Help with engine positioning

Discussion

Hello Chaps, long time no foruming, but I'm still here, just never find the time to get on here.

I'd like a bit of advice if possible. Bare with me it could be a long one as I want to try explain myself as best as possible. And please feel free to correct me wherever possible as I was doing rough measurements, though I don't think they are too far out.

I have a project in mind and want to use a Subaru Engine/Drive Train, however to fit the engine in the chassis properly and leave the car with good balance I would like to move the engine back in the car.

I've had a look at the position of the engine and front drive shafts in my car and have figured this so far:

The engine is 815mm wide x (approx) 320mm Long x 650mm high. The front drive shafts are 435mm from the front of the engine (on gearbox) and enter the wheel hubs 380mm from front of engine, meaning that the shafts are at approximately 7 degrees facing forward if looking from above.

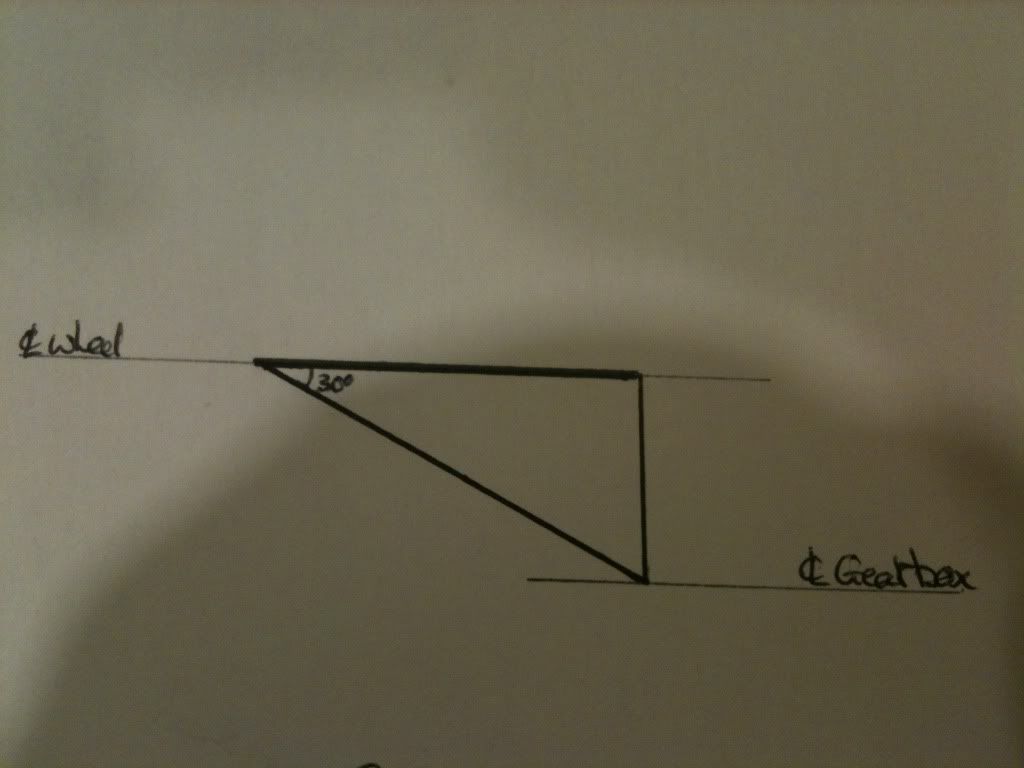

I would like to move the engine 175mm (or even more if I can) toward the back of the car to get better weight distribution, this would increase the angle of the front drive shafts to 30 degrees +. Do you think this would be possible? if not, what angle would be sensible? 20 Degrees?

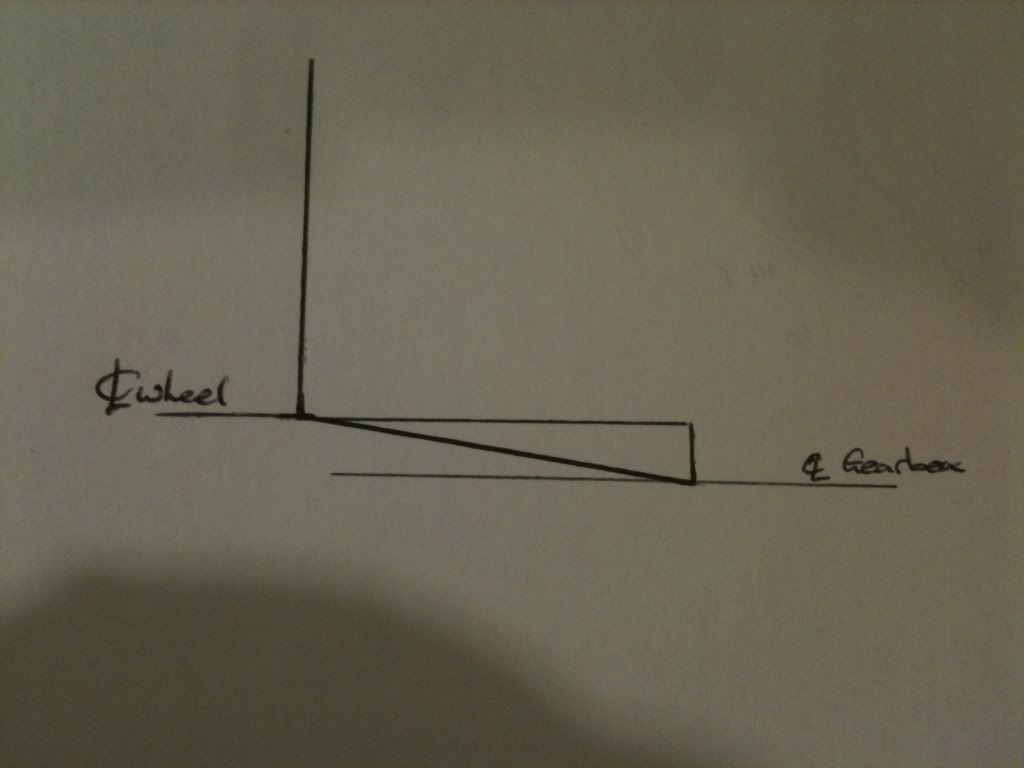

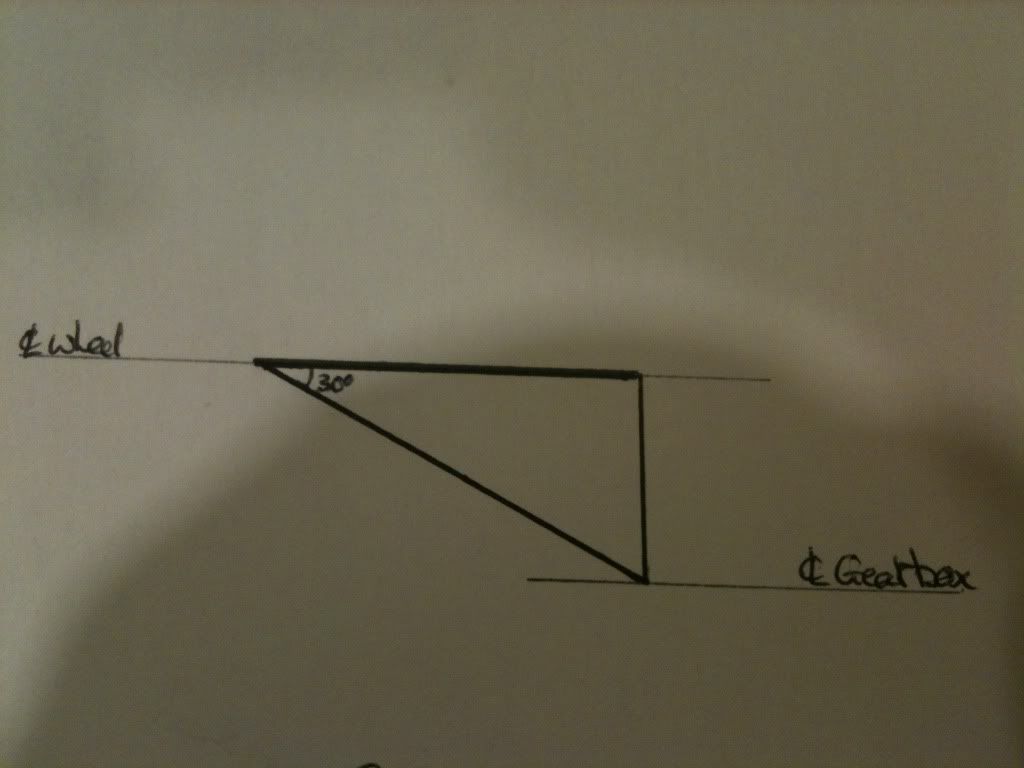

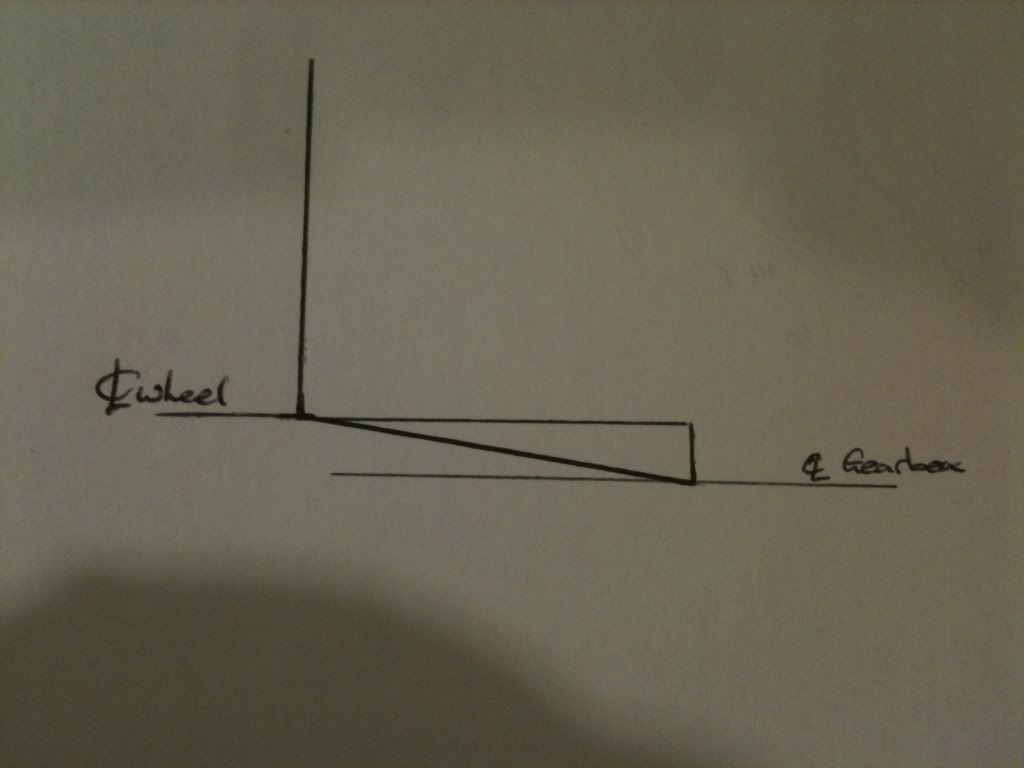

Here are some scale drawings of how they look now, at 20 degrees and at 30 degrees. I have no idea why I drew the vertical line in the "now" drawing.

Now

20 Degree

30 Degree

I'd like a bit of advice if possible. Bare with me it could be a long one as I want to try explain myself as best as possible. And please feel free to correct me wherever possible as I was doing rough measurements, though I don't think they are too far out.

I have a project in mind and want to use a Subaru Engine/Drive Train, however to fit the engine in the chassis properly and leave the car with good balance I would like to move the engine back in the car.

I've had a look at the position of the engine and front drive shafts in my car and have figured this so far:

The engine is 815mm wide x (approx) 320mm Long x 650mm high. The front drive shafts are 435mm from the front of the engine (on gearbox) and enter the wheel hubs 380mm from front of engine, meaning that the shafts are at approximately 7 degrees facing forward if looking from above.

I would like to move the engine 175mm (or even more if I can) toward the back of the car to get better weight distribution, this would increase the angle of the front drive shafts to 30 degrees +. Do you think this would be possible? if not, what angle would be sensible? 20 Degrees?

Here are some scale drawings of how they look now, at 20 degrees and at 30 degrees. I have no idea why I drew the vertical line in the "now" drawing.

Now

20 Degree

30 Degree

cptsideways said:

Either your drawing is wrong or your measuring your angles very very wrong, either way amend the drawing to show the centre lines of the wheels & gearbox through the diff as its not exactly clear!

I'm not sure what you mean. I've just re-measured my drawings and all stack up to what I've said.LukeSi said:

Mid or front engine positioning, rear engined isn't worth the risk.

Front mounted, same as the Impreza, just wanting the engine moved back so the balance is better and the lines of the car are sleeker.davepoth said:

You'll have to narrow the track massively, and you'll end up with all kinds of odd suspension geometry as the wheels move up and down. I'd avoid it if you can.

doogz said:

I really don't see driveshafts lasting very long.

I assume your pictures have taken into account the fact that the hypotenuse of the triangle will always be the same length, thus the transverse distance will change depending on the angle, meaning you'll need longer shafts or narrower track width to make it work?

I'll be making new drive shafts. The Subaru track is pretty much what I want, bit I may make it a little wider, meaning the angle will be reduced.I assume your pictures have taken into account the fact that the hypotenuse of the triangle will always be the same length, thus the transverse distance will change depending on the angle, meaning you'll need longer shafts or narrower track width to make it work?

thinfourth2 said:

Keep it standard as the driveshafts will be destroyed and you will get much wierdness in suspension geometry

Don't forget the front wheels will also steer so even with 20degrees of steering plus 30degrees of driveshaft angle give you 50degrees which will just break the CV joints

Good point, well made Don't forget the front wheels will also steer so even with 20degrees of steering plus 30degrees of driveshaft angle give you 50degrees which will just break the CV joints

I knew there was something obvious I'd miss.

I knew there was something obvious I'd miss.doogz said:

What sort of resources do you have?

You could get rid of the steering angle issue by having cv 'boxes' of some sort inboard of the hub. Then a seperate transversely mounted 'stub' shaft going straight into the hub.

Would require some jiggery pokery in the machine shop, but would let you put the engine a bit further aft. Still limited by the angle the shaft makes coming out of the box, with the transverse direction.

That is another option I have. If 30 or even 20 degrees is unachievable then just moving the engine a little way aft is better than nothing. Luckily if all fails, the engine is only 125kg wet, so not a major burden, just screws up the lines a little and means I have approximately 350 litres of empty space between the engine and the bulkhead.

You could get rid of the steering angle issue by having cv 'boxes' of some sort inboard of the hub. Then a seperate transversely mounted 'stub' shaft going straight into the hub.

Would require some jiggery pokery in the machine shop, but would let you put the engine a bit further aft. Still limited by the angle the shaft makes coming out of the box, with the transverse direction.

Edited by WorAl on Sunday 6th November 21:54

rhinochopig said:

Unless you know how to calculate roll-centre, ackerman angles, etc. and all those other suspension design black arts I'd stick with what subaru spent millions getting right. For better balance look at relocating other bits.

It's only the engine, drive train, steering, brakes and wiring harness from the Subaru which is going to be used. The suspension won't work.WorAl said:

rhinochopig said:

Unless you know how to calculate roll-centre, ackerman angles, etc. and all those other suspension design black arts I'd stick with what subaru spent millions getting right. For better balance look at relocating other bits.

It's only the engine, drive train, steering, brakes and wiring harness from the Subaru which is going to be used. The suspension won't work.So, let me get this right. You are designing a car from scratch, but are not able to work out for yourself if driveshafts at 30Deg are a good idea or not??? God help us all.

(here's a hint, go look at some production cars, hey, how about a std scooby, check what angles everyone else uses. or hows about talk to oh i don't know, perhaps GKN about their recommendations for CV joints and the plunge capabilites of said joints)

I might try a bit of brain surgery myself, anyone know if you can just stick the knife in a wiggle it around, or do you have to know which bits not to cut out???? ;-)

(here's a hint, go look at some production cars, hey, how about a std scooby, check what angles everyone else uses. or hows about talk to oh i don't know, perhaps GKN about their recommendations for CV joints and the plunge capabilites of said joints)

I might try a bit of brain surgery myself, anyone know if you can just stick the knife in a wiggle it around, or do you have to know which bits not to cut out???? ;-)

Can you reduce the bell housing length at all, this might free up some space?

look at the way F1 cars and other aero dependent designs do the outboad cv joints, they put the tripod joint inside the wheel bearing, resulting in a longer axle length and less of an angle for a given miss match in output - wheel centre line.

failing that change it to a sierra type gearbox and transfer case, mount another diff infront of the engine and put the boxer behind the front axle line, sounds like you are within 100mm of that being a posibility.

Ryan

look at the way F1 cars and other aero dependent designs do the outboad cv joints, they put the tripod joint inside the wheel bearing, resulting in a longer axle length and less of an angle for a given miss match in output - wheel centre line.

failing that change it to a sierra type gearbox and transfer case, mount another diff infront of the engine and put the boxer behind the front axle line, sounds like you are within 100mm of that being a posibility.

Ryan

Gassing Station | General Gassing | Top of Page | What's New | My Stuff