opinion on bearing wear - physical symptom = end float

Discussion

Firstly, this is a really long post, sorry,

I wanted to get information I currently have to hand in the initial post, so it might be clearer to certain readers, please do follow the post through before asking stuff that might be answered within it (that's why it's here, not on fb or other forums)

I have my own view on this which becomes clear, but am interested in thoughts from others familiar with bearing wear characteristics and the logic of what does what or why within a motor

Short term back story is that the car this engine was fitted to, by a third party, developed a prominent groan when taking up drive, manual car, not every time but a loaded quicker pull away from the video I've seen seemed to generate the noise

The motor had just been repaired for someone, having suffered a spun bearing on No.3 iirc, in general the engine received a donor crank, four donor pistons as its originals were all cracked, a replacement donor rod in lieu of the damaged one, plus another donor to replace one that was a fair amount heavier than the other three, plus a donor cylinder head, as the original was found to have about four cracks in it, then just bearings and rings, stem seals etc.

The person the motor was repaired for sold it on before it saw their car, via the third party, who put it into the mentioned car with a donor gearbox from a breaker

Donor crank

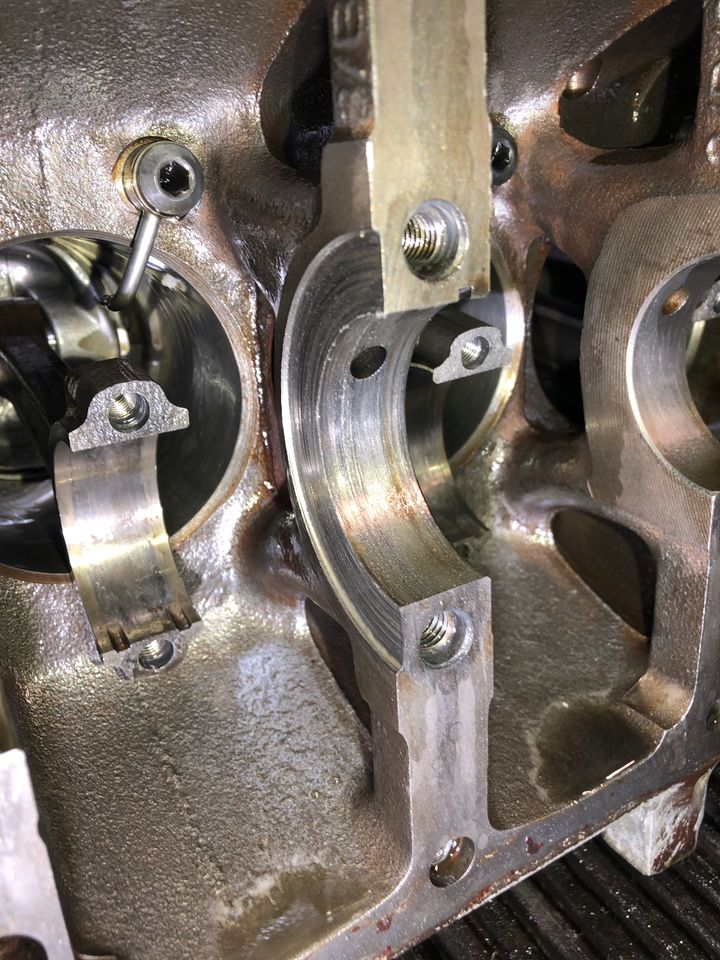

Block before bearings installed:

Block with bearings:

After install and cranking as directed with no plugs installed, they say it got oil pressure, then after initial starting and whatever period running by the third party, I was told the oil light came on with no noises and a replacement switch resolved it, then the ECU was sent for a map to be loaded, and the car later collected, where it drove ~51 miles to the destination by the owner before the pull away noise was later discussed with the third party

My opinion was asked regarding the noise pulling away, and I said clutch related was likely, I've heard similar before, apparently someone else who saw the clip had the same opinion

Said third party collected the car via recovery and took the motor assy out, and for some reason opened the gearbox, which was found to have damage to the gear teeth foremost on the input shaft

The gearbox as said above was apparently from a breakers, so not run before on this engine, only used because it was an LSD type

The third party also felt the engine for end float while out and sent me a clip of that too, which was clearly excessive

I collected the engine, and when at the address found the gearbox closed up again, but it was available to check for movement in the input shaft, nothing excessive I thought, although with each rotation of it some resistance could be felt which the third party said was the worn teeth

I also saw the clutch that had been removed, which didn't show anything particularly alarming looking at it quickly, some significant loading wear on the back of the release bearing from the fork, and it was handed to me with the centre plate lying on the cover the wrong way around which was said to be just by chance, it wasn't a new clutch kit, and notably, the centre plate was the original type with a fixed hub for use with a DMF but in use on a SMF conversion, instead of the sprung hub type that should have been used

The engine having been sold, was sold with the SMF and same clutch that had run on the engine previously, just with a different box

I hadn't recalled sight of any dowels in that gearbox, and prior to removal of the engine we'd lifted into the car, I went to look at that to see if any were in it, and found one of two, the rear one, was missing

Missing dowel just visible by chain at the back:

I asked for pics of the box it had been run with, and there were no dowels in it

I also learned the engine for first use had been filled with normal oil after asking out of curiosity

Once back here, I split the block to get the crank out, and found the rear thrust washer detached from the caged centre main that had spun, washer still in the recess, but heavily worn, the block consequentially also heavily worn the same side, and the bearing journal scored

Bedplate/bearing ladder thrust face:

Block thrust face:

The front thrust washer is completely unharmed

Front thrust washer shown below detached rear, above another used OEM front washer for comparison:

The main bearings have all been significantly wiped yet remained in position bar the centre main

No.2 main was barely affected although has an alignment type wear pattern forming

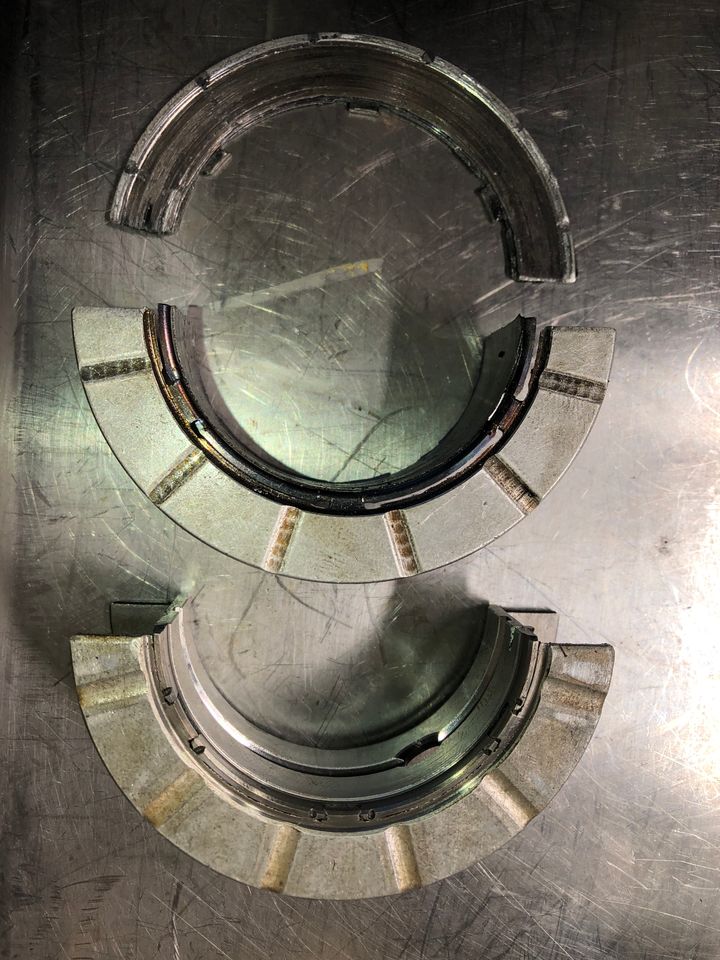

Bearing shells in 1-5 order > flywheel:

Centre main at this stage appearing possibly fused to the crank:

Closer:

The only heat mark on the crank at initial check appears to be around the thrust washer location, not so clear in the above two pics

There is no journal discolouration otherwise, on the crank or on the block

In my view there is a pattern to the main shell wear by the looks of it, heaviest wiping coming from the flywheel end

Big end shells are pretty much unharmed, minor marks, pressure will have been a bit lower I expect, and was told there was no oil light which previously had been confirmed to be functional

Big end shells/caps:

The centre main that appeared fused/hot shorted to the crank was in fact not, it was joined at its parting line by wiping and the tabs fusing, easily removed, although with marks on the crank that on the main journal appears to be transfer more than damage looking at it briefly, the thrust face has some other marking, some I think transfer, and also a degree of wear

Centre main fused halves:

The detached thrust washer's oiling grooves appear to have very slightly uneven wear with two slightly visible, and the three tabs that are normally held on the side of the main upper shell, appear to have tails which to me signify the direction of departure from said shell, or the shell from it which is what this looks like to me, the washer sits in the block, they only have a half washer, so clockwise direction of rotation suggests to me at least it wasn't the thrust washer dragging the shell, it was I think, the shell dragging the thrust washer with it, at least until it wore thin enough and hot enough to free itself from the shell, leaving the tails I refer to, but, that doesn't necessarily mean it wasn't the thrust that first grabbed the shells free

Rear thrust washer front face:

I have another block, it actually gave up its crank for the affected engine, and I've six cranks here, also for example three other used centre mains, an OEM, an NPR, and a King, the NPR from a set the donor crank ran in before, the King from a set one of the other cranks ran in, out of my own car, all of them fit nicely in the other block, and nicely in every crank centre main journal, including that of the affected crank, with the same sliding fit, and no lateral movement in the block. I can't use the affected block, that's scrap now, but do have another and due to collect more soon

I lay a spare crank in the other block, along with the NPR main uppers, added a SMF, and stock clutch, to test a scenario, run out measured at No.1 main was .04~.05mm without going mad cleaning anything, then I dug out some spare box casings and an input shaft, loosely threw them together and mounted them deliberately with only one dowel which at first was in the opposite location to that of the affected engine, my curiosity being the affect on the crank with the alignment of the box changed, so I added the DTI to the crank and levered the box up and down and roughly (because at the time it was a rough experiment) saw .15~.17mm, then I fixed the box in both limits of potential movement to see the effect on a journal, it would have been more I think but as it was a brief test I'd not closed up the box halves fully as one was quite corroded, and it was moving independently, so some of the crank's movement was I think transferred back into the end bearing of the input shaft that was free to move a little, pivoting the rear half case on its dowels

Where the crank rotated evenly and freely giving the run out value it had, the crank now bound up at half a revolution on No.5 in particular, and the run out at No.1 was more like 1.75~2.25mm, basically it being lifted, and bearing material was soon picked up in the oil film on No.5

As said, that was a rough check of something that needs more time, however, to me, it does show potential as a contributory factor

My curiosity for those still reading is about thoughts of others on potential causes of this sort of damage?

I've put a number of engines together over the last 43yrs, ~12yrs working around this type of vehicle as a hobby and ~6+yrs of those doing a fair bit more with them, none have failed, and this is the first one I did to help someone out at a lower cost than normal for the donor parts, where the assembled lump was then delivered to a third party to install, the rest are all installed here. The engine didn't let go, but the noise I described as sounding like a clutch in my experience, was what led to the discovery, no doubt before it got a lot worse

What I know:

Original repair had a low budget, the third party was hoping to chuck shells in after a spun end and go again

The motor only had to last two events before the car got sold/broken anyway

Standard parts were requested, and reconfirmed

Oil pump replacement was advised but the budget wasn't there, it was just opened and cleaned up

Timing chain although appearing recent was also advised as showing wear in that the tensioner had to be packed out

There were battle scars on the front of the block in the chain cavity from I think previous chain related damage, partially affecting No.1 main journal which had scored away the front edge of the shells, I redressed the bearing saddle to protect the new shells going in, there is no evidence of repeat wear here that I've noticed

Normal oil was used on initial fill

One gearbox locating dowel was left out

A DMF solid clutch disc was used instead of a sprung clutch disc on a SMF conversion

A damaged gearbox was mated to the engine

Previous damage in front of No.1 main saddle:

Saddle area redressed:

What the third party believes:

Engine failed, unrelated to their work assembling the car

Engine damaged the gearbox, unrelated to their work assembling the car

Regardless of the above information, the engine should have lasted more than 51 miles

They have now acknowledged the dowel was on them but refuse to consider it a factor

They have said now that if there is proof the box defect could have affected the crank they will pursue the breaker, but that evidence potential aside, they are still looking at the motor as the problem first

(also discounting the potential relevance of no sprung connection between the box and the crank on the basis the motor ran previously like it (regardless of the symptom which was noise during take up of drive resulting in vehicle recovery), and them being aware other people run the same combination (albeit probably with both dowels and good boxes)

What others the third party have spoken to or sent a couple of pictures to have apparently said:

Main shells in back to front

Main shells too big

Oil starvation

Incorrect assembly

A couple apparently said "would a dowel cause an issue? Yes perhaps eventually but unlikely this issue so soon"

So, looking for unbiased opinion, if readers know the motor or owner or middle guy involved, please keep names away, this isn't here seeking to embarrass anyone

I'm aware of information online discussing overloading in regard to premature thrust or main wear although there's little talking about wear patterns that I've seen, maybe someone knows where I'll find more on that

Any other pics or info I can help with just ask

Currently, I can't un-see the potential for the two shaft's to have been misaligned slightly, and running in two different circles with the clutch engaged, the shorter shaft running on roller bearings, the longer on plain bearings where I'm considering the affect on oil film disruption, possibly resulting in sustained bearing contact

I wanted to get information I currently have to hand in the initial post, so it might be clearer to certain readers, please do follow the post through before asking stuff that might be answered within it (that's why it's here, not on fb or other forums)

I have my own view on this which becomes clear, but am interested in thoughts from others familiar with bearing wear characteristics and the logic of what does what or why within a motor

Short term back story is that the car this engine was fitted to, by a third party, developed a prominent groan when taking up drive, manual car, not every time but a loaded quicker pull away from the video I've seen seemed to generate the noise

The motor had just been repaired for someone, having suffered a spun bearing on No.3 iirc, in general the engine received a donor crank, four donor pistons as its originals were all cracked, a replacement donor rod in lieu of the damaged one, plus another donor to replace one that was a fair amount heavier than the other three, plus a donor cylinder head, as the original was found to have about four cracks in it, then just bearings and rings, stem seals etc.

The person the motor was repaired for sold it on before it saw their car, via the third party, who put it into the mentioned car with a donor gearbox from a breaker

Donor crank

Block before bearings installed:

Block with bearings:

After install and cranking as directed with no plugs installed, they say it got oil pressure, then after initial starting and whatever period running by the third party, I was told the oil light came on with no noises and a replacement switch resolved it, then the ECU was sent for a map to be loaded, and the car later collected, where it drove ~51 miles to the destination by the owner before the pull away noise was later discussed with the third party

My opinion was asked regarding the noise pulling away, and I said clutch related was likely, I've heard similar before, apparently someone else who saw the clip had the same opinion

Said third party collected the car via recovery and took the motor assy out, and for some reason opened the gearbox, which was found to have damage to the gear teeth foremost on the input shaft

The gearbox as said above was apparently from a breakers, so not run before on this engine, only used because it was an LSD type

The third party also felt the engine for end float while out and sent me a clip of that too, which was clearly excessive

I collected the engine, and when at the address found the gearbox closed up again, but it was available to check for movement in the input shaft, nothing excessive I thought, although with each rotation of it some resistance could be felt which the third party said was the worn teeth

I also saw the clutch that had been removed, which didn't show anything particularly alarming looking at it quickly, some significant loading wear on the back of the release bearing from the fork, and it was handed to me with the centre plate lying on the cover the wrong way around which was said to be just by chance, it wasn't a new clutch kit, and notably, the centre plate was the original type with a fixed hub for use with a DMF but in use on a SMF conversion, instead of the sprung hub type that should have been used

The engine having been sold, was sold with the SMF and same clutch that had run on the engine previously, just with a different box

I hadn't recalled sight of any dowels in that gearbox, and prior to removal of the engine we'd lifted into the car, I went to look at that to see if any were in it, and found one of two, the rear one, was missing

Missing dowel just visible by chain at the back:

I asked for pics of the box it had been run with, and there were no dowels in it

I also learned the engine for first use had been filled with normal oil after asking out of curiosity

Once back here, I split the block to get the crank out, and found the rear thrust washer detached from the caged centre main that had spun, washer still in the recess, but heavily worn, the block consequentially also heavily worn the same side, and the bearing journal scored

Bedplate/bearing ladder thrust face:

Block thrust face:

The front thrust washer is completely unharmed

Front thrust washer shown below detached rear, above another used OEM front washer for comparison:

The main bearings have all been significantly wiped yet remained in position bar the centre main

No.2 main was barely affected although has an alignment type wear pattern forming

Bearing shells in 1-5 order > flywheel:

Centre main at this stage appearing possibly fused to the crank:

Closer:

The only heat mark on the crank at initial check appears to be around the thrust washer location, not so clear in the above two pics

There is no journal discolouration otherwise, on the crank or on the block

In my view there is a pattern to the main shell wear by the looks of it, heaviest wiping coming from the flywheel end

Big end shells are pretty much unharmed, minor marks, pressure will have been a bit lower I expect, and was told there was no oil light which previously had been confirmed to be functional

Big end shells/caps:

The centre main that appeared fused/hot shorted to the crank was in fact not, it was joined at its parting line by wiping and the tabs fusing, easily removed, although with marks on the crank that on the main journal appears to be transfer more than damage looking at it briefly, the thrust face has some other marking, some I think transfer, and also a degree of wear

Centre main fused halves:

The detached thrust washer's oiling grooves appear to have very slightly uneven wear with two slightly visible, and the three tabs that are normally held on the side of the main upper shell, appear to have tails which to me signify the direction of departure from said shell, or the shell from it which is what this looks like to me, the washer sits in the block, they only have a half washer, so clockwise direction of rotation suggests to me at least it wasn't the thrust washer dragging the shell, it was I think, the shell dragging the thrust washer with it, at least until it wore thin enough and hot enough to free itself from the shell, leaving the tails I refer to, but, that doesn't necessarily mean it wasn't the thrust that first grabbed the shells free

Rear thrust washer front face:

I have another block, it actually gave up its crank for the affected engine, and I've six cranks here, also for example three other used centre mains, an OEM, an NPR, and a King, the NPR from a set the donor crank ran in before, the King from a set one of the other cranks ran in, out of my own car, all of them fit nicely in the other block, and nicely in every crank centre main journal, including that of the affected crank, with the same sliding fit, and no lateral movement in the block. I can't use the affected block, that's scrap now, but do have another and due to collect more soon

I lay a spare crank in the other block, along with the NPR main uppers, added a SMF, and stock clutch, to test a scenario, run out measured at No.1 main was .04~.05mm without going mad cleaning anything, then I dug out some spare box casings and an input shaft, loosely threw them together and mounted them deliberately with only one dowel which at first was in the opposite location to that of the affected engine, my curiosity being the affect on the crank with the alignment of the box changed, so I added the DTI to the crank and levered the box up and down and roughly (because at the time it was a rough experiment) saw .15~.17mm, then I fixed the box in both limits of potential movement to see the effect on a journal, it would have been more I think but as it was a brief test I'd not closed up the box halves fully as one was quite corroded, and it was moving independently, so some of the crank's movement was I think transferred back into the end bearing of the input shaft that was free to move a little, pivoting the rear half case on its dowels

Where the crank rotated evenly and freely giving the run out value it had, the crank now bound up at half a revolution on No.5 in particular, and the run out at No.1 was more like 1.75~2.25mm, basically it being lifted, and bearing material was soon picked up in the oil film on No.5

As said, that was a rough check of something that needs more time, however, to me, it does show potential as a contributory factor

My curiosity for those still reading is about thoughts of others on potential causes of this sort of damage?

I've put a number of engines together over the last 43yrs, ~12yrs working around this type of vehicle as a hobby and ~6+yrs of those doing a fair bit more with them, none have failed, and this is the first one I did to help someone out at a lower cost than normal for the donor parts, where the assembled lump was then delivered to a third party to install, the rest are all installed here. The engine didn't let go, but the noise I described as sounding like a clutch in my experience, was what led to the discovery, no doubt before it got a lot worse

What I know:

Original repair had a low budget, the third party was hoping to chuck shells in after a spun end and go again

The motor only had to last two events before the car got sold/broken anyway

Standard parts were requested, and reconfirmed

Oil pump replacement was advised but the budget wasn't there, it was just opened and cleaned up

Timing chain although appearing recent was also advised as showing wear in that the tensioner had to be packed out

There were battle scars on the front of the block in the chain cavity from I think previous chain related damage, partially affecting No.1 main journal which had scored away the front edge of the shells, I redressed the bearing saddle to protect the new shells going in, there is no evidence of repeat wear here that I've noticed

Normal oil was used on initial fill

One gearbox locating dowel was left out

A DMF solid clutch disc was used instead of a sprung clutch disc on a SMF conversion

A damaged gearbox was mated to the engine

Previous damage in front of No.1 main saddle:

Saddle area redressed:

What the third party believes:

Engine failed, unrelated to their work assembling the car

Engine damaged the gearbox, unrelated to their work assembling the car

Regardless of the above information, the engine should have lasted more than 51 miles

They have now acknowledged the dowel was on them but refuse to consider it a factor

They have said now that if there is proof the box defect could have affected the crank they will pursue the breaker, but that evidence potential aside, they are still looking at the motor as the problem first

(also discounting the potential relevance of no sprung connection between the box and the crank on the basis the motor ran previously like it (regardless of the symptom which was noise during take up of drive resulting in vehicle recovery), and them being aware other people run the same combination (albeit probably with both dowels and good boxes)

What others the third party have spoken to or sent a couple of pictures to have apparently said:

Main shells in back to front

Main shells too big

Oil starvation

Incorrect assembly

A couple apparently said "would a dowel cause an issue? Yes perhaps eventually but unlikely this issue so soon"

So, looking for unbiased opinion, if readers know the motor or owner or middle guy involved, please keep names away, this isn't here seeking to embarrass anyone

I'm aware of information online discussing overloading in regard to premature thrust or main wear although there's little talking about wear patterns that I've seen, maybe someone knows where I'll find more on that

Any other pics or info I can help with just ask

Currently, I can't un-see the potential for the two shaft's to have been misaligned slightly, and running in two different circles with the clutch engaged, the shorter shaft running on roller bearings, the longer on plain bearings where I'm considering the affect on oil film disruption, possibly resulting in sustained bearing contact

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff