Minimum depth of solvent weld waste pipe fittings

Discussion

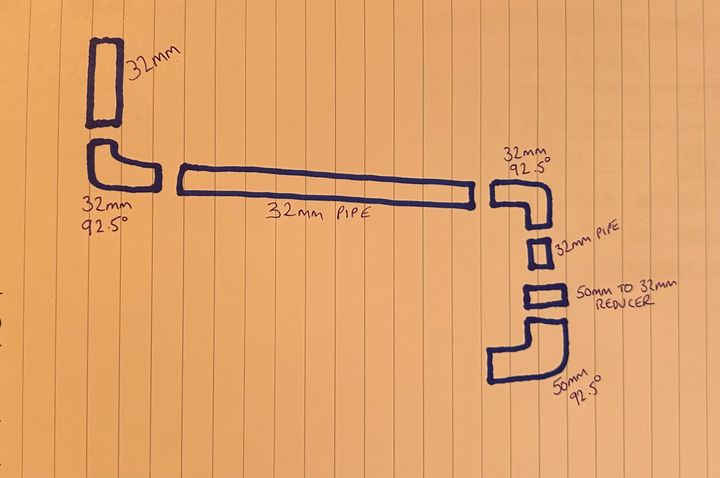

I’m looking to run a sink and new waste pipe in to some existing solvent welded pipes but I’m restricted with what’s there due to the angles.

If I cut to the red line, that leaves just 18mm of 50mm pipe for me to put an elbow fitting pointing upwards. Is that likely to be enough penetration for the solvent joint? Appreciate it should go fully home but I don’t have the length (oo er)

The existing pipe goes through to the house but is all neatly boxed in, otherwise I would just cut, twist and reduce the initial elbow.

This is what I’m proposing to do - interested to hear if there are other ways to do it that I haven’t thought of.

If I cut to the red line, that leaves just 18mm of 50mm pipe for me to put an elbow fitting pointing upwards. Is that likely to be enough penetration for the solvent joint? Appreciate it should go fully home but I don’t have the length (oo er)

The existing pipe goes through to the house but is all neatly boxed in, otherwise I would just cut, twist and reduce the initial elbow.

This is what I’m proposing to do - interested to hear if there are other ways to do it that I haven’t thought of.

I haven't thought through to total solution but want to contribute this -

The reduction from 50mm to 32mm doesn't have to occur right at the very point you indicate.

The reduction could occur towards or at the end of the straight pipe.

I think this might simplify the complexity of your planned layout?

LooneyTunes said:

Are you using the other larger vertical pipe?

If not, perhaps go round the corner and drop into that, trimmed/modified as appropriate? Either with a tee or adapter.

Unless the wall has to stay clear, I'd do that. Just rotate the elbow at the sink trap 90 degrees. Saves potential hassle as you can leave the existing pipework undisturbed.If not, perhaps go round the corner and drop into that, trimmed/modified as appropriate? Either with a tee or adapter.

Some useful suggestions here, thanks - neither of which I’d thought of!

The upright section is redundant. The previous owners had a washing machine out in the garage here. Odd place to bung one, but at least it gives me the water supply and waste to add this hand wash basin.

Tapping in to the upright and going around the wall would probably be the easiest solution. It does extend the piping beyond what’s necessary though. Not that the wall space is currently used for anything’, but would be restrictive.

Leaving my original plan and the dremel inside the wall joining option. I thought I had nothing to lose by chopping it off at the line and mocking up the original idea.

I picked up the conversion bend and joiner so will do some measuring as there’s some mortar around the pipe that may need some adjustment.

The upright section is redundant. The previous owners had a washing machine out in the garage here. Odd place to bung one, but at least it gives me the water supply and waste to add this hand wash basin.

Tapping in to the upright and going around the wall would probably be the easiest solution. It does extend the piping beyond what’s necessary though. Not that the wall space is currently used for anything’, but would be restrictive.

Leaving my original plan and the dremel inside the wall joining option. I thought I had nothing to lose by chopping it off at the line and mocking up the original idea.

I picked up the conversion bend and joiner so will do some measuring as there’s some mortar around the pipe that may need some adjustment.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff