike. Most people will usually lower the compression ratio or just use low boost if engine internals aren't changed. Plenty of people turbocharge stock engines without any rod issues.

This was pretty much my thinking. But I couldn't think of a technical reason as to why you would need vastly upgraded rods to cope with more power. Only revs.I will be lowering the compression but 8 rods is a large expense so I want to know i'm putting the money into the right areas.

From doing some reading i'll be putting around 1.5 bar of boost into the engine (Based on another similarly tuned engine) but how that relates to the peak cylinder pressure I don't know how to work it out.

Dave!

Don't be cheap,get a good set of rods with thick piston pins.Lightweights are NOT good in a turbo/supercharged situation...

It's all in relation to peak ppressures- although rods have an easier time of it in a boosted engine than a normally aspirated engine with the same peak cylinder pressures.

This is because on an N/A engine the rod is being stretched on the intake stroke and compressed on the other three- on a boosted engine it is always under compression. This eliminates the transfer between the two different states.

As mentioned above though, build a good bottom end you can rely on. Pay particular attention to oil volume and pressure and remove every bung and plug in the oil galleries once the machining is complete on the block- it's the only way to ensure that a bit of swarf isn't going to shift and plug an oilway in six months time.

It's also worth spending the time to fit piston oil squirters. This will drop your piston crown temperatures drastically. BMW ones tend to be pretty cheap and also have an inbuilt pressure valve to prevent them working below a set pressure (60psi, I think).

This is because on an N/A engine the rod is being stretched on the intake stroke and compressed on the other three- on a boosted engine it is always under compression. This eliminates the transfer between the two different states.

As mentioned above though, build a good bottom end you can rely on. Pay particular attention to oil volume and pressure and remove every bung and plug in the oil galleries once the machining is complete on the block- it's the only way to ensure that a bit of swarf isn't going to shift and plug an oilway in six months time.

It's also worth spending the time to fit piston oil squirters. This will drop your piston crown temperatures drastically. BMW ones tend to be pretty cheap and also have an inbuilt pressure valve to prevent them working below a set pressure (60psi, I think).

Edited by BB-Q on Wednesday 20th August 18:41

BB-Q said:

It's all in relation to peak ppressures- although rods have an easier time of it in a boosted engine than a normally aspirated engine with the same peak cylinder pressures.

This is because on an N/A engine the rod is being stretched on the intake stroke and compressed on the other three- on a boosted engine it is always under compression. This eliminates the transfer between the two different states.

As mentioned above though, build a good bottom end you can rely on. Pay particular attention to oil volume and pressure and remove every bung and plug in the oil galleries once the machining is complete on the block- it's the only way to ensure that a bit of swarf isn't going to shift and plug an oilway in six months time.

It's also worth spending the time to fit piston oil squirters. This will drop your piston crown temperatures drastically. BMW ones tend to be pretty cheap and also have an inbuilt pressure valve to prevent them working below a set pressure (60psi, I think).

Ahh, so the lack of transition between the stretch and compression is what gives it an easier time. This is because on an N/A engine the rod is being stretched on the intake stroke and compressed on the other three- on a boosted engine it is always under compression. This eliminates the transfer between the two different states.

As mentioned above though, build a good bottom end you can rely on. Pay particular attention to oil volume and pressure and remove every bung and plug in the oil galleries once the machining is complete on the block- it's the only way to ensure that a bit of swarf isn't going to shift and plug an oilway in six months time.

It's also worth spending the time to fit piston oil squirters. This will drop your piston crown temperatures drastically. BMW ones tend to be pretty cheap and also have an inbuilt pressure valve to prevent them working below a set pressure (60psi, I think).

Edited by BB-Q on Wednesday 20th August 18:41

Piston squirters, is this a common modification that can be retrofitted to most engines? I've only seen it on our diesels and it was all precast into the block itself, but I presume a decent feed to a fabricated rail would do the same thing, aslong as you angled them right (We had perspex plates with a hole in and adjusted the squirters from the top).

Also, is it best to find pistons that match my bore or close to my bore size and then have rods to suit, or the other way around? I know that rod length can change the piston side loading but how important this is in a low revving (6000rpm) engine i'm not sure.

Dave!

I'm no expert on v8's, but the design of most of them is pretty ancient and would greatly benefit from updating. My area of expertise is Volvo redblocks, but the same principles apply.

Here is a comparison of the old and new assemblies for my redblock- the new assembly on the right includes longer rods, which allow a much smaller height between pin and piston crown, made permissable by improvements in material technologies since the originals were designed.They're made by CP, are forged and cost $740 (set of 4) including pins, clips and rings. Rods were custom made in a batch for our turbobricks forum and cost $100 each including ARP bolts. They're made in the same foundry in China as the Eagle rods. They've been thoroughly tested and conform to all specifications that were set out for their production:

That little lot saves a pound in weight per cylinder.With piston speeds around 50mph, that's a massive improvement and much less strain on the crank/block. I'll happily rev this engine to 8000rpm now if it will make power up that high.

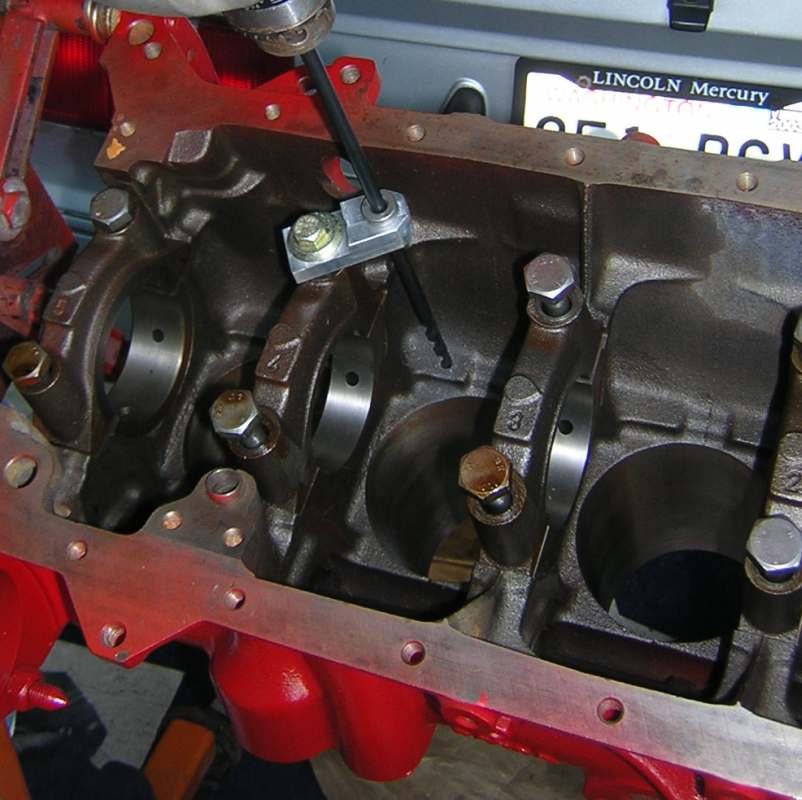

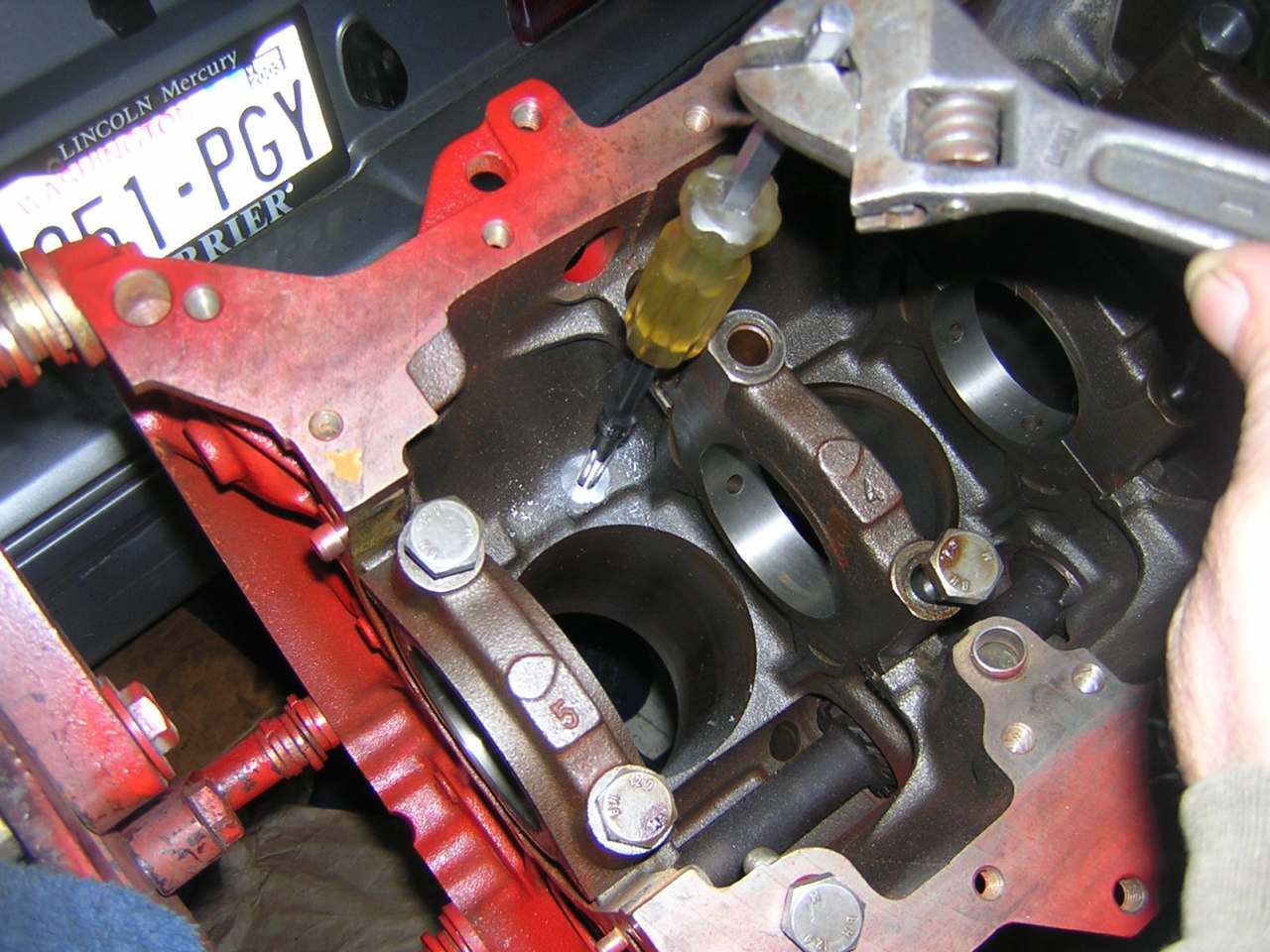

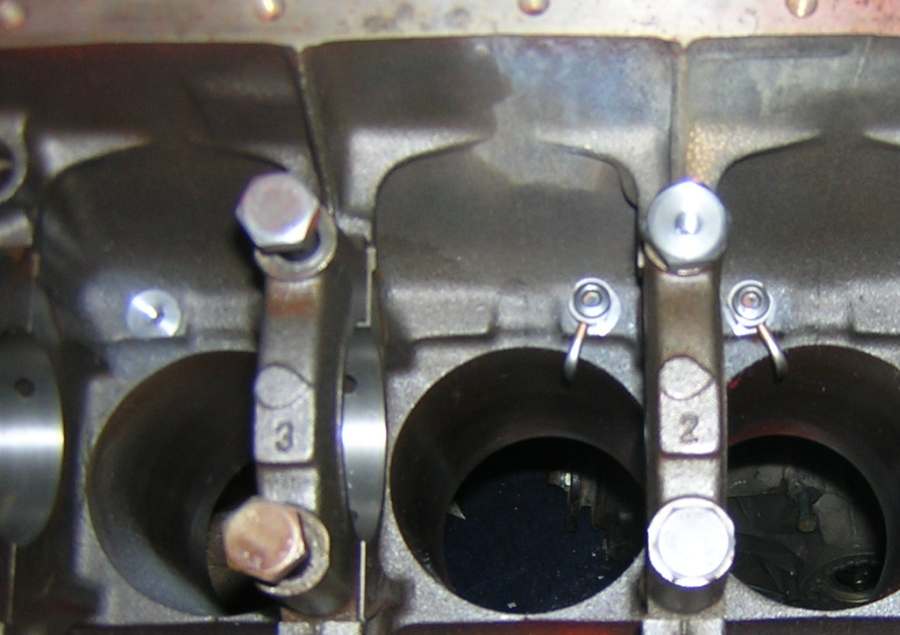

For piston oil squirters it's not that difficult to drill straight into the oil gallery to retrofit them. Here's some pictures of them being fitted to a block using a kit made my one of the members which is shared around the forum. It's an hour's work that can be done at home in this case. The squirters are BMW ones:

Prices are in $ as I get all my engine stuff from the same guy in Seattle.

Here is a comparison of the old and new assemblies for my redblock- the new assembly on the right includes longer rods, which allow a much smaller height between pin and piston crown, made permissable by improvements in material technologies since the originals were designed.They're made by CP, are forged and cost $740 (set of 4) including pins, clips and rings. Rods were custom made in a batch for our turbobricks forum and cost $100 each including ARP bolts. They're made in the same foundry in China as the Eagle rods. They've been thoroughly tested and conform to all specifications that were set out for their production:

That little lot saves a pound in weight per cylinder.With piston speeds around 50mph, that's a massive improvement and much less strain on the crank/block. I'll happily rev this engine to 8000rpm now if it will make power up that high.

For piston oil squirters it's not that difficult to drill straight into the oil gallery to retrofit them. Here's some pictures of them being fitted to a block using a kit made my one of the members which is shared around the forum. It's an hour's work that can be done at home in this case. The squirters are BMW ones:

Prices are in $ as I get all my engine stuff from the same guy in Seattle.

Edited by BB-Q on Thursday 21st August 09:18

That's excellent BBQ, very much appreciated.

I see the squirters are pretty much the same design as the ones we used on our Perkins diesels.

I'm surprised at the cost of the custom rods, that's very very good indeed, were these designed by the manufacturer or was a piston and rod assembly given along with a deck height and then they had the expertise to design them to suit?

The engine i'm using is quite old, a M117 unit from the old 560SEL Merc and a good strong unit. It's been turbocharged before but finding information regarding it has proven very tough.

Have you had any oil flow issues with the squirters? We used to fit a higher flow oil pump on the turbo models fitted with squirters.

Dave!

I see the squirters are pretty much the same design as the ones we used on our Perkins diesels.

I'm surprised at the cost of the custom rods, that's very very good indeed, were these designed by the manufacturer or was a piston and rod assembly given along with a deck height and then they had the expertise to design them to suit?

The engine i'm using is quite old, a M117 unit from the old 560SEL Merc and a good strong unit. It's been turbocharged before but finding information regarding it has proven very tough.

Have you had any oil flow issues with the squirters? We used to fit a higher flow oil pump on the turbo models fitted with squirters.

Dave!

Howitzer said:

That's excellent BBQ, very much appreciated.

I see the squirters are pretty much the same design as the ones we used on our Perkins diesels.

I'm surprised at the cost of the custom rods, that's very very good indeed, were these designed by the manufacturer or was a piston and rod assembly given along with a deck height and then they had the expertise to design them to suit?

The engine i'm using is quite old, a M117 unit from the old 560SEL Merc and a good strong unit. It's been turbocharged before but finding information regarding it has proven very tough.

Have you had any oil flow issues with the squirters? We used to fit a higher flow oil pump on the turbo models fitted with squirters.

Dave!

The pistons and rods are a custom design, not an adaptation of an existing one (though I suspect that the pistons would have come from some sort of standard blank). The guy who designed them is the guy I bought them from- an engineer, racer and generally very experienced and knowledgeable old fart.I see the squirters are pretty much the same design as the ones we used on our Perkins diesels.

I'm surprised at the cost of the custom rods, that's very very good indeed, were these designed by the manufacturer or was a piston and rod assembly given along with a deck height and then they had the expertise to design them to suit?

The engine i'm using is quite old, a M117 unit from the old 560SEL Merc and a good strong unit. It's been turbocharged before but finding information regarding it has proven very tough.

Have you had any oil flow issues with the squirters? We used to fit a higher flow oil pump on the turbo models fitted with squirters.

Dave!

Rods can be made for any engine you like, subject to a minimum order (of about 40 rods I think, but I'd have to check that). If you want to give me exact specs I can pass them on for you to see if there's anything that's suitable already in production. Bear in mind that the price we got was due to a massive group buy and so you may end up paying a bit more for the rods, but not fortunes more.

With the Volvo engines the turbo motors got a higher flowing oil pump anyway, but they didn't get squirters as standard until 1993. With the typical turbobricker being completely broke, John made this kit and supplies the squirters to save people hunting down a late block. BMW ones are used because the Volvo ones are no longer available. As I mentioned before, they have a check valve built into them to prevent them working at low pressures. Your oil pump should have plenty of spare capacity at higher rpm, but you should check with the Merc engine experts on that one.

I've got a reply back from Carillo and they want $378 dollars per rod and that obviously wont include any carrige or tax payable in the uk.

I would also have to do all the measurements myself and they would then spec the rod to my needs.

They did send me a very handy measurement sheet though with everything they need on it, so i'd need to know the gudgeon pin size etc anyway depending on which piston I used.

Dave!

I would also have to do all the measurements myself and they would then spec the rod to my needs.

They did send me a very handy measurement sheet though with everything they need on it, so i'd need to know the gudgeon pin size etc anyway depending on which piston I used.

Dave!

[quote=BB-Q]I'm no expert on v8's, but the design of most of them is pretty ancient and would greatly benefit from updating. My area of expertise is Volvo redblocks, but the same principles apply.

Here is a comparison of the old and new assemblies for my redblock- the new assembly on the right includes longer rods, which allow a much smaller height between pin and piston crown, made permissable by improvements in material technologies since the originals were designed.They're made by CP, are forged and cost $740 (set of 4) including pins, clips and rings. Rods were custom made in a batch for our turbobricks forum and cost $100 each including ARP bolts. They're made in the same foundry in China as the Eagle rods. They've been thoroughly tested and conform to all specifications that were set out for their production................. etc. [/quote=BB-Q]

Very well put indeed! Excellent pictures to illustrate as well. Should be submitted to Haynes' Manuals immediately to be included with their next update on the Volvo Redblock manual!

Here is a comparison of the old and new assemblies for my redblock- the new assembly on the right includes longer rods, which allow a much smaller height between pin and piston crown, made permissable by improvements in material technologies since the originals were designed.They're made by CP, are forged and cost $740 (set of 4) including pins, clips and rings. Rods were custom made in a batch for our turbobricks forum and cost $100 each including ARP bolts. They're made in the same foundry in China as the Eagle rods. They've been thoroughly tested and conform to all specifications that were set out for their production................. etc. [/quote=BB-Q]

Very well put indeed! Excellent pictures to illustrate as well. Should be submitted to Haynes' Manuals immediately to be included with their next update on the Volvo Redblock manual!

Unless the rods are seriously over spec'd by the factory I doubt you'll get away with running 1.5bar boost on them.

This is the result of running an RS2 turbo at 1.4bar on std audi S2 rods

I don't think it's ever been proved that it was the huge increase in torque that caused this or an issue of 'spark hop' in the distrbutor, either way I'd get some uprated rods. If the engine does go bang because of an issue with the factory rods it will cost you a lot more to rebuild than a set of uprated rods will do now.

This is the result of running an RS2 turbo at 1.4bar on std audi S2 rods

I don't think it's ever been proved that it was the huge increase in torque that caused this or an issue of 'spark hop' in the distrbutor, either way I'd get some uprated rods. If the engine does go bang because of an issue with the factory rods it will cost you a lot more to rebuild than a set of uprated rods will do now.

Gassing Station | Drag Racing | Top of Page | What's New | My Stuff