BMW readies flax composite for series production

Carbon fibre is not especially kind to the environment; BMW is prepping a renewable raw material alternative

We’ve had more than 20 years now of BMW M cars with a carbon roof; bravo if you remembered the M3 CSL as the first. Since then, it’s featured on just about every model, including the standard M3, M4, M6, and M8. In more recent times, BMW has flirted with more significant carbon construction - see the i3 and i8 - as well as the Carbon Cage in an iX and Carbon Core in the 7 Series. And that’s before you get to the iffy add-ons available in the BMW M Performance catalogue. Carbon is a big deal for BMW. For lots of manufacturers, really.

But the future of the material has been called into question thanks to its environmental impact. While recent suggestions that carbon fibre was going to be banned in cars in Europe later this decade have subsequently been dismissed, concerns remain about its manufacturing impact and end-of-life recycling. On the one hand is the argument that cars featuring a lot of carbon content will never reach that stage; a carbon-tubbed supercar will be restored and kept on the road, not junked. But something like an i3 will, sadly, end up on the scrapheap eventually. If they haven’t already. (Make your own jokes now about iXs and junk.)

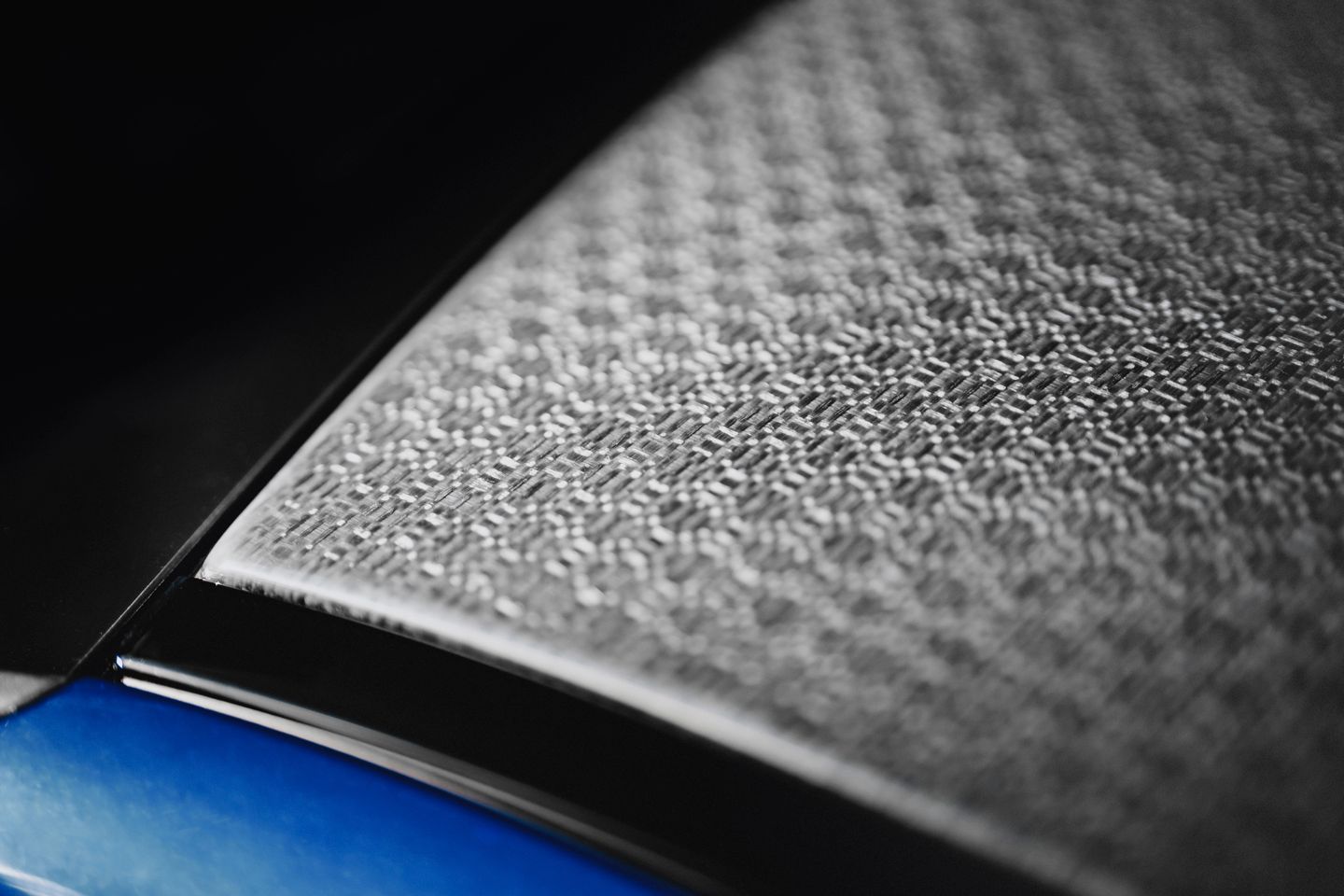

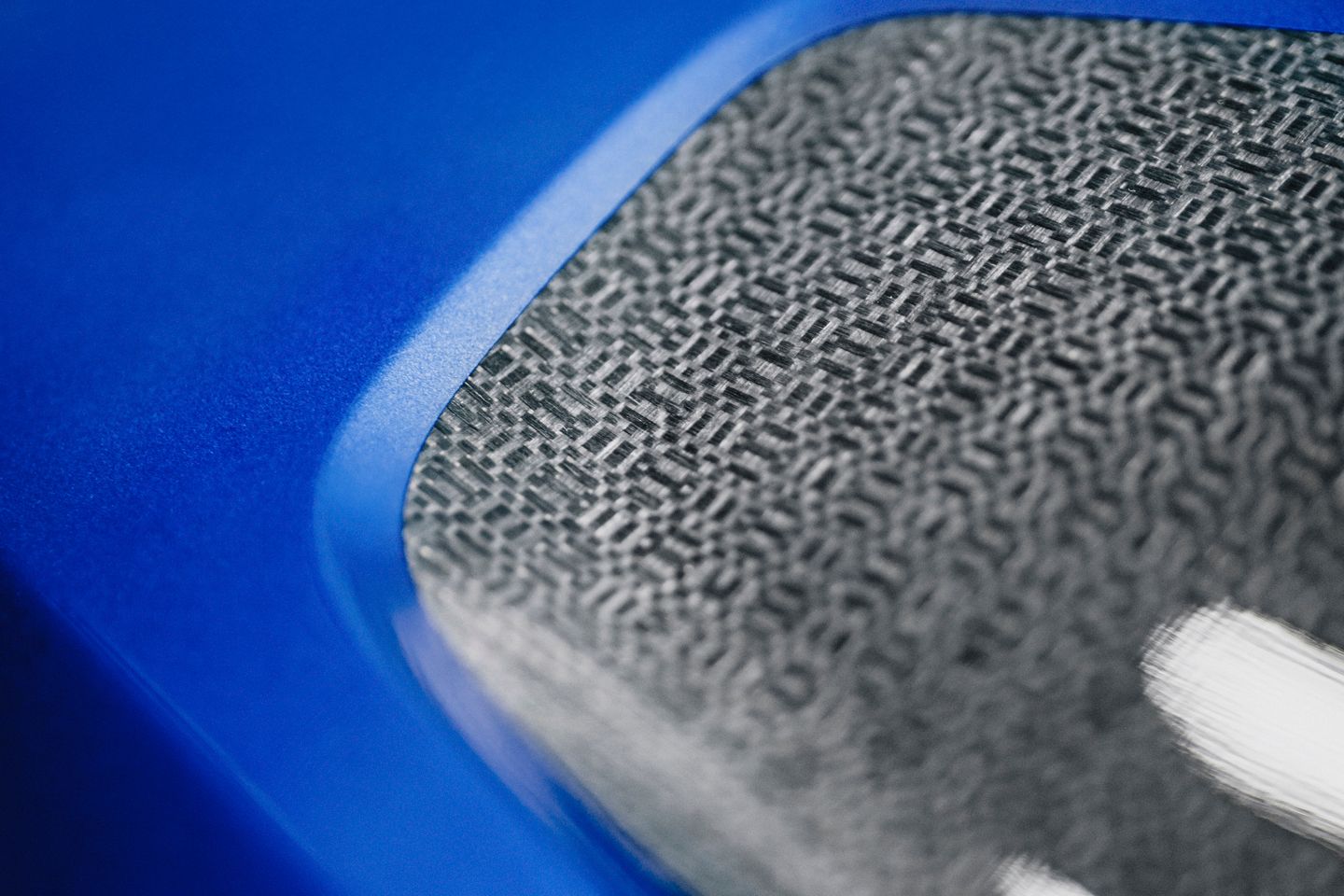

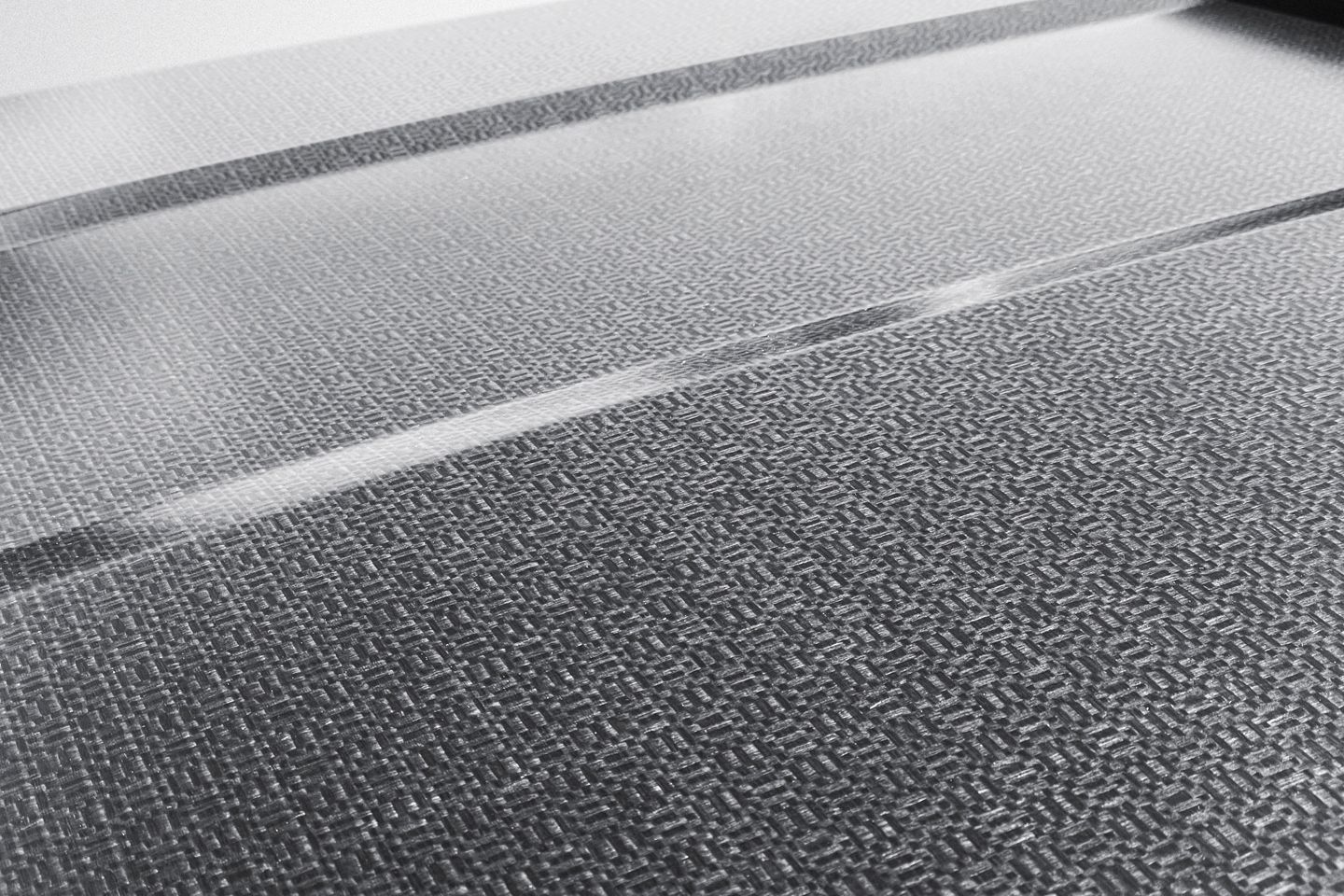

Presumably with that in mind - and with a motorsport link to boast about as well - BMW has confirmed that ‘natural fibre composites’ are now ready for series production on its road cars. It has been working with Swiss company Bcomp (which BMW i Ventures actually has a stake in) to create lightweight parts with a reduced carbon footprint. The prototype parts seen here, a roof and rear diffuser, offer up ‘a CO2e-reduction of around 40 per cent in production plus additional end-of-life considerations’, reckons BMW.

The company has been experimenting with natural fibre composites in motorsport since 2019, when they were used in a Formula E car. Subsequently, the DTM and GT4-spec M4 have also employed the carbon alternative; one of the latter will be at the Nürburgring 24-Hour this weekend. While natural fibre composites may not be the first thing that comes to mind when considering motorsport technology making its way to the road, if it’s strong enough for the rough and tumble of competition, then it can probably survive the worst a production M3 will see.

BMW M CEO Franciscus van Meel said: “Natural fiber composites are a vital element of innovative lightweight solutions in motorsport, allowing for a reduction in CO2e emissions in the manufacturing process. Natural fiber is an innovation that perfectly exemplifies BMW M’s claim ‘Born on the racetrack. Made for the streets.’”

Catchy. While a fixed date has not been set for natural fibre parts on showroom models, given they meet homologation requirements, it’s hard to imagine them being far away. Expect to see the technology bundled into an M Ultimate pack before you know it.

It's not necessarily/wholly the fibre that's the issue, but the 'system' including the resins.

Besides, I thought they'd worked around the problem somewhat by convincing people that 'forged carbon' is somehow premium instead of dogs

t with none of the redeeming qualities of proper composite materials/design?

t with none of the redeeming qualities of proper composite materials/design?I didn't think there were any 'natural' or recyclable resins available that had any sort of UV resistance?

In principal yes it is recyclable but in reality it never will be. The fiber panels themselves may involve less CO2 but you also have to consider the resins used, how the original crop is harvested, where its grown etc.

Recyclability is a nightmare and basically like everything sold int he supermarket as recyclable - yes, but only if processed at a certain place in a certain way. in reality these are still ending up in landfill.

It's great for marketing though...

In principal yes it is recyclable but in reality it never will be. The fiber panels themselves may involve less CO2 but you also have to consider the resins used, how the original crop is harvested, where its grown etc.

Recyclability is a nightmare and basically like everything sold int he supermarket as recyclable - yes, but only if processed at a certain place in a certain way. in reality these are still ending up in landfill.

It's great for marketing though...

https://parts.tuthill.uk/products/flax-steering-wh...

https://parts.tuthill.uk/products/tuthill-porsche-...

And as for BMW virtue signalling about saving the planet, perhaps they could devise a way of manufacturing eco-friendly wind turbine blades, rather than embellishing their pig-ugly, overweight cars with flax fibre diffusers ...

All those screens and plastics are not going to be recycled in a few years when they become uneconomical to repair.

A lot of carbon is just tat on heavy cars to show how much money one has.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff