pneumatic valve spring technology

Discussion

The basic idea is not complicated, just replace the wire spring with a pneumatic one. But of course the devil is in the details! Most systems use either a resevoir or a pump (early systems used a converted single cylinder RC plane "glow" engine piston and rod as a piston compressor driven off the cam!). The seals all leak slowly, so you need some method to keep the pressure (and hence spring rate) constant over the race duration. One of the big issues is controlling the dynamics, as you have very little damping (usually the steel spring acts as a system damper) and air systems tend to have a narrow fundamental frequency, and high harmonic content.

The advantages of the system are that you do not run into the fatigue issues associated with wire springs at large strains, and your dynamic mass is minimised, allowing higher valve accelerations whilst keeping cam and follower loads within material limits .

Broadly speaking, only F1 and DTCC engines have ever run airsprings sucessfully (not sure if CART engines got them too??)

The advantages of the system are that you do not run into the fatigue issues associated with wire springs at large strains, and your dynamic mass is minimised, allowing higher valve accelerations whilst keeping cam and follower loads within material limits .

Broadly speaking, only F1 and DTCC engines have ever run airsprings sucessfully (not sure if CART engines got them too??)

stevieturbo said:

Why havent springless systems like Ducati use or the rotary valves come into mainstream yet ?

Every now and then a rotary valve system pops up with a working prototype, then disappears again.

Generaly because they don't offer the OEM's any genuine real world advantages, and often come with a lot of genuine real world disadvantages !!!Every now and then a rotary valve system pops up with a working prototype, then disappears again.

A wiresprung, rotary cam lobe activated poppet valve is still the best choice when you consider cost, durability, versatility, performance and packaging.....

Max_Torque said:

stevieturbo said:

Why havent springless systems like Ducati use or the rotary valves come into mainstream yet ?

Every now and then a rotary valve system pops up with a working prototype, then disappears again.

Generaly because they don't offer the OEM's any genuine real world advantages, and often come with a lot of genuine real world disadvantages !!!Every now and then a rotary valve system pops up with a working prototype, then disappears again.

A wiresprung, rotary cam lobe activated poppet valve is still the best choice when you consider cost, durability, versatility, performance and packaging.....

Max, or anyone else, have you heard of the coating you can have applied to springs that is supposed to help reduce the fetigue issues by about 25%. I think its a coating that helps them reject the heat into the oil better and thus keeps them running cooler. Might have got it mixed up though.

chuntington101 said:

Dont forget that an OEM isn't going to wantyou to be reving your 2.0ltr 4 pot to 13K rpm as the stress on the rest of the engine would be massive. as max siad there is just no point on road cars.

Max, or anyone else, have you heard of the coating you can have applied to springs that is supposed to help reduce the fetigue issues by about 25%. I think its a coating that helps them reject the heat into the oil better and thus keeps them running cooler. Might have got it mixed up though.

Looking at the properties of most spring steels, i don't think that the sort of temperatures experienced would cause significant material property degredation?Max, or anyone else, have you heard of the coating you can have applied to springs that is supposed to help reduce the fetigue issues by about 25%. I think its a coating that helps them reject the heat into the oil better and thus keeps them running cooler. Might have got it mixed up though.

You are probably talking about "superfinished" springs, where they are vibration media bathed to polish the outside surface and remove any stress raisers (crack propogation loci). I have also heard about a "plastic" coating designed to add extra "damping" to the spring to help control harmonic content, but i have no idea if anyones ever used this yet in a racing or OEM application.

Of course, even with all the tricks, a wire spring system cannot match an airspring system for lift and strain resistance (when comparing the same "package envelope", obviously you could just make your spring system very "long" to avoid high strain, but this is conterproductive when trying to build a compact engine, and increases dynamic masses)

Just have a look around you, see all that air? yup, same stuff is used in air-springs... ;-)

Actually, they mostly use pure nitrogen to avoid moisture and thermal effects causing a shift in system resonse.

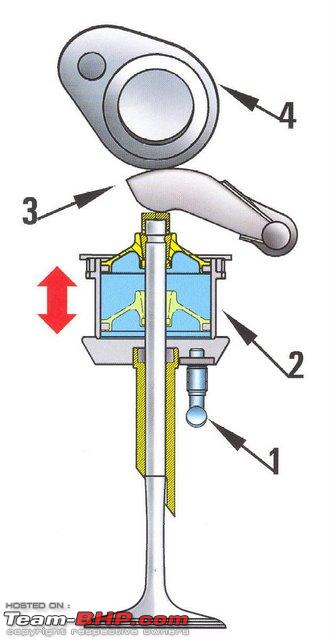

more usefully:

and

Although the actual sealing arrangement is somewhat different in reality.

Actually, they mostly use pure nitrogen to avoid moisture and thermal effects causing a shift in system resonse.

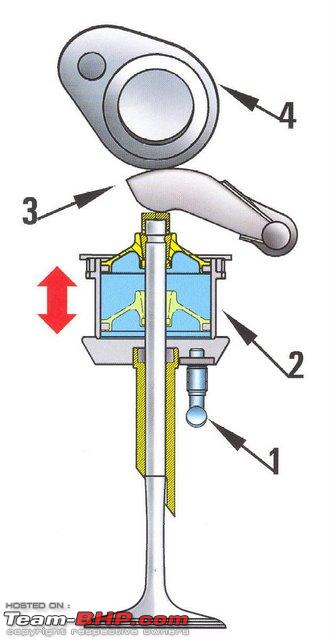

more usefully:

and

Although the actual sealing arrangement is somewhat different in reality.

Edited by anonymous-user on Sunday 1st May 23:02

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff