Vantage chrome trim adhesive

Discussion

Well, something had to fall off the (VH) Vantage at one point

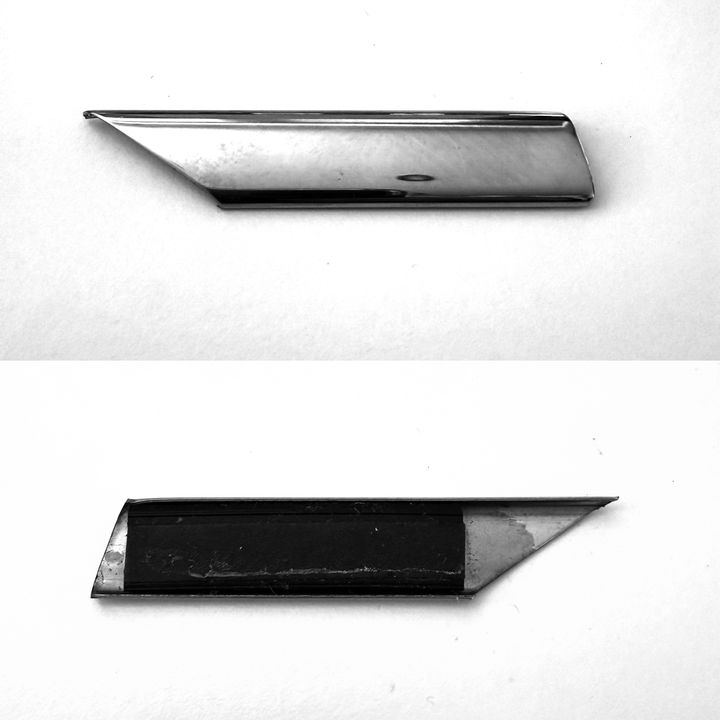

Thankfully, it's just the very small chrome trim strip that's located between the wing mirror arms:

I caught the sharp corner of the trim whilst drying it after washing a few weeks ago. It's only held on with black adhesive tape, approximately 7mm wide.

Does anybody know the most suitable brand and spec of tape to use? I don't want it disappearing at speed when travelling!

Thanks!

Thankfully, it's just the very small chrome trim strip that's located between the wing mirror arms:

I caught the sharp corner of the trim whilst drying it after washing a few weeks ago. It's only held on with black adhesive tape, approximately 7mm wide.

Does anybody know the most suitable brand and spec of tape to use? I don't want it disappearing at speed when travelling!

Thanks!

3M VHB acrylic foam. Comes in various thicknesses and widths but readily available from the itinternet. It's pressure sensitive, so you have to press it on really firmly for a few seconds to initiate the curing - I'd also not do it in the cold, or onto cold metal. The thickness needs to be enough to follow imperfections in the surface, but not so thick that the trim piece stands proud and gets snagged again. You might be able to measure how thick the piece is on your trim.

Like all adhesives, the trick is getting both surfaces scrupulously clean and degreased, so you'll need something like isopropanol - also available off the web if you don't already have any.

I also lost the same piece as you and I think this originally came supplied as part of the mirror arm, so you're trying to get it to stick to the painted casting and not smooth BIW topcoat paint, which makes it a little trickier. You could also take the time to tailor the shape to fit the brightware piece exactly, rather than just use square-cut ends - this might help adhesion.

edited to add

Forgot to add that there's various grades of VHB - have a look at this

https://multimedia.3m.com/mws/media/1989867O/01-pr...

Depending on the foam thickness you need it looks like you'll need one of the 59xx products

Like all adhesives, the trick is getting both surfaces scrupulously clean and degreased, so you'll need something like isopropanol - also available off the web if you don't already have any.

I also lost the same piece as you and I think this originally came supplied as part of the mirror arm, so you're trying to get it to stick to the painted casting and not smooth BIW topcoat paint, which makes it a little trickier. You could also take the time to tailor the shape to fit the brightware piece exactly, rather than just use square-cut ends - this might help adhesion.

edited to add

Forgot to add that there's various grades of VHB - have a look at this

https://multimedia.3m.com/mws/media/1989867O/01-pr...

Depending on the foam thickness you need it looks like you'll need one of the 59xx products

Edited by LTP on Friday 2nd January 16:55

LTP said:

3M VHB acrylic foam. Comes in various thicknesses and widths but readily available from the itinternet. It's pressure sensitive, so you have to press it on really firmly for a few seconds to initiate the curing - I'd also not do it in the cold, or onto cold metal. The thickness needs to be enough to follow imperfections in the surface, but not so thick that the trim piece stands proud and gets snagged again. You might be able to measure how thick the piece is on your trim.

Like all adhesives, the trick is getting both surfaces scrupulously clean and degreased, so you'll need something like isopropanol - also available off the web if you don't already have any.

I also lost the same piece as you and I think this originally came supplied as part of the mirror arm, so you're trying to get it to stick to the painted casting and not smooth BIW topcoat paint, which makes it a little trickier. You could also take the time to tailor the shape to fit the brightware piece exactly, rather than just use square-cut ends - this might help adhesion

Thank you! That's great detail and really appreciated.Like all adhesives, the trick is getting both surfaces scrupulously clean and degreased, so you'll need something like isopropanol - also available off the web if you don't already have any.

I also lost the same piece as you and I think this originally came supplied as part of the mirror arm, so you're trying to get it to stick to the painted casting and not smooth BIW topcoat paint, which makes it a little trickier. You could also take the time to tailor the shape to fit the brightware piece exactly, rather than just use square-cut ends - this might help adhesion

I will go and hunt these things down.

That bit coming off did make me laugh a bit. The first time I saw a VH Vantage in the metal properly (not the pre-production one before its release, in testing through my home city, broken down and having to be collected...) was at the major UK motorshow (NEC, I presume). I remember looking around it closely but noticing this piece had already fallen off

TBH - I would prefer that this is a weak point, but that the engine, driver train and heavy engineering is all holding up really well!

nickv12 said:

Thank you! That's great detail and really appreciated.

I will go and hunt these things down.

That bit coming off did make me laugh a bit. The first time I saw a VH Vantage in the metal properly (not the pre-production one before its release, in testing through my home city, broken down and having to be collected...) was at the major UK motorshow (NEC, I presume). I remember looking around it closely but noticing this piece had already fallen off

TBH - I would prefer that this is a weak point, but that the engine, driver train and heavy engineering is all holding up really well!

You were a bit quick - I've just added an extra bit about the grade of VHB you'll need.I will go and hunt these things down.

That bit coming off did make me laugh a bit. The first time I saw a VH Vantage in the metal properly (not the pre-production one before its release, in testing through my home city, broken down and having to be collected...) was at the major UK motorshow (NEC, I presume). I remember looking around it closely but noticing this piece had already fallen off

TBH - I would prefer that this is a weak point, but that the engine, driver train and heavy engineering is all holding up really well!

And I agree - if the only problem you get is a little piece of almost missable brightware falling off then Happy Days!

nickv12 said:

Don't worry - still searching. That PDF helps a lot, thank you, as I was trying to find tape thinner than 1.1mm and there are various options on there which are 0.5 or 0.6mm.

I wouldn't go too thin. The brightware piece is hollow, and there needs to be enough foam depth to take up any imperfections in the cast and texture-painted mirror arm. I'd guess you'll probably need 1.5 mmLTP said:

I wouldn't go too thin. The brightware piece is hollow, and there needs to be enough foam depth to take up any imperfections in the cast and texture-painted mirror arm. I'd guess you'll probably need 1.5 mm

The foam layer present in the chrome extrusion appears to be contoured and perfectly made for it. I think the adhesive is a thin layer on top of that.nickv12 said:

The foam layer present in the chrome extrusion appears to be contoured and perfectly made for it. I think the adhesive is a thin layer on top of that.

Nope. It’s just that the foam of the tape has taken up the form and deformed to fit, something 3M says is a feature of the tape.The core has the dual properties of behaving like a very viscous liquid and an elastic solid. This is known as viscoelasticity. The “visco” properties allow the adhesive to flow into the microscopic irregularities of the surface to form a very strong bond.

EVR said:

Can I suggest contact glue? Fairly easy and clean to apply (unlike the super glues), and resistant to water, heat, cold.

I used it in my previous VH Vantage to fix some foam on top of the fan housing in the engine, has been perfect forever.

I appreciate suggestion, but I’d prefer not to glue it as there’s more chance of damage if it needs to be removed in the future (eg. respray).I used it in my previous VH Vantage to fix some foam on top of the fan housing in the engine, has been perfect forever.

LTP said:

Nope. It s just that the foam of the tape has taken up the form and deformed to fit, something 3M says is a feature of the tape.

The core has the dual properties of behaving like a very viscous liquid and an elastic solid. This is known as viscoelasticity. The visco properties allow the adhesive to flow into the microscopic irregularities of the surface to form a very strong bond.

Ah… in which case I need much thicker foam. Cheers for the advice.The core has the dual properties of behaving like a very viscous liquid and an elastic solid. This is known as viscoelasticity. The visco properties allow the adhesive to flow into the microscopic irregularities of the surface to form a very strong bond.

Gassing Station | Aston Martin | Top of Page | What's New | My Stuff