Can I add a insulation sleeve over existing spade connector?

Discussion

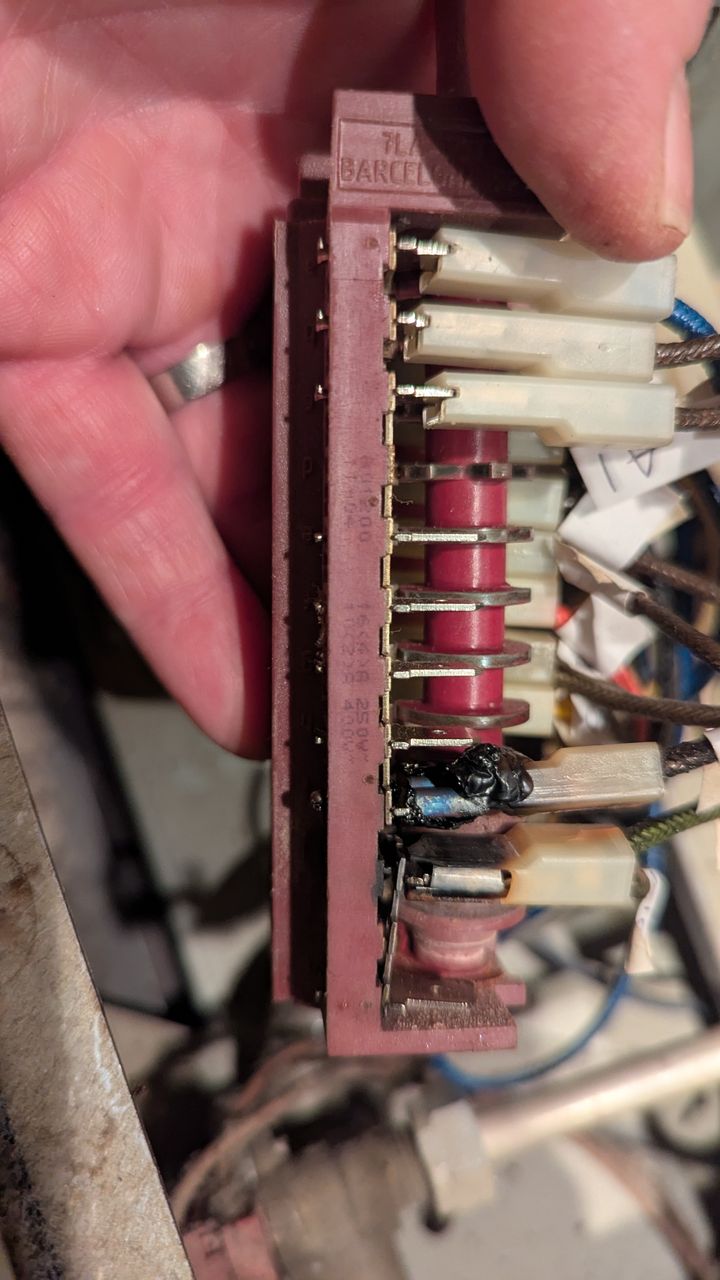

The control switch for our oven has burnt out, taking the insulation sleeve on a couple of spade connectors with it. The actual connectors are fine.

I've ordered a new switch. I'm loathed to change the spade connectors as there is hardly any slack and access is awkward. Is there any way I can get a sleeve over the existing spades?

Thanks

I've ordered a new switch. I'm loathed to change the spade connectors as there is hardly any slack and access is awkward. Is there any way I can get a sleeve over the existing spades?

Thanks

Dr Mike Oxgreen said:

Yeah, I would definitely just cover that over and pretend there s no problem.

I'm replacing the switch first. It's the broken switch which I think caused the problem. You can feel that the switch doesn't click properly or consistently when you turn it. Do you have a different view?

GasEngineer said:

Presumably OP will cut off the damaged / burnt bit before applying the heat shrink tubing, rather than just covering it over.

I wasn’t being serious. And to be honest I didn’t think the OP was being serious either!

You’ve got to consider why that spade connector has melted. It’s almost certainly due to a duff connection causing arcing within the spade. So I disagree that the connector is fine - it needs replacing. And so too does its neighbour, which has also suffered from the heat.

If it were the switch arcing then the damage would be at the switch, not at this spade.

Given that there’s some disruption to the board itself, I’d be replacing the whole board unless it’s very expensive or unobtainable.

If you really insist on not replacing the spade connector(s), I would at least use a sharp knife to cut away enough of the plastic to expose the metal contacts in the “female” half of the connector, and use a pair of pliers to squeeze them up tighter. Maybe a squirt of contact cleaner and insert/remove it a few times to remove any corrosion. Then heat shrink the whole lot. But it feels like a bodge.

Dr Mike Oxgreen said:

If it were the switch arcing then the damage would be at the switch, not at this spade.

The spade has overheated because the switch has overheated internally, it's all just due to conduction back to the connector, and the nylon has melted closest to the source of the heat. Spade connectors don't really fail except at the crimp to the wire and that's not where it got hot. The rest of it is pressed metal making a large area tight connection and just doesn't go wrong. I'd check the flex is OK (looks to be high temp glass sleeved but check it isn't crispy), and I'd cut the rest of the nylon off and maybe scrape those corrosion bits off (likely caused by byproducts of the melted plastic) but I wouldn't worry too much.

New switch and a bit of suitable grade/sized heatshink over the top of the two damaged spades, maybe a couple of layers, and it should be fine.

Don't squeeze them to tighten them as they look fine and squeezing spade female halves just distorts them; if they were that knackered you'd be better crimping new ones but I think they're fine as-is.

Edited by JoshSm on Tuesday 16th December 12:47

The damaged wire connectors as well as the insulating covers need to be replaced because they have over heated too, this can result in reduced contact pressure and is another potential ignition point.

It is nuts to spend a chunk of change on the switch, then skimp pennies on the fastons and leave a fire risk.

That is dangerous bodging in my book.

It is nuts to spend a chunk of change on the switch, then skimp pennies on the fastons and leave a fire risk.

That is dangerous bodging in my book.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff