PH Origins: Electronic throttle control

How a cutting-edge V12 brought the oft-divisive concept of throttle-by-wire systems into the public domain

Many lament the phasing out of the simple Bowden cable-operated throttle. There is, after all, often an immense amount of gratification to be derived from what could feel like a direct, responsive link between driver and engine.

There are drawbacks to cable-operated throttles, though, many of which could ultimately annoy those not otherwise fussed by the perceived immediacy or purity of an engine's response to their inputs.

Firstly, there are problems with wear and improper adjustment, resulting in binding or partial throttle openings. There's also only so much you can do with a cable-actuated throttle. If you wanted to enable a traction or cruise control system, you'd have to add a motor- or vacuum-actuated module that would interact with the throttle body - increasing cost and complexity.

Then you have the issue of a physical connection between engine and pedal, along with a cable that runs through the bulkhead. This could, if you were focusing on refinement, induce NVH-related complications. Routing a cable and hooking it up adds several assembly steps on the production line, too, which could be a concern for those seeking the most streamlined production process possible.

The amount of throttle commanded by the driver might also not be ideal for the engine at that given moment. Allowing the engine to automatically modulate its throttle could help cut emissions in certain conditions, for example. This capability could further be used to help stabilise the engine's idle when it was undergoing heavy ancillary loads, or warming up, or serve as a form of speed regulation - instead of a spark- or fuel-cut limiter.

The way to overcome these problems is fairly obvious: ditch the physical connection between pedal and throttle. This move might have initially sounded questionable to some but the aerospace industry had comprehensively proven the potential of 'fly-by-wire' systems. Besides making the aircraft easier to pilot, the increased degree of control afforded by these electronic systems made them more flexible and capable - accomplishments that could be replicated in the automotive industry.

The concept of electronically actuating a throttle was itself not a particularly new one. Production cruise control systemsintroduced the late 1950s had utilised electric motors to adjust the throttle position in order to achieve and maintain the desired target speed, yet these setups still otherwise involved a physical connection between the pedal and throttle.

As demand for improved functionality and safety increased, additional systems were added - such as Bosch's 'Automatic Skid Regulation' traction control, which would override the driver's input and adjust the throttle position to reduce wheel spin. These, however, were again still cable-based setups.

It was Bosch that seemingly got ahead of the curve with the development of a production throttle control system that did away with cables; reputedly, it began trialling such a set-up in motorsports applications in the 1980s. Using an electronic system could potentially grant improved performance, or address design issues ranging from packaging problems to enabling functions such as traction control without bulky add-on units.

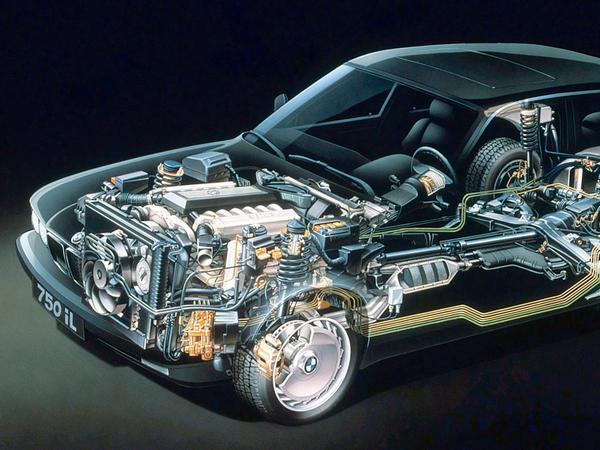

Bosch had long been supplying BMW with engine management systems, among other things, by this point. Then, in 1986, BMW unveiled its second-generation 7 Series - the E32. It was a remarkably advanced car, featuring a CAN bus, traction control, electronic damper control and common creature comforts such as cruise control.

The quest to build the ultimate luxury saloon didn't stop there, though, with BMW announcing a V12-engined flagship version that would be unveiled in March 1987. It would utilise the new 'M70' 5.0-litre V12, which was designed to be as smooth and as quiet as possible.

Achieving this would require precise control systems and, of course, it would be preferential to not clutter the top of the powerplant with servomotors and numerous awkwardly routed cables. To facilitate this, along with all the required driver aids, BMW equipped its advanced V12 with twin Bosch Motronic engine control systems - and a pair of Bosch-produced electronically controlled throttle bodies.

Each Motronic ECU controlled one bank of the V12, while throttle control and synchronisation was carried out by BMW's 'Electronic Power Regulation' system - or 'Elektronische Motorleistungsregelung', dubbed with the acronym EML. It would monitor the accelerator pedal position, process information from the Motronic units and safety systems, then deliver a signal to the throttle bodies that would move the throttle blades to the optimum position.

This meant that the EML could accurately control the engine speed based on a host of inputs, including temperature, air-con load and transmission modes. It could alter the idle speed by cracking the throttles open, work with the traction control system to cut wheel spin, comply with cruise control requests and limit maximum engine speed.

It also, for the first time in BMW's history, would automatically close down the throttles to limit the top-spec V12 7 Series to 155mph. Both banks could function independently, too, allowing the owner to continue driving if one bank suffered a fuel or ignition-related failure.

The M70 engine, which produced a silky 300hp and 332lb ft, went into the 750i and 750iL initially. It was then used in the 850i and 850Ci, and later revisions included Siemens throttle bodies with a dual-motor drive for redundancy. The expense and complication of 'throttle-by-wire' systems meant that they didn't suddenly dominate the market overnight, but BMW and Bosch's innovation drew much attention from rivals - including GM.

GM was so curious about this new technology that, in 1988, it bought a new 750iL and pulled the electronically throttled heart out of the $69,325 luxury saloon. It didn't just test it in the BMW and on the bench, though; the V12 ended up in a Chevrolet Caprice, which GM used to further evaluate this new 'drive-by-wire' technology.

It took until 1997, and the public release of the new Corvette C5, for GM to emulate BMW's configuration in production form. The new Corvette's LS1 V8 was equipped with 'Electronic Throttle Control', which enabled the integration of traction control, cruise control and more into a compact, lightweight assembly. It was also cited to improve the engine's response and performance, further bolstering the system's credentials.

As the cost of the required components fell, and the need for more comfort and safety functions rose, the use of throttle-by-wire systems began to increase exponentially. Careful pedal calibration could also deliver the ideal amount of resistance and predictable throttle behaviour; this, in conjunction with advances such as different accelerator pedal maps depending on drive mode or gear, could grant an engine response that would sate even the most enthusiastic driver.

You don't, for example, hear many complaining about the responsiveness of the Ferrari 458 Speciale's electronically throttled 4.5-litre V8. That said, some manufacturers sometimes entirely misjudge their pedal calibration - resulting in myriad mildly annoyed motorists.

1) Throttle angle is not directly proportional to engine torque, as it also depends upon engine speed. At say 2000rpm, as little as 25% throttle is effectively 'full' throttle, where as at 6000rpm, it needs 90% before the throttle stops, er, throttling the incoming air stream. Back in the day, when everyone was used to cable throttles, we had learn't to drive with the non linear gain, and hence, when the first ETCs appeared and suddenly did make constant torque vs accelerator pedal angle across all engine speeds it felt weird and unresponsive.

Later systems fixed this by deliberately re-engineering in that low engine speed over-response. Beloved of some Premium German Brands (yes Audi, i'm looking at you!!) it makes the car feel very perky indeed at low throttle openings. Great for the 'Sales Test drive' when the purchaser thinks, "Wow, if this is how fast this car is at 25% throttle, it's going to be ballistic when i floor it" only to find when they get the car home after buying it that there is actually no more performance to come.....

2) Drivers often berate the fact that the throttle response feels 'laggy' with the engine seemingly only ramping up it's output some time after they have accelerated. Well, what they miss is what would happen if the Torque response wasn't artificially damped. Back-in-the-day, lame, low tune N/A engine struggled to make 75Nm/litre, so a typical 2.0 family car had say 150Nm of torque. With a cable throttle, even that low amount of torque could cause uncomfortable windup/shuffle and even bunny-hopping (remember learners doing that off the lights?). Today, a typical turbo diesel hatchback sticks out at least twice that torque, and sometimes even more. With a cable throttle that would actually be very difficult to drive smoothly. In conjunction, drivetrain stiffness has fallen in order to return the best NVH (when was the last time you could actually feel the engine running through the steering wheel?) and lower cylinder counts (down to 3 cyls) means that torque is delivered in a more un-even fashion.

Early on during development, we often have to drive prototype cars where the 'Driveability' functions have not been calibrated, or are deliberately turned off (in order to do some test or other on another function), and i can tell you, that makes for a really NASTY drive. The average modern driver has no idea what-so-ever just how much work the electronics are doing to enable them to move comfortably, quietly, and smoothly down the road....

(There is of course a valid counter argument that "easy to drive cars" are one of the reasons driving standards have fallen as literally anyone can drive a modern car........)

1) Throttle angle is not directly proportional to engine torque, as it also depends upon engine speed. At say 2000rpm, as little as 25% throttle is effectively 'full' throttle, where as at 6000rpm, it needs 90% before the throttle stops, er, throttling the incoming air stream. Back in the day, when everyone was used to cable throttles, we had learn't to drive with the non linear gain, and hence, when the first ETCs appeared and suddenly did make constant torque vs accelerator pedal angle across all engine speeds it felt weird and unresponsive.

Later systems fixed this by deliberately re-engineering in that low engine speed over-response. Beloved of some Premium German Brands (yes Audi, i'm looking at you!!) it makes the car feel very perky indeed at low throttle openings. Great for the 'Sales Test drive' when the purchaser thinks, "Wow, if this is how fast this car is at 25% throttle, it's going to be ballistic when i floor it" only to find when they get the car home after buying it that there is actually no more performance to come.....

2) Drivers often berate the fact that the throttle response feels 'laggy' with the engine seemingly only ramping up it's output some time after they have accelerated. Well, what they miss is what would happen if the Torque response wasn't artificially damped. Back-in-the-day, lame, low tune N/A engine struggled to make 75Nm/litre, so a typical 2.0 family car had say 150Nm of torque. With a cable throttle, even that low amount of torque could cause uncomfortable windup/shuffle and even bunny-hopping (remember learners doing that off the lights?). Today, a typical turbo diesel hatchback sticks out at least twice that torque, and sometimes even more. With a cable throttle that would actually be very difficult to drive smoothly. In conjunction, drivetrain stiffness has fallen in order to return the best NVH (when was the last time you could actually feel the engine running through the steering wheel?) and lower cylinder counts (down to 3 cyls) means that torque is delivered in a more un-even fashion.

Early on during development, we often have to drive prototype cars where the 'Driveability' functions have not been calibrated, or are deliberately turned off (in order to do some test or other on another function), and i can tell you, that makes for a really NASTY drive. The average modern driver has no idea what-so-ever just how much work the electronics are doing to enable them to move comfortably, quietly, and smoothly down the road....

(There is of course a valid counter argument that "easy to drive cars" are one of the reasons driving standards have fallen as literally anyone can drive a modern car........)

My E34 540i has ASC and Cruise Control and they're both actuated by complex motors, cable and vacuum line setups mentioned in the above article.

Iirc the only other BMW at the time that had electronic throttle were some E34s had BMWs other traction control option of the time that I can't quite remember the name of.

Might not sound like a real world problem but on a track day I find it incredibly frustrating.

My Clio seems alright, it’ll cut the throttle if you use the brake for too long but all the VAG stuff I’ve driven seems to cut the power straight away, very aggressively and then the throttle doesn’t work again for about half a second.

Wouldn’t happen with a cable...

Might not sound like a real world problem but on a track day I find it incredibly frustrating.

My Clio seems alright, it’ll cut the throttle if you use the brake for too long but all the VAG stuff I’ve driven seems to cut the power straight away, very aggressively and then the throttle doesn’t work again for about half a second.

Wouldn’t happen with a cable...

I then had an E34 M5 with the S38 straight six, ITB’s and a beautiful bell-cranked throttle linkage as per Mc F1. It had a long throttle travel, so you had to move the pedal quite a lot to substantially increase torque output, but even tiny movements had a palpable effect. This made you feel very in control of the engine, which made it easy to maintain chosen speed without cruise and reduced fatigue on journeys of hundreds of miles. The response to throttle changes was also as close could be to instant, because of the short path between butterflies and inlet valves.

I then had a 530i Sport. Oh dear. 90% torque came in the first half of throttle travel - a “sport” map to show off “response”, which wasn’t the same thing as the response from the S38. The pedal was also too light, made my ankle ache keeping my foot up on a cruise, and the combination of the lightness and “responsive” map made it difficult to modulate when driving hard eg over humps in the road when you might want to trim the car’s attitude. I sold it within a year, an otherwise excellent car spoiled by its accelerator pedal, and bought another S38-engined M5.

I’ve no idea what the S55 in a modern M3/4 is like, but about two inches travel to control all that torque? No wonder tests describe it as “spiky”.

I then had an E34 M5 with the S38 straight six, ITB’s and a beautiful bell-cranked throttle linkage as per Mc F1. It had a long throttle travel, so you had to move the pedal quite a lot to substantially increase torque output, but even tiny movements had a palpable effect. This made you feel very in control of the engine, which made it easy to maintain chosen speed without cruise and reduced fatigue on journeys of hundreds of miles. The response to throttle changes was also as close could be to instant, because of the short path between butterflies and inlet valves.

I then had a 530i Sport. Oh dear. 90% torque came in the first half of throttle travel - a “sport” map to show off “response”, which wasn’t the same thing as the response from the S38. The pedal was also too light, made my ankle ache keeping my foot up on a cruise, and the combination of the lightness and “responsive” map made it difficult to modulate when driving hard eg over humps in the road when you might want to trim the car’s attitude. I sold it within a year, an otherwise excellent car spoiled by its accelerator pedal, and bought another S38-engined M5.

I’ve no idea what the S55 in a modern M3/4 is like, but about two inches travel to control all that torque? No wonder tests describe it as “spiky”.

Sport Plus - Fairly Aggressive throttle response and limited stability control I am leaving this one alone for now, I know you are all heros who go everywhere sideways and turn off all the "electronic nannies" the minute you get in the car, but I am quite happy to be nannied for now.

Sport, as above with less crashes

Comfort, sort of middle of the road compromise, easy to drive smoothly, great for when you arent fussed, softens the throttle response, quietens the exhaust, makes the gearbox less silly and engages Radio 2, well maybe not the latter.

Eco Pro, a sort of purgatorial, self inflicted limp mode, nicely simulates a 1990 E30 316 Auto Touring we had briefly.

Someone will say its all crap, give me the pure, undiluted experience etc etc, I love it, I know throttle and engine mapping are only part of it but it means you almost get two cars (Sport and Comfort), four if you count "No Claims Bonus Bingo" and "I cant believe its not broken" modes.

Only possible with DBW, and means the manufacturers dont have to give us a complete compromise setup.

I’ve no issue with electronic throttles and the safety systems they support, do have a problem with BS calibration and modes. Concentrating most of a performance engine’s torque in one half of the accelerator travel makes the car harder to drive briskly, ironically creates more need for safety systems, and creates false impressions which feels dishonest.

However, I have to say I have generally found cable throttles to be easier and more intuitive to drive than electronic ones.

Also, I'm not sure why he states that cars with over 100ft/lbs of torque are difficult to drive with cable throttles. My old Chevy with only 240ft/lbs or so is perfectly tractable with its 4bbl carb and cable throttle. Very responsive yet easy to drive slowly, as well as modulate wheelspin and heel n' toe - all things I have often found trickier with an electronic throttle.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff