Kelvinators 2009 Suzuki Swift Sport ZC31S

Discussion

Once again, I prove that I can't be trusted to be on the internet without supervision; I've added a fifth car to the fleet.

I like to keep an eye on the latest and greatest cars for sale, just you know, to see what the market is doing. Occasionally, like the 318ti, a deal comes up and its too good to just ignore.

That's what happened in the case of the new car. It had been listed for less than an hour, and after consulting with my wife, I pounced. The seller didn't use a whole lot of words when listing it, just "Tidey car got wof out of rego but will put new one on sale selling bc we don't need it manual transmission".

The photos weren't bad, but had been taken on a potato.

It was enough to hook me, so I asked some questions.

Are there any issues with the car? "Nah its perfect".

Any issues with the clutch or gearbox? "No the car runs great".

Paint is all good yeah, no peeling or fading? "Yep"

Well hell, who can argue with answers like that? I make an offer below the asking price, which was accepted (pending me viewing the car) and we agree on a time to drive up the next morning.

After raiding some cash machines to get a fat stack of 20s, gassing up the Honda, we were ready.

The next day the weather was lovely and clear, the Honda performed flawlessly and we made the 2.5 hour drive to see the car.

Initial thoughts of the car were that it wasn't "perfect" as had been described. The headlights were cloudy and yellow to a point they won't pass the next WOF, there was a decent scrape on the LH front corner which has popped the bumper out of the retainer, and the rear tires were low on tread (legal, but only just). Still, the paint was good otherwise (if a bit hard to see under all the dirt, dust and cobwebs) and the interior although disgusting was in decent condition.

I got the key from the seller, who proceeded to say "oops I forgot to tell you the key is broken" and hand me a taped up key blade from the remote locking system. The remote was in the car but didn't work, neither did the remote locking buttons on the doors.

I inserted the key into the ignition, turned it, and after being reminded I needed to press the clutch down to start, the engine fired into life and settled to a nice cold idle. Promising.

We set off on a test drive. Immediately I noted the engine was flat when accelerating. This is the same thing I experienced when buying the last Sport, and it's from being run on 91 octane and the ECU pulling timing to protect the high compression engine. Everything else seemed to be fine; the clutch bit fairly low on the pedal but didn't slip and wasn't dragging, the gearbox shifted nicely if a bit firm, and it tracked nice and straight. All the electrics worked, as did the heater and AC.

Strangely I did notice the RH side wing mirror wobbled and vibrated like crazy over bumps. It seems a pivot is broken and the whole mirror wobbles about. The electric adjustment and folding still work correctly.

We get back and after some discussion with the seller, and negotiations with his mother, we settle on a reduced price. Hand over the cash, wait for them to count the stack of 20s, change ownership online and off we go - straight to the nearby BP for a full tank of (not so cheap) 98 octane.

After a quick lunch, we had to pop to a local shop and buy some cheap spanners since weirdly neither of the cars have a 10mm spanner in their tool kits, so I could disconnect the battery and reset the ECU for the new fuel.

There was a bit of a scare after resetting the ECU when the anti-skid light started flashing when the key was turned on, something that didn't happen before disconnecting the ECU, but it went away once on the move and hasn't come back.

The drive back was mostly uneventful other than two things. First, the 98 octane really started to wake the engine up. It's gone from feeling very flat and lethargic to revving harder and being more punchy. Secondly, the clutch started to drag and cause me grief.

Yes, the clutch that was fine during the test drive, start to get worse and worse as the drive progressed, to a point where the clutch wouldn't completely disengage and would drag when at idle in gear, making it unpleasant to sit at intersections in gear, but the flip side to that is that it got really hard to get into gear when stopped with the engine running, so it ended up being a game of "don't stop" and just rolling through any intersections I could. As long as I rev-matched up and down the box it was fine when moving.

We made it home OK. So what did I have?

Well, its a 2009 Suzuki Swift Sport with 146,000km. Facelift, JDM import, in a fetching shade of Techno Blue Metallic. Powered by the 1.6L M16A Twin cam engine, with a 5 speed manual box behind (beside?) it.

Unlike my previous one, this doesn't have the Mega Option kit with the projector HID headlights or Recaro seats. I'm stuck with the old black housing halogen headlights and the (still quite heavily bolstered) Suzuki seats. Neither of which is a dealbreaker, or an issue. It does have the remote keyless entry and start though (albeit currently non-functional).

This one is also completely stock standard. Unlike the last one with 17" wheels, adjustable suspension, aftermarket intake and exhaust, this one is as it comes from the factory.

It's far from perfect, but its what I wanted and for the price I paid I'm very happy with it, clutch issues and all.

The photos are quite deceptive, as the whole car is filthy inside and out. The paint should look really good when it's clean though. I much prefer blue to the yellow.

Being a later facelift car there are a couple of changes over the early ones like the yellow one. The obvious one is moving the side repeater lamp up into the mirror, instead of on the front guard. The less obvious ones are that the facelift has a higher 7000rpm redline (up from 6800rpm) and allegedly a taller first gear and shorter final drive.

The goal is to upgrade a few things on the car and have it as a fun weekend/track car. It's cheap enough and parts are plentiful, that I don't have to worry too much about it. This will replace the BMW, and possibly the Tomcat.

Yes, the first modification was to send those pink plate frames right to the bin.

I like to keep an eye on the latest and greatest cars for sale, just you know, to see what the market is doing. Occasionally, like the 318ti, a deal comes up and its too good to just ignore.

That's what happened in the case of the new car. It had been listed for less than an hour, and after consulting with my wife, I pounced. The seller didn't use a whole lot of words when listing it, just "Tidey car got wof out of rego but will put new one on sale selling bc we don't need it manual transmission".

The photos weren't bad, but had been taken on a potato.

It was enough to hook me, so I asked some questions.

Are there any issues with the car? "Nah its perfect".

Any issues with the clutch or gearbox? "No the car runs great".

Paint is all good yeah, no peeling or fading? "Yep"

Well hell, who can argue with answers like that? I make an offer below the asking price, which was accepted (pending me viewing the car) and we agree on a time to drive up the next morning.

After raiding some cash machines to get a fat stack of 20s, gassing up the Honda, we were ready.

The next day the weather was lovely and clear, the Honda performed flawlessly and we made the 2.5 hour drive to see the car.

Initial thoughts of the car were that it wasn't "perfect" as had been described. The headlights were cloudy and yellow to a point they won't pass the next WOF, there was a decent scrape on the LH front corner which has popped the bumper out of the retainer, and the rear tires were low on tread (legal, but only just). Still, the paint was good otherwise (if a bit hard to see under all the dirt, dust and cobwebs) and the interior although disgusting was in decent condition.

I got the key from the seller, who proceeded to say "oops I forgot to tell you the key is broken" and hand me a taped up key blade from the remote locking system. The remote was in the car but didn't work, neither did the remote locking buttons on the doors.

I inserted the key into the ignition, turned it, and after being reminded I needed to press the clutch down to start, the engine fired into life and settled to a nice cold idle. Promising.

We set off on a test drive. Immediately I noted the engine was flat when accelerating. This is the same thing I experienced when buying the last Sport, and it's from being run on 91 octane and the ECU pulling timing to protect the high compression engine. Everything else seemed to be fine; the clutch bit fairly low on the pedal but didn't slip and wasn't dragging, the gearbox shifted nicely if a bit firm, and it tracked nice and straight. All the electrics worked, as did the heater and AC.

Strangely I did notice the RH side wing mirror wobbled and vibrated like crazy over bumps. It seems a pivot is broken and the whole mirror wobbles about. The electric adjustment and folding still work correctly.

We get back and after some discussion with the seller, and negotiations with his mother, we settle on a reduced price. Hand over the cash, wait for them to count the stack of 20s, change ownership online and off we go - straight to the nearby BP for a full tank of (not so cheap) 98 octane.

After a quick lunch, we had to pop to a local shop and buy some cheap spanners since weirdly neither of the cars have a 10mm spanner in their tool kits, so I could disconnect the battery and reset the ECU for the new fuel.

There was a bit of a scare after resetting the ECU when the anti-skid light started flashing when the key was turned on, something that didn't happen before disconnecting the ECU, but it went away once on the move and hasn't come back.

The drive back was mostly uneventful other than two things. First, the 98 octane really started to wake the engine up. It's gone from feeling very flat and lethargic to revving harder and being more punchy. Secondly, the clutch started to drag and cause me grief.

Yes, the clutch that was fine during the test drive, start to get worse and worse as the drive progressed, to a point where the clutch wouldn't completely disengage and would drag when at idle in gear, making it unpleasant to sit at intersections in gear, but the flip side to that is that it got really hard to get into gear when stopped with the engine running, so it ended up being a game of "don't stop" and just rolling through any intersections I could. As long as I rev-matched up and down the box it was fine when moving.

We made it home OK. So what did I have?

Well, its a 2009 Suzuki Swift Sport with 146,000km. Facelift, JDM import, in a fetching shade of Techno Blue Metallic. Powered by the 1.6L M16A Twin cam engine, with a 5 speed manual box behind (beside?) it.

Unlike my previous one, this doesn't have the Mega Option kit with the projector HID headlights or Recaro seats. I'm stuck with the old black housing halogen headlights and the (still quite heavily bolstered) Suzuki seats. Neither of which is a dealbreaker, or an issue. It does have the remote keyless entry and start though (albeit currently non-functional).

This one is also completely stock standard. Unlike the last one with 17" wheels, adjustable suspension, aftermarket intake and exhaust, this one is as it comes from the factory.

It's far from perfect, but its what I wanted and for the price I paid I'm very happy with it, clutch issues and all.

The photos are quite deceptive, as the whole car is filthy inside and out. The paint should look really good when it's clean though. I much prefer blue to the yellow.

Being a later facelift car there are a couple of changes over the early ones like the yellow one. The obvious one is moving the side repeater lamp up into the mirror, instead of on the front guard. The less obvious ones are that the facelift has a higher 7000rpm redline (up from 6800rpm) and allegedly a taller first gear and shorter final drive.

The goal is to upgrade a few things on the car and have it as a fun weekend/track car. It's cheap enough and parts are plentiful, that I don't have to worry too much about it. This will replace the BMW, and possibly the Tomcat.

Yes, the first modification was to send those pink plate frames right to the bin.

Like all cars I buy, especially ones this cheap, there are issues. Not for long though.

The first fix was to get the remote locking working. The previous owner had flattened the remote battery and broken the key blade by just being ham-fisted.

It turns out that just changing the battery (CR2032 button cell) wasn't enough to get the remote working, so I started to look further into it. I suspected that it had lost its programming due to being left flat for so long, so I did some digging and found the instructions to code the remote to a car.

From this helpful thread

[QUOTE]

1 Sit in driver's seat. Close all doors and ensure all doors are unlocked.

2 Insert key into ignition lock cylinder (do not turn at this time).

(the next three steps must be done within 25 seconds).

3.Push the manual lock on the driver's door to lock, then unlock three timesm then to lock position again. (this is the lock button at the inside door release handlem NOT the power door lock switch). Lock, unlock, lock, unlock, lock, unlock, lock.

4.Pull the key out of the lock cylinder and back in four times. Out, in, out, in, out, in, out, in. (when you do this, be sure to push the key all the way in and pull the key all the way out; be methodical, not speedy. 25 seconds is a lot of time.

5. Immediately after step four, start the engine. Count three seconds, then turn off the ignition-DO NOT REMOVE THE KEY! At this point, if you have been sucessful, you will hear two audible "beeps", the door locks will cycle and you are now in programming mode.

6. Push and hold either the lock or unlock button on the remote to be programmed. The locks will again cycle indicating the remote was sucessfully programmed. Repeat step 6 for all other remotes. Once all remotes are programmed, open and close the door, then test each remote for function. You may also remove the key at this point

[/QUOTE]

The bonus 7th step is to start the engine briefly, to confirm the programming.

Following these steps, I could get the door locks to cycle and beep, and when I pressed the remote button sometimes it would trigger the locks, but it was very intermittent, and the outside buttons still didn't work, nor did the keyless start.

I did some more research and found someone that mentioned a similar issue, and he fixed his remote by bending the battery tabs to improve the contact.

When you split the key, there are contacts in the top and bottom housings. All of them were flat against the circuit board.

The ones under the battery also needed to be tweaked up. The blue arrow is pointing to the contacts that bridge the two halves of the remote, I tweaked this up slightly too.

After that, the remote, the keyless start and the keyless entry buttons on the doors all started to work flawlessly. Obviously, the battery contacts weren't good enough to power the remote fully and just tweaking them to make better contact has revived it.

Feeling pretty chuffed with myself on that fix, I moved on to checking out the clutch issue. The pedal would bite pretty close to the floor, and it wouldn't disengage fully causing it to drag in gear at idle and make it very hard to shift into first and reverse at a stop. It was fine on the go because you could rev match, but otherwise it wasn't good. I have my suspicions the seller knew this was an issue, and was the reason the car "hasn't been used for weeks" and the low asking price.

The first port of call was to check the clutch hydraulics. If these are failing it can cause a lack of hydraulic pressure and the clutch won't fully operate. This would be consistent with the fact the issue got worse once the car was at operating temp.

The master cylinder looked nice and clean, with no signs of moisture on either side of the firewall. The slave cylinder on the other hand...

Was covered in filth, and there was a large damp spot on the gearbox in the general vicinity of the slave. Interesting.

Pulling the boot back revealed moisture, indicating the slave cylinder had been leaking internally. It's hard to photograph but the boot was covered in brake fluid on the inside.

Knowing that wasn't a good sign, I reached out to the local Suzuki dealer and ordered a new slave. It's such a common issue with these that they had it on the shelf, and it was a reasonable price.

After work, I set to the task of replacing it. It's not quite as straightforward as a normal car.

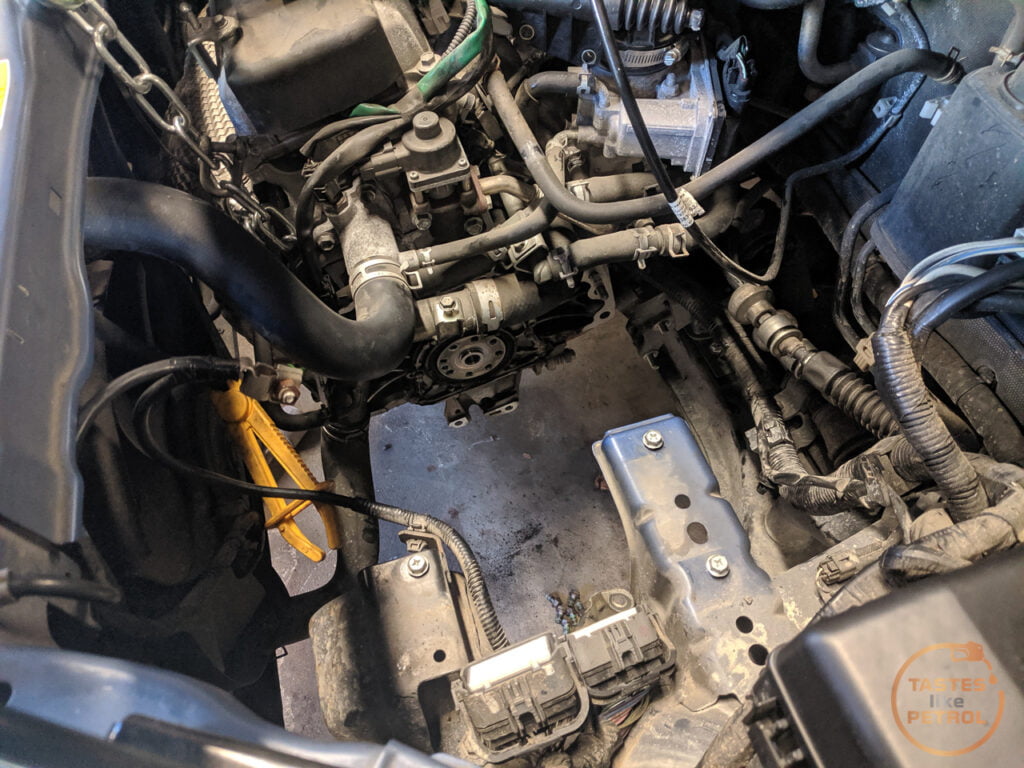

Start with the engine

All I needed to do was remove the large SUZUKI cover (just pulls off), remove the air intake hose near the battery (also just pulls off) and relocate the coolant overflow tank (lifts up off its bracket)

The slave then resides down in the empty space

So, the special features of the slave on these cars. The pink arrow indicates the plastic bleed tube/nipple. This has no nut to open or close it, it's just a tube moulded into the cylinder. The blue arrow is the pipe retaining clip. You push this down to release the pipe. And finally, the orange arrow is the hydraulic pipe.

To remove the cylinder you need to disconnect the pipe from the cylinder. This is done by pressing down on the clips (blue arrow) and firmly pulling the pipe out (toward the front of the car). It will come out in two stages. The first click is where you would pull it to if you wanted to bleed the system, as this opens up the bleed tube. Pull it again and the pipe will come completely out. I was concerned removing this pipe might drain the system, but barely any fluid gravity drained when this was removed.

Then there are two 12mm bolts to remove. I found swinging this counterweight to the right gave me more space to get at the bolts. Just be aware that moving this counterweight actually changes gear (it's on the end of the shifter linkages), so always check the car is in neutral before starting.

The pushrod in the cylinder is spring-loaded and will try to push the cylinder away from the clutch lever as you undo the bolts, so just take care.

Once removed I drained the fluid that was in the cylinder and it was black. Obviously hasn't been changed in years, and probably part of the reason the cylinder failed. I have a feeling a lot of workshops probably don't know how to bleed these systems, so just ignore them during servicing.

Before fitting the new cylinder I thoroughly cleaned the clutch lever (inside the cup), and then applied silicone grease to it (as per the manual).

The new cylinder went in as expected. You need to compress the pushrod whilst installing the bolts, which can be a real fiddle. Once bolted in its a case of just pushing the pipe back into the new cylinder, you don't even need to compress the clip.

To bleed the cylinder all you do is press down on the clip, and gently pull the pipe out of the cylinder until it stops. This is the bleed point; the bleed tube will now be open and air/fluid should start to come out of the cylinder.

At this point, I followed the instructions in the manual. Press the pipe in to close the bleed tube, pump the pedal a few times, pull the pipe out to its stop and let air/fluid bleed. Rinse and repeat a few times. Once air stops coming through, have an assistant slowly push the clutch pedal down with the bleed tube open and then press the pipe in to block off the system. As long as all the air is out, that's the job done. Always keep an eye on the master cylinder fluid level (as the clutch shares fluid with the brakes) and keep it topped up.

A quick test drive after replacing the cylinder showed that although the bite point was now about mid pedal, and much nicer to use, the dragging and difficulty shifting gears was still there. Damn.

One last thing I found online, was someone mentioning that they found a bolt on their floor mat one day, which coincided with them having difficulty shifting. That bolt had come out of the top of the clutch pedal bracket assembly, where it mounts under the dash

This all sounds familiar.... it's exactly the same issue I had with the M328i way back when.

Once home from the test drive, I stuck my head up under the dash, and sure enough, I spotted this

Way up here somewhere

Yes, that is indeed the hole for a bolt that should be securing the bracket to the firewall. The effect of not having the bolt was obvious just by pressing the clutch pedal by hand and watching the bracket move and flex.

I guess at some point the owner found a random bolt on the floor, wondered where it came from, and threw it out the window.

A suitable M8 bolt, washer and lock/spring washer were sourced

And after some fiddling under the dash, it was installed and tightened with a long extension on a rachet. It ain't going anywhere.

The bracket doesn't move a mm now when the pedal is pressed. It's solid as a rock.

Immediately, just putting the car into reverse to back out of the garage, the difference could be felt. The pedal was firmer and more predictable, and the shifter just popped into reverse without any force or grinding. Once in reverse, the rough idle shunting from the dragging clutch wasn't present.

A quick drive around the block revealed the extent of this fix. The gearbox shifts perfectly, with the shifter popping nicely into gear, there is no more dragging at idle, and I can shift into first when stationary without having to force the shifter into gear.

A couple of slip tests (drive along in 4th or 5th, press the clutch in, rev the engine up and drop the clutch; a good clutch should immediately drop back down to the correct rpm with a lurch, and a slipping clutch will slip and slur the revs as they drop) show the clutch isn't slipping at all and has a good bite.

Overall I'm very happy since it shows I don't need to replace the clutch (at least not yet), and the car is back to being drivable, without risking damage to the gearbox.

Now I'm looking forward to getting out and driving it more.

The first fix was to get the remote locking working. The previous owner had flattened the remote battery and broken the key blade by just being ham-fisted.

It turns out that just changing the battery (CR2032 button cell) wasn't enough to get the remote working, so I started to look further into it. I suspected that it had lost its programming due to being left flat for so long, so I did some digging and found the instructions to code the remote to a car.

From this helpful thread

[QUOTE]

1 Sit in driver's seat. Close all doors and ensure all doors are unlocked.

2 Insert key into ignition lock cylinder (do not turn at this time).

(the next three steps must be done within 25 seconds).

3.Push the manual lock on the driver's door to lock, then unlock three timesm then to lock position again. (this is the lock button at the inside door release handlem NOT the power door lock switch). Lock, unlock, lock, unlock, lock, unlock, lock.

4.Pull the key out of the lock cylinder and back in four times. Out, in, out, in, out, in, out, in. (when you do this, be sure to push the key all the way in and pull the key all the way out; be methodical, not speedy. 25 seconds is a lot of time.

5. Immediately after step four, start the engine. Count three seconds, then turn off the ignition-DO NOT REMOVE THE KEY! At this point, if you have been sucessful, you will hear two audible "beeps", the door locks will cycle and you are now in programming mode.

6. Push and hold either the lock or unlock button on the remote to be programmed. The locks will again cycle indicating the remote was sucessfully programmed. Repeat step 6 for all other remotes. Once all remotes are programmed, open and close the door, then test each remote for function. You may also remove the key at this point

[/QUOTE]

The bonus 7th step is to start the engine briefly, to confirm the programming.

Following these steps, I could get the door locks to cycle and beep, and when I pressed the remote button sometimes it would trigger the locks, but it was very intermittent, and the outside buttons still didn't work, nor did the keyless start.

I did some more research and found someone that mentioned a similar issue, and he fixed his remote by bending the battery tabs to improve the contact.

When you split the key, there are contacts in the top and bottom housings. All of them were flat against the circuit board.

The ones under the battery also needed to be tweaked up. The blue arrow is pointing to the contacts that bridge the two halves of the remote, I tweaked this up slightly too.

After that, the remote, the keyless start and the keyless entry buttons on the doors all started to work flawlessly. Obviously, the battery contacts weren't good enough to power the remote fully and just tweaking them to make better contact has revived it.

Feeling pretty chuffed with myself on that fix, I moved on to checking out the clutch issue. The pedal would bite pretty close to the floor, and it wouldn't disengage fully causing it to drag in gear at idle and make it very hard to shift into first and reverse at a stop. It was fine on the go because you could rev match, but otherwise it wasn't good. I have my suspicions the seller knew this was an issue, and was the reason the car "hasn't been used for weeks" and the low asking price.

The first port of call was to check the clutch hydraulics. If these are failing it can cause a lack of hydraulic pressure and the clutch won't fully operate. This would be consistent with the fact the issue got worse once the car was at operating temp.

The master cylinder looked nice and clean, with no signs of moisture on either side of the firewall. The slave cylinder on the other hand...

Was covered in filth, and there was a large damp spot on the gearbox in the general vicinity of the slave. Interesting.

Pulling the boot back revealed moisture, indicating the slave cylinder had been leaking internally. It's hard to photograph but the boot was covered in brake fluid on the inside.

Knowing that wasn't a good sign, I reached out to the local Suzuki dealer and ordered a new slave. It's such a common issue with these that they had it on the shelf, and it was a reasonable price.

After work, I set to the task of replacing it. It's not quite as straightforward as a normal car.

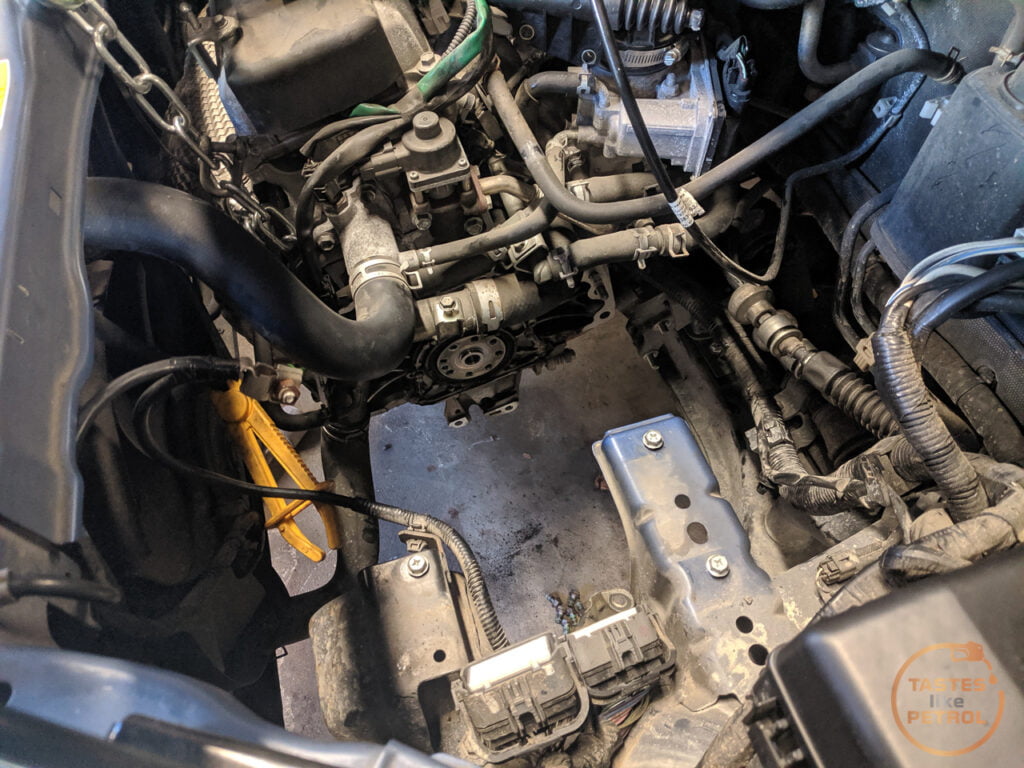

Start with the engine

All I needed to do was remove the large SUZUKI cover (just pulls off), remove the air intake hose near the battery (also just pulls off) and relocate the coolant overflow tank (lifts up off its bracket)

The slave then resides down in the empty space

So, the special features of the slave on these cars. The pink arrow indicates the plastic bleed tube/nipple. This has no nut to open or close it, it's just a tube moulded into the cylinder. The blue arrow is the pipe retaining clip. You push this down to release the pipe. And finally, the orange arrow is the hydraulic pipe.

To remove the cylinder you need to disconnect the pipe from the cylinder. This is done by pressing down on the clips (blue arrow) and firmly pulling the pipe out (toward the front of the car). It will come out in two stages. The first click is where you would pull it to if you wanted to bleed the system, as this opens up the bleed tube. Pull it again and the pipe will come completely out. I was concerned removing this pipe might drain the system, but barely any fluid gravity drained when this was removed.

Then there are two 12mm bolts to remove. I found swinging this counterweight to the right gave me more space to get at the bolts. Just be aware that moving this counterweight actually changes gear (it's on the end of the shifter linkages), so always check the car is in neutral before starting.

The pushrod in the cylinder is spring-loaded and will try to push the cylinder away from the clutch lever as you undo the bolts, so just take care.

Once removed I drained the fluid that was in the cylinder and it was black. Obviously hasn't been changed in years, and probably part of the reason the cylinder failed. I have a feeling a lot of workshops probably don't know how to bleed these systems, so just ignore them during servicing.

Before fitting the new cylinder I thoroughly cleaned the clutch lever (inside the cup), and then applied silicone grease to it (as per the manual).

The new cylinder went in as expected. You need to compress the pushrod whilst installing the bolts, which can be a real fiddle. Once bolted in its a case of just pushing the pipe back into the new cylinder, you don't even need to compress the clip.

To bleed the cylinder all you do is press down on the clip, and gently pull the pipe out of the cylinder until it stops. This is the bleed point; the bleed tube will now be open and air/fluid should start to come out of the cylinder.

At this point, I followed the instructions in the manual. Press the pipe in to close the bleed tube, pump the pedal a few times, pull the pipe out to its stop and let air/fluid bleed. Rinse and repeat a few times. Once air stops coming through, have an assistant slowly push the clutch pedal down with the bleed tube open and then press the pipe in to block off the system. As long as all the air is out, that's the job done. Always keep an eye on the master cylinder fluid level (as the clutch shares fluid with the brakes) and keep it topped up.

A quick test drive after replacing the cylinder showed that although the bite point was now about mid pedal, and much nicer to use, the dragging and difficulty shifting gears was still there. Damn.

One last thing I found online, was someone mentioning that they found a bolt on their floor mat one day, which coincided with them having difficulty shifting. That bolt had come out of the top of the clutch pedal bracket assembly, where it mounts under the dash

This all sounds familiar.... it's exactly the same issue I had with the M328i way back when.

Once home from the test drive, I stuck my head up under the dash, and sure enough, I spotted this

Way up here somewhere

Yes, that is indeed the hole for a bolt that should be securing the bracket to the firewall. The effect of not having the bolt was obvious just by pressing the clutch pedal by hand and watching the bracket move and flex.

I guess at some point the owner found a random bolt on the floor, wondered where it came from, and threw it out the window.

A suitable M8 bolt, washer and lock/spring washer were sourced

And after some fiddling under the dash, it was installed and tightened with a long extension on a rachet. It ain't going anywhere.

The bracket doesn't move a mm now when the pedal is pressed. It's solid as a rock.

Immediately, just putting the car into reverse to back out of the garage, the difference could be felt. The pedal was firmer and more predictable, and the shifter just popped into reverse without any force or grinding. Once in reverse, the rough idle shunting from the dragging clutch wasn't present.

A quick drive around the block revealed the extent of this fix. The gearbox shifts perfectly, with the shifter popping nicely into gear, there is no more dragging at idle, and I can shift into first when stationary without having to force the shifter into gear.

A couple of slip tests (drive along in 4th or 5th, press the clutch in, rev the engine up and drop the clutch; a good clutch should immediately drop back down to the correct rpm with a lurch, and a slipping clutch will slip and slur the revs as they drop) show the clutch isn't slipping at all and has a good bite.

Overall I'm very happy since it shows I don't need to replace the clutch (at least not yet), and the car is back to being drivable, without risking damage to the gearbox.

Now I'm looking forward to getting out and driving it more.

Like all new toys, it's hard to leave things alone long. The first upgrade I wanted to do was fit a better headunit.

The headunit in the car although decent, NZ market and modern, doesn't have Bluetooth, so it's useless to me. By a stroke of luck I have a good headunit with Bluetooth in my inventory... so put two and two together, and the Swift gets an upgrade.

For a standard Swift there are two screws you need to undo to remove the headunit, these are on either side of the radio unit and accessed by removing the glovebox on one side, and the under dash panel on the other. In my case, the car already has an aftermarket headunit, which was only held in with the clips on the facia. A good hard tug on the facia had the assembly out and in my hands. Dont forget to remove the connector for the hazard light button, it's quite short.

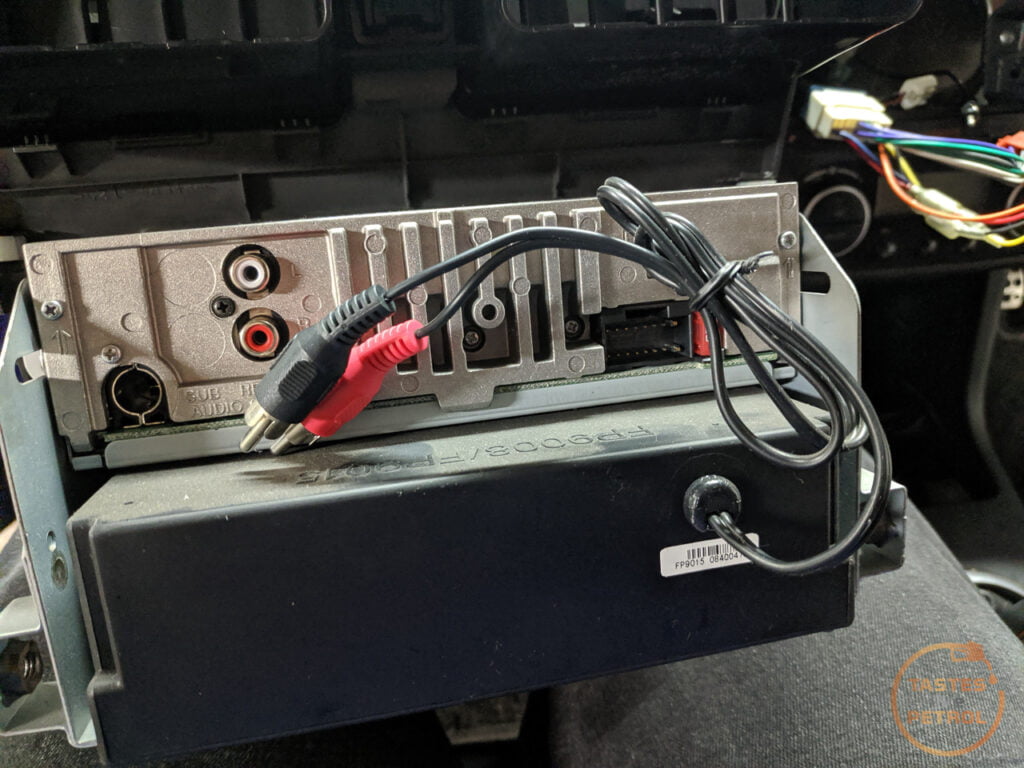

Yes, you are seeing that right, ISO connectors! I hate it when people cut OE plugs off and hardwire the radio in, so seeing ISO plugs makes me happy.

The tray under the headunit was interesting. It had a really nicely assembled AUX cable integrated into it, so you could rest your phone in the front of the tray and the cables are plugged into the back of the headunit (instead of plugging into the front)

The replacement headunit has Bluetooth, and no AUX in the back of it, so the cable was now redundant. I tried to disassemble it without cutting the cable but had no success, so ended up chopping it and pulling it out. The tray will still be handy though.

With the facia assembly out, to replace the headunit you need to remove the metal cage from the facia. There are two screws on each side.

I swapped the headunits over in the cage and swapped the wiring over to suit the replacement headunit. I swear you can do as bad of a wrap job as you like, but as long as it's done in fabric tape it looks super professional. Insulation tape wraps are so last year.

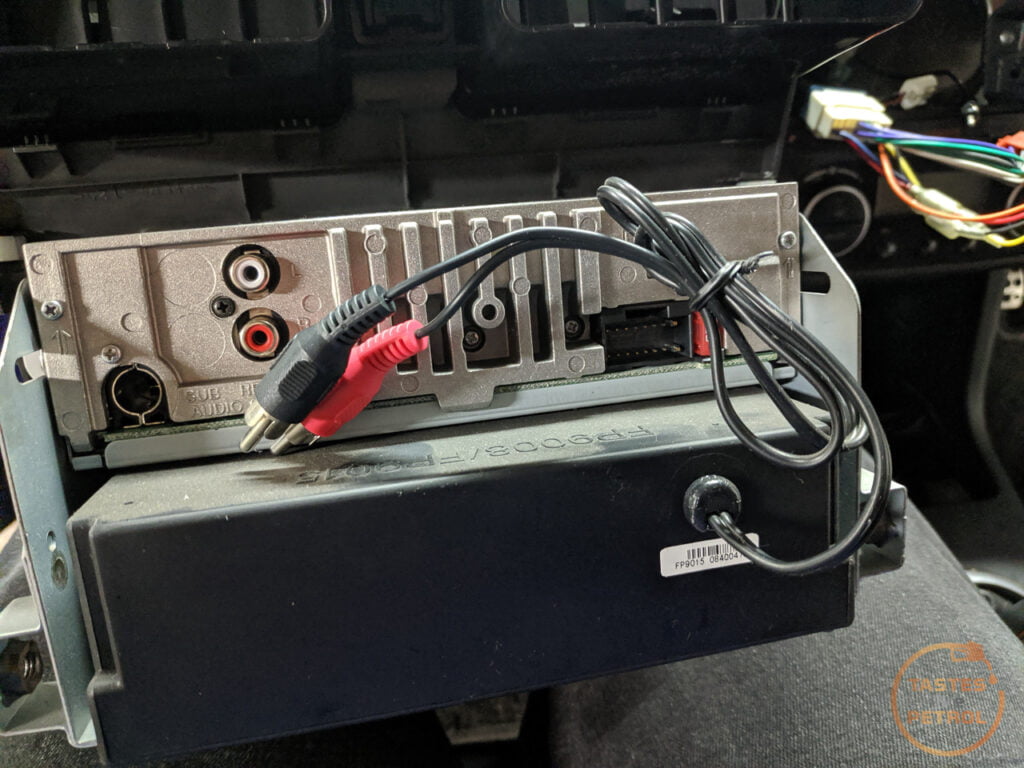

A quick test plug to make sure everything works

And after checking all the wiring was good, the unit was reinstalled into the dash. The sound quality is far better than the old Sony headunit. Shame about the blue backlight, but it does the job.

Unfortunately it was at this point I realised that I forgot to run the wire for the microphone... so out it all came again, so I could run it through the dash to the steering column shroud.

With that sorted, and sounding great, the next quick mod was to change the room lamp to an LED, which is a case of using a slim trim tool or screwdriver to pop the cover off

And the boot light got the same treatment. This one comes out by hand with some wiggling

Finally, I decided to look into the wobbly mirror. It drives you a bit mad when you are cruising along and this thing is bouncing and wobbling all over the place.

The key to knowing if it's the same issue as mine or not, is that the head of the mirror is wobbly, but the base is firmly affixed to the door. If the base is wobbly too, it'll be the bolts behind the tweeter, holding the mirror assembly to the door.

In my case it was just the head of the mirror that wobbled. I googled around and sure enough, I wasn't alone. Turns out, way back in about 2010 Suzuki issued a Techincal Service Bulletin, and even recalls, about this issue. On some/all 2008-2010 Swifts and SX4s, they forgot to use thread locker on the screws that affix the mirror head to the base. Over time these vibrate loose and come out. If all three come out, the mirror head can come off the base and fall off, dangling by just the wiring.

The TSB is available here, https://static.nhtsa.gov/odi/rcl/2010/RCRIT-10V513...

The TSB advises the technician to remove the mirror from the door and then repair it. I'm lazy and didn't want to do that, so my way means you can do it on the car.

First, look under the mirror for this cover

Use a thin flat blade screwdriver, or other thin flat tool, to gently lever that trim panel off. I did this about where the arrow above is pointing

Once you pop the cover off you will see what has happened

I could already see a pair of screws sitting on the plastic cover

I carefully removed the cover, retaining the loose screws. These three circles are where the screws should be. You can just make out on the one on the right has a screw in it, but the other two are empty.

That one screw was the only thing holding the mirror on

I used a small amount of thread locker and a "Naro Driver" tool to refit the screws and make sure they were tight. The Naro Driver is amazing because you can use it in such small spaces. Because the mirror is right up against the door, you cannot use a standard screwdriver, and even my 1/4" ratchet was too big. A small spanner on the screwdriver bit might work too.

With the screws refitted, the little cover can just be clipped into place. The mirror is now solid, not a mm of unwanted movement in it. I popped the cover off the passengers side mirror too, and the screws on that were snugged up, but not tight. I gave them a tweak and went on my way.

I think other than a couple of cosmetic issues, that's all the fixes I needed to do. The only repair that has cost me money was the slave cylinder, which I probably could have got away with not replacing, but it was leaking so was on borrowed time. Everything else has just been a case of actually fixing something, not replacing it.

The headunit in the car although decent, NZ market and modern, doesn't have Bluetooth, so it's useless to me. By a stroke of luck I have a good headunit with Bluetooth in my inventory... so put two and two together, and the Swift gets an upgrade.

For a standard Swift there are two screws you need to undo to remove the headunit, these are on either side of the radio unit and accessed by removing the glovebox on one side, and the under dash panel on the other. In my case, the car already has an aftermarket headunit, which was only held in with the clips on the facia. A good hard tug on the facia had the assembly out and in my hands. Dont forget to remove the connector for the hazard light button, it's quite short.

Yes, you are seeing that right, ISO connectors! I hate it when people cut OE plugs off and hardwire the radio in, so seeing ISO plugs makes me happy.

The tray under the headunit was interesting. It had a really nicely assembled AUX cable integrated into it, so you could rest your phone in the front of the tray and the cables are plugged into the back of the headunit (instead of plugging into the front)

The replacement headunit has Bluetooth, and no AUX in the back of it, so the cable was now redundant. I tried to disassemble it without cutting the cable but had no success, so ended up chopping it and pulling it out. The tray will still be handy though.

With the facia assembly out, to replace the headunit you need to remove the metal cage from the facia. There are two screws on each side.

I swapped the headunits over in the cage and swapped the wiring over to suit the replacement headunit. I swear you can do as bad of a wrap job as you like, but as long as it's done in fabric tape it looks super professional. Insulation tape wraps are so last year.

A quick test plug to make sure everything works

And after checking all the wiring was good, the unit was reinstalled into the dash. The sound quality is far better than the old Sony headunit. Shame about the blue backlight, but it does the job.

Unfortunately it was at this point I realised that I forgot to run the wire for the microphone... so out it all came again, so I could run it through the dash to the steering column shroud.

With that sorted, and sounding great, the next quick mod was to change the room lamp to an LED, which is a case of using a slim trim tool or screwdriver to pop the cover off

And the boot light got the same treatment. This one comes out by hand with some wiggling

Finally, I decided to look into the wobbly mirror. It drives you a bit mad when you are cruising along and this thing is bouncing and wobbling all over the place.

The key to knowing if it's the same issue as mine or not, is that the head of the mirror is wobbly, but the base is firmly affixed to the door. If the base is wobbly too, it'll be the bolts behind the tweeter, holding the mirror assembly to the door.

In my case it was just the head of the mirror that wobbled. I googled around and sure enough, I wasn't alone. Turns out, way back in about 2010 Suzuki issued a Techincal Service Bulletin, and even recalls, about this issue. On some/all 2008-2010 Swifts and SX4s, they forgot to use thread locker on the screws that affix the mirror head to the base. Over time these vibrate loose and come out. If all three come out, the mirror head can come off the base and fall off, dangling by just the wiring.

The TSB is available here, https://static.nhtsa.gov/odi/rcl/2010/RCRIT-10V513...

The TSB advises the technician to remove the mirror from the door and then repair it. I'm lazy and didn't want to do that, so my way means you can do it on the car.

First, look under the mirror for this cover

Use a thin flat blade screwdriver, or other thin flat tool, to gently lever that trim panel off. I did this about where the arrow above is pointing

Once you pop the cover off you will see what has happened

I could already see a pair of screws sitting on the plastic cover

I carefully removed the cover, retaining the loose screws. These three circles are where the screws should be. You can just make out on the one on the right has a screw in it, but the other two are empty.

That one screw was the only thing holding the mirror on

I used a small amount of thread locker and a "Naro Driver" tool to refit the screws and make sure they were tight. The Naro Driver is amazing because you can use it in such small spaces. Because the mirror is right up against the door, you cannot use a standard screwdriver, and even my 1/4" ratchet was too big. A small spanner on the screwdriver bit might work too.

With the screws refitted, the little cover can just be clipped into place. The mirror is now solid, not a mm of unwanted movement in it. I popped the cover off the passengers side mirror too, and the screws on that were snugged up, but not tight. I gave them a tweak and went on my way.

I think other than a couple of cosmetic issues, that's all the fixes I needed to do. The only repair that has cost me money was the slave cylinder, which I probably could have got away with not replacing, but it was leaking so was on borrowed time. Everything else has just been a case of actually fixing something, not replacing it.

Bunch of parts are en route to make this car better, but in the mean time I pulled the gearbox out to find out why the clutch was being a dick

Ah, oodles of clutch dust in the bellhousing, and a clutch release lever and bearing that barely move. That wont help.

And an aftermarket Exedy clutch that had been shredded to the point its almost at the rivets and the flywheel has piles of clutch fibers (not dust) on it. Im guessing this is from the previous owner trying to learn to drive in it with a clutch that doesnt completely disengage (due to the missing clutch pedal bracket bolt and the seized clutch release arm).

Ah, oodles of clutch dust in the bellhousing, and a clutch release lever and bearing that barely move. That wont help.

And an aftermarket Exedy clutch that had been shredded to the point its almost at the rivets and the flywheel has piles of clutch fibers (not dust) on it. Im guessing this is from the previous owner trying to learn to drive in it with a clutch that doesnt completely disengage (due to the missing clutch pedal bracket bolt and the seized clutch release arm).

Excellent thread, looking forward to more! I love little detail fixes like the mirror and keys. Instead of just binning it and throwing a new one on, actually taking 5 minutes to look into it and fixing it for free saving both waste and money.

Had a similar issue with my Mazda and the contact points on the key battery. A little time and effort and you're left a perfectly working key for no money and a little bit of time you'd otherwise spend watching nonsense on TV and (in my case) eating rubbish.

Had a similar issue with my Mazda and the contact points on the key battery. A little time and effort and you're left a perfectly working key for no money and a little bit of time you'd otherwise spend watching nonsense on TV and (in my case) eating rubbish.

RazerSauber said:

Excellent thread, looking forward to more! I love little detail fixes like the mirror and keys. Instead of just binning it and throwing a new one on, actually taking 5 minutes to look into it and fixing it for free saving both waste and money.

Had a similar issue with my Mazda and the contact points on the key battery. A little time and effort and you're left a perfectly working key for no money and a little bit of time you'd otherwise spend watching nonsense on TV and (in my case) eating rubbish.

The little, actual, fixes are always quite satisfying.Had a similar issue with my Mazda and the contact points on the key battery. A little time and effort and you're left a perfectly working key for no money and a little bit of time you'd otherwise spend watching nonsense on TV and (in my case) eating rubbish.

The clutch was still playing up, so it was time to find out why.

The work I did on the clutch hydraulics, and adding the missing bolt to the clutch pedal bracket, helped the clutch issues a bit, but it was far from perfect. It was drivable now, but the clutch still bit right off on the floor, had a really long engagement, almost no feel in the pedal and would drag if you didn't keep your foot planted on the pedal as hard as you could. Not to mention the engagement was a bit on the soft side.

I ordered an OEM replacement Exedy clutch kit, a new clutch fork (pre-empting a potential failure point), new fork bushes, and bolts for the flywheel and clutch cover (you can probably reuse the cover bolts safely, but the flywheel bolts must be replaced each time).

Last weekend I got stuck into removing the gearbox. The first job is to remove all the gubbins around the gearbox in the engine bay, so first the intake ducting comes out, then the coolant overflow bottle, followed by the battery and its hold down.

Next, the battery support needs to come out. There are three 10mm bolts on the base, and then the ECU can be disconnected, The ECU can remain attached to the support. The ECU plugs have a latching lever to lock them into place.

The shifter cables were next to go. These were a bit of a pain, and different to the videos I had seen of the UK cars. First, this clip needs to be removed (partly removed in photo). You need to lift the end the arrow is point to upwards to clear the locking piece, and then the clip can slide out, allowing you to lift the cap and cable off the shifter mechanism.

The other cable just levered out. It has a soft plastic bushing inside it, which remained on the mechanism for me, so I levered that off and inserted it back into the cable.

With the cables disconnected from the shifter mechanism, I needed to remove the cables from the gearbox. They are retained in this bracket.

This seems to be where the JDM cars differ from the UKDM ones. The cables on the JDM cars are retained to the bracket via a pair of metal clips with tangs that stop the cable from coming out.

I used a tiny flatblade screwdriver to press these tangs in so they were flush with the clip, and the cable could then be removed. I later bent the tangs back out before refitting.

With everything up top sorted, the engine was supported by my engine support brace (which was a pain on the Swift, as the engine bay is very short, so it had to almost go on the slam panel and gave very little space to work up top). The axles were then removed, which was also a pain as the outer CVs were seized in the hubs and needed to be smashed out with a sledgehammer. Before the axles were removed I was sure to drain the old gearbox oil, which was very dark, stank and was about as viscous as water; far too thin.

Finally, all the various (excessively tight) nuts and bolts around the gearbox, including the rear and LH mounts, were removed and the gearbox gently manhandled down to the ground, using my belly as support.

With the gearbox out it was immediately obvious what the issue was

The bellhousing was packed with old clutch dust, and the release fork and bearing barely moved by hand. It was all binding badly. The bearing was also really rumbly; no Bueno.

I removed the clutch and flywheel next.

Interestingly the clutch was already an Exedy, so either they are an OEM supplier, or the clutch has already been changed (from my research it appears it could have been the original OEM clutch plate; its slightly different to the aftermarket kit I got and the pressure plate has no markings)

You can see in the photo above that the plate is heavily worn, and almost down to the rivets. There are no signs of the diagonal recesses in the friction material that they have when new.

The flywheel had clumps of fibrous clutch material on it

Whilst the surface the clutch plate runs on had some bad heat spotting

During the week I sent the flywheel off to be machined, and it came back looking really nice

I also took the time to knock out the old top bush and remove the clutch fork. There is a special tool to remove this bushing, but I don't have one.

So I made do with what I had. The same job can be done with an old 5/8" spark plug socket, cut in half and the end with the square in it cut off. A section of pipe of the same OD would work too.

Combine this with a hammer and punch

And you can drive the seal and bush out

This high-tech tool may scratch up the surface of the clutch fork, which I'm replacing anyway, but do this at your own risk.

With the bushing removed, the clutch fork can then also be removed and after a clean, thoroughly inspected.

Due to a bad design where the welding is only halfway around the rod, they are prone to cracking at the ends of the weld, causing many issues, since this is what translates the movement in the hydraulic system from your foot, to actually moving the release bearing and pressing on the clutch pressure plate (which takes a lot of force).

Mine wasn't cracked and would probably be fine to reuse, but I wasn't taking the risk since I was already here. I had a replacement genuine part on hand, and it's good to see that Suzuki realised it was a flawed design and superseded it with a newer design that is fully welded.

I can only really come up with a couple of conclusions as to how this issue happened. The obvious one is that over time the factory fitted grease that should be on all the pivot points, but is now completely missing, wore away and was replaced with high friction clutch dust. This issue was compounded by the leaking slave cylinder, and the flexing pedal bracket which failed to allow the clutch to fully disengage, which caused even more clutch dust, and just bound up the fork and bearing. The alternate theory is the same, except when the clutch was replaced, the mechanic failed to grease the pivot points and it's been operating dry this whole time.

I don't know if the clutch was replaced, the car has no service history, so we can only speculate.

I cleaned out the bellhousing, and cleaned the lower bush. It appeared ok and cleaned up well, so I chose to reuse it rather than try and work out how to remove it.

The replacement fork had a new roll pin fitted

both bushes were lubed up, and the new fork fitted

I used the old bushing and another 5/8" spark plugs socket (complete this time) to drive the new bush in

Followed by the new seal

Lots of the fancy purple Exedy grease was used on the snout, input shaft and contact patches of the fork, and the new release bearing was fitted

The clutch fork more or less flops about and takes no force to move, which is a huge difference from how it was before.

While the gearbox was out, I took the opportunity to also replace the rear engine mount. There was some movement in the engine when coming on and off the throttle, and there would never be an easier time to get at the mount than now. The old one wasn't cracking or torn, but had slumped slightly due to the weight of the engine.

Once that was loosely in place (it cant be fully installed until all the other bolts around it are tight, as it and the bracket that attaches to it are in the way) the freshly machined flywheel (with new bearing) was fitted. My paint pen is rubbish, but the marks on the new bolts indicate I have torqued them to spec.

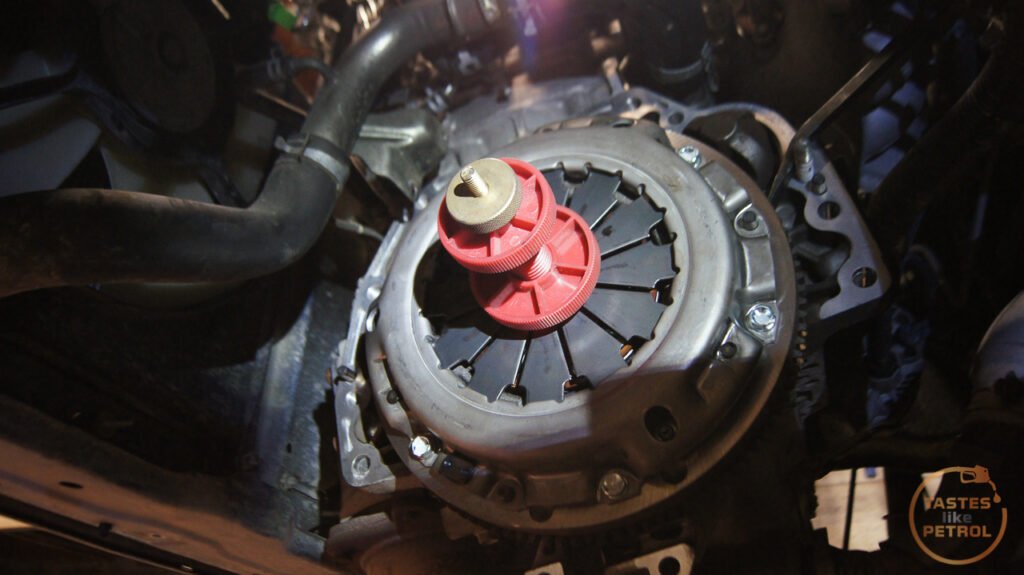

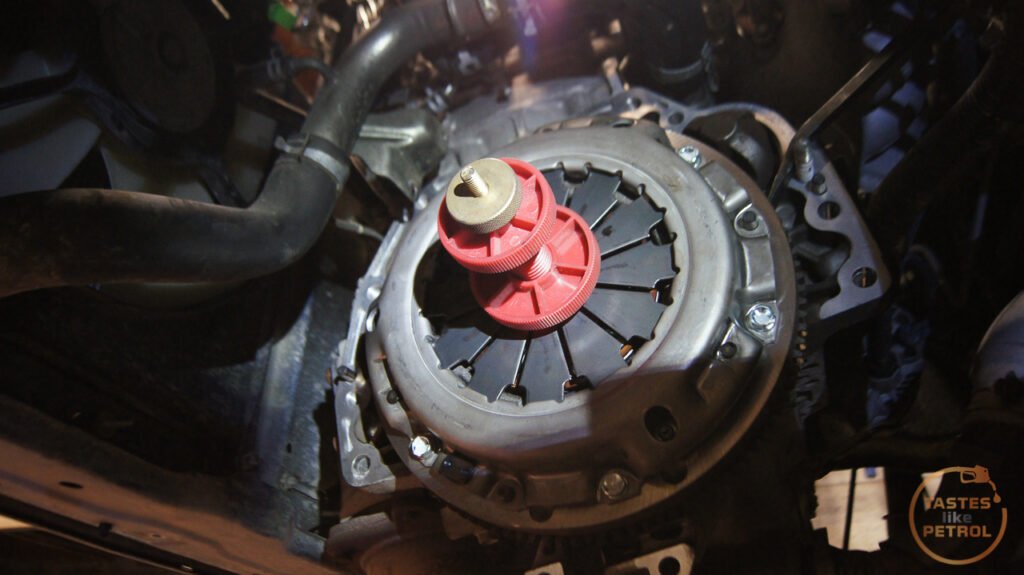

The new clutch getting ready to fit

And here you can see the recesses that had been worn down on the old clutch. That's quite a lot of material to be missing from the plate

The kit came with a spline type alignment tool but I prefer my old style universal one. It seems to be quite accurate. I tested the spline type one once the clutch was fitted and there was enough play in it that I could see it being annoying to use.

Now the gearbox could finally go back on. I tried the reverse of removal and lifted the gearbox up onto my torso and tried to bench press it into place, but it was getting hung up somewhere and my lack of upper body strength was starting to show, so I moved on from that technique. The tried and true jack it up and slip it on technique was the winner here, after a few tries. I found that it was easiest if I used the support bar to lower that end of the engine down about as far as it would go, as this put it on a steep angle and gave me more room to fit the gearbox in. Eventually, after some wiggling, the input shaft found its way through the clutch and it all slid together nicely.

All that was left was to do the reverse of disassembly. Install lots of annoying to get to bolts, line everything up, and refit all the gubbins. I made sure to clean and grease the splines on the outer CV joints when I refitted them so they come out easier next time.

Don't forget to fill the gearbox with your favourite flavour of GL4 oil in about 75W90 weight. Mine is Penrite, it just tastes better (and is a lot thicker than what came out).

Before I wrap up the clutch job, there are a few other things I was doing at the same time. One of them was to pull the front off the car and make it look far worse than before.

The bumper comes off really easily. Four bolts and two clips up top above the grille, three bolts on the underside, a few clips for the front guard liners, and then a screw on each side in the wheel arch going into the bumper retainer. It then unclips from the retainers and basically falls off.

There were two reasons for this work. One, was to replace (or in this case, fit) the ambient temp sensor as mine wasn't working, showing as a series of dashes on the temp display, and a lack of average fuel consumption display (it's a weird thing to be joined). I can't stand things that don't work.

It should be here, attached to wires that should be coming out of this sleeve. The sensor clips into that oval hole.

The wires are still there, thankfully, but either torn or cut off

I grabbed a sensor and a section of the loom a while ago from Pick A Part, so set about joining a new plug onto the remains of the loom. I cut the sleeve back, and stripped back the wires

The sensor just clips in

And because I'm lazy, I used these solder joiner sleeve things. The wiring here isn't critical, and will be wrapped in tape, so should be ok.

A final wrap in some loom tape, and zipped into the little zip tie fasteners, and it all plugged in nicely.

A quick test with a jump pack balanced precariously in the engine bay, and we finally had an ambient temp display (and on the test drive the average consumption came to life too)

The second task was to replace the headlights. Mine were very cloudy and very yellow. Didn't look too bad in photos but was horrible in person. They were also a bit dubious for the warrant check in a few months. I came across a pair of black housing halogen lights like mine on a local Facebook group, being sold due to upgrade, and they looked spotlessly clear, so I snapped them up.

These were the old ones. They are worse in person.

They are only three bolts each to remove

And the replacements.

It's not hard to see the difference. The only little quirk is that these are from an NZDM Swift Sport, which obviously didn't have electronic height control (via a dial, not automatic) as these didn't have the height control motors, and it looks like they couldn't be retrofitted. Not an issue though as they work fine as manual lights, and I hate the height control thing anyway as I never use it (designed for if you have a heavy load in the rear of the car, so you can dip the lights down further and not blind traffic). I'll get a blanking panel and pull the dial out of the dash at some point.

The bumper was refitted (as were the wheels, and being lowered to the ground), and it looked like a car again.

So, back to the clutch. With the car still up on the Quickjacks I checked that the clutch worked, and all the gears could be found, which they could, so on went the wheels and down onto the ground the car went. It was test drive time.

The first drive was just a short one around the block to make sure everything worked and nothing fell off. It was a good start, as the clutch felt good right off the bat. The pedal had a nice spring to it, and a bite point was dead center in the travel. Full disengagement was obtained way before the pedal was fully pressed, so no chance of the clutch dragging anymore. The new rubber pedal stop cushion makes for a nice gentle stop, as opposed to the old one which was completely mashed by having to press the pedal right to the floor and then some.

A quick spanner and leak check at home, and then another drive to get dinner. This time I covered a few more KM, and it's all working very well, as it should. It's taking a bit of getting used to as the clutch bites a lot firmer now, I didn't realise just how soft the old clutch engagement was; you could basically dump the clutch as quick as you wanted between gears. I still have 500km or so to bed the clutch in, so oh noooo, I will have to drive the car as much as possible and try and get the miles on it; what a shame.

Even with the new clutch, mount, hydraulics etc, it still cost me less than it would for the next cheapest Swift Sport in this condition, mileage and year.

I have a couple of modifications to fit soon, including a new rear muffler and some wider wheels. That'll come in the next instalment of Swifty fun times.

The work I did on the clutch hydraulics, and adding the missing bolt to the clutch pedal bracket, helped the clutch issues a bit, but it was far from perfect. It was drivable now, but the clutch still bit right off on the floor, had a really long engagement, almost no feel in the pedal and would drag if you didn't keep your foot planted on the pedal as hard as you could. Not to mention the engagement was a bit on the soft side.

I ordered an OEM replacement Exedy clutch kit, a new clutch fork (pre-empting a potential failure point), new fork bushes, and bolts for the flywheel and clutch cover (you can probably reuse the cover bolts safely, but the flywheel bolts must be replaced each time).

Last weekend I got stuck into removing the gearbox. The first job is to remove all the gubbins around the gearbox in the engine bay, so first the intake ducting comes out, then the coolant overflow bottle, followed by the battery and its hold down.

Next, the battery support needs to come out. There are three 10mm bolts on the base, and then the ECU can be disconnected, The ECU can remain attached to the support. The ECU plugs have a latching lever to lock them into place.

The shifter cables were next to go. These were a bit of a pain, and different to the videos I had seen of the UK cars. First, this clip needs to be removed (partly removed in photo). You need to lift the end the arrow is point to upwards to clear the locking piece, and then the clip can slide out, allowing you to lift the cap and cable off the shifter mechanism.

The other cable just levered out. It has a soft plastic bushing inside it, which remained on the mechanism for me, so I levered that off and inserted it back into the cable.

With the cables disconnected from the shifter mechanism, I needed to remove the cables from the gearbox. They are retained in this bracket.

This seems to be where the JDM cars differ from the UKDM ones. The cables on the JDM cars are retained to the bracket via a pair of metal clips with tangs that stop the cable from coming out.

I used a tiny flatblade screwdriver to press these tangs in so they were flush with the clip, and the cable could then be removed. I later bent the tangs back out before refitting.

With everything up top sorted, the engine was supported by my engine support brace (which was a pain on the Swift, as the engine bay is very short, so it had to almost go on the slam panel and gave very little space to work up top). The axles were then removed, which was also a pain as the outer CVs were seized in the hubs and needed to be smashed out with a sledgehammer. Before the axles were removed I was sure to drain the old gearbox oil, which was very dark, stank and was about as viscous as water; far too thin.

Finally, all the various (excessively tight) nuts and bolts around the gearbox, including the rear and LH mounts, were removed and the gearbox gently manhandled down to the ground, using my belly as support.

With the gearbox out it was immediately obvious what the issue was

The bellhousing was packed with old clutch dust, and the release fork and bearing barely moved by hand. It was all binding badly. The bearing was also really rumbly; no Bueno.

I removed the clutch and flywheel next.

Interestingly the clutch was already an Exedy, so either they are an OEM supplier, or the clutch has already been changed (from my research it appears it could have been the original OEM clutch plate; its slightly different to the aftermarket kit I got and the pressure plate has no markings)

You can see in the photo above that the plate is heavily worn, and almost down to the rivets. There are no signs of the diagonal recesses in the friction material that they have when new.

The flywheel had clumps of fibrous clutch material on it

Whilst the surface the clutch plate runs on had some bad heat spotting

During the week I sent the flywheel off to be machined, and it came back looking really nice

I also took the time to knock out the old top bush and remove the clutch fork. There is a special tool to remove this bushing, but I don't have one.

So I made do with what I had. The same job can be done with an old 5/8" spark plug socket, cut in half and the end with the square in it cut off. A section of pipe of the same OD would work too.

Combine this with a hammer and punch

And you can drive the seal and bush out

This high-tech tool may scratch up the surface of the clutch fork, which I'm replacing anyway, but do this at your own risk.

With the bushing removed, the clutch fork can then also be removed and after a clean, thoroughly inspected.

Due to a bad design where the welding is only halfway around the rod, they are prone to cracking at the ends of the weld, causing many issues, since this is what translates the movement in the hydraulic system from your foot, to actually moving the release bearing and pressing on the clutch pressure plate (which takes a lot of force).

Mine wasn't cracked and would probably be fine to reuse, but I wasn't taking the risk since I was already here. I had a replacement genuine part on hand, and it's good to see that Suzuki realised it was a flawed design and superseded it with a newer design that is fully welded.

I can only really come up with a couple of conclusions as to how this issue happened. The obvious one is that over time the factory fitted grease that should be on all the pivot points, but is now completely missing, wore away and was replaced with high friction clutch dust. This issue was compounded by the leaking slave cylinder, and the flexing pedal bracket which failed to allow the clutch to fully disengage, which caused even more clutch dust, and just bound up the fork and bearing. The alternate theory is the same, except when the clutch was replaced, the mechanic failed to grease the pivot points and it's been operating dry this whole time.

I don't know if the clutch was replaced, the car has no service history, so we can only speculate.

I cleaned out the bellhousing, and cleaned the lower bush. It appeared ok and cleaned up well, so I chose to reuse it rather than try and work out how to remove it.

The replacement fork had a new roll pin fitted

both bushes were lubed up, and the new fork fitted

I used the old bushing and another 5/8" spark plugs socket (complete this time) to drive the new bush in

Followed by the new seal

Lots of the fancy purple Exedy grease was used on the snout, input shaft and contact patches of the fork, and the new release bearing was fitted

The clutch fork more or less flops about and takes no force to move, which is a huge difference from how it was before.

While the gearbox was out, I took the opportunity to also replace the rear engine mount. There was some movement in the engine when coming on and off the throttle, and there would never be an easier time to get at the mount than now. The old one wasn't cracking or torn, but had slumped slightly due to the weight of the engine.

Once that was loosely in place (it cant be fully installed until all the other bolts around it are tight, as it and the bracket that attaches to it are in the way) the freshly machined flywheel (with new bearing) was fitted. My paint pen is rubbish, but the marks on the new bolts indicate I have torqued them to spec.

The new clutch getting ready to fit

And here you can see the recesses that had been worn down on the old clutch. That's quite a lot of material to be missing from the plate

The kit came with a spline type alignment tool but I prefer my old style universal one. It seems to be quite accurate. I tested the spline type one once the clutch was fitted and there was enough play in it that I could see it being annoying to use.

Now the gearbox could finally go back on. I tried the reverse of removal and lifted the gearbox up onto my torso and tried to bench press it into place, but it was getting hung up somewhere and my lack of upper body strength was starting to show, so I moved on from that technique. The tried and true jack it up and slip it on technique was the winner here, after a few tries. I found that it was easiest if I used the support bar to lower that end of the engine down about as far as it would go, as this put it on a steep angle and gave me more room to fit the gearbox in. Eventually, after some wiggling, the input shaft found its way through the clutch and it all slid together nicely.

All that was left was to do the reverse of disassembly. Install lots of annoying to get to bolts, line everything up, and refit all the gubbins. I made sure to clean and grease the splines on the outer CV joints when I refitted them so they come out easier next time.

Don't forget to fill the gearbox with your favourite flavour of GL4 oil in about 75W90 weight. Mine is Penrite, it just tastes better (and is a lot thicker than what came out).

Before I wrap up the clutch job, there are a few other things I was doing at the same time. One of them was to pull the front off the car and make it look far worse than before.

The bumper comes off really easily. Four bolts and two clips up top above the grille, three bolts on the underside, a few clips for the front guard liners, and then a screw on each side in the wheel arch going into the bumper retainer. It then unclips from the retainers and basically falls off.

There were two reasons for this work. One, was to replace (or in this case, fit) the ambient temp sensor as mine wasn't working, showing as a series of dashes on the temp display, and a lack of average fuel consumption display (it's a weird thing to be joined). I can't stand things that don't work.

It should be here, attached to wires that should be coming out of this sleeve. The sensor clips into that oval hole.

The wires are still there, thankfully, but either torn or cut off

I grabbed a sensor and a section of the loom a while ago from Pick A Part, so set about joining a new plug onto the remains of the loom. I cut the sleeve back, and stripped back the wires

The sensor just clips in

And because I'm lazy, I used these solder joiner sleeve things. The wiring here isn't critical, and will be wrapped in tape, so should be ok.

A final wrap in some loom tape, and zipped into the little zip tie fasteners, and it all plugged in nicely.

A quick test with a jump pack balanced precariously in the engine bay, and we finally had an ambient temp display (and on the test drive the average consumption came to life too)

The second task was to replace the headlights. Mine were very cloudy and very yellow. Didn't look too bad in photos but was horrible in person. They were also a bit dubious for the warrant check in a few months. I came across a pair of black housing halogen lights like mine on a local Facebook group, being sold due to upgrade, and they looked spotlessly clear, so I snapped them up.

These were the old ones. They are worse in person.

They are only three bolts each to remove

And the replacements.

It's not hard to see the difference. The only little quirk is that these are from an NZDM Swift Sport, which obviously didn't have electronic height control (via a dial, not automatic) as these didn't have the height control motors, and it looks like they couldn't be retrofitted. Not an issue though as they work fine as manual lights, and I hate the height control thing anyway as I never use it (designed for if you have a heavy load in the rear of the car, so you can dip the lights down further and not blind traffic). I'll get a blanking panel and pull the dial out of the dash at some point.

The bumper was refitted (as were the wheels, and being lowered to the ground), and it looked like a car again.

So, back to the clutch. With the car still up on the Quickjacks I checked that the clutch worked, and all the gears could be found, which they could, so on went the wheels and down onto the ground the car went. It was test drive time.

The first drive was just a short one around the block to make sure everything worked and nothing fell off. It was a good start, as the clutch felt good right off the bat. The pedal had a nice spring to it, and a bite point was dead center in the travel. Full disengagement was obtained way before the pedal was fully pressed, so no chance of the clutch dragging anymore. The new rubber pedal stop cushion makes for a nice gentle stop, as opposed to the old one which was completely mashed by having to press the pedal right to the floor and then some.

A quick spanner and leak check at home, and then another drive to get dinner. This time I covered a few more KM, and it's all working very well, as it should. It's taking a bit of getting used to as the clutch bites a lot firmer now, I didn't realise just how soft the old clutch engagement was; you could basically dump the clutch as quick as you wanted between gears. I still have 500km or so to bed the clutch in, so oh noooo, I will have to drive the car as much as possible and try and get the miles on it; what a shame.

Even with the new clutch, mount, hydraulics etc, it still cost me less than it would for the next cheapest Swift Sport in this condition, mileage and year.

I have a couple of modifications to fit soon, including a new rear muffler and some wider wheels. That'll come in the next instalment of Swifty fun times.

It has been a bit quiet on the Swift front, but with the annual WOF check looming, it was time to get it into the garage and get it ready.

The quietness has been both in terms of working on the car and also driving it. I put quite a few KM on it when I first got it, but recently it's been parked for weeks at a time without being touched.

One of the main reasons for this was that the rear tyres are bad. I ignored them long enough and then decided I needed to replace them before I drove the car again as I can't trust them.

They aren't even that old, date stamped 2015, and they're Falkens not some cheap ditchfinders, but the sidewalls are perished and cracking, there is cracking in the tread, and somehow there is a big crack/gash round the whole circumference of the tyre. This is all present on both sides. The tread is just above the wear markers too, so it's time for them to go regardless.

I had originally planned to get some different wheels, going so far as to buy a set of Nissan Skyline R32 GTST alloys, which look ace on these cars, but once Lucas came along I had to reign in the spending (they needed to be refurbished, repainted and four new wider than stock tyres) so they were quickly onsold and a pair of Yokohama ES32 in the stock size were purchased.

There is a bit of a shake in the car at around 80kph, so the plan is to have the rear tyres replaced, and all four wheels balanced.

That plan fell to bits when I replaced the clutch, as, during my use of a sledgehammer to free the axle from its home in the hub, I clipped a stud and made a slight mess of the threads. To keep the car on the road, after that work I just went full send on the rattlegun to get the nut back on.

I know, I know, that's a horrible thing to do. It was only temporary; a new stud was purchased, but with Lucas taking up all the garage space recently it's been hard to find the time to replace it. I couldn't in good conscience take the car to have the tyres done knowing one of the studs/nuts was buggered.

So, Lucas was outside again after all his work, so there was free space in the garage this weekend. It was Swift time. It helps to have a deadline; the WOF is booked for Wednesday.

I wanted to start with the job I knew was the most important to do, but would probably be the most annoying to do (little did it know...); the stud.

The nut came off fine, but there is an awful lot of metal in the thread of the stud

I removed the caliper and then tried to remove the disc, only to find it was rusted to the hub. Thankfully like Toyota, Suzuki has threaded holes in their rotors too. A pair of M8 bolts were sourced and threaded in

A couple of uggas and a single dugga with the rattle gun had the bolts press the disc off nicely

With the disc off, it was time to remove the damaged stud. Having done this before, using the balljoint press, I set about doing that method again.

Then its all turned to custard. Most cars have enough space, or maybe a small cutout, behind the hub in one spot to allow you to remove the studs on the car. This isn't the case on the Swift. The stud quickly ran into a solid lip once I had it moving.

You can see my solution to that in the above photo, I used the cutoff wheel to chop off the head of the stud off and it hammered out fine. The next problem was getting the replacement in; obviously I cant just cut the head off that and hammer it in.

The first modification applies to the stud itself. Using the bench grinder I flattened off one side of the head to allow it to pass that lip. Some studs come like this factory, to allow this work to be carried out on the car; not Suzuki though.

The second modification was the rotor backing shield and hub. I cut a section of the backing shield away, and using a flap disc took a small amount off the side of the hub to allow the stud to slip passed it.

It didn't need much, but it was just enough to slip the stud into place and use the balljoint press again to wind it home.

That took so much longer than it should have, and I'm glad only one stud was damaged as It was a pain in the arse. In hindsight, when using a BFH on the axle, pop some wheel nuts on the studs to protect them.

With that s tty job done I moved on to the next task; removing the front struts and replacing the top mounts.

tty job done I moved on to the next task; removing the front struts and replacing the top mounts.

I had quite a bad clunk from the front end when going over bumps, and the most common reason for that seems to be these top rubber mounts. They wear out and allow the strut to move up and down slightly.

I purchased a pair of replacement mounts and bearings and set about replacing them. First, you need to remove the wipers and plastic cowl trim.

I found quite a lot of built-up junk on one side of the scuttle panel. It was completely blocking the drain on one side, so that's not ideal.

A quick vacuum opened that up again. The otherside was clear, but it's a rubbish design.

I removed the two lower bolts to the knuckle, the brake hose, ABS sensor, and swaybar link. That left only the top nut holding the strut in. Once that was removed, the strut wiggles out of place.

The top mount is the big doughnut of rubber on the left of the strut.

Annoyingly, to remove this you need to compress the spring (well, youtube will show you don't have to, but I value not taking a mount to the face). Thankfully there isn't much tension on the spring, so one spring compressor did the job fine.

Then the top nut can be removed. You will need to use a hex key to stop the shaft from spinning.

It's just a matter of removing the old mount, removing the bearing, and fitting the replacements. I found this job was made a lot easier by using offset spanners. I only bought these recently after years of never using one, and they're becoming a regular part of my tool kit now.