LS3/ E-rod engine - first try at starting... won't fire up

Discussion

Anyone got any experience of LS3/ e-rod engines? I've been determined to get mine fired up before end of 2012 and it looks like I've failed!

The engine is cranking ok and if you crank it long enough it seems to fire the odd cylinder but it doesn't 'catch' and fire up.

I've checked there's fuel, sparks and the injectors are working - all ok. I've improved the earths and bought a bigger battery (Camaro sized).

I just feel that there's something fundamental I've missed.

Questions:

1) For the 'ignition' input to the PCM, do you feed it the ignition voltage (12V when the ignition is engaged) or the starter voltage (12V only when you're cranking)? Note: I've tried feeding either to the PCM and neither seem to work

2) I've not installed the exhaust but I've connected the o2 sensors to the loom so theres at least a signal going to the PCM. Do I need maybe to add an earth to the sensors?

Surely a modern engine like this should fire up pretty immediately if everything is ok?

The engine is cranking ok and if you crank it long enough it seems to fire the odd cylinder but it doesn't 'catch' and fire up.

I've checked there's fuel, sparks and the injectors are working - all ok. I've improved the earths and bought a bigger battery (Camaro sized).

I just feel that there's something fundamental I've missed.

Questions:

1) For the 'ignition' input to the PCM, do you feed it the ignition voltage (12V when the ignition is engaged) or the starter voltage (12V only when you're cranking)? Note: I've tried feeding either to the PCM and neither seem to work

2) I've not installed the exhaust but I've connected the o2 sensors to the loom so theres at least a signal going to the PCM. Do I need maybe to add an earth to the sensors?

Surely a modern engine like this should fire up pretty immediately if everything is ok?

Steve_D said:

The ECU will require both permanent 12v and ignition switched 12v going to the appropriate pins. The ECU does not use 12v from the start circuit.

Are you sure you have 60psi fuel pressure?

Steve

According to the all-too-short instructions it gets the 12V permanent feed from the battery but needs the 'ignition' to sequence the start-up, but does it mean 'ignition' or 'starter'? My guess is the starter rather than 'ignition'...Are you sure you have 60psi fuel pressure?

Steve

As for fuel pressure, well I bought the high flow fuel pump as recommended in the LS1 instructions - you'd have thought that would be ok. Good point though, I'll check it out.

http://www.popularhotrodding.com/tech/1201phr_gmpp...

Does 'keyed 12V' mean the 12V from the ignition switch or from the starter? I wish they'd stick to one terminology!

Does 'keyed 12V' mean the 12V from the ignition switch or from the starter? I wish they'd stick to one terminology!

fatbutt said:

.....As for fuel pressure, well I bought the high flow fuel pump as recommended in the LS1 instructions - you'd have thought that would be ok. Good point though, I'll check it out.

Your pump will produce perhaps 200 or more psi so the system has to have a pressure regulator. For your LS3 the regulator should be set at 59psi. Without a reg you will have way to much fuel, fouled plugs and no start.The ECU takes its power directly from the battery but is essentially asleep until the ignition is switched on. The connection is from the ignition switch and must stay on during cranking.

A basic check of the system is to listen for the pump running when you switch on the ignition. It will run for a few seconds then stop. It should start running again when the ECU detects the engine is turning over.

Steve

fatbutt said:

Anyone got any experience of LS3/ e-rod engines? I've been determined to get mine fired up before end of 2012 and it looks like I've failed!

The engine is cranking ok and if you crank it long enough it seems to fire the odd cylinder but it doesn't 'catch' and fire up.

I've checked there's fuel, sparks and the injectors are working - all ok. I've improved the earths and bought a bigger battery (Camaro sized).

I just feel that there's something fundamental I've missed.

Questions:

1) For the 'ignition' input to the PCM, do you feed it the ignition voltage (12V when the ignition is engaged) or the starter voltage (12V only when you're cranking)? Note: I've tried feeding either to the PCM and neither seem to work

2) I've not installed the exhaust but I've connected the o2 sensors to the loom so theres at least a signal going to the PCM. Do I need maybe to add an earth to the sensors?

Surely a modern engine like this should fire up pretty immediately if everything is ok?

A few more details about your exact build would help.The engine is cranking ok and if you crank it long enough it seems to fire the odd cylinder but it doesn't 'catch' and fire up.

I've checked there's fuel, sparks and the injectors are working - all ok. I've improved the earths and bought a bigger battery (Camaro sized).

I just feel that there's something fundamental I've missed.

Questions:

1) For the 'ignition' input to the PCM, do you feed it the ignition voltage (12V when the ignition is engaged) or the starter voltage (12V only when you're cranking)? Note: I've tried feeding either to the PCM and neither seem to work

2) I've not installed the exhaust but I've connected the o2 sensors to the loom so theres at least a signal going to the PCM. Do I need maybe to add an earth to the sensors?

Surely a modern engine like this should fire up pretty immediately if everything is ok?

Is the kit you are using a bespoke kit for a custom vehicle ? or have you tried to adapt from another vehicle. ie, are immobiliser functions still present ? Is wiring all correct, or have you had to adapt the wiring from another vehicle ?

You've mentioned fuel pump briefly...LS3 would run a dead end with pump/regulator in tank. Have you replicated that setup ?

You say you have fuel and sparks.....is this 100% confirmed at each cylinder when cranking and also sparks confirmed correct time and cylinder with a timing light ? Or is there a lot of assumption in that statement ?

And absolutely it will start up very quickly when everything is right. Clearly everything is not right at present.

Do you have an OBD diagnostic plug available, and are any fault codes present ? If not, you should have a plug available to read codes.

And after all this cranking. Are the plugs wet or dry ?

Edited by stevieturbo on Tuesday 1st January 10:09

Steve_D said:

Your pump will produce perhaps 200 or more psi so the system has to have a pressure regulator. For your LS3 the regulator should be set at 59psi. Without a reg you will have way to much fuel, fouled plugs and no start.

The ECU takes its power directly from the battery but is essentially asleep until the ignition is switched on. The connection is from the ignition switch and must stay on during cranking.

A basic check of the system is to listen for the pump running when you switch on the ignition. It will run for a few seconds then stop. It should start running again when the ECU detects the engine is turning over.

Steve

Hi - are you sure you don't mean GPH rather than PSI? My pump is a ACDelco 25115899 Fuel pump, 72gph, 8 PSI. Its hellishly noisy so I know its on, and it comes on with the ignition (the PCM controls the fuel pump on the e-rod setup). I disconnected it from the fuel rail and its certainly delivering fuel as most of it is now on the garage floor! The plugs are dry but with a mild brown dust on there - I don't think its fouling.The ECU takes its power directly from the battery but is essentially asleep until the ignition is switched on. The connection is from the ignition switch and must stay on during cranking.

A basic check of the system is to listen for the pump running when you switch on the ignition. It will run for a few seconds then stop. It should start running again when the ECU detects the engine is turning over.

Steve

What I did notice on the link I put in one of the post above is that the harness minor earths are supposed to be connected to the bulkhead whereas I have mine connected to the engine block (and the engine block earthed to the chassis). I'm going to move them to the bulkhead as the 'trouble shooting' section of the LS1 instructions says that the engine won't start if the earth for the oil pressure sensor is not 100%.

stevieturbo said:

A few more details about your exact build would help.

Is the kit you are using a bespoke kit for a custom vehicle ? or have you tried to adapt from another vehicle. ie, are immobiliser functions still present ? Is wiring all correct, or have you had to adapt the wiring from another vehicle ?

You've mentioned fuel pump briefly...LS3 would run a dead end with pump/regulator in tank. Have you replicated that setup ?

You say you have fuel and sparks.....is this 100% confirmed at each cylinder when cranking and also sparks confirmed correct time and cylinder with a timing light ? Or is there a lot of assumption in that statement ?

And absolutely it will start up very quickly when everything is right. Clearly everything is not right at present.

Do you have an OBD diagnostic plug available, and are any fault codes present ? If not, you should have a plug available to read codes.

And after all this cranking. Are the plugs wet or dry ?

The engine is a new e-rod package from Chevy that comes with a harness unique to the e-rod. It all comes labelled and easy to install. The instructions that come with it though are 'plug A to B and it will work', no trouble shooting section. I've also bought the LS1 installation document as recommended by Chevy and that gives some hints but its not tailored to the e-rod (which is basically an LS3 from a 2010 Camaro).Is the kit you are using a bespoke kit for a custom vehicle ? or have you tried to adapt from another vehicle. ie, are immobiliser functions still present ? Is wiring all correct, or have you had to adapt the wiring from another vehicle ?

You've mentioned fuel pump briefly...LS3 would run a dead end with pump/regulator in tank. Have you replicated that setup ?

You say you have fuel and sparks.....is this 100% confirmed at each cylinder when cranking and also sparks confirmed correct time and cylinder with a timing light ? Or is there a lot of assumption in that statement ?

And absolutely it will start up very quickly when everything is right. Clearly everything is not right at present.

Do you have an OBD diagnostic plug available, and are any fault codes present ? If not, you should have a plug available to read codes.

And after all this cranking. Are the plugs wet or dry ?

Edited by stevieturbo on Tuesday 1st January 10:09

From the link you have posted it looks like an E67 ecu we've had problems with one of these, the software checksums were faulty we used EFiLive software to fix it.

Another one I've seen is the cam sensor someone had removed the small sub loom from the front of the block & plugged the wiring loom directly into the cam sensor (the sub loom swaps some of the wires around!)

Steve defo meant 60 psi too although the fuel pump is priming is it 100% still running while cranking?

To the best of my knowledge the oil pressure won't stop it starting although it can be set to put it into limp home if the pressure falls to low.

Check your crank sensor plug is in correctly too (it should iirc be grey)

Another one I've seen is the cam sensor someone had removed the small sub loom from the front of the block & plugged the wiring loom directly into the cam sensor (the sub loom swaps some of the wires around!)

Steve defo meant 60 psi too although the fuel pump is priming is it 100% still running while cranking?

To the best of my knowledge the oil pressure won't stop it starting although it can be set to put it into limp home if the pressure falls to low.

Check your crank sensor plug is in correctly too (it should iirc be grey)

fatbutt said:

Yep, I think its the fuel pump pressure. The one I bought from the Chevy catalogue is high output but low pressure. According to the e-rod instructions I need 60PSI with a minimum of 40gph.

I'm going to have to order something else.

Cheers m'dears

Again, please detail your existing fuel system.I'm going to have to order something else.

Cheers m'dears

8psi is not enough to run any modern fuel injection car.

But detail what you have now, from tank to rails. The original vehicle would have had the pump in tank, and regulator in-tank, regulated to a fixed 60psi.

You can achieve that 60psi many ways, but it will depend on your configuration, and it will require more than just a fuel pump. All fuel lines and clips etc will also need to be suitable for such pressures, and your fuel tank needs to be designed so that the efi pump never sees air during fuel slosh etc.

stevieturbo said:

Again, please detail your existing fuel system.

8psi is not enough to run any modern fuel injection car.

But detail what you have now, from tank to rails. The original vehicle would have had the pump in tank, and regulator in-tank, regulated to a fixed 60psi.

You can achieve that 60psi many ways, but it will depend on your configuration, and it will require more than just a fuel pump. All fuel lines and clips etc will also need to be suitable for such pressures, and your fuel tank needs to be designed so that the efi pump never sees air during fuel slosh etc.

Its a 1980 Rolls Royce Silver Shadow 2. The old system had an external fuel pump and plumbing below the body - I have (so far) installed a new pump and ran cabling to the PCM while re-using the old hose run. I have just ordered a new HP pump (external, in line), filter and HP braided hose to replace the old plumbing. The e-rod is not supposed to need a regulator but I have seen them on other installations so I will look into that.8psi is not enough to run any modern fuel injection car.

But detail what you have now, from tank to rails. The original vehicle would have had the pump in tank, and regulator in-tank, regulated to a fixed 60psi.

You can achieve that 60psi many ways, but it will depend on your configuration, and it will require more than just a fuel pump. All fuel lines and clips etc will also need to be suitable for such pressures, and your fuel tank needs to be designed so that the efi pump never sees air during fuel slosh etc.

fatbutt said:

Its a 1980 Rolls Royce Silver Shadow 2. The old system had an external fuel pump and plumbing below the body - I have (so far) installed a new pump and ran cabling to the PCM while re-using the old hose run. I have just ordered a new HP pump (external, in line), filter and HP braided hose to replace the old plumbing. The e-rod is not supposed to need a regulator but I have seen them on other installations so I will look into that.

Was the car originally fuel injected, or carburettor ?Unless the E-rod package comes with the fuel tank/pump etc, then it absolutely needs a regulator. You must ensure you have a fixed 60psi at the rail which is typically what the LS platform uses.

Make sure your filter is suitable for efi pressures and the flow levels required of an efi system. As for braided, wouldnt say that is needed, and may even complicate matters due to the fittings it requires. There are rubber hose options that are quite suitable for efi pressures. Just ensure you use proper clips throughout, and any metal pipes have a bead around them if at all possible.

stevieturbo said:

Was the car originally fuel injected, or carburettor ?

Unless the E-rod package comes with the fuel tank/pump etc, then it absolutely needs a regulator. You must ensure you have a fixed 60psi at the rail which is typically what the LS platform uses.

Make sure your filter is suitable for efi pressures and the flow levels required of an efi system. As for braided, wouldnt say that is needed, and may even complicate matters due to the fittings it requires. There are rubber hose options that are quite suitable for efi pressures. Just ensure you use proper clips throughout, and any metal pipes have a bead around them if at all possible.

The roller was SU carbs.Unless the E-rod package comes with the fuel tank/pump etc, then it absolutely needs a regulator. You must ensure you have a fixed 60psi at the rail which is typically what the LS platform uses.

Make sure your filter is suitable for efi pressures and the flow levels required of an efi system. As for braided, wouldnt say that is needed, and may even complicate matters due to the fittings it requires. There are rubber hose options that are quite suitable for efi pressures. Just ensure you use proper clips throughout, and any metal pipes have a bead around them if at all possible.

Further problem.

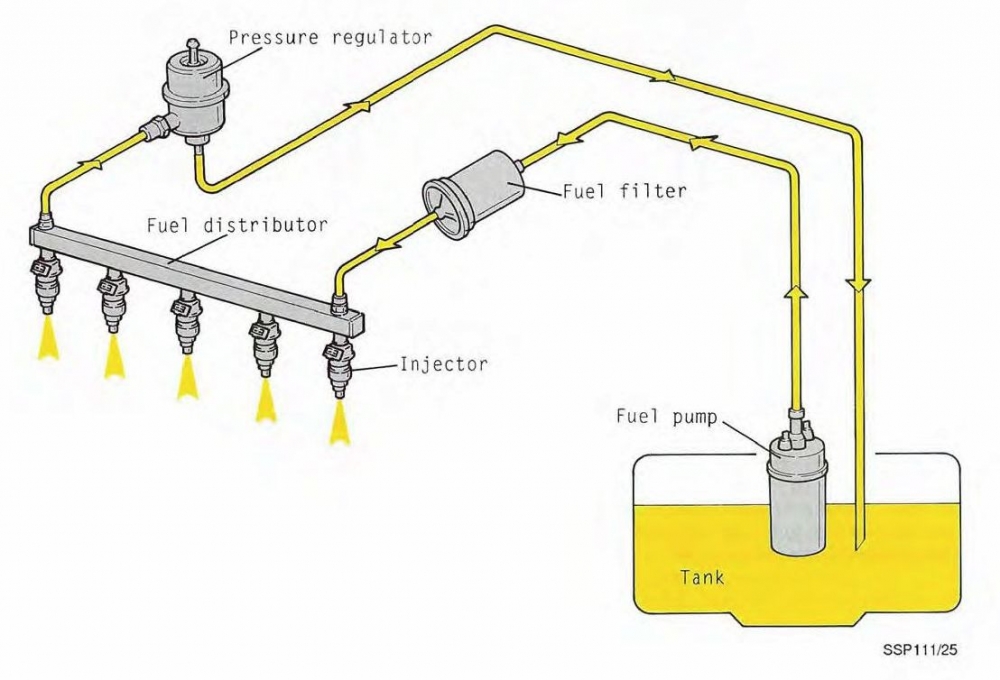

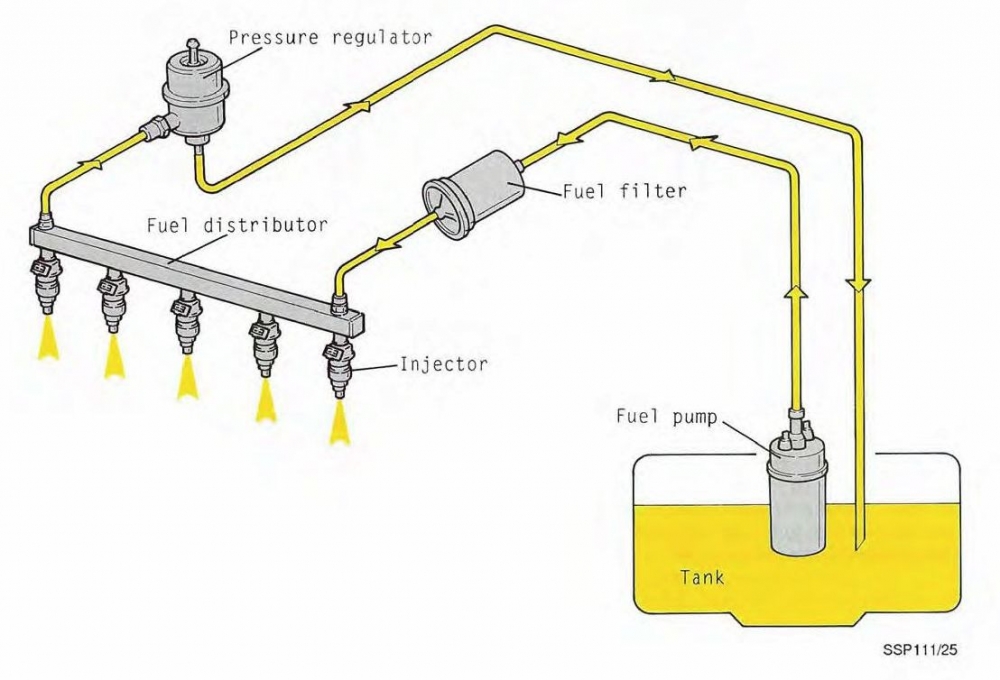

Your fuel tank will not have been designed with EFI in mind. The fuel pickup will not have adequate provision to prevent fuel slosh, and also highly likely the tank outlet will not be of adequate size for an efi setup. Although these images do not show it, all efi tanks will have some form of internal collector to ensure as best as possible, that there is always a reservoir of fuel at the pump. The return line will always return to this area too.

And in general, an efi setup will have a flow and return, although many modern cars have a single line, with the pump and regulator in-tank, which is what the modern LS has.

ie, and this shows a basic in-tank pump arrangement with an external regulator

External pump arrangement. Although ideally there would be a filter to protect the pump.

In your case, an arrangement like this may be more foolproof, but it will still require adding a return to the main tank. Your original carb pump you bought may be suitable as the primary pump as long as it flows enough, which at 72GPH should be fine.

The fitment of a small swirl tank will largely get around the fuel slosh problem.

EFI pumps must NEVER see air during operation. The engine will falter immediately, and it will drastically reduce pump life.

http://uk.images.search.yahoo.com/images/view;_ylt...

Your fuel tank will not have been designed with EFI in mind. The fuel pickup will not have adequate provision to prevent fuel slosh, and also highly likely the tank outlet will not be of adequate size for an efi setup. Although these images do not show it, all efi tanks will have some form of internal collector to ensure as best as possible, that there is always a reservoir of fuel at the pump. The return line will always return to this area too.

And in general, an efi setup will have a flow and return, although many modern cars have a single line, with the pump and regulator in-tank, which is what the modern LS has.

ie, and this shows a basic in-tank pump arrangement with an external regulator

External pump arrangement. Although ideally there would be a filter to protect the pump.

In your case, an arrangement like this may be more foolproof, but it will still require adding a return to the main tank. Your original carb pump you bought may be suitable as the primary pump as long as it flows enough, which at 72GPH should be fine.

The fitment of a small swirl tank will largely get around the fuel slosh problem.

EFI pumps must NEVER see air during operation. The engine will falter immediately, and it will drastically reduce pump life.

http://uk.images.search.yahoo.com/images/view;_ylt...

To further give you an idea.

Here is some info on the 2010 Camaro fuel system, which again your E-Rod package would require something similar. Especially if it was to maintain the full emissions compliance. In reality to maintain this, it would need a full fuel tank and vapour system to ensure no fuel vapours whatsoever were expelled to atmosphere. Much more than just an engine and wiring package.

http://www.camaroperformers.com/project-cars/magaz...

Here is some info on the 2010 Camaro fuel system, which again your E-Rod package would require something similar. Especially if it was to maintain the full emissions compliance. In reality to maintain this, it would need a full fuel tank and vapour system to ensure no fuel vapours whatsoever were expelled to atmosphere. Much more than just an engine and wiring package.

http://www.camaroperformers.com/project-cars/magaz...

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff