Bobs "how to change a 'K' Series headgasket thread..."

Discussion

Some months ago the headgasket blew on my trusty old 1.4 8v 'K' Series powered Rover, a mixture of work and general laziness meant that I have only got around to looking at the old girl now.

So, in true PH tradition, I've decided to start a thread recording my exploits during what will no doubt be a lengthy and troubled strip down and rebuild (please note work and laziness above...)

The car:

The fun started yesterday when I tried to get the car into my garage (which is currently occupied by my M535i) as the car is completely dead, I had the bright idea of rolling the car down the drive and onto the road so I could back the BMW out. Unfortunately, once the car was on the road, four of us couldn't push it back up the drive and into the garage. I even tried to start the engine and reverse up (yes I know, not good with an all alloy engine suffering from HGF, but I was desperate) this was a none starter (literally) as even with a jump from my BMW the engine barely turned over and made some odd noises. In the end, using much manouvering on the drive I managed to tow the stricken Rover back up and beside the house, as without about ten people, the car is staying where it is.

So far I have bought a load of nice shiny replacement gaskets and a new cam belt from our local MG Rover specialist, including an uprated head gasket with steel dowls, oil, coolant, replacement studs which incidentally cost more than ten quid for the long ones which for some reason only come in packs of five. I treated myself to a new torque wrench, a Haynes manual and some other odds and sods.

The new shiny stuff:

Looking under the bonnet, I have no coolant left in the expansion tank, the engine bay is really quite rusty for a nine year old car, the rocker box gasket has been leaking as they all seem to and there is visible evidence of HGF at the cam belt end of the engine. The exhaust manifold bolts and studs are very badly corroded and I've been dousing them in penetrating oil over the past few days in the hope it will help when I attempt to shift the rotten nuts.

The engine:

Due to the fact the weather has been cold, and I have been mostly inebriated I have yet to start the actual task of stripping the head and removing it for a poke around inside and to find what the nasty noise was when I turned the engine over, see what the state of the head is and find out whether it is warped or not. If it is all too badly gone and the engine I scrap, I could always follow up on my idea of dropping a 1.8 'K' Series in and making a cheapo track car...

Tommorow I will start stripping the top end down and post up some more pictures and an update.

Wish me luck!

DISCLAIMER: All and any advice given in this thread is purely spurious and I'm making it up as I go along. All spelling and punctuation errors are my own and are probably caused by my not too inconsiderate beer intake.

So, in true PH tradition, I've decided to start a thread recording my exploits during what will no doubt be a lengthy and troubled strip down and rebuild (please note work and laziness above...)

The car:

The fun started yesterday when I tried to get the car into my garage (which is currently occupied by my M535i) as the car is completely dead, I had the bright idea of rolling the car down the drive and onto the road so I could back the BMW out. Unfortunately, once the car was on the road, four of us couldn't push it back up the drive and into the garage. I even tried to start the engine and reverse up (yes I know, not good with an all alloy engine suffering from HGF, but I was desperate) this was a none starter (literally) as even with a jump from my BMW the engine barely turned over and made some odd noises. In the end, using much manouvering on the drive I managed to tow the stricken Rover back up and beside the house, as without about ten people, the car is staying where it is.

So far I have bought a load of nice shiny replacement gaskets and a new cam belt from our local MG Rover specialist, including an uprated head gasket with steel dowls, oil, coolant, replacement studs which incidentally cost more than ten quid for the long ones which for some reason only come in packs of five. I treated myself to a new torque wrench, a Haynes manual and some other odds and sods.

The new shiny stuff:

Looking under the bonnet, I have no coolant left in the expansion tank, the engine bay is really quite rusty for a nine year old car, the rocker box gasket has been leaking as they all seem to and there is visible evidence of HGF at the cam belt end of the engine. The exhaust manifold bolts and studs are very badly corroded and I've been dousing them in penetrating oil over the past few days in the hope it will help when I attempt to shift the rotten nuts.

The engine:

Due to the fact the weather has been cold, and I have been mostly inebriated I have yet to start the actual task of stripping the head and removing it for a poke around inside and to find what the nasty noise was when I turned the engine over, see what the state of the head is and find out whether it is warped or not. If it is all too badly gone and the engine I scrap, I could always follow up on my idea of dropping a 1.8 'K' Series in and making a cheapo track car...

Tommorow I will start stripping the top end down and post up some more pictures and an update.

Wish me luck!

DISCLAIMER: All and any advice given in this thread is purely spurious and I'm making it up as I go along. All spelling and punctuation errors are my own and are probably caused by my not too inconsiderate beer intake.

Vixpy1 said:

bob1179 said:

Plus I've just cracked open a beer.

I want to see the first K series headgasket changed while rat-arsed thread

I did give the car a bit of a wipe down today, took some piccies of the engine bay for reference and looked at it for a while whilst sucking air through my front teeth, before any work commences I have to look and stare at it for a while.

What a hideously designed, nasty, horrible, unfriendly, badly thought up engine they are to work on. And thats from a Renault lover.

Best of luck, and watch the 80 foot long head bolts, I get the distinct impression they hold much more than just the head down. I Darent turn it over with em out.

Best thing I ever did on the 416 I had was scrap it.

Best of luck, and watch the 80 foot long head bolts, I get the distinct impression they hold much more than just the head down. I Darent turn it over with em out.

Best thing I ever did on the 416 I had was scrap it.

Good thread

I had a similarly auspicious start today on my new car - started by snapping my rubber wrench attempting to remove the oil filter housing top (thanks whoever last changed the filter - the filter cap even has the required torque setting on), I think VW sell a specific tool - ££. Next up the VW OE air filter was too big for the housing despite being the correct part #. Binned it and bought one from Halfords which fits perfectly.

(thanks whoever last changed the filter - the filter cap even has the required torque setting on), I think VW sell a specific tool - ££. Next up the VW OE air filter was too big for the housing despite being the correct part #. Binned it and bought one from Halfords which fits perfectly.

Hope things pick up for you (and me).

I had a similarly auspicious start today on my new car - started by snapping my rubber wrench attempting to remove the oil filter housing top

(thanks whoever last changed the filter - the filter cap even has the required torque setting on), I think VW sell a specific tool - ££. Next up the VW OE air filter was too big for the housing despite being the correct part #. Binned it and bought one from Halfords which fits perfectly.

(thanks whoever last changed the filter - the filter cap even has the required torque setting on), I think VW sell a specific tool - ££. Next up the VW OE air filter was too big for the housing despite being the correct part #. Binned it and bought one from Halfords which fits perfectly.Hope things pick up for you (and me).

Well, it's been an interesting day today...

I woke up nice and early (10 am) had a brew and went outside to finally start on the car.

Right from the start thing went tits up. The bolt that holds the battery clamp down had rusted badly and was round so I had to work around the battery without removing it.

Rusty bolt:

I then cracked on with a beer to keep me company!

Bob working hard:

Once the oil and coolant had been drained and I had removed the radiator, I had a go at the rusty exhaust manifold nuts and studs. Amazingly six of the seven came out with little effort, as is typical the last one had pretty much rusted away and I couldn't get it off for love nor money. In the end I decided to leave the manifold attached to the head and remove it as a single piece.

My rusty nut:

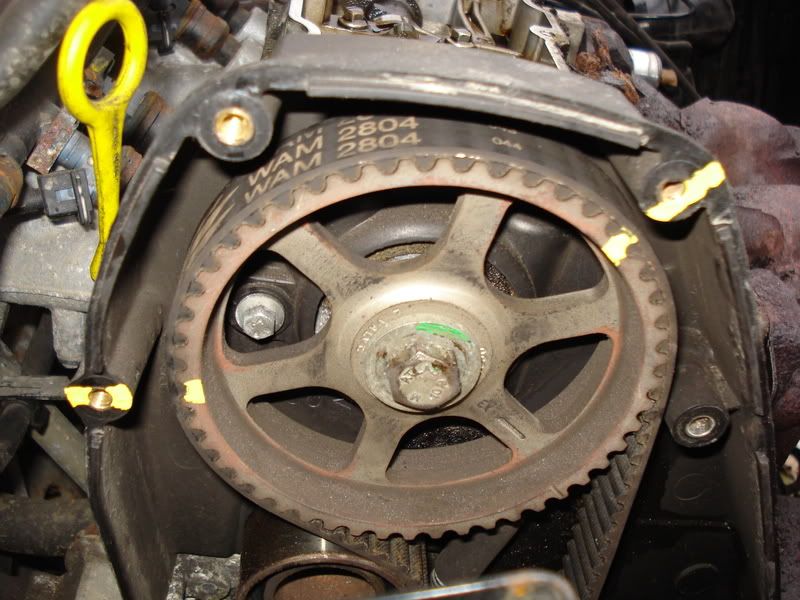

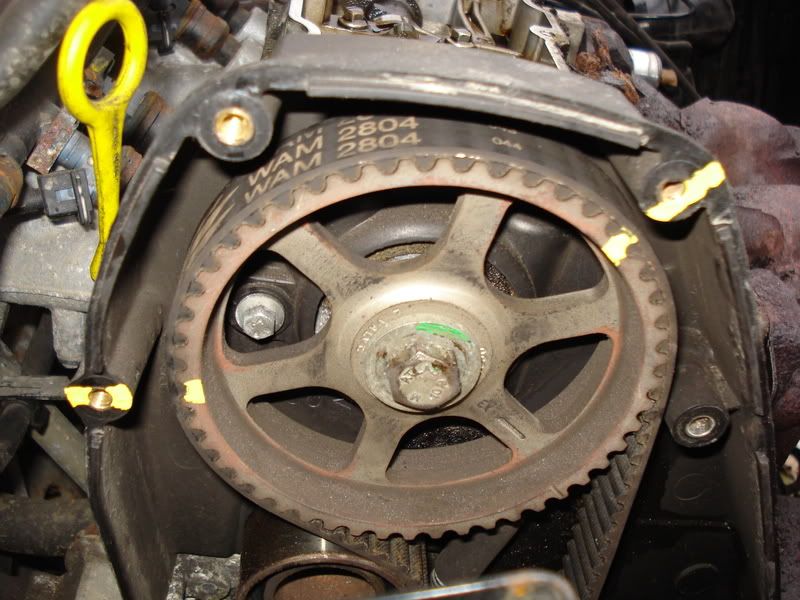

I had a good look around the head and the area around number one and number two cylinders, this seems to be where the headgasket failed. I removed the rocker cover and took off the cam cover then thought it prudent to mark up the position of the cam pulley due to the fact once the head is off I can't turn to crank so I thought it better to leave everything where it is and jut slip a new cam belt on in the same position when I put it all together again.

Marked up with a little yellow paint:

It was at this point that I took out the spark plugs and decided to crank the engine over by hand to see what the funny noise was the other day when I tried to start it desperation.

This is when I discovered that I couldn't turn it over by hand and that the engine seems to be seized.

Bugger.

So I decided to carry on and get the head off and have a look and see what exactly is wrong. After much swearing and skinning of knuckles removing multiplugs and that really annoying vacuum pipe that goes from the manifold to the servo I loosened the cylinder head bolts, took them out and labelled them. I then got the head off and had a peak inside.

To be honest, it doesn't look that bad, the crowns aren't burnt, the spark plugs look healthy and there didn't seem to be any coolant mixed in with the oil.

The inside bits:

After I got the head off, number one cylinder seems to be the one that has seized but it's at TDC and I can't see the bore and with the head removed I can't turn the crank as it will dislodge the liners. The engine has covered less than sixty thousand miles and has always been well serviced, without stripping down the block, I am not going to find out how badly number one cylinder is damaged.

Number one cylinder bore:

Number two cylinder has a fairly deep horizontal score about half way down, but other than that there seems to be very little wear. I think this may have been caused by corrosion due to coolant getting in when the gasket went and the car being sat for a few months, although if anybody else can offer a better explanation I'd love to know it!

Number two cylinder bore with the score visible half way down:

The cylinder head, inlet and exhaust manifolds in all their glory:

That's about it so far, it started to get dark and I needed more beer. I am going to take the block and gearbox out and strip it down but as I have to go to work on Monday morning (in South Wales) I am going to have to leave it until the next time I am back up in Lancaster to continue.

So a typical DIY engine job, something you expect to be fairly straight forward and take a day has turned into a major piece of automotive open heart surgery!

The engine before I poured some oil into the bores to protect it and wrapped it up in plastic to be left until I am home again to scratch my head and wonder in which direction I should continue:

Any comments and advice welcome!

I woke up nice and early (10 am) had a brew and went outside to finally start on the car.

Right from the start thing went tits up. The bolt that holds the battery clamp down had rusted badly and was round so I had to work around the battery without removing it.

Rusty bolt:

I then cracked on with a beer to keep me company!

Bob working hard:

Once the oil and coolant had been drained and I had removed the radiator, I had a go at the rusty exhaust manifold nuts and studs. Amazingly six of the seven came out with little effort, as is typical the last one had pretty much rusted away and I couldn't get it off for love nor money. In the end I decided to leave the manifold attached to the head and remove it as a single piece.

My rusty nut:

I had a good look around the head and the area around number one and number two cylinders, this seems to be where the headgasket failed. I removed the rocker cover and took off the cam cover then thought it prudent to mark up the position of the cam pulley due to the fact once the head is off I can't turn to crank so I thought it better to leave everything where it is and jut slip a new cam belt on in the same position when I put it all together again.

Marked up with a little yellow paint:

It was at this point that I took out the spark plugs and decided to crank the engine over by hand to see what the funny noise was the other day when I tried to start it desperation.

This is when I discovered that I couldn't turn it over by hand and that the engine seems to be seized.

Bugger.

So I decided to carry on and get the head off and have a look and see what exactly is wrong. After much swearing and skinning of knuckles removing multiplugs and that really annoying vacuum pipe that goes from the manifold to the servo I loosened the cylinder head bolts, took them out and labelled them. I then got the head off and had a peak inside.

To be honest, it doesn't look that bad, the crowns aren't burnt, the spark plugs look healthy and there didn't seem to be any coolant mixed in with the oil.

The inside bits:

After I got the head off, number one cylinder seems to be the one that has seized but it's at TDC and I can't see the bore and with the head removed I can't turn the crank as it will dislodge the liners. The engine has covered less than sixty thousand miles and has always been well serviced, without stripping down the block, I am not going to find out how badly number one cylinder is damaged.

Number one cylinder bore:

Number two cylinder has a fairly deep horizontal score about half way down, but other than that there seems to be very little wear. I think this may have been caused by corrosion due to coolant getting in when the gasket went and the car being sat for a few months, although if anybody else can offer a better explanation I'd love to know it!

Number two cylinder bore with the score visible half way down:

The cylinder head, inlet and exhaust manifolds in all their glory:

That's about it so far, it started to get dark and I needed more beer. I am going to take the block and gearbox out and strip it down but as I have to go to work on Monday morning (in South Wales) I am going to have to leave it until the next time I am back up in Lancaster to continue.

So a typical DIY engine job, something you expect to be fairly straight forward and take a day has turned into a major piece of automotive open heart surgery!

The engine before I poured some oil into the bores to protect it and wrapped it up in plastic to be left until I am home again to scratch my head and wonder in which direction I should continue:

Any comments and advice welcome!

Vixpy1 said:

bob1179 said:

Vixpy1 said:

Del 203 said:

bob1179 said:

Any comments and advice welcome!

Don't short the beer can on the beverage holder

HTH

Cheers lads.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff