Copper spinning 2

Discussion

My first attempt to make a small dome from a copper disk almost worked. I had to re-anneal it three times, used the back of a gouge as a tool and candle wax to reduce friction. It took a couple of hours, but I'm not satisfied with the result.

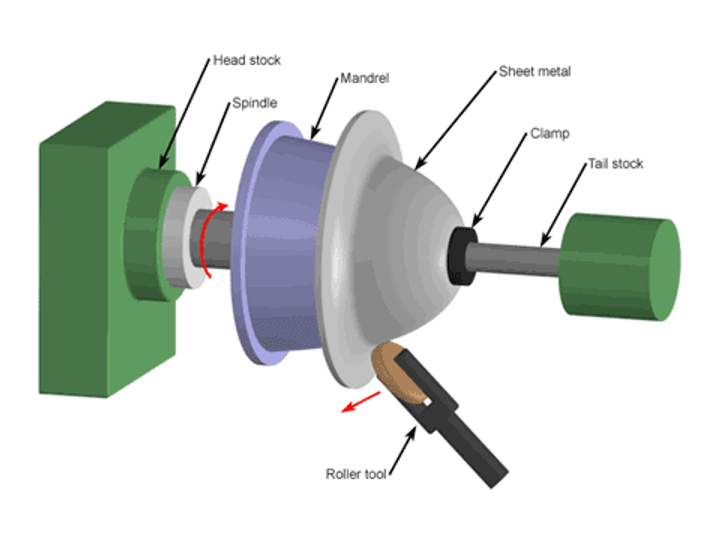

It would be much easier with a 'roller tool' as shown in this image:

It's just a wheel mounted in the end of a handle, but I can't find one for sale. I have one of these, but obviously the knurled wheel rules it out:

Has anyone seen a roller tool for sale?

It would be much easier with a 'roller tool' as shown in this image:

It's just a wheel mounted in the end of a handle, but I can't find one for sale. I have one of these, but obviously the knurled wheel rules it out:

Has anyone seen a roller tool for sale?

Can’t help with the tooling but this might be of interest to you silver spinning. One of a number of films made by Ken Hawley trying to document the work of Sheffield’s ‘Little mesters’ in the city’s twilight years of manufacturing, some of the men being filmed at the end of their 50-60 year working lives.

TGCOTF-dewey said:

Can't you just replace the knurled wheel with a standard bearing with the correct ID?

In theory but I don't have the metalworking skills/kit/materials. I can't even tell how the knurled wheel is fitted. I could make a wooden wheel though!wolfracesonic said:

Can’t help with the tooling but this might be of interest to you silver spinning. One of a number of films made by Ken Hawley trying to document the work of Sheffield’s ‘Little mesters’ in the city’s twilight years of manufacturing, some of the men being filmed at the end of their 50-60 year working lives.

Thanks. Yes, it's much like wood turning, only different, and whilst there are videos showing it, it seems quite a black art.thebraketester said:

How thick is the material?

About 0.5mm. After annealing it's very soft, but of course work hardens as you go, perhaps aided by the friction from the gouge back. A wheel would remove the friction almost completely.Googling 'metal spinning tool' and looking at images found some references, and https://www.maytool.com/metal-shops make them.

Not the most obvious thing for people to hold in stock and there seem to be lots of different shapes of wheel so not the easiest thing to buy from what I see.

As they're all basically a rod, with a slot in the end, cross drilled for a pin, with a shaped wheel with a bearing in the middle it wouldn't be too hard for any basic machine shop to knock one or more up. The Google images given all the basic info for how the things are constructed.

Not the most obvious thing for people to hold in stock and there seem to be lots of different shapes of wheel so not the easiest thing to buy from what I see.

As they're all basically a rod, with a slot in the end, cross drilled for a pin, with a shaped wheel with a bearing in the middle it wouldn't be too hard for any basic machine shop to knock one or more up. The Google images given all the basic info for how the things are constructed.

Also here's a maybe useful suitably ancient book on the subject including the various tools and their uses:

https://www.gutenberg.org/files/49275/49275-h/4927...

https://www.gutenberg.org/files/49275/49275-h/4927...

If you've got some wood work skills, just make a similar shaped wooden tuning fork shaped handle, buy a nylock nut and bolt with a shank the same depth as the gap in your fork and a cheap bearing with the same ID as the shank.

Probably cost ten quid and take half an hour to make. You can even change wheel diameters then with a bearing swap.

Or drill out the shaft in the tool you have and buy same sized bolt + matching bearing.

Probably cost ten quid and take half an hour to make. You can even change wheel diameters then with a bearing swap.

Or drill out the shaft in the tool you have and buy same sized bolt + matching bearing.

Thanks for the ideas, all good stuff.

My first problem is holding the work. All the videos show a block of something, presumably wood, held against the work by the tailstock. So I cut a short length of dowel and located that between the live centre on the tailstock and the work. Applied as much pressure as I thought reasonable.

Then I tried forming the copper - being a woodturner by instinct I used a woodturning rest and just the end of a candle to shove with.To start with it went well - but then the copper moved off-centre and I had to stop. The wood block wasn't adequate. So I added a small screw in the centre of the work into the former underneath to keep it centred. But now somehow the whole thing is off centre... time for a break.

Plan B is to buy a chunk of solid copper and turn it into a dome, but that will be expensive.

My first problem is holding the work. All the videos show a block of something, presumably wood, held against the work by the tailstock. So I cut a short length of dowel and located that between the live centre on the tailstock and the work. Applied as much pressure as I thought reasonable.

Then I tried forming the copper - being a woodturner by instinct I used a woodturning rest and just the end of a candle to shove with.To start with it went well - but then the copper moved off-centre and I had to stop. The wood block wasn't adequate. So I added a small screw in the centre of the work into the former underneath to keep it centred. But now somehow the whole thing is off centre... time for a break.

Plan B is to buy a chunk of solid copper and turn it into a dome, but that will be expensive.

Its definitely a dark art, I had an interview at an old skool metal spinners when I was about 18 and watched one guy spin up a large industrial lamp surround.

It's a bit like throwing a clay pot on a wheel, he used a couple of different gouge type tools and a trimming tool to finish the job.

His rest was movable and had movable metal pins in to provide somewhere to position the gouge tools.

I didn't take the job as every one of the 4 blokes working there had at least one finger missing.

It's a bit like throwing a clay pot on a wheel, he used a couple of different gouge type tools and a trimming tool to finish the job.

His rest was movable and had movable metal pins in to provide somewhere to position the gouge tools.

I didn't take the job as every one of the 4 blokes working there had at least one finger missing.

dudleybloke said:

Its definitely a dark art, I had an interview at an old skool metal spinners when I was about 18 and watched one guy spin up a large industrial lamp surround.

It's a bit like throwing a clay pot on a wheel, he used a couple of different gouge type tools and a trimming tool to finish the job.

His rest was movable and had movable metal pins in to provide somewhere to position the gouge tools.

I didn't take the job as every one of the 4 blokes working there had at least one finger missing.

Metal spinning by hand is definitely one of those skills where it looks easy but is in fact incredibly difficult.It's a bit like throwing a clay pot on a wheel, he used a couple of different gouge type tools and a trimming tool to finish the job.

His rest was movable and had movable metal pins in to provide somewhere to position the gouge tools.

I didn't take the job as every one of the 4 blokes working there had at least one finger missing.

I was at a machine tool show years back watching an old boy with decades of experience turn a disc of aluminium into a spraygun pot in a matter of minutes but I bet he would've struggled to explain the subtleties of his technique as he probably just 'knew' from his years of experience what to do.

Simpo Two said:

Thanks for the ideas, all good stuff.

My first problem is holding the work. All the videos show a block of something, presumably wood, held against the work by the tailstock. So I cut a short length of dowel and located that between the live centre on the tailstock and the work. Applied as much pressure as I thought reasonable.

Then I tried forming the copper - being a woodturner by instinct I used a woodturning rest and just the end of a candle to shove with.To start with it went well - but then the copper moved off-centre and I had to stop. The wood block wasn't adequate. So I added a small screw in the centre of the work into the former underneath to keep it centred. But now somehow the whole thing is off centre... time for a break.

Plan B is to buy a chunk of solid copper and turn it into a dome, but that will be expensive.

You were asking for a "rolling tool" My first problem is holding the work. All the videos show a block of something, presumably wood, held against the work by the tailstock. So I cut a short length of dowel and located that between the live centre on the tailstock and the work. Applied as much pressure as I thought reasonable.

Then I tried forming the copper - being a woodturner by instinct I used a woodturning rest and just the end of a candle to shove with.To start with it went well - but then the copper moved off-centre and I had to stop. The wood block wasn't adequate. So I added a small screw in the centre of the work into the former underneath to keep it centred. But now somehow the whole thing is off centre... time for a break.

Plan B is to buy a chunk of solid copper and turn it into a dome, but that will be expensive.

The tailstock part of the setup I saw had a pretty big wheel to move it, was probably about 6ft diameter and put quite a lot of force on the workpiece.

The contact point might have had leather on it but I could be totally wrong.

The whole demo piece he did took about a minute to do including talking to me.

The contact point might have had leather on it but I could be totally wrong.

The whole demo piece he did took about a minute to do including talking to me.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff