Insulating suspended floor

Discussion

I know this has been done a few times but just looking for some confirmation/opinions

Will shortly be renovating the offiice in my 1950's cottage. its not a cold house per say but could do with all the help it can get. I havent had the floor boards up yet but looking at the external ground height/Air bricks im expecting should have a suitable gap underneath the suspended floor. theres an also an air brick from this room which faces an exposed side which faces the wind direction so happy there will be enough ventilation.

the room is 9m2

been lookg at rockwool/mineralwool type insulation vs PIR.

PIR performance wise would be optimal but the downsize being the cost and installation difficulty. Im not super confident i could get a airtight fit without the use of Gapotape (mega money) so the thermal performance benefit may be moot.

Wool seems the easier installation with the plan of breathable membrane creating a hammock over the joists, insulation chucked in and vapour control layer over the top.

basically following this guiide but planning to avoid the name branded jazz:

https://www.ecologicalbuildingsystems.com/post/bes...

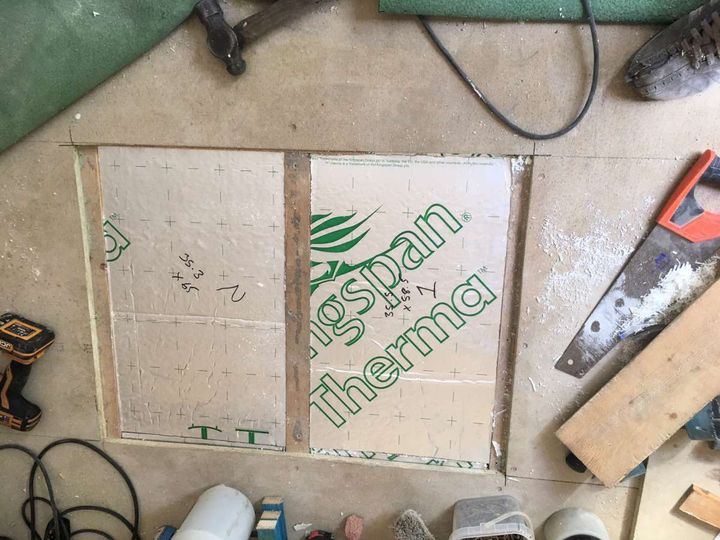

some images of what i am planning found elsewhere:

Any suggestions/opinions? is PIR really worth the cost/hassle per thickness, im presuming an aspect of the insulation will be draft reduction rather than pure thermal resistance.

im not really clued up on how all the EPC stuff type works in terms if you can get this included if can meet the regs which i think is 0,22 u value for retrofit

Will shortly be renovating the offiice in my 1950's cottage. its not a cold house per say but could do with all the help it can get. I havent had the floor boards up yet but looking at the external ground height/Air bricks im expecting should have a suitable gap underneath the suspended floor. theres an also an air brick from this room which faces an exposed side which faces the wind direction so happy there will be enough ventilation.

the room is 9m2

been lookg at rockwool/mineralwool type insulation vs PIR.

PIR performance wise would be optimal but the downsize being the cost and installation difficulty. Im not super confident i could get a airtight fit without the use of Gapotape (mega money) so the thermal performance benefit may be moot.

Wool seems the easier installation with the plan of breathable membrane creating a hammock over the joists, insulation chucked in and vapour control layer over the top.

basically following this guiide but planning to avoid the name branded jazz:

https://www.ecologicalbuildingsystems.com/post/bes...

some images of what i am planning found elsewhere:

Any suggestions/opinions? is PIR really worth the cost/hassle per thickness, im presuming an aspect of the insulation will be draft reduction rather than pure thermal resistance.

im not really clued up on how all the EPC stuff type works in terms if you can get this included if can meet the regs which i think is 0,22 u value for retrofit

I was concerned by 100+ yr old joists that were in perfect condition rotting due to promised vapour control breathability,not being that breathable, and the joists being effectively wrapped in something that if it did trap moisture would cause issue. As I was carpeting the room, I'd be blocking a lot of drafts anyway, so I took a more conservative approach.

I used open wire netting to create the hammocks, which are then stuffed with actual wool, with nothing above it.

It's not as perfect as what you proposed, but I was willing to forgo some heat for air movement around joists.

I used open wire netting to create the hammocks, which are then stuffed with actual wool, with nothing above it.

It's not as perfect as what you proposed, but I was willing to forgo some heat for air movement around joists.

Lotobear said:

A waste of time sticking a bit of loft roll between the joists when considering all of the other work involved. PIR, though clearly more expensive, would be the way to go if you wish to enjoy a real benefit.

Would you care to put some numbers to that?Joists are probably 6 inches?

6 inches of loft roll might well be enough that heat loss through it more or less falls out of the equation compared to other heat loss from the room.

The thermal bridging by the joists probably gets significant?

Bearing in mind that heat tends to rise rather than head for the floor, and the void under the house is probably rarely really cold.

There are risks in insulating the joists with something non-breathable.

If the void is deep enough to allow inserting whole sheets of PIR under the joists it might be optimal?

I did the whole house ground floor a couple of years back

But the house was built on a concrete raft and I had a 2 to 3 ft crawl space under the floor - it took me months to do it all from underneath but we had a lot of either tiled floor surfaces or 25mm Oak flooring which I really didn't want to destroy so process was

1. Make a hole in the one floor where it was carpet

2. crawl in from a hatch - scoot around on a garage floor creeper

3. Measure the gaps between the joists - scoot back to the hatch and climb out

4. Cut 75mm foil covered PIR "man handle to destination" creeper time

5. Fit section hold up with cut tile batten (foam fill any gaps - to be honest I only used 1 tin of expanding foam for the whole job and not all of it either and the floor area was 52 m2)

I started with this

Cut to size and installed

The pile got smaller and smaller

Eventually I got to fill the access hole before re-instating the floor above

And then having destroyed the carpet - I fitted 25mm Oak flooring to the whole room

(I still have access under the floor and I've been under to check no dampness down there but it was never suitable to slide 1.2 or 2.4 m lengths of 75mm PIR cos it's under the stairs)

It has made a massive difference to the house heat loss and room comfort - no drafts at all now

But the house was built on a concrete raft and I had a 2 to 3 ft crawl space under the floor - it took me months to do it all from underneath but we had a lot of either tiled floor surfaces or 25mm Oak flooring which I really didn't want to destroy so process was

1. Make a hole in the one floor where it was carpet

2. crawl in from a hatch - scoot around on a garage floor creeper

3. Measure the gaps between the joists - scoot back to the hatch and climb out

4. Cut 75mm foil covered PIR "man handle to destination" creeper time

5. Fit section hold up with cut tile batten (foam fill any gaps - to be honest I only used 1 tin of expanding foam for the whole job and not all of it either and the floor area was 52 m2)

I started with this

Cut to size and installed

The pile got smaller and smaller

Eventually I got to fill the access hole before re-instating the floor above

And then having destroyed the carpet - I fitted 25mm Oak flooring to the whole room

(I still have access under the floor and I've been under to check no dampness down there but it was never suitable to slide 1.2 or 2.4 m lengths of 75mm PIR cos it's under the stairs)

It has made a massive difference to the house heat loss and room comfort - no drafts at all now

Hi

I did my whole ground floor last year.

Similar idea with a breathable but waterproof membrane suspended between the joists, infilled with 100mm PIR. With care (and 'persuasion'') you can get a reasonable fit

I had all the floor up and replaced all the nails with screws. We've had Amtico put back down on top, so no air leakage upwards.

I think that the fact that the joists are open to atmosphere below should mean that they shouldn't get damp,as long as you keep the air bricks clear. I had to shape the PIR round these under my floor to prevent obstruction.

My approach was to do the best job possible with my own skillset. The floors are coming back up for nothing!

I think I worked out that I would have needed about 8" of rockwool to get the same level of insulation.

If using PIR you will need to set aside a whole room/shed etc for cutting as the dust and mess can be considerable, unless you have professional tools for cutting and dust extraction.

In hindsight I think I would go for the maximum possible thickness of rockwool if I were doing it again, but I am very happy with the end product.

Ironically, the money I saved on this was spent having an arthroscopy on a damaged knee, caused (probably) by all the kneeling work!

Good luck!

I did my whole ground floor last year.

Similar idea with a breathable but waterproof membrane suspended between the joists, infilled with 100mm PIR. With care (and 'persuasion'') you can get a reasonable fit

I had all the floor up and replaced all the nails with screws. We've had Amtico put back down on top, so no air leakage upwards.

I think that the fact that the joists are open to atmosphere below should mean that they shouldn't get damp,as long as you keep the air bricks clear. I had to shape the PIR round these under my floor to prevent obstruction.

My approach was to do the best job possible with my own skillset. The floors are coming back up for nothing!

I think I worked out that I would have needed about 8" of rockwool to get the same level of insulation.

If using PIR you will need to set aside a whole room/shed etc for cutting as the dust and mess can be considerable, unless you have professional tools for cutting and dust extraction.

In hindsight I think I would go for the maximum possible thickness of rockwool if I were doing it again, but I am very happy with the end product.

Ironically, the money I saved on this was spent having an arthroscopy on a damaged knee, caused (probably) by all the kneeling work!

Good luck!

If you are planning on staying in the house then use gapotape and PIR boards. It's sooo much better and worth the money - the real cost is the time doing the job and if you are going to spend the time, then I would definitely do it the better way.

Once you've squeezed the tape and boards into the not straight gaps, you see why they say it's 5X better than no gapotape or rockwool.

Here was one of the last threads on this topic with some pics of what I did : https://www.pistonheads.com/gassing/topic.asp?h=0&...

I still haven't fitted the rad back in our hallway after insulating under the floorboards and while it got a little bit chilly out there during the cold snap the other week, beforehand it would have been baltic. Proper underfloor insulation makes a massive difference to the room temps imho.

Once you've squeezed the tape and boards into the not straight gaps, you see why they say it's 5X better than no gapotape or rockwool.

Here was one of the last threads on this topic with some pics of what I did : https://www.pistonheads.com/gassing/topic.asp?h=0&...

I still haven't fitted the rad back in our hallway after insulating under the floorboards and while it got a little bit chilly out there during the cold snap the other week, beforehand it would have been baltic. Proper underfloor insulation makes a massive difference to the room temps imho.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff