The future of kit car manufacturing lies with 3D printing

Discussion

I was at the 3D Printshow today. A bit of an eye-opener! This technology is moving so fast. It's not just about bits of plastic any more. There were examples of 3D parts printed in various metals, including jewelry and car parts. One guy was printing 3D titanium parts that were incredibly light and strong but even steel parts are significant improvements on current manufacturing methods.

For low volumes, this is going to be a perfect technology once the prices come down a bit more. I'm already assuming I will use this technology on my next car. It removes weaknesses from weld points, you can brace tubes internally, complex parts can be designed by software to minimise weight, materials and maximise strength.

The days of machining large lumps of metal are numbered. Stock control is less of an issue too. You can already put your parts to be printed out to tender to online services.

What I also like is that you can print in cheap plastic, to validate parts before you commit to the metal equivalent.

This technology is not just the domain of F1 outfits any more. It's just around the corner and I'm really looking forward to the opportunities that this brings. You are not going to use it to build a whole car but, it really does have a lot of potential.

I dream that one day I will be able to 3D print something that is close to carbon fibre ;-)

Rob

For low volumes, this is going to be a perfect technology once the prices come down a bit more. I'm already assuming I will use this technology on my next car. It removes weaknesses from weld points, you can brace tubes internally, complex parts can be designed by software to minimise weight, materials and maximise strength.

The days of machining large lumps of metal are numbered. Stock control is less of an issue too. You can already put your parts to be printed out to tender to online services.

What I also like is that you can print in cheap plastic, to validate parts before you commit to the metal equivalent.

This technology is not just the domain of F1 outfits any more. It's just around the corner and I'm really looking forward to the opportunities that this brings. You are not going to use it to build a whole car but, it really does have a lot of potential.

I dream that one day I will be able to 3D print something that is close to carbon fibre ;-)

Rob

I'm not sure how long it'll take for the price of parts to come down!

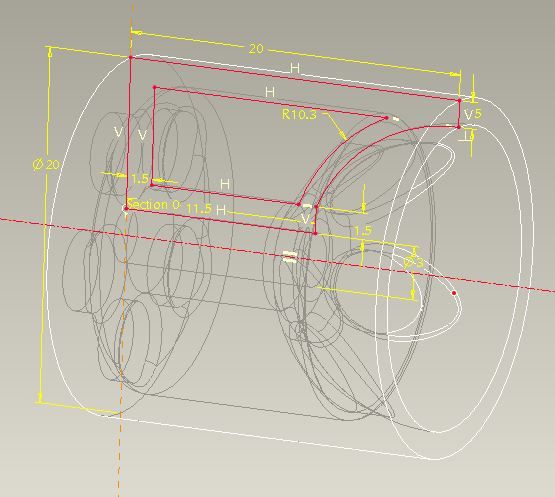

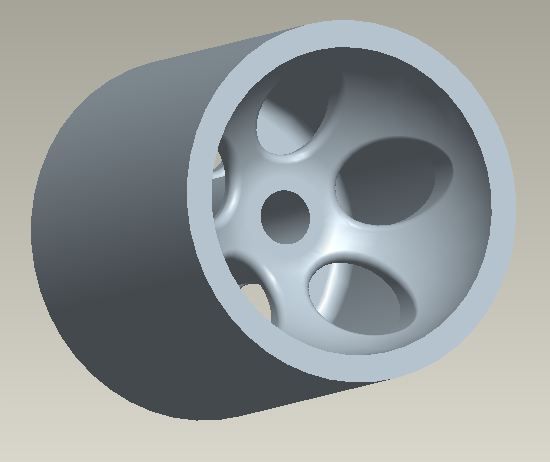

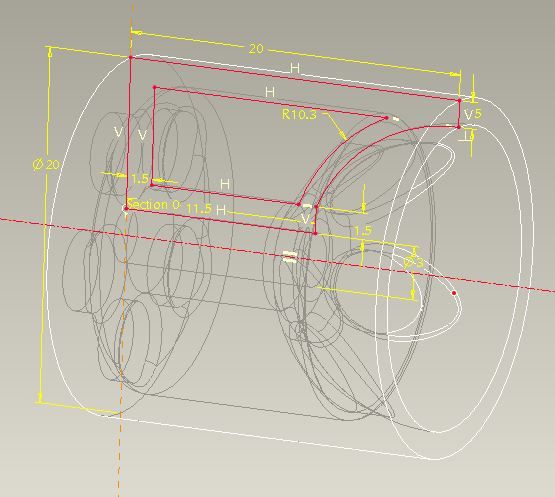

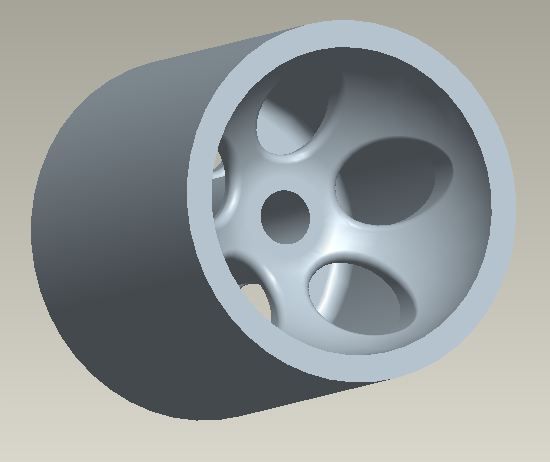

However you're right that it's useful to make parts that can't be machined or moulded. Here's a hollow wheel I got made which would otherwise have to be made in two parts and bonded

It's in 1:32 scale, so price is a lot easier to take!

Drawing

3D model

Parts

These are made by SLS process because I need strength, low price but not too fussed about the detail. Shapeways and iMaterialise are great because you upload the model and you get a price almost immediately, iMaterialise's website ordering in particular is very slick.

However you're right that it's useful to make parts that can't be machined or moulded. Here's a hollow wheel I got made which would otherwise have to be made in two parts and bonded

It's in 1:32 scale, so price is a lot easier to take!

Drawing

3D model

Parts

These are made by SLS process because I need strength, low price but not too fussed about the detail. Shapeways and iMaterialise are great because you upload the model and you get a price almost immediately, iMaterialise's website ordering in particular is very slick.

This technology is a one to look at for the future for sure.Working in cnc machining at the moment you still can't beat parts made from solid steel or aluminium for strength and durability.In 3d printing the size of the part is also a limiting factor.

The steel sintered parts tend to be of a cast like construction so not so good for strength critical parts but excellent for prototyping like you say.

There's not much you can't machine IE 5 or 6 axis cnc's or mould for that matter using 2 3 or even 4 stage moulding.

One day this may change but i can't see it being for a while until the speed of the process increases.I love new technologies and follow them closely through the job i'm in.Maybe one day our company will get one and move the buisiness to the next level.The future is there...it may just take some time

The steel sintered parts tend to be of a cast like construction so not so good for strength critical parts but excellent for prototyping like you say.

There's not much you can't machine IE 5 or 6 axis cnc's or mould for that matter using 2 3 or even 4 stage moulding.

One day this may change but i can't see it being for a while until the speed of the process increases.I love new technologies and follow them closely through the job i'm in.Maybe one day our company will get one and move the buisiness to the next level.The future is there...it may just take some time

This is something we've been offering for the past 4 years. With our background in Automotive Body Engineering for 30+ years we decided to make this Automotive Design process available to anyone who can use it through our company Impossible Creations Ltd. We've invested in 3D printers to produce functional components in ABS plastic, ideal for internal/external trim, substrates, right down to replacement clips for door trim panels & wiring looms. We can also offer bespoke design and the parts can be finished ready for paint, electroplating etc. We had a stand at the NEC Classic Car Show last year and we'll be there again this year on November 16th - 18th, Stand 8T63, demonstrating the process with a printer and scanning equipment, showing how we can achieve the full reverse engineering process. If you are attending the show it would be great if you could stop by and discuss your project with us.

I think Jay Leno does the same kind of reverse engineering for restoring some of his cars too.

If only we were 32 times smaller we could make cars this way...

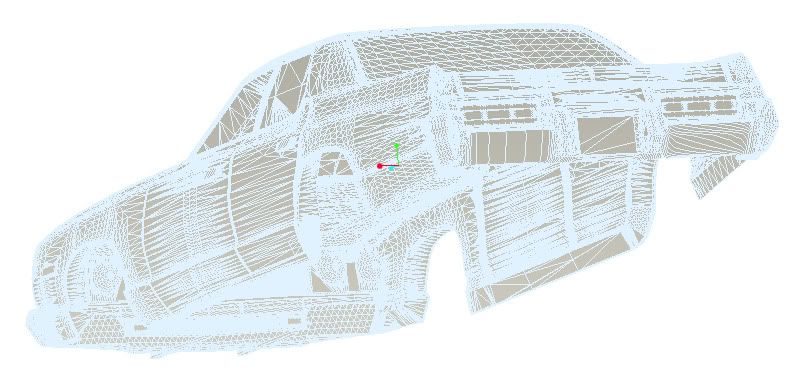

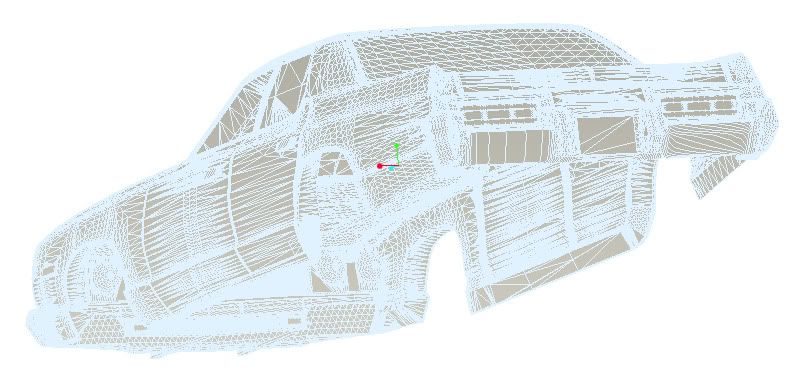

3D render model

Meshed surfaces

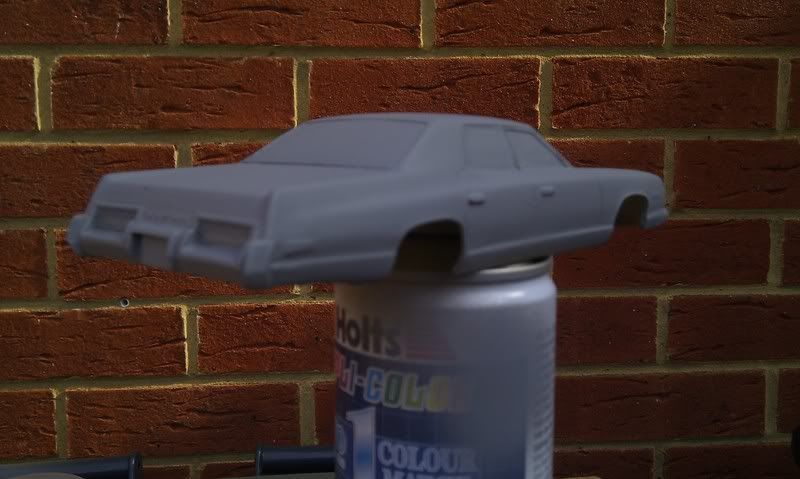

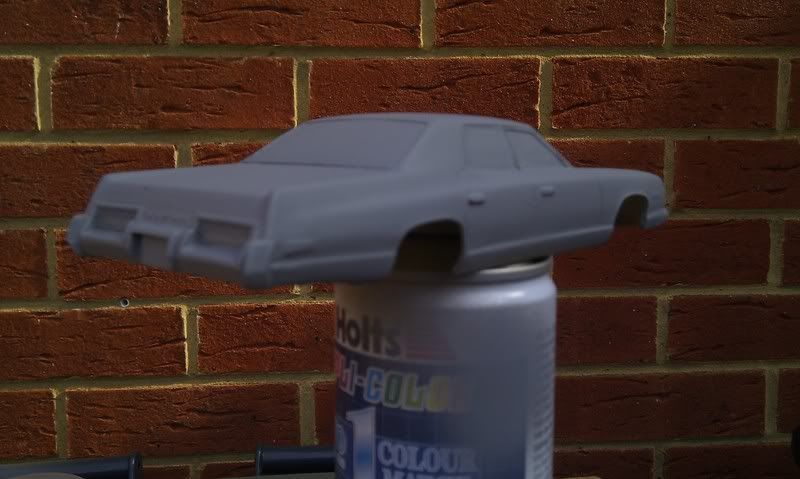

3D printed model

Resin casts (because racing 3D printed models is expensive!)

With paint

And graphics

And speed!

We're lucky that there are bureau services to do this 3D printing for us, it means that creating parts is a lot easier than it used to be!

If only we were 32 times smaller we could make cars this way...

3D render model

Meshed surfaces

3D printed model

Resin casts (because racing 3D printed models is expensive!)

With paint

And graphics

And speed!

We're lucky that there are bureau services to do this 3D printing for us, it means that creating parts is a lot easier than it used to be!

Gassing Station | Kit Cars | Top of Page | What's New | My Stuff