Typhon conundrum

Discussion

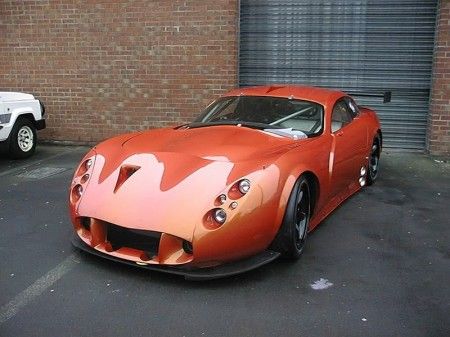

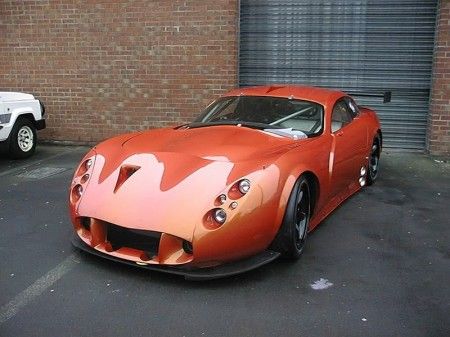

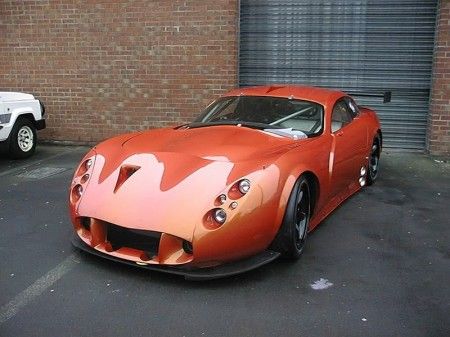

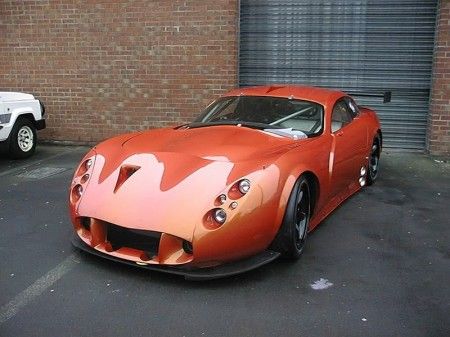

Last summer we completed most of the restoration of the orange Typhon and fitted a completely new engine that was built by Racing Green.

The car is really quite startling to drive and the engine revs like a 3.6 to 8000+ and delivers about 410 bhp. The engine that has been built should at this point be delivering closer to 440 bhp and investigations have shown that it is being starved of air at higher RPM.

With the Tuscan set up the air is drawn into the box from below via a very short and wide pipe and the same engine in a Tuscan is delivering the numbers that we should be achieving. In fact, in theory we should get more as the Tuscan exhaust is more restrictive than the set up on the Typhon.

The problem is that TVR originally built this car with a super charger so breathing wasn't an issue, from the image below you can see that long pipes ran into the air box via two intercoolers having originally been drawn in via quite a small airbox and filter behind the fans, out of view.

We have removed the intercoolers and are now running two pipes from the filter to the engine (originally it was just the one) but it is all too restrictive and I also suspect that the actual length of the ducting isn't going to help either.

There is one simple solution and it is to do exactly what TVR did with the normally asperated cars as they knew about this issue and this was to simply duct the air straight in to theengine via a bonnet scoop as can be seen here with one of the race cars:

I suspect that this will solve our issue instantly and we do need to solve it because we are planning to fir the VVT system this year to get the most out of the top end, when all the power is and this will just highlight the issue further.

The issue is that I am reluctant to cut a hole in the lower part of the bonnet as it will change the look of the original car.

One thought that I had was that the space on the drivers side wing where one of the intercoolers were is still available and we could fit a large airbox and filter in there and draw air via the grill scoop but I'm not sure if the length of the ducting required to ferry the air to the engine will cause problems with travel and heat etc.

Any thoughts?

The ultimate aim is to get as close to 475 bhp as we can with improved torque above the already 350. If I can sort this breathing issue then I think we should be clearing 450 with the VVT system quite easily. Then we need to modify the rad and fans to get some better cooling to cope with this output, but that's another hurdle

The car is really quite startling to drive and the engine revs like a 3.6 to 8000+ and delivers about 410 bhp. The engine that has been built should at this point be delivering closer to 440 bhp and investigations have shown that it is being starved of air at higher RPM.

With the Tuscan set up the air is drawn into the box from below via a very short and wide pipe and the same engine in a Tuscan is delivering the numbers that we should be achieving. In fact, in theory we should get more as the Tuscan exhaust is more restrictive than the set up on the Typhon.

The problem is that TVR originally built this car with a super charger so breathing wasn't an issue, from the image below you can see that long pipes ran into the air box via two intercoolers having originally been drawn in via quite a small airbox and filter behind the fans, out of view.

We have removed the intercoolers and are now running two pipes from the filter to the engine (originally it was just the one) but it is all too restrictive and I also suspect that the actual length of the ducting isn't going to help either.

There is one simple solution and it is to do exactly what TVR did with the normally asperated cars as they knew about this issue and this was to simply duct the air straight in to theengine via a bonnet scoop as can be seen here with one of the race cars:

I suspect that this will solve our issue instantly and we do need to solve it because we are planning to fir the VVT system this year to get the most out of the top end, when all the power is and this will just highlight the issue further.

The issue is that I am reluctant to cut a hole in the lower part of the bonnet as it will change the look of the original car.

One thought that I had was that the space on the drivers side wing where one of the intercoolers were is still available and we could fit a large airbox and filter in there and draw air via the grill scoop but I'm not sure if the length of the ducting required to ferry the air to the engine will cause problems with travel and heat etc.

Any thoughts?

The ultimate aim is to get as close to 475 bhp as we can with improved torque above the already 350. If I can sort this breathing issue then I think we should be clearing 450 with the VVT system quite easily. Then we need to modify the rad and fans to get some better cooling to cope with this output, but that's another hurdle

Couple of ideas off the top of my head, not sure if they are any good mind you

Could you run a pipe into the inner wing behind the wheel arch? Should be short enough and there will be similar air flow (maybe more) than the Tuscans pipe under the car.

If you can find a combined main and side light unit that fits in the current main placement you'd have an empty recess that you could run a pipe from. Would be the same length as the racer so at least you know that works. Looks about the same size inlet as the scoop on the racer and saves cutting the bonnet.

Could you run a pipe into the inner wing behind the wheel arch? Should be short enough and there will be similar air flow (maybe more) than the Tuscans pipe under the car.

If you can find a combined main and side light unit that fits in the current main placement you'd have an empty recess that you could run a pipe from. Would be the same length as the racer so at least you know that works. Looks about the same size inlet as the scoop on the racer and saves cutting the bonnet.

spartridge said:

Supercharge it.

TVRs aim with the SC was 500 bhp. In reality I think they got more but they were not able to keep the engine cool and the whole thing used to over heat.

I've always used my Tivs as and when I've wanted to and the main build criteria of this one was that it must not restrict me in any way or be temperamental.

I'll be getting not far off their performance with the NA. Plus, everything is being done with SC in mind at a later date but until someone builds a top quality SC system and proves categorically to me that it works then I'm not going to waste my time and money financing someone's pipe dream.

Re the engine temps we are running the Syvecs system which means that we can fit modern, state of the art cooling fans that not just draw far more volume than the conventional fans in Tivs but can be programmed to be dynamic to various driving settings. Also there are much more modern rads now which can cool more volume more quickly. The aim will be to fit a system which maintains a steady 85 degrees at all times while also monitoring alternator drain etc.

SteveTusc said:

Couple of ideas off the top of my head, not sure if they are any good mind you

Could you run a pipe into the inner wing behind the wheel arch? Should be short enough and there will be similar air flow (maybe more) than the Tuscans pipe under the car.

If you can find a combined main and side light unit that fits in the current main placement you'd have an empty recess that you could run a pipe from. Would be the same length as the racer so at least you know that works. Looks about the same size inlet as the scoop on the racer and saves cutting the bonnet.

There's a big chunk of carbon fibre honeycomb to get through.

Could you run a pipe into the inner wing behind the wheel arch? Should be short enough and there will be similar air flow (maybe more) than the Tuscans pipe under the car.

If you can find a combined main and side light unit that fits in the current main placement you'd have an empty recess that you could run a pipe from. Would be the same length as the racer so at least you know that works. Looks about the same size inlet as the scoop on the racer and saves cutting the bonnet.

It would be quite easy to run a pipe into the front of te wing and fit the box in that space and draw through the existing air vent next to the grill.

I'm just not sure what it will lose through running the extra length and the twists in contrast to just ramming it in in a straight and short line via the bonnet.

I know it's an obvious question, but is there any reason why you can't go back to the original Speed6 Airbox design with bottom feed ?? From what I remember, there's no real obstructions on that side of the engine except the alternator, but I've never seen inside a Typhon engine bay with the airbox off. I notice Str8six have a very good looking airbox on their new-build cars.

T350, Tuscan and Sagaris all have the same cold air feed

T350, Tuscan and Sagaris all have the same cold air feed

RedSpike66 said:

I know it's an obvious question, but is there any reason why you can't go back to the original Speed6 Airbox design with bottom feed ?? From what I remember, there's no real obstructions on that side of the engine except the alternator, but I've never seen inside a Typhon engine bay with the airbox off. I notice Str8six have a very good looking airbox on their new-build cars.

T350, Tuscan and Sagaris all have the same cold air feed

Then there would be no issue T350, Tuscan and Sagaris all have the same cold air feed

Sadly there isn't any space to take the pipe due south, only forward.

The race cars did it deliberately as at high speed a direct feed from head on gives the extra benefit of ram air.

There is enough pedigree to cut a hole but it's a tough call.

DonkeyApple said:

Last summer we completed most of the restoration of the orange Typhon and fitted a completely new engine that was built by Racing Green.

The car is really quite startling to drive and the engine revs like a 3.6 to 8000+ and delivers about 410 bhp. The engine that has been built should at this point be delivering closer to 440 bhp and investigations have shown that it is being starved of air at higher RPM.

With the Tuscan set up the air is drawn into the box from below via a very short and wide pipe and the same engine in a Tuscan is delivering the numbers that we should be achieving. In fact, in theory we should get more as the Tuscan exhaust is more restrictive than the set up on the Typhon.

The problem is that TVR originally built this car with a super charger so breathing wasn't an issue, from the image below you can see that long pipes ran into the air box via two intercoolers having originally been drawn in via quite a small airbox and filter behind the fans, out of view.

We have removed the intercoolers and are now running two pipes from the filter to the engine (originally it was just the one) but it is all too restrictive and I also suspect that the actual length of the ducting isn't going to help either.

There is one simple solution and it is to do exactly what TVR did with the normally asperated cars as they knew about this issue and this was to simply duct the air straight in to theengine via a bonnet scoop as can be seen here with one of the race cars:

I suspect that this will solve our issue instantly and we do need to solve it because we are planning to fir the VVT system this year to get the most out of the top end, when all the power is and this will just highlight the issue further.

The issue is that I am reluctant to cut a hole in the lower part of the bonnet as it will change the look of the original car.

One thought that I had was that the space on the drivers side wing where one of the intercoolers were is still available and we could fit a large airbox and filter in there and draw air via the grill scoop but I'm not sure if the length of the ducting required to ferry the air to the engine will cause problems with travel and heat etc.

Any thoughts?

The ultimate aim is to get as close to 475 bhp as we can with improved torque above the already 350. If I can sort this breathing issue then I think we should be clearing 450 with the VVT system quite easily. Then we need to modify the rad and fans to get some better cooling to cope with this output, but that's another hurdle

Can your existing head be modified to take the VVT system, or are you going to have to swap it for a new one?The car is really quite startling to drive and the engine revs like a 3.6 to 8000+ and delivers about 410 bhp. The engine that has been built should at this point be delivering closer to 440 bhp and investigations have shown that it is being starved of air at higher RPM.

With the Tuscan set up the air is drawn into the box from below via a very short and wide pipe and the same engine in a Tuscan is delivering the numbers that we should be achieving. In fact, in theory we should get more as the Tuscan exhaust is more restrictive than the set up on the Typhon.

The problem is that TVR originally built this car with a super charger so breathing wasn't an issue, from the image below you can see that long pipes ran into the air box via two intercoolers having originally been drawn in via quite a small airbox and filter behind the fans, out of view.

We have removed the intercoolers and are now running two pipes from the filter to the engine (originally it was just the one) but it is all too restrictive and I also suspect that the actual length of the ducting isn't going to help either.

There is one simple solution and it is to do exactly what TVR did with the normally asperated cars as they knew about this issue and this was to simply duct the air straight in to theengine via a bonnet scoop as can be seen here with one of the race cars:

I suspect that this will solve our issue instantly and we do need to solve it because we are planning to fir the VVT system this year to get the most out of the top end, when all the power is and this will just highlight the issue further.

The issue is that I am reluctant to cut a hole in the lower part of the bonnet as it will change the look of the original car.

One thought that I had was that the space on the drivers side wing where one of the intercoolers were is still available and we could fit a large airbox and filter in there and draw air via the grill scoop but I'm not sure if the length of the ducting required to ferry the air to the engine will cause problems with travel and heat etc.

Any thoughts?

The ultimate aim is to get as close to 475 bhp as we can with improved torque above the already 350. If I can sort this breathing issue then I think we should be clearing 450 with the VVT system quite easily. Then we need to modify the rad and fans to get some better cooling to cope with this output, but that's another hurdle

DonkeyApple said:

RedSpike66 said:

I know it's an obvious question, but is there any reason why you can't go back to the original Speed6 Airbox design with bottom feed ?? From what I remember, there's no real obstructions on that side of the engine except the alternator, but I've never seen inside a Typhon engine bay with the airbox off. I notice Str8six have a very good looking airbox on their new-build cars.

T350, Tuscan and Sagaris all have the same cold air feed

Then there would be no issue T350, Tuscan and Sagaris all have the same cold air feed

Sadly there isn't any space to take the pipe due south, only forward.

The race cars did it deliberately as at high speed a direct feed from head on gives the extra benefit of ram air.

There is enough pedigree to cut a hole but it's a tough call.

Gassing Station | Speed Six Engine | Top of Page | What's New | My Stuff