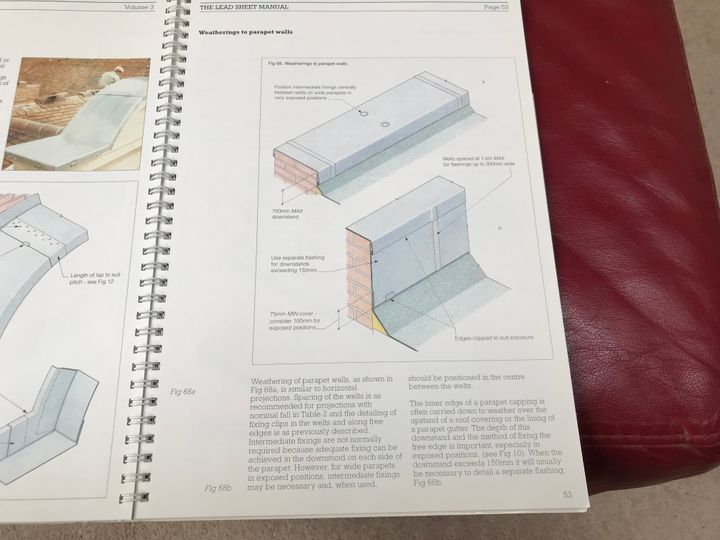

Parapet wall coping

Discussion

I've tacked a single skin garage along the side of the house to be used for storage and a workshop. It's 10x3 and I had the parapet top capped with timber over the blocks and an edpm roof. Come spring 150mm x 50m green oak timbers will be bolted to the exterior at intervals and larch board cladding between them to give the look of it being an oak frame building. Planning would allow it to be built as an oak frame but we can clad as such.

On to the coping aspect.

Stone won't be stable as the total width needs to be 100mm of wall + 50mm of cladding + 20-30mm of overhang on either side so a total width around 200mm but with only half of that available for solid fixing.

Aluminium looks a simple solution in regard to fixing but it's going to look too modern and 'on trend' for the main building and the faux oak garage.

So my thinking is to cut 18mm osb into 200mm strips and to screw atop the parapet so as to form the coping. Then cover with code 4 lead (300mm wide) tapping it over far enough that water can't run to the wood.

This would arguably give the best look as the lead finish will blend far better with the old style timber and old stone walls.

Or maybe use some form of plastic boarding rather than osb and lead that?

On to the coping aspect.

Stone won't be stable as the total width needs to be 100mm of wall + 50mm of cladding + 20-30mm of overhang on either side so a total width around 200mm but with only half of that available for solid fixing.

Aluminium looks a simple solution in regard to fixing but it's going to look too modern and 'on trend' for the main building and the faux oak garage.

So my thinking is to cut 18mm osb into 200mm strips and to screw atop the parapet so as to form the coping. Then cover with code 4 lead (300mm wide) tapping it over far enough that water can't run to the wood.

This would arguably give the best look as the lead finish will blend far better with the old style timber and old stone walls.

Or maybe use some form of plastic boarding rather than osb and lead that?

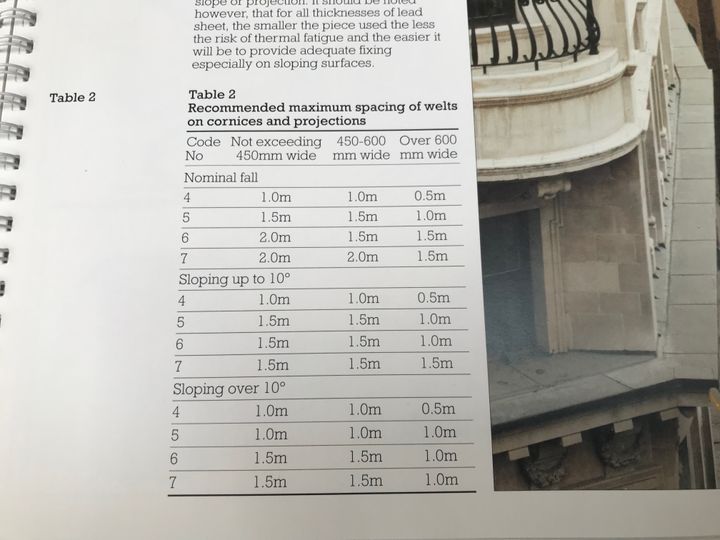

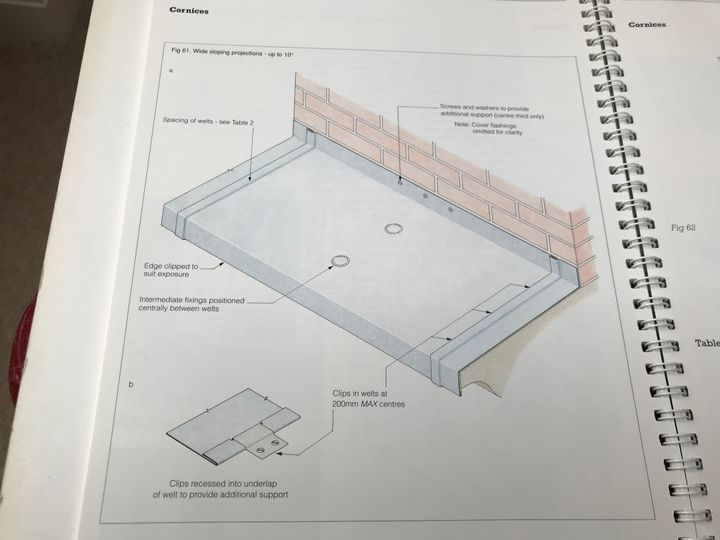

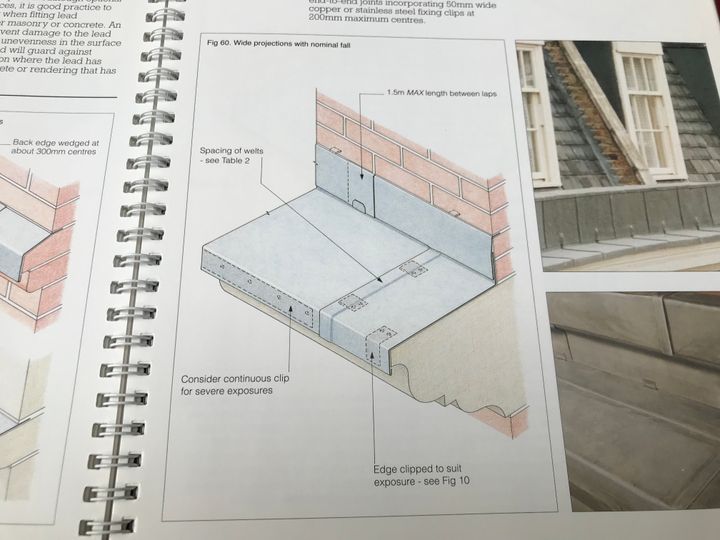

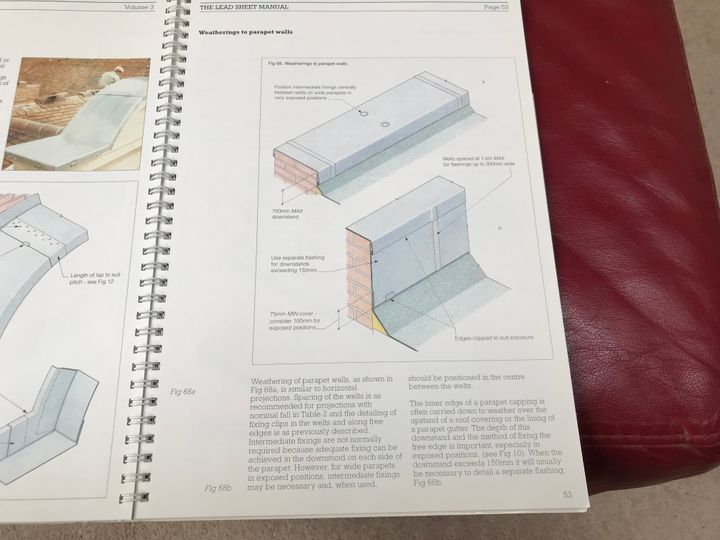

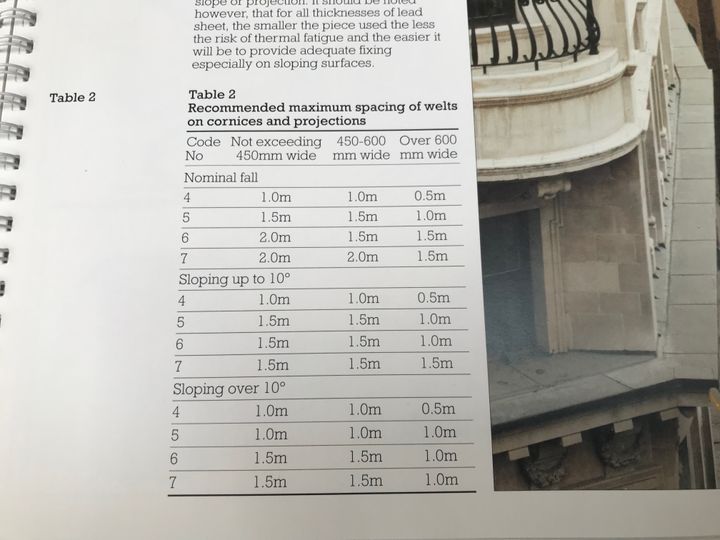

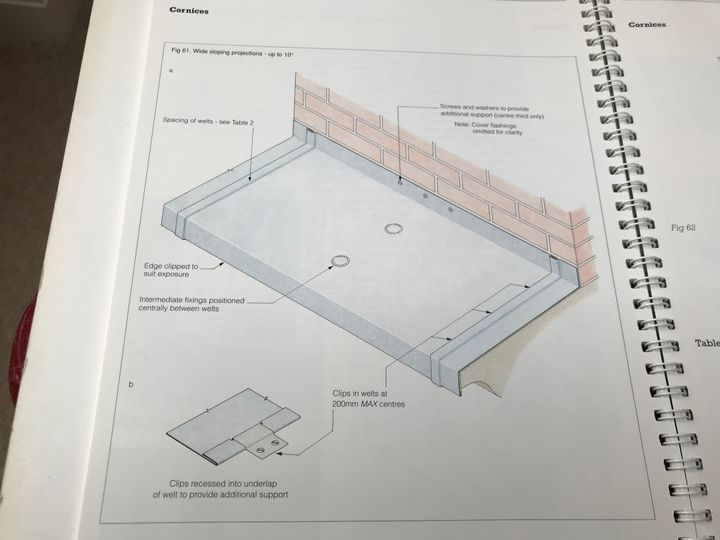

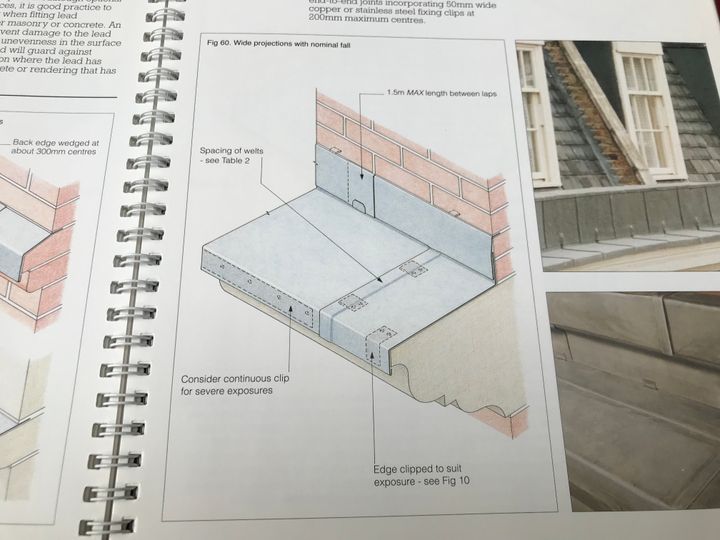

Lead would be okay but you need to limit your runs to 1.5m with code 4 so a welted joint will be required every 1.35m or so. A 25mm x 50mm tanalised drip (slate) batten on each side would deal with the run off.

Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Edited by Lotobear on Tuesday 21st January 10:37

Lotobear said:

Lead would be okay but you need to limit your runs to 1.5m with code 4 so a welted joint will be required every 1.35m or so. A 25mm x 50mm tanalised drip (slate) batten on each side would deal with the run off.

Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Thanks. Didn't have much joy googling for zinc copings earlier. Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Edited by Lotobear on Tuesday 21st January 10:37

Is the run length for lead really that short? I thought I'd get away with longer runs before risking expansion issues?

DonkeyApple said:

Lotobear said:

Lead would be okay but you need to limit your runs to 1.5m with code 4 so a welted joint will be required every 1.35m or so. A 25mm x 50mm tanalised drip (slate) batten on each side would deal with the run off.

Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Thanks. Didn't have much joy googling for zinc copings earlier. Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Edited by Lotobear on Tuesday 21st January 10:37

Is the run length for lead really that short? I thought I'd get away with longer runs before risking expansion issues?

I would try and fin a zinc firm who can pre run the required profile off site and then you could probably fit it yourself.

I toyed with lead to cap a parapet on a timber framed garden building, but the numbers scared me.

I did it in GRP, you can buy 90 degree profiles to form the 2 edges with a suitable overhang for drip detail, then just do the matting on top of the OSB. Grey topcoat looks like lead from a small distance.

I did it in GRP, you can buy 90 degree profiles to form the 2 edges with a suitable overhang for drip detail, then just do the matting on top of the OSB. Grey topcoat looks like lead from a small distance.

Lotobear said:

No that's the limit set by the Lead Sheet Association if you wish to avoid thermal cracking. You can go up a code and increase the intervals but it becomes much harder to work with and form the necessary joints as well as increasing the cost.

I would try and fin a zinc firm who can pre run the required profile off site and then you could probably fit it yourself.

Yeah 1.5m is the rule. I found out the hard way with a run I did of a full 5m roll cracking in two or three places I would try and fin a zinc firm who can pre run the required profile off site and then you could probably fit it yourself.

Maybe lead grey coloured powder coated ally could work?

If you’re doing it yourself I’d go for aluminium, Alumasc do a range of finishes, I’m sure there is something to match the aesthetic of chez Apple. Lead would look the part no doubt but it does require a certain amount of specialist skill and knowledge, especially if lead burning and complicated bossing is required: will cost an arm and a leg as well. Here’s some pics to put you off

wolfracesonic said:

If you’re doing it yourself I’d go for aluminium, Alumasc do a range of finishes, I’m sure there is something to match the aesthetic of chez Apple. Lead would look the part no doubt but it does require a certain amount of specialist skill and knowledge, especially if lead burning and complicated bossing is required: will cost an arm and a leg as well. Here’s some pics to put you off

Thanks. The issue with the alumasc solution is that it is too sharp and clean. Let oks fantastic on a modern design but will look awkward in a rustic setting.

Lead would have the right look but as pointed out by yourself and others, will not be the simple case of rolling out and tapping to shape.

This guy is the best lead worker I’ve seen on YouTube I’ve seen, gives you an idea what’s involved. Lead capping to copings

Lotobear said:

Lead would be okay but you need to limit your runs to 1.5m with code 4 so a welted joint will be required every 1.35m or so. A 25mm x 50mm tanalised drip (slate) batten on each side would deal with the run off.

Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

This, don’t forget the welt on the drip for the authentic look. Take your time, watch some vids. Quite therapeutic.Another option would be zinc - AIUI you are pretty much limitless on the run length. Fixed using secret stainless clips fixings - any joint would require a standing seam. You need a roller and bender for this so it would mean getting a specialist in but IMO it would look great.

Edited by Lotobear on Tuesday 21st January 10:37

If you’re near Chelmsford, I’ll come and give you a crash course

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff