A bit of a report from Donington GP on Saturday.

Discussion

Before Donington I had a bit of work to do...

I needed a new splitter after breaking the other one at Brands....

I`ve been modifying the splitter with every version, I`m probably up to V5 or 6 now...

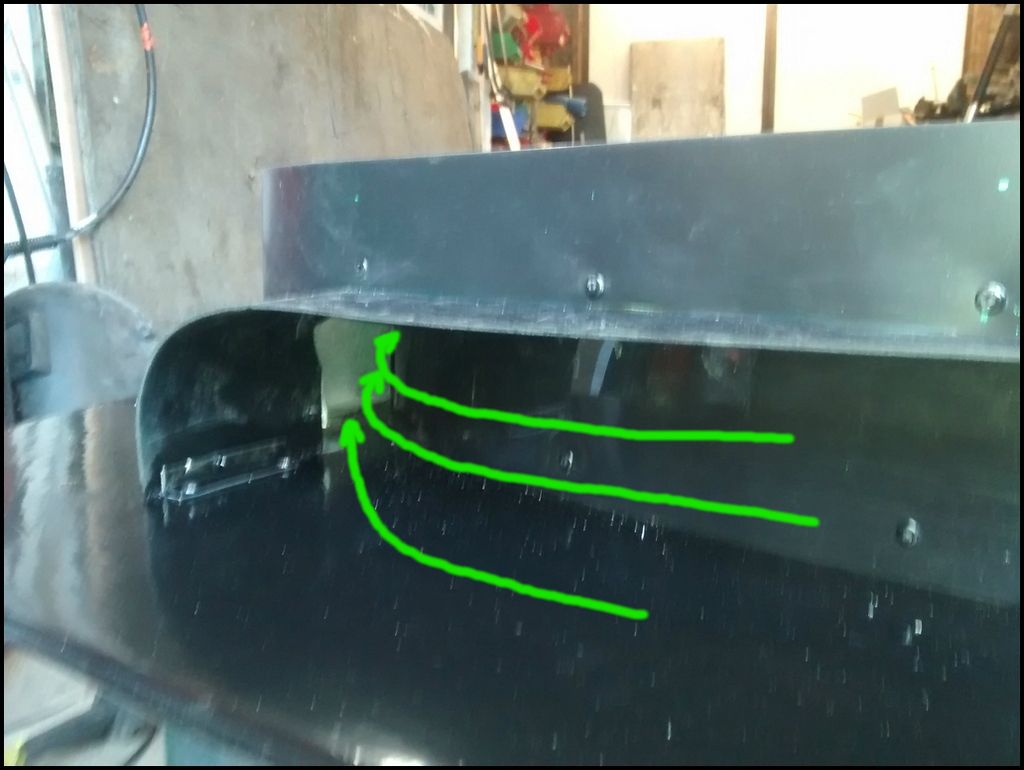

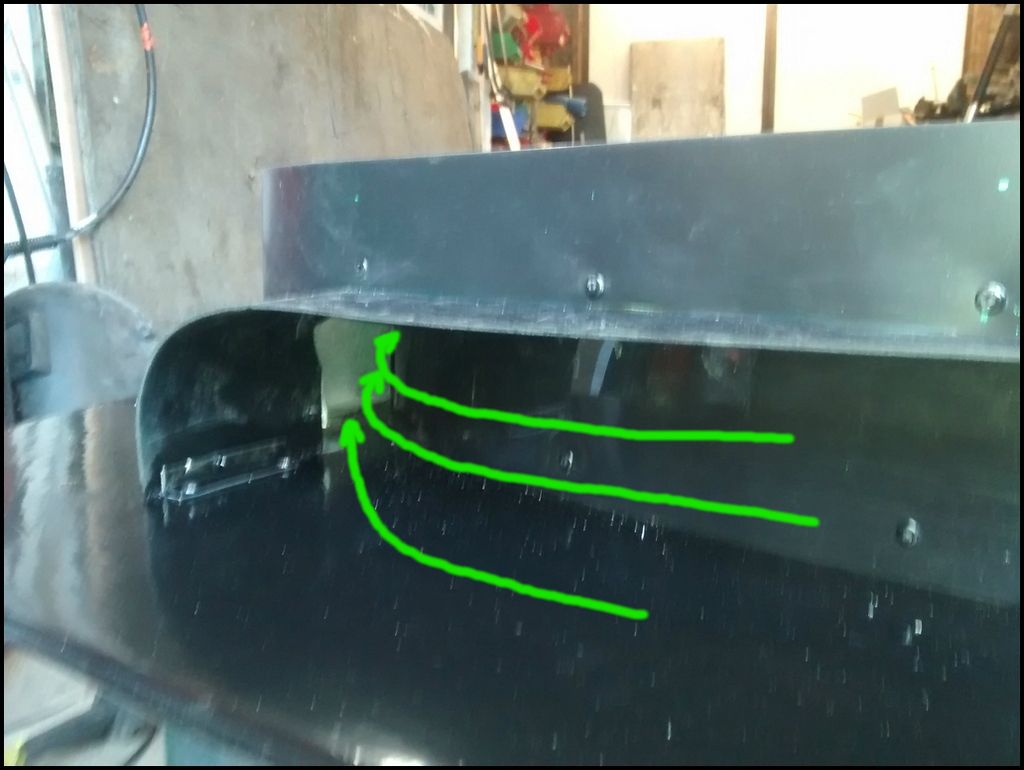

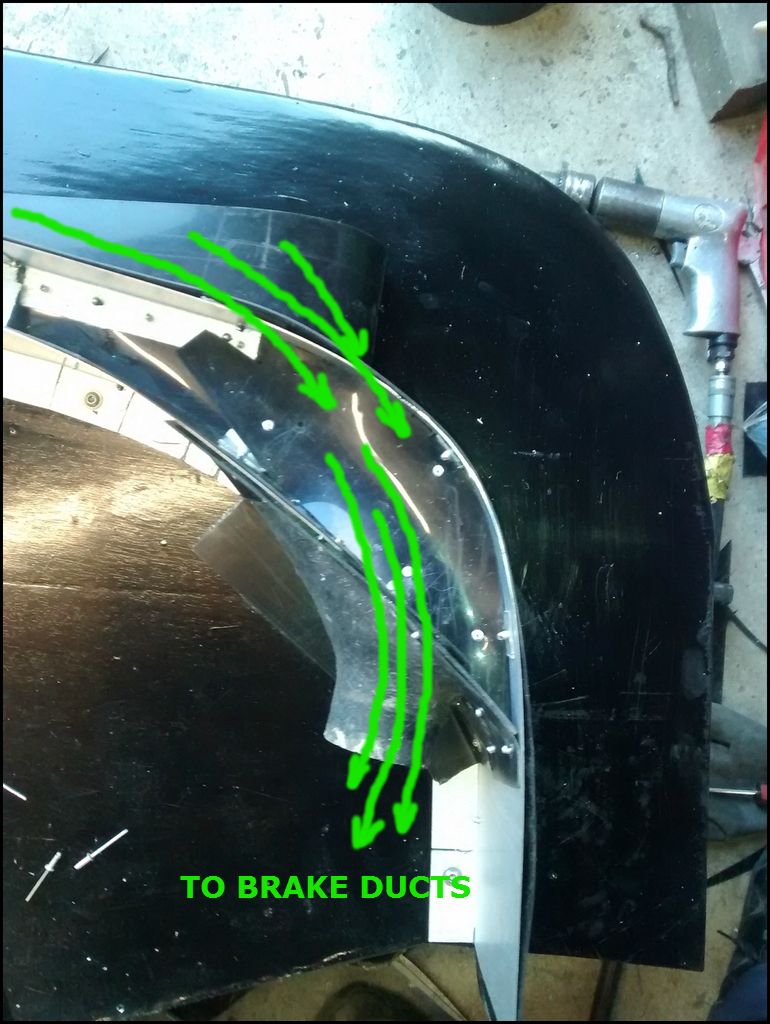

I wanted to improve the ducting to the brakes so thought I`d try a `stepped` airdam...

12mm Plywood, cut to shape and painted with several coats of Varnish then Black paint. First vertical fence fitted.

Add the `main` airdam with an opening cut out and recessed.

I then rivetted the old fibreglass ducts to the back of the rear opening, sealing it off along the top and sides

The IDEA is that air hitting the airdam will move sideways across the face of the dam. The `scoops` will then direct it into the ducts adding a LOT of cooling to the brakes.

By having the stepped airdam, I also increase the effective length of the splitter but without any further overhang. ie it`s as deep as before, but more of the splitter is visible and effective.

Next up after fitting some grilles to cover the old fog light holes was to sort the fence ahead of the wheel

I made some 1mm aluminium side fences to join the vertical fence, but left an opening in the bottom corner with a directed airflow out of it. The aim being to direct air away from the wheel well, reducing the wheelarch pressure rather than adding to it.

Added the stays and stood on it. It didn`t break...

The air that is caught by the central `scoop` is pushed down this channel

Looking from above, you can see the air is forced through the channel and then the duct hose is connected to this which is then secured to the back of the brakes, hopefully directing lots of nice cool air from the splitter into the brake discs :thumb:

I also refitted the flat floor. I`m still hesitant about fitting the full floor and boxing in the exhaust. Whilst it will be more effective, it made the tunnel pretty hot before !

Whilst the car was jacked up I tool this pic. I`ve cut the old Aluminium floor in half and added a vertical bend to give fence either side of the exhaust. I`ll live with the centre being turbulent air, but hopefully by having the fences it will separate the linear air flowing along the rest of the floor.

In effect giving me to large `channels` either side of the central exhaust leading into the diffuser

Matt has been building a Raspberry Pi to datalog his E36 but we`re also using it on the Golf. I mounted a few Thermocouples in various places, one on the Turbo outlet, just cable tied to the outside.

Another inside the `airbox`

I also changed the airfilter. It was pointed out the old one was looking a little worse for wear, so I fitted a K&N 9" Cone filter as a replacement

There is a distinct lack of photos from Donington. I forgot the small camera I usually take and have only a few from my phone and others I`ve borrowed from various people.

I ran a 2mm wire feed to the secondary fuel pump the other year but I happened to move the wire at Brands and it felt pretty hot ! I replaced it with 4mm wire and also a 4mm Earth wire from the pump to the Chassis. This goes through a 70A relay so the terminals are capable of handling the current. As soon as I started the pump, it sounded better then ever before and the AFR on idle went slightly richer. Even though I didn`t realise at the time, it appears the 2mm wire wasn`t man enough to properly supply the pump. Prawn has the same and I suggested he temporarily connects a jump lead to the pump whilst it`s running with the 2mm wire and if the tone changes with the thicker wires, it means he needs to run something thicker too...

Anyway, arrived at Donington in plenty of time to get signed on and start unloading. Chatted to a few people whilst doing so, including Adey who unfortunately had issues and I never saw him again.

Out for the sighting laps and I asked to go out last as I was bedding the brakes in and also wanted to check the fuelling and boost was OK after the Turbo, Actuator and air filter changes.

Brakes felt AWFUL. Really not nice at all. I had to press the pedal hard and retardation didn`t seem that good. NOT what I was expecting

Fortunately when I accelerated for the first time the Turbo spooled quickly and there were no clouds of smoke out of the exhaust. This was a big relief and it`s the single biggest issue I have with this not being road legal. I`ve fitted a new Turbo but couldn`t test it until I drove on track at Donington .

Unfortunately just as we were returning to the pits on the sighting lap, it broke down. Exactly the same as Silverstone !!

Pushed back into the pits and knew pretty quickly it was a wiring issue. That`s right, this wiring that I said "I need to redo the ECU loom, it`s been changed so much it`ll cause an issue one day and lose me tracktime...." Spent about an hour and a half trying to find the dodgy connection, but couldn`t. In the end I tucked the loom up in a way that seemed to work and lived with it for the rest of the day...

You`re sat there thinking "Well why didn`t you do it before Donington then..." Good question. It was absolutely fine at Brands and I didn`t realise there was a loose connection somewhere. If I had it would have been sorted before Donington. It WILL be done before the Ring...

Even though it was only on Actuator pressure, it still peaked at just under a Bar but the fuelling needed tweaking. I made the mistake of using MSDroid to tweak the fuel as it was only a little change. I`ve spoken to Trev about this as when I do this, it sometimes corrupts the ECU just like back in Goodwood in 2014. Frustrating but fortunately we`d taken the laptop so could reflash a working map and use that for tuning.

Map tweaked and back out on track. Fuelling was good although a little rich from 3 to 4.5k which had a noticeable effect on spool but no big problem, I`ll just turn on the boost control.

BANG, instantly hit the hard limiter This was only at 4,000rpm so tried again and the same thing happened

This was only at 4,000rpm so tried again and the same thing happened

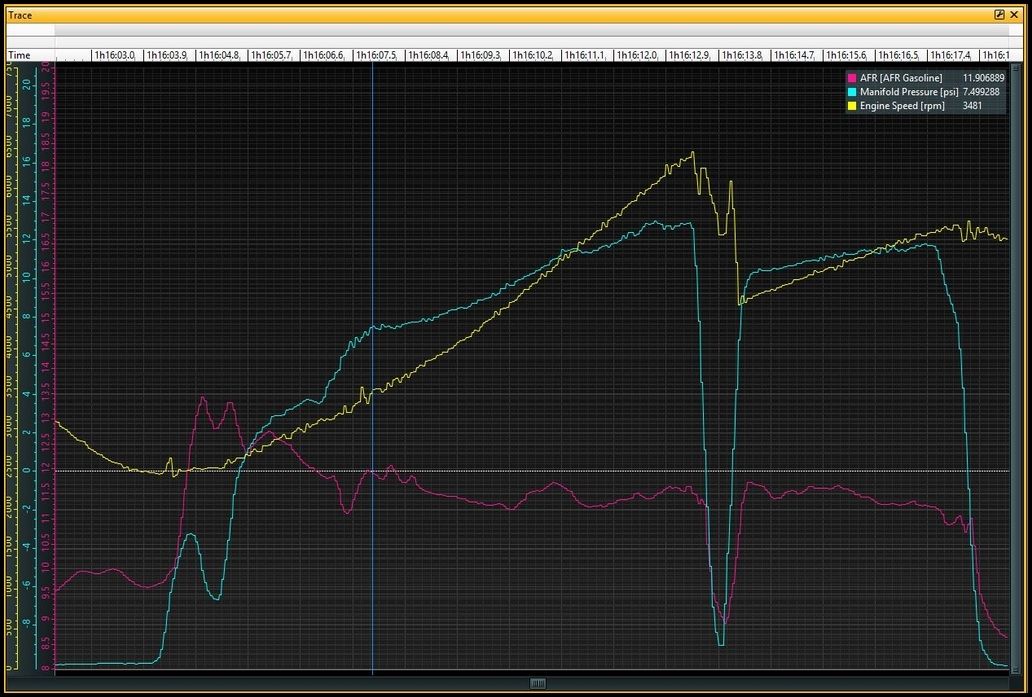

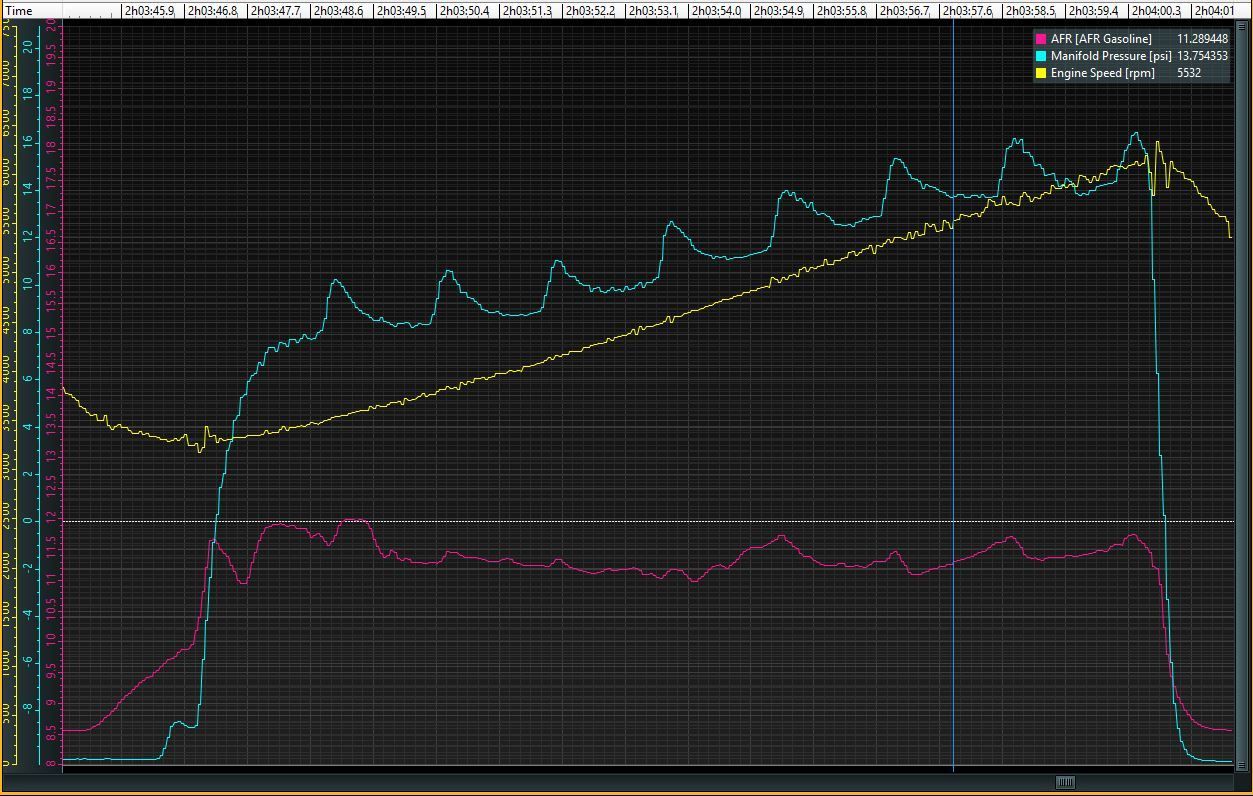

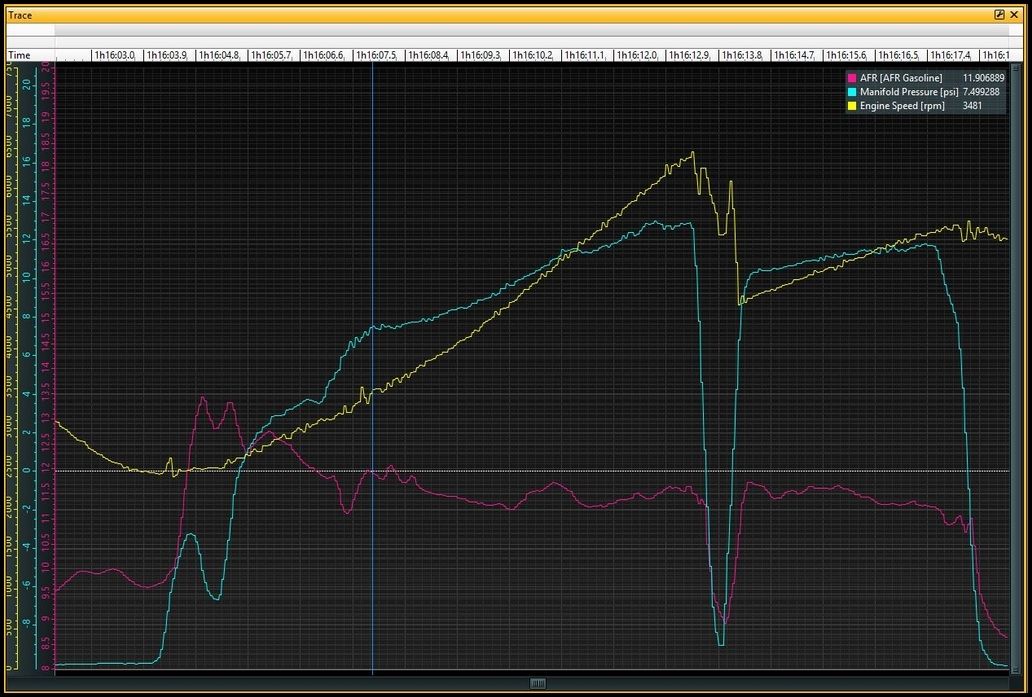

The Cyan trace is the boost, Hard limit is 20psi.

Ran the rest of the session on Actuator pressure but really struggled out of the Melbourne hairpin. 3rd gear and it just bogged down.

Waited for Ste and Prawn for a couple of laps together. Really good fun but after this session I started using 2nd, 3rd was just too tall and Ste drove straight past me before Goddards. Even with the normal delivery I reckon with Ste`s power to weight it would be very close, which is just what we want ! It`s certainly a different animal to the standard engined car it was back at Brands in 2014

http://www.youtube.com/watch?v=rttsJDyUohk

I was one of the few who tried to stay ON the circuit with at least 2 wheels when going onto the GP loop through the Esses. Ste / Prawn, I`m looking at you here...

I was on Cups but the car still felt fantastic through the faster stuff, particularly stable through craners. Looked at the data after and it confirmed what I`d felt. My slowest speed through craners was 7mph faster than I`ve ever gone before. That didn`t even feel floaty either but it`s not a corner where I wanted to try and find the absolute limits...

That didn`t even feel floaty either but it`s not a corner where I wanted to try and find the absolute limits...

Not only did it feel more stable whilst at speed, it also felt really good at direction changing in the high speed sections, I was able to stay flat from the Old Hairpin, until hitting the brakes for McLeans. Whilst that made braking interesting, it gave me a lot of confidence in the recent Aero tweaks before we head to Spa and the Ring.

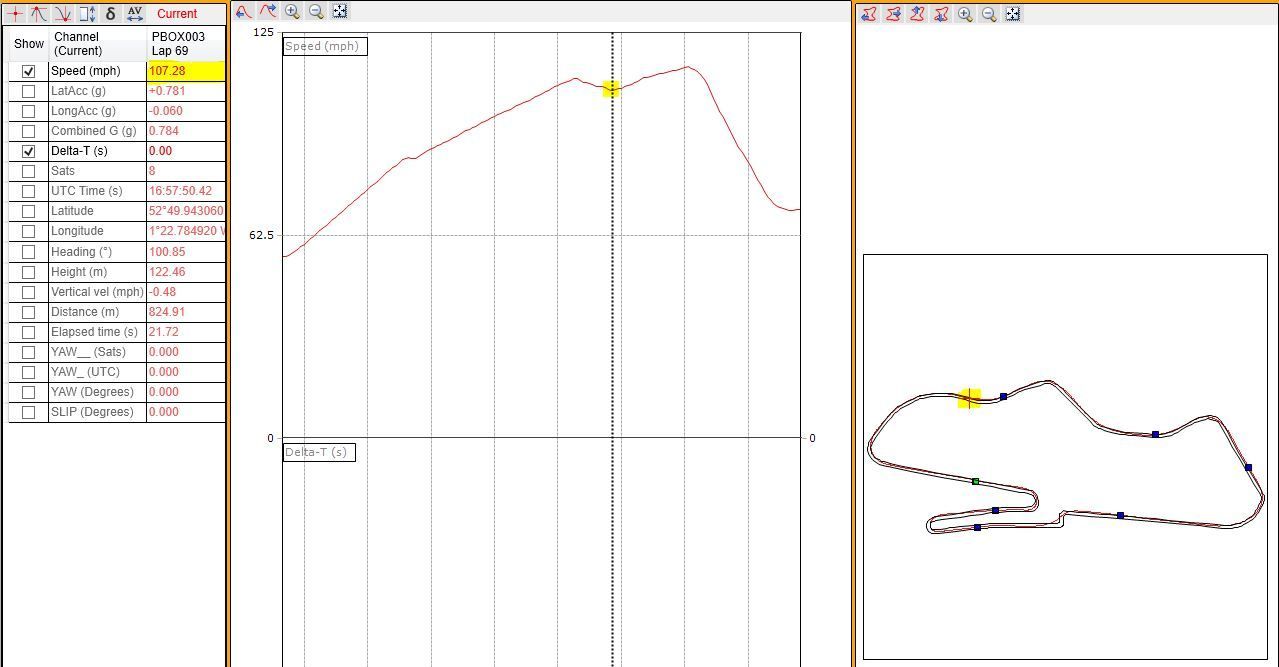

I looked at the data and this is a simple 3rd gear pull from low revs to 6,500k

Even though the boost trace (Cyan) rises, it`s too low until I hit 5,000rpm and also just over 11.2AFR which is too rich and blunts performance noticeably

I fitted a new Actuator with the new Turbo over the winter. A slightly higher rated one which I thought might help. Unfortunately, this was causing the hard limit issue.

No problem, we dropped the boost duty cycle to 5% instead of 40. This should have the effect of just lifting the boost by a small amount. If that worked, we could tweak the profile as before to get the delivery I want.

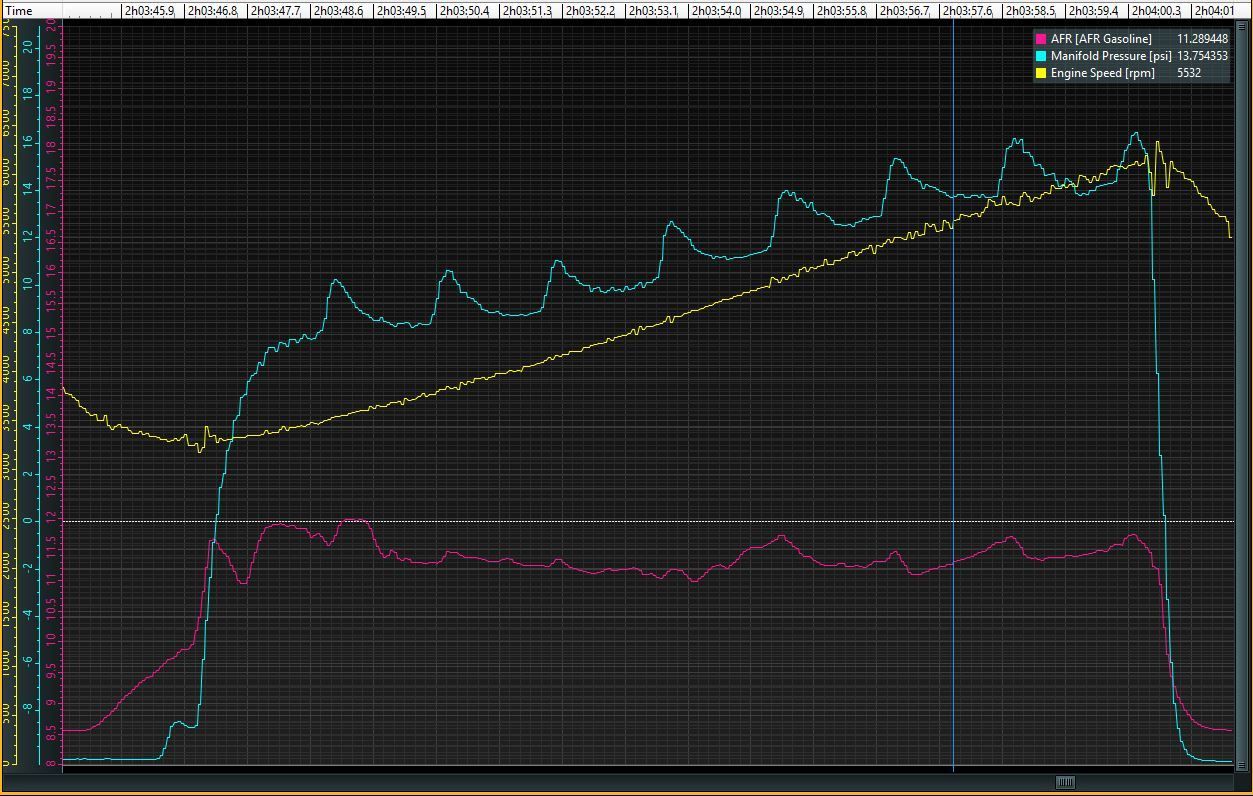

However, it had the weirdest result and I still don`t really know why. The boost started surging. See the peaks on the Cyan line ? They should be there.

It felt most unpleasant to drive and I`m still not 100% sure what caused it.

All I can imagine is that the really low duty cycle, coupled with the uprated actuator is having some odd side effect as the pressure is vented / not vented and the boost matches it.

This is on OPEN LOOP only there is no feedback involved so it`s purely a one way thing from the ECU TO the Actuator via the N75 valve. The wiring and plumbing hasn`t changed for the last 2 years so this is a slight concern.

What I`m going to do is refit the lower rated actuator for Spa and hopefully it`ll be back to normal and will just need the boost delivery reprofiling between sessions

Out on track with Prawn in close attendance. Once I was above 5,000rpm and it was producing the usual boost there was NOTHING in them at all. That pleases me. Prawn isn`t quite so thrilled.....

Matt hasn`t driven the Golf for a while and I want him to drive it at Spa so I convinced him to drive it for a session.

He`s always a little apprehensive driving the Golf, but never thinks twice about driving his 328. I think a lot of that comes from Thruxton.......

Anyway he went out and did really well. He`s learned to slow down a bit and build up to speed instead of going to try and set a laptime on lap 1. As a passenger this is much more relaxing...

He`s still very light on the controls but still struggles to judge the width of the Golf and doesn`t always use all the track. He had no issues with it being FWD and commented how stable it was.

We both get on the power too soon, have to lift then get on the power again which isn`t something either of us have really done before but will concentrate on next time out.

I hope he goes to Spa happier to drive it now..

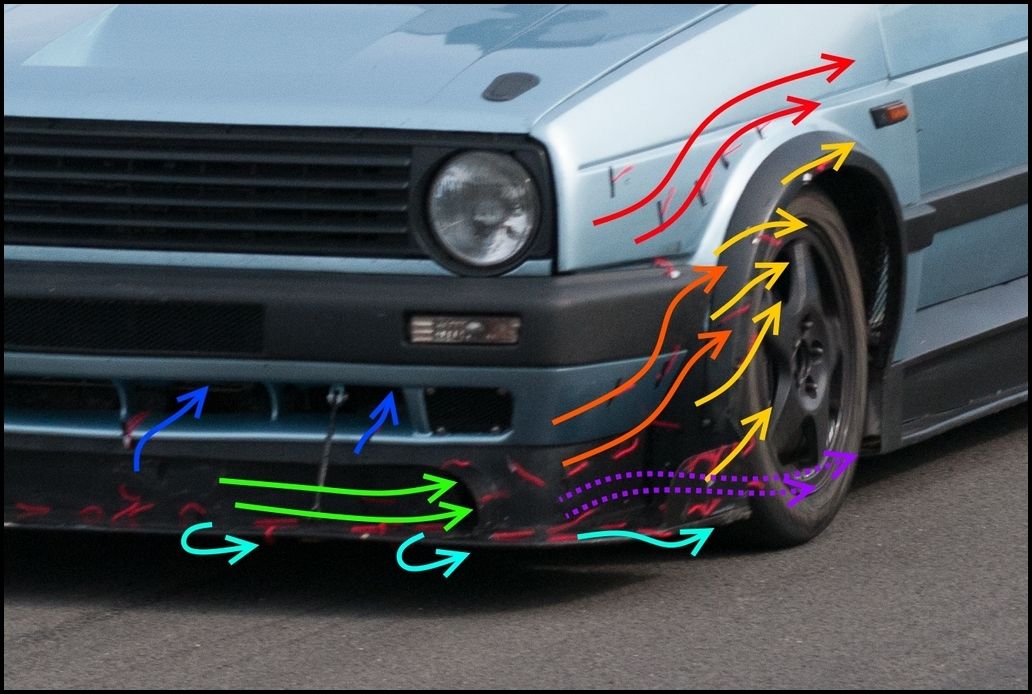

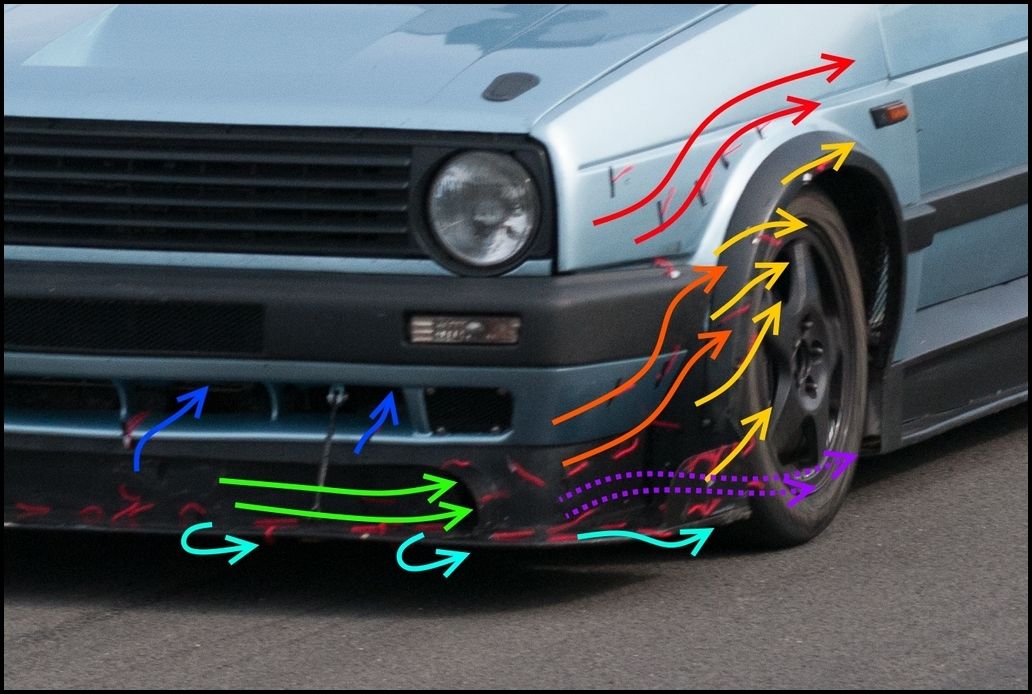

Did some `tuft testing` at Donington.

It appeared to do exactly as I hoped

I`ve added different coloured arrows to show the airflow in various places. There was a clear flow into the brake ducts and a low pressure turbulent area to the right of that (look at tufts tot he right of the green arrows)

This isn`t the most Aesthetically pleasing version but it is certainly the most Aero effective. Front end grip at speed was fantastic at Donington as I`ll explain later

From a distance I don`t think it looks that bad

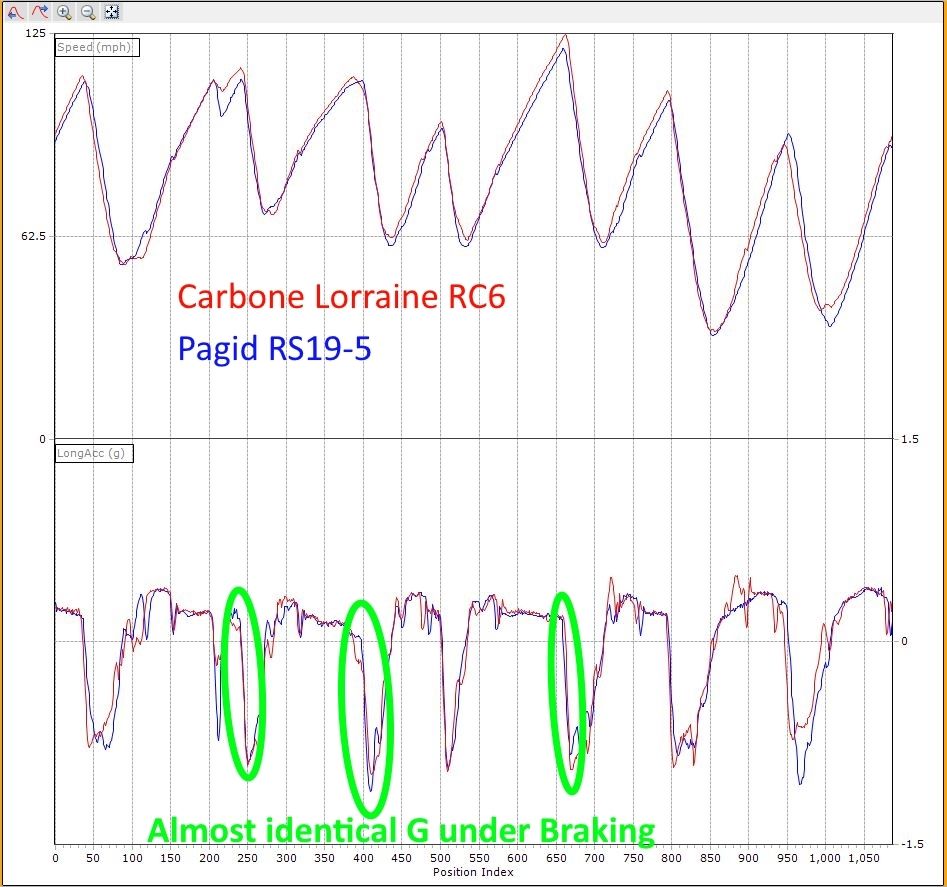

Lunchtime and I wanted to remove the Pagids. I just wasn`t liking the feel. Swapping to a 7" Servo AND changing compound at the same time didn`t work out as expected, the pedal feel just wasn`t there.

When removed they`d smeared quite a lot too. No idea why.

Fitted my RC6`s that were too grabby with the 9" Servo and they instantly felt much better

I`m in a bit of a quandary for Spa. Do I fit the 9" Servo and the RS19-`5s or get some PF08`s and the 7" Servo ?

I`m leaning towards the 9" Servo and RS19-5`s but will also get a set of PF08`s and take those along with the 7" Servo to Spa / The ring incase I need them. I can swap the Servo without needing to bleed the brakes so whilst it`s not something I WANT to do, I can if needed.

The RC6 pads worked well but they were getting hot after 15 minutes or so. Even with the cooling I have, I could feel them warming up. Stace had told me Donington GP was hard on brakes and that certainly seemed to be the case for me with the high speed stops I was making.

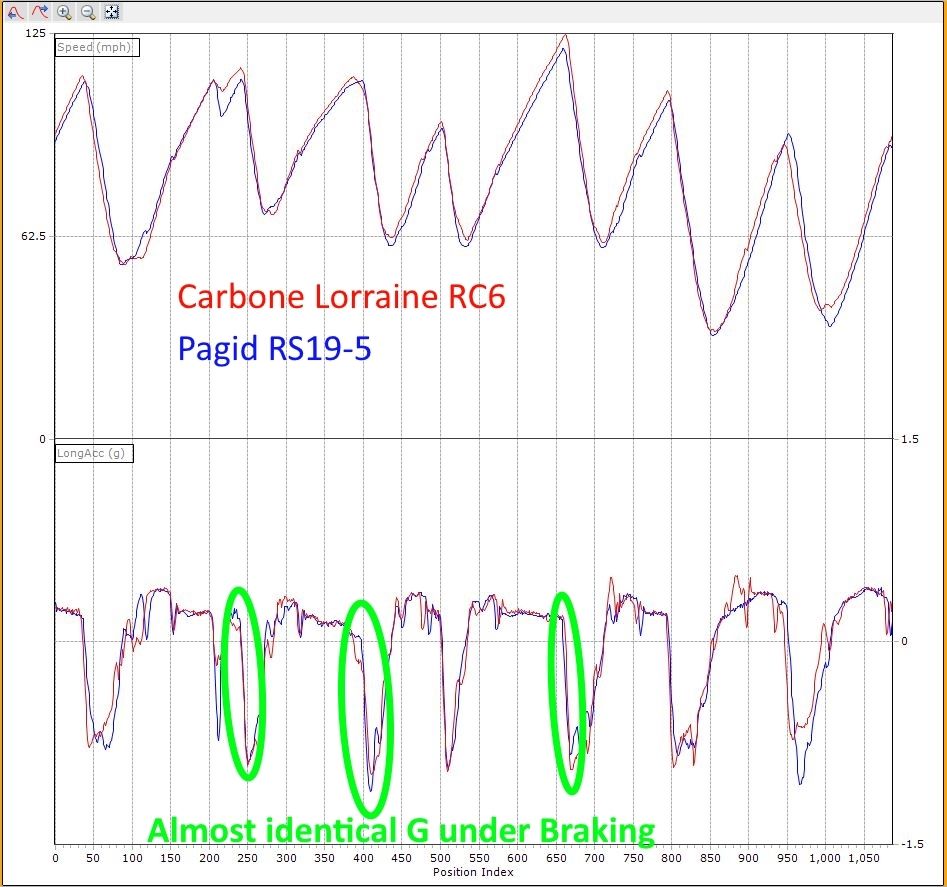

However when I compared the braking logs afterwards, it showed there was almost zero difference in actual braking performance between the Pagids and Carbon Lorraines. I`ve highlighted a few sections where I brake to around 1G with both compounds.

Simon appeared in my mirror. I`d tried following him before but with 500HP he just pulled away on the straights. He could have done the same this time but feathered on the straights so we could have some fun. With fronts at 40psi and rears at 36, I really should have come in but the temptation to have a play proved too much..

http://www.youtube.com/watch?v=eT4BYpN3u3A

Late afternoon and I took Andy out for a session. It felt really sluggish, only making 8psi. Knew something was amiss so came back into the pits and had a look. The Turbo was spinning, no boost leaks but only half the usual boost.

Removed the Turbo Blanket and it was obvious what had happened. The actuator arm had dropped off the wastegate. It`s held on by an R clip, but that had disappeared. On this pic, the arm has been refitted but there`s no clip.

Everything was HOT. I don`t just mean warm I mean bloody HOT ! Neil donated a small keyring and I tried to feed it through the hole without touching any of the metal

Eventually managed to get it fitted and secure.

Back out for a drive and it was fine, boosting again as usual. Nice and easy fix but meant I had to remove the Blanket when it was hot which wasn`t a good idea...

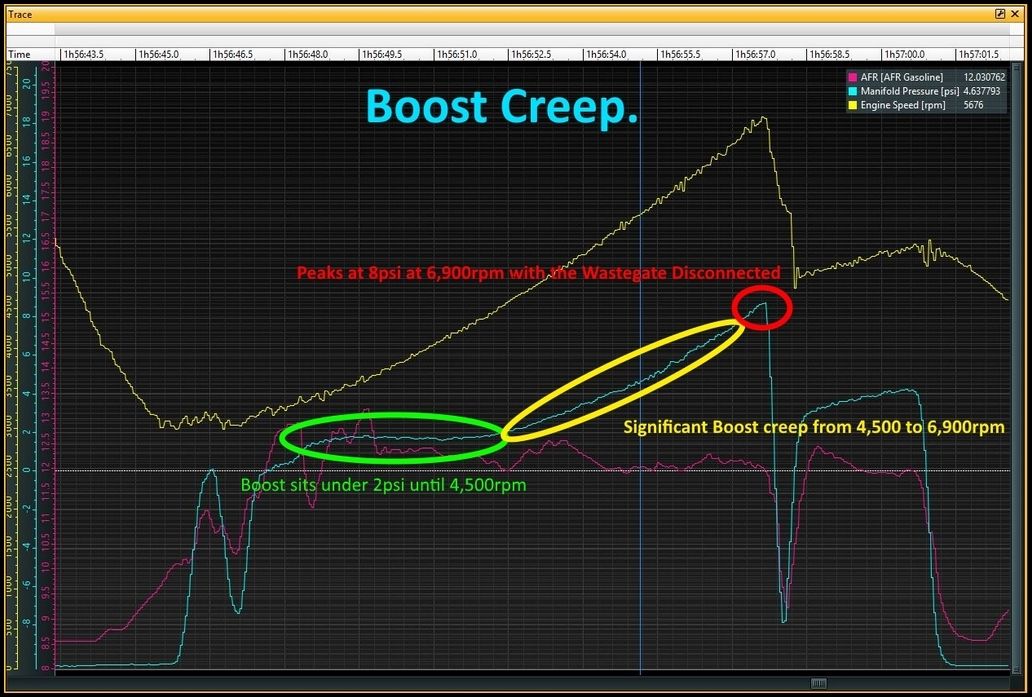

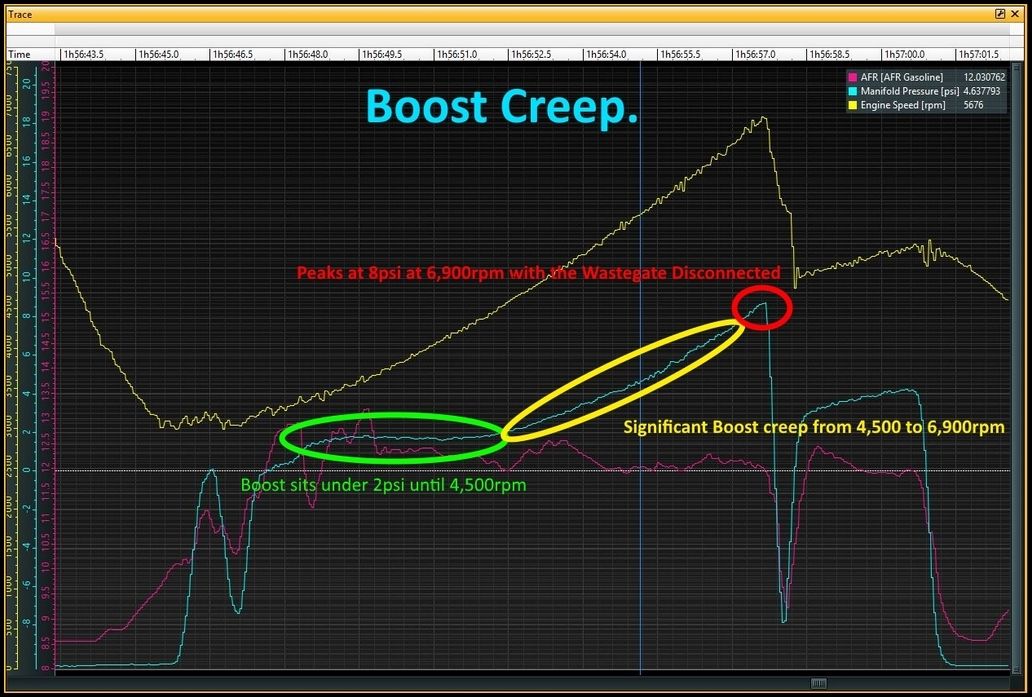

I do have boost creep. What`s boost creep you ask. Well it`s when the Turbo is producing boost even when the wastegate is fully open and venting the gases. Most Turbos do it to some degree. By looking at a datalog from when the actuator was disconnected and the wastegate was fully open I can see it is fine until 4,500rpm, sitting at just under 2psi but then it starts climbing to 6,900, peaking at 8psi. That`s 8psi with the wastegate open..... Fortunately I already try and map in rising boost as the revs rise so this is desireable to some extent but I`ll need to be careful on cold days not to overboost with this uncontrolled rise.

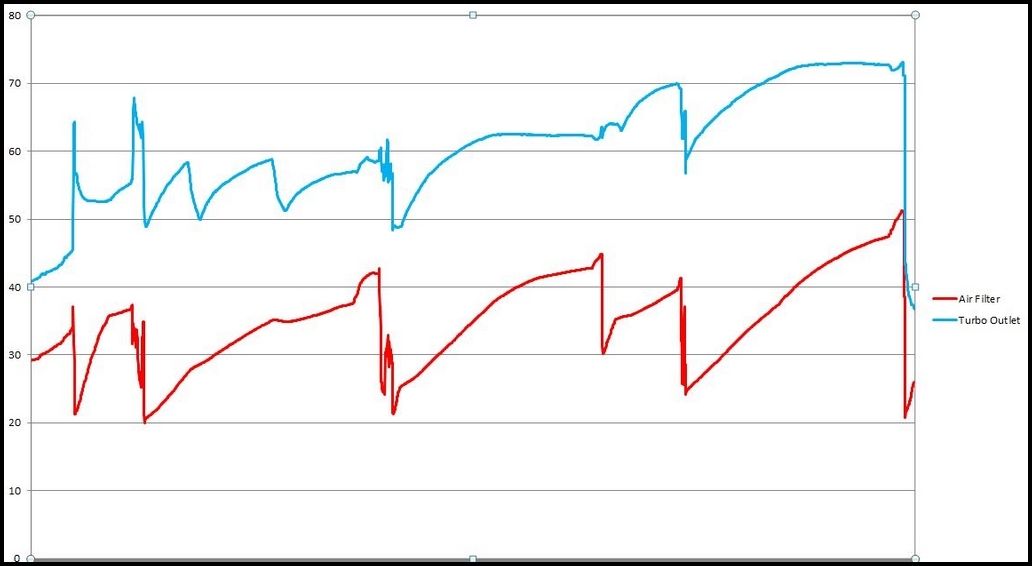

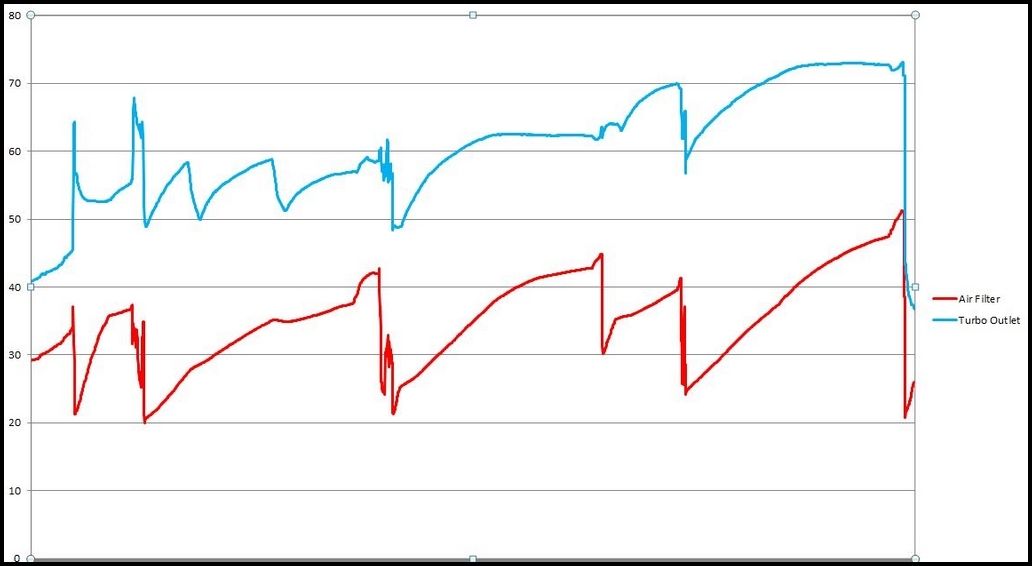

I haven`t forgotten about the temp logs by the way.

The results were surprising. The air filter is boxed in with heat reflective matting between the Turbo to intercooler pipe and the filter but just look at this graph.

The air being sucked into the filter is in Red. That gets up to over 40 degrees when ambient was under 15.

The Blue trace is the temperature sensor cable tied to the outside of the turbo exit. The compressed air will obviously be hotter but this is a good indication of what`s happening. The temperature follows the inlet temps quite a lot.When the inlet temps are 20 degrees the Turbo outlet is 50. When the Air is 40 degrees, the Turbo outlet is 60.

If I can keep the air being sucked into the filter at ambient, I`m instantly making a big contribution to lowering the air temperature in the entire inlet system.

I`m lucky, I have space under the inner wing to box in the air coming through the Fog light mesh and up to the airfilter.

This is looking from the wheel arch towards the bumper. I`ll make a box as marked in Red on this photo to seal the air coming through the bumper and direct it to the filter. That`ll give an uninterrupted cold air supply to the filter. I will also seal the airbox in the engine bay and insulate it a little bit more.

Thoughts from the Day ?

There were loads of people around and it was a really pleasant atmosphere in the pits and paddock. My wiring and actuator issues cost me around 2hours of tracktime which was annoying and put pressure on me to take people out in the time I had left. These things do happen and I`m doing all I can to address any likely issues before April.

The weather couldn`t have been better. It was the 12th of March and could easily have been mid May. We were certainly very fortunate !

I approached the day a little apprehensive after all the work I`d done over the winter. Whilst nothing was particularly major, not being able to test it beforehand meant I was glad when the first session was out of the way.

As it turned out the Golf was fantastic. I really felt comfortable straight away. OK the brake feel was poor but it stopped well enough. Handling is spot on and I thrashed it for a 20 minute session just to highlight ANY issues. There were none whatsoever, all temps remained rock solid and nothing fell off

I now have 3 weeks to get it ready for the Javelin Trackday at Spa on the 6th and 7th April followed by a full OpenPitlane Trackday on the Ring with Circuit Days on the 8th. Not only is a long way to go and costs a fair bit but more importantly it`s also a rare opportunity to drive both circuits on one visit so I certainly do NOT want to be spending time fixing issues I could have sorted before we go out.

To really put the pressure on it being `right`, I`m planning to leave the Golf in Germany ready for DN14 on April 28th....

Am I excited ? Just a bit !

I needed a new splitter after breaking the other one at Brands....

I`ve been modifying the splitter with every version, I`m probably up to V5 or 6 now...

I wanted to improve the ducting to the brakes so thought I`d try a `stepped` airdam...

12mm Plywood, cut to shape and painted with several coats of Varnish then Black paint. First vertical fence fitted.

Add the `main` airdam with an opening cut out and recessed.

I then rivetted the old fibreglass ducts to the back of the rear opening, sealing it off along the top and sides

The IDEA is that air hitting the airdam will move sideways across the face of the dam. The `scoops` will then direct it into the ducts adding a LOT of cooling to the brakes.

By having the stepped airdam, I also increase the effective length of the splitter but without any further overhang. ie it`s as deep as before, but more of the splitter is visible and effective.

Next up after fitting some grilles to cover the old fog light holes was to sort the fence ahead of the wheel

I made some 1mm aluminium side fences to join the vertical fence, but left an opening in the bottom corner with a directed airflow out of it. The aim being to direct air away from the wheel well, reducing the wheelarch pressure rather than adding to it.

Added the stays and stood on it. It didn`t break...

The air that is caught by the central `scoop` is pushed down this channel

Looking from above, you can see the air is forced through the channel and then the duct hose is connected to this which is then secured to the back of the brakes, hopefully directing lots of nice cool air from the splitter into the brake discs :thumb:

I also refitted the flat floor. I`m still hesitant about fitting the full floor and boxing in the exhaust. Whilst it will be more effective, it made the tunnel pretty hot before !

Whilst the car was jacked up I tool this pic. I`ve cut the old Aluminium floor in half and added a vertical bend to give fence either side of the exhaust. I`ll live with the centre being turbulent air, but hopefully by having the fences it will separate the linear air flowing along the rest of the floor.

In effect giving me to large `channels` either side of the central exhaust leading into the diffuser

Matt has been building a Raspberry Pi to datalog his E36 but we`re also using it on the Golf. I mounted a few Thermocouples in various places, one on the Turbo outlet, just cable tied to the outside.

Another inside the `airbox`

I also changed the airfilter. It was pointed out the old one was looking a little worse for wear, so I fitted a K&N 9" Cone filter as a replacement

There is a distinct lack of photos from Donington. I forgot the small camera I usually take and have only a few from my phone and others I`ve borrowed from various people.

I ran a 2mm wire feed to the secondary fuel pump the other year but I happened to move the wire at Brands and it felt pretty hot ! I replaced it with 4mm wire and also a 4mm Earth wire from the pump to the Chassis. This goes through a 70A relay so the terminals are capable of handling the current. As soon as I started the pump, it sounded better then ever before and the AFR on idle went slightly richer. Even though I didn`t realise at the time, it appears the 2mm wire wasn`t man enough to properly supply the pump. Prawn has the same and I suggested he temporarily connects a jump lead to the pump whilst it`s running with the 2mm wire and if the tone changes with the thicker wires, it means he needs to run something thicker too...

Anyway, arrived at Donington in plenty of time to get signed on and start unloading. Chatted to a few people whilst doing so, including Adey who unfortunately had issues and I never saw him again.

Out for the sighting laps and I asked to go out last as I was bedding the brakes in and also wanted to check the fuelling and boost was OK after the Turbo, Actuator and air filter changes.

Brakes felt AWFUL. Really not nice at all. I had to press the pedal hard and retardation didn`t seem that good. NOT what I was expecting

Fortunately when I accelerated for the first time the Turbo spooled quickly and there were no clouds of smoke out of the exhaust. This was a big relief and it`s the single biggest issue I have with this not being road legal. I`ve fitted a new Turbo but couldn`t test it until I drove on track at Donington .

Unfortunately just as we were returning to the pits on the sighting lap, it broke down. Exactly the same as Silverstone !!

Pushed back into the pits and knew pretty quickly it was a wiring issue. That`s right, this wiring that I said "I need to redo the ECU loom, it`s been changed so much it`ll cause an issue one day and lose me tracktime...." Spent about an hour and a half trying to find the dodgy connection, but couldn`t. In the end I tucked the loom up in a way that seemed to work and lived with it for the rest of the day...

You`re sat there thinking "Well why didn`t you do it before Donington then..." Good question. It was absolutely fine at Brands and I didn`t realise there was a loose connection somewhere. If I had it would have been sorted before Donington. It WILL be done before the Ring...

Even though it was only on Actuator pressure, it still peaked at just under a Bar but the fuelling needed tweaking. I made the mistake of using MSDroid to tweak the fuel as it was only a little change. I`ve spoken to Trev about this as when I do this, it sometimes corrupts the ECU just like back in Goodwood in 2014. Frustrating but fortunately we`d taken the laptop so could reflash a working map and use that for tuning.

Map tweaked and back out on track. Fuelling was good although a little rich from 3 to 4.5k which had a noticeable effect on spool but no big problem, I`ll just turn on the boost control.

BANG, instantly hit the hard limiter

This was only at 4,000rpm so tried again and the same thing happened

This was only at 4,000rpm so tried again and the same thing happenedThe Cyan trace is the boost, Hard limit is 20psi.

Ran the rest of the session on Actuator pressure but really struggled out of the Melbourne hairpin. 3rd gear and it just bogged down.

Waited for Ste and Prawn for a couple of laps together. Really good fun but after this session I started using 2nd, 3rd was just too tall and Ste drove straight past me before Goddards. Even with the normal delivery I reckon with Ste`s power to weight it would be very close, which is just what we want ! It`s certainly a different animal to the standard engined car it was back at Brands in 2014

http://www.youtube.com/watch?v=rttsJDyUohk

I was one of the few who tried to stay ON the circuit with at least 2 wheels when going onto the GP loop through the Esses. Ste / Prawn, I`m looking at you here...

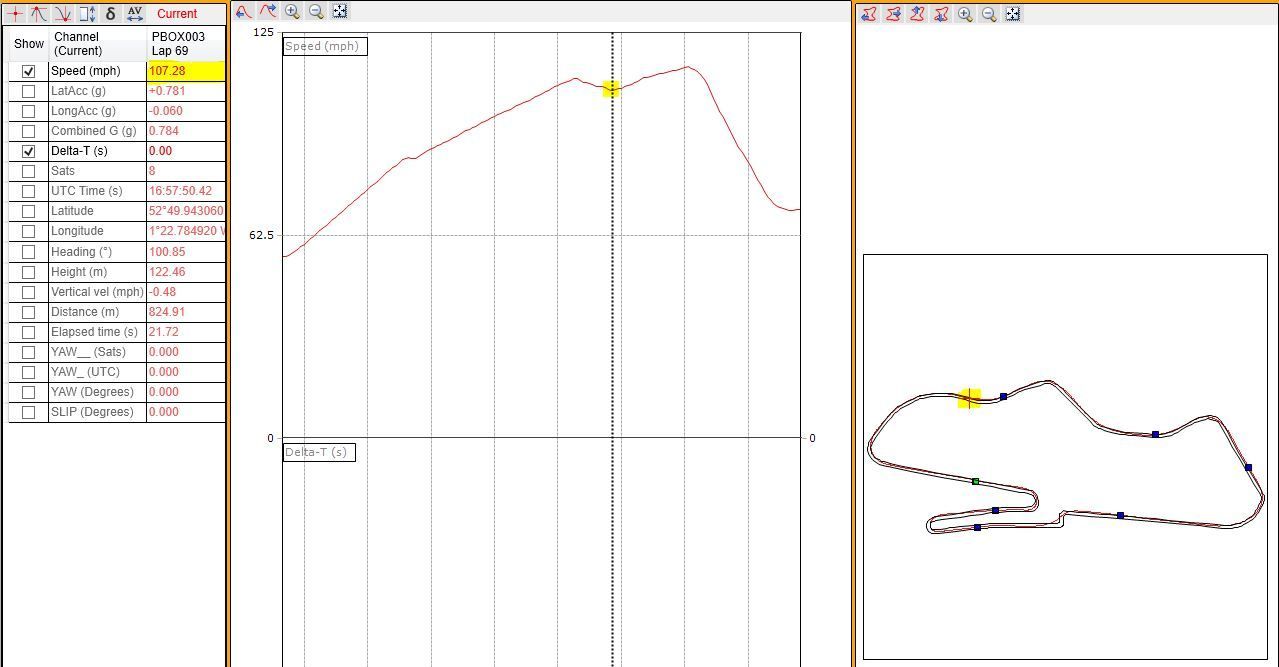

I was on Cups but the car still felt fantastic through the faster stuff, particularly stable through craners. Looked at the data after and it confirmed what I`d felt. My slowest speed through craners was 7mph faster than I`ve ever gone before.

That didn`t even feel floaty either but it`s not a corner where I wanted to try and find the absolute limits...

That didn`t even feel floaty either but it`s not a corner where I wanted to try and find the absolute limits...

Not only did it feel more stable whilst at speed, it also felt really good at direction changing in the high speed sections, I was able to stay flat from the Old Hairpin, until hitting the brakes for McLeans. Whilst that made braking interesting, it gave me a lot of confidence in the recent Aero tweaks before we head to Spa and the Ring.

I looked at the data and this is a simple 3rd gear pull from low revs to 6,500k

Even though the boost trace (Cyan) rises, it`s too low until I hit 5,000rpm and also just over 11.2AFR which is too rich and blunts performance noticeably

I fitted a new Actuator with the new Turbo over the winter. A slightly higher rated one which I thought might help. Unfortunately, this was causing the hard limit issue.

No problem, we dropped the boost duty cycle to 5% instead of 40. This should have the effect of just lifting the boost by a small amount. If that worked, we could tweak the profile as before to get the delivery I want.

However, it had the weirdest result and I still don`t really know why. The boost started surging. See the peaks on the Cyan line ? They should be there.

It felt most unpleasant to drive and I`m still not 100% sure what caused it.

All I can imagine is that the really low duty cycle, coupled with the uprated actuator is having some odd side effect as the pressure is vented / not vented and the boost matches it.

This is on OPEN LOOP only there is no feedback involved so it`s purely a one way thing from the ECU TO the Actuator via the N75 valve. The wiring and plumbing hasn`t changed for the last 2 years so this is a slight concern.

What I`m going to do is refit the lower rated actuator for Spa and hopefully it`ll be back to normal and will just need the boost delivery reprofiling between sessions

Out on track with Prawn in close attendance. Once I was above 5,000rpm and it was producing the usual boost there was NOTHING in them at all. That pleases me. Prawn isn`t quite so thrilled.....

Matt hasn`t driven the Golf for a while and I want him to drive it at Spa so I convinced him to drive it for a session.

He`s always a little apprehensive driving the Golf, but never thinks twice about driving his 328. I think a lot of that comes from Thruxton.......

Anyway he went out and did really well. He`s learned to slow down a bit and build up to speed instead of going to try and set a laptime on lap 1. As a passenger this is much more relaxing...

He`s still very light on the controls but still struggles to judge the width of the Golf and doesn`t always use all the track. He had no issues with it being FWD and commented how stable it was.

We both get on the power too soon, have to lift then get on the power again which isn`t something either of us have really done before but will concentrate on next time out.

I hope he goes to Spa happier to drive it now..

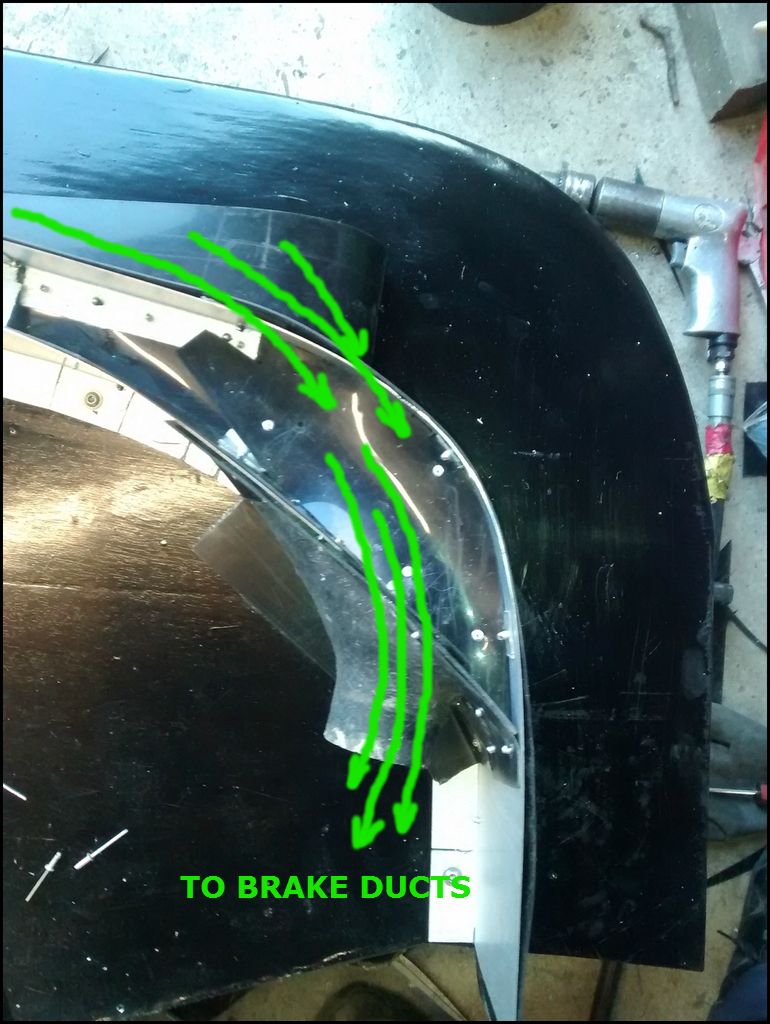

Did some `tuft testing` at Donington.

It appeared to do exactly as I hoped

I`ve added different coloured arrows to show the airflow in various places. There was a clear flow into the brake ducts and a low pressure turbulent area to the right of that (look at tufts tot he right of the green arrows)

This isn`t the most Aesthetically pleasing version but it is certainly the most Aero effective. Front end grip at speed was fantastic at Donington as I`ll explain later

From a distance I don`t think it looks that bad

Lunchtime and I wanted to remove the Pagids. I just wasn`t liking the feel. Swapping to a 7" Servo AND changing compound at the same time didn`t work out as expected, the pedal feel just wasn`t there.

When removed they`d smeared quite a lot too. No idea why.

Fitted my RC6`s that were too grabby with the 9" Servo and they instantly felt much better

I`m in a bit of a quandary for Spa. Do I fit the 9" Servo and the RS19-`5s or get some PF08`s and the 7" Servo ?

I`m leaning towards the 9" Servo and RS19-5`s but will also get a set of PF08`s and take those along with the 7" Servo to Spa / The ring incase I need them. I can swap the Servo without needing to bleed the brakes so whilst it`s not something I WANT to do, I can if needed.

The RC6 pads worked well but they were getting hot after 15 minutes or so. Even with the cooling I have, I could feel them warming up. Stace had told me Donington GP was hard on brakes and that certainly seemed to be the case for me with the high speed stops I was making.

However when I compared the braking logs afterwards, it showed there was almost zero difference in actual braking performance between the Pagids and Carbon Lorraines. I`ve highlighted a few sections where I brake to around 1G with both compounds.

Simon appeared in my mirror. I`d tried following him before but with 500HP he just pulled away on the straights. He could have done the same this time but feathered on the straights so we could have some fun. With fronts at 40psi and rears at 36, I really should have come in but the temptation to have a play proved too much..

http://www.youtube.com/watch?v=eT4BYpN3u3A

Late afternoon and I took Andy out for a session. It felt really sluggish, only making 8psi. Knew something was amiss so came back into the pits and had a look. The Turbo was spinning, no boost leaks but only half the usual boost.

Removed the Turbo Blanket and it was obvious what had happened. The actuator arm had dropped off the wastegate. It`s held on by an R clip, but that had disappeared. On this pic, the arm has been refitted but there`s no clip.

Everything was HOT. I don`t just mean warm I mean bloody HOT ! Neil donated a small keyring and I tried to feed it through the hole without touching any of the metal

Eventually managed to get it fitted and secure.

Back out for a drive and it was fine, boosting again as usual. Nice and easy fix but meant I had to remove the Blanket when it was hot which wasn`t a good idea...

I do have boost creep. What`s boost creep you ask. Well it`s when the Turbo is producing boost even when the wastegate is fully open and venting the gases. Most Turbos do it to some degree. By looking at a datalog from when the actuator was disconnected and the wastegate was fully open I can see it is fine until 4,500rpm, sitting at just under 2psi but then it starts climbing to 6,900, peaking at 8psi. That`s 8psi with the wastegate open..... Fortunately I already try and map in rising boost as the revs rise so this is desireable to some extent but I`ll need to be careful on cold days not to overboost with this uncontrolled rise.

I haven`t forgotten about the temp logs by the way.

The results were surprising. The air filter is boxed in with heat reflective matting between the Turbo to intercooler pipe and the filter but just look at this graph.

The air being sucked into the filter is in Red. That gets up to over 40 degrees when ambient was under 15.

The Blue trace is the temperature sensor cable tied to the outside of the turbo exit. The compressed air will obviously be hotter but this is a good indication of what`s happening. The temperature follows the inlet temps quite a lot.When the inlet temps are 20 degrees the Turbo outlet is 50. When the Air is 40 degrees, the Turbo outlet is 60.

If I can keep the air being sucked into the filter at ambient, I`m instantly making a big contribution to lowering the air temperature in the entire inlet system.

I`m lucky, I have space under the inner wing to box in the air coming through the Fog light mesh and up to the airfilter.

This is looking from the wheel arch towards the bumper. I`ll make a box as marked in Red on this photo to seal the air coming through the bumper and direct it to the filter. That`ll give an uninterrupted cold air supply to the filter. I will also seal the airbox in the engine bay and insulate it a little bit more.

Thoughts from the Day ?

There were loads of people around and it was a really pleasant atmosphere in the pits and paddock. My wiring and actuator issues cost me around 2hours of tracktime which was annoying and put pressure on me to take people out in the time I had left. These things do happen and I`m doing all I can to address any likely issues before April.

The weather couldn`t have been better. It was the 12th of March and could easily have been mid May. We were certainly very fortunate !

I approached the day a little apprehensive after all the work I`d done over the winter. Whilst nothing was particularly major, not being able to test it beforehand meant I was glad when the first session was out of the way.

As it turned out the Golf was fantastic. I really felt comfortable straight away. OK the brake feel was poor but it stopped well enough. Handling is spot on and I thrashed it for a 20 minute session just to highlight ANY issues. There were none whatsoever, all temps remained rock solid and nothing fell off

I now have 3 weeks to get it ready for the Javelin Trackday at Spa on the 6th and 7th April followed by a full OpenPitlane Trackday on the Ring with Circuit Days on the 8th. Not only is a long way to go and costs a fair bit but more importantly it`s also a rare opportunity to drive both circuits on one visit so I certainly do NOT want to be spending time fixing issues I could have sorted before we go out.

To really put the pressure on it being `right`, I`m planning to leave the Golf in Germany ready for DN14 on April 28th....

Am I excited ? Just a bit !

Edited by Wh00sher on Tuesday 15th March 22:41

Steve H said:

Impressive and obsessive in equal measure as usual Nige

7mph down Craners is a good effort, definitely not dabbing now

Have a great time at Spa/Ring, hopefully I'll get chance to catch a ride some time over the summer .

.

I enjoy the `obsessing` or `tweaking` as I prefer to call it

7mph down Craners is a good effort, definitely not dabbing now

Have a great time at Spa/Ring, hopefully I'll get chance to catch a ride some time over the summer

.

.

Humour said:

Great report. Thanks for sharing.

Good to see factual data on a Turbocharged car.

That new front splitter is something else, if not a work of art, but function over looks right.

Look forward to reports from Spa and the Ring.

Good luck and have fun.

I agree, not the nicest looking splitter I`ve had but it seems to be the most effective.Good to see factual data on a Turbocharged car.

That new front splitter is something else, if not a work of art, but function over looks right.

Look forward to reports from Spa and the Ring.

Good luck and have fun.

I`m really looking forward to the ring on the 8th.

It opened for the first TF laps of 2016 yesterday, apparently the reprofiled Flugplatz is quicker which should give greater SX approach speed. It felt pretty rapid when hitting 156 on the GPS last year..

Humour said:

156Mph?

what's that thing geared to do, NASA shuttle speeds?

Our e36 with 3.23 CW&P is unlikely to go beyond 150Mph in 5th now, but that's hardly usable with the power to weight of our toy.

I reckon it`ll hit a little over 163 flat out. It`s a 3.6 Final drive, 205/50/15`s and 7,400 hard rev limit.

what's that thing geared to do, NASA shuttle speeds?

Our e36 with 3.23 CW&P is unlikely to go beyond 150Mph in 5th now, but that's hardly usable with the power to weight of our toy.

Initially I ran the car with a 4.2, but that soon proved too short once I fitted the Turbo. Then I tried a 3.9 but that wasn`t tall enough and so last year I switched to a 3.6 which is pretty much perfect. It`s not as if running into the limiter at 163 is going to cause a regular problem is it

I fitted a 3.73 CW&P in Matt`s 328, that hits the limiter at about 130. We`ve had the limiter lifted from 6,500 to 7,000 to get that !

I like your determination to log and monitor EVERYTHING, what are you using to do it?

The probe strapped to the outside of the pipe is terrible though. I used a similar one, but managed to get it through a pipe to get a more accurate reading. I took a bluntish copper tube cutter and rolled two shallow grooves which held E clips, using those, some silicone sealant and fibre washers secured it well. Maybe something you could try?

The probe strapped to the outside of the pipe is terrible though. I used a similar one, but managed to get it through a pipe to get a more accurate reading. I took a bluntish copper tube cutter and rolled two shallow grooves which held E clips, using those, some silicone sealant and fibre washers secured it well. Maybe something you could try?

Edited by 227bhp on Friday 25th March 12:45

227bhp said:

I like your determination to log and monitor EVERYTHING, what are you using to do it?

The probe strapped to the outside of the pipe is terrible though. I used a similar one, but managed to get it through a pipe to get a more accurate reading.

You are absolutely right, it`s not a great position for an accurate reading.The probe strapped to the outside of the pipe is terrible though. I used a similar one, but managed to get it through a pipe to get a more accurate reading.

I have an Inlet Air sensor in the plenum which is accurate and measure the air going into the engine.

This was a `first test`, just to check if the datalogger worked. I`m looking at improved placement before next week but I probably won`t be putting it into the airflow. This is more for a general overview rather than an exact temp. What I will be doing is putting another probe on the outside of the pipe to the plenum, that way I can correlate the actual temp from the IAT to the one secured to the outside of the pipe to give me a better idea of what the Turbo outlet temp sensor is reading.

The ECU stuff, Throttle, RPM, Boost etc is all logged directly from the ECU. I use Megasquirt V1 so it`s pretty long in the tooth now but does the job. GPS is taken from a PBox.

Gassing Station | Track Days | Top of Page | What's New | My Stuff