When a standard 987 just won't do... Track/Race/Turbo Build

Discussion

After more than ten years of E36 tinkering, many engine iterations and lots of seat time from track days to racing, it was time so start something new. An accident in the E36 at Cadwell Park in April 2023 was the ultimate deciding factor for this. The car was repairable, but it's fate was already decided - break it for parts and retain what I needed, then sell the rest to fund the next project.

It's final spec is listed in the video description if you are interested. The platform and interchangeability of the M5x engine parts will never go away, but fun was had and it was time to move on.

|

|  |

|  |

|

The remainder of 2023 went by, slowly stripping the E36, and after a few months going back and forth over options decided on a Cayman.

I wanted an un-modified 987.1 Base, for a couple of reasons - the 2.7s are less desirable and cheaper for that, secondly I wanted to go slower bringing the fun of track days back in line with the rest of the group for the time being. The E36 became too quick in comparison, and you would simply be driving round on your own. The track day fun factor had gone. In time I would realise you really do have to ring the neck of the 2.7 to make it work, and really think about the cars momentum round a lap - something that is easily overlooked when you have plenty of power like many modern cars do. The engine can always be changed and/or power added down the line...

In reality it's coming up to 2 years from when I started on this build, and many people have asked am I posting updates anywhere... In years gone by I did when there were a lot of active forums all over the internet, but now it seems PH is the only real one left, so here we are. There is a lot to deal with on an 18 year old Porsche to bring it to a level that I was happy with.

At the time of starting this thread, the car has done 15x track days since being built, and has gone through many improvements and changes... as you're about to find out.

December 2023

After looking at a few Caymans and them not being right for the plans I had, eventually one came up that fit the requirements. I wasn't set on colour, but did not want silver or black. This was mechanically standard, recently having waterpump and new crossover pipes, with decent history and an owner replacing it with a newer model. Deal was done and I brought it back on the trailer.

January 2024

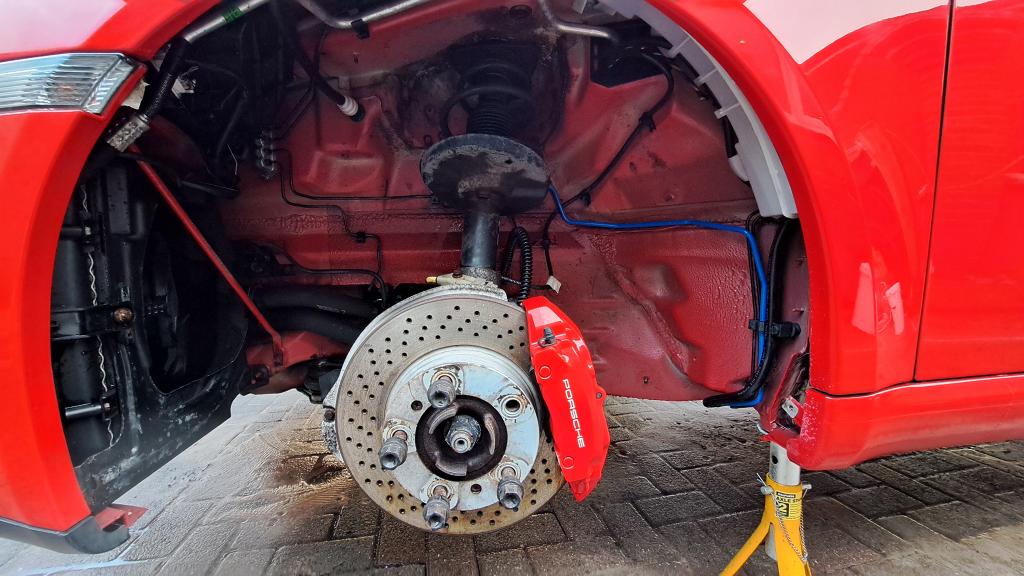

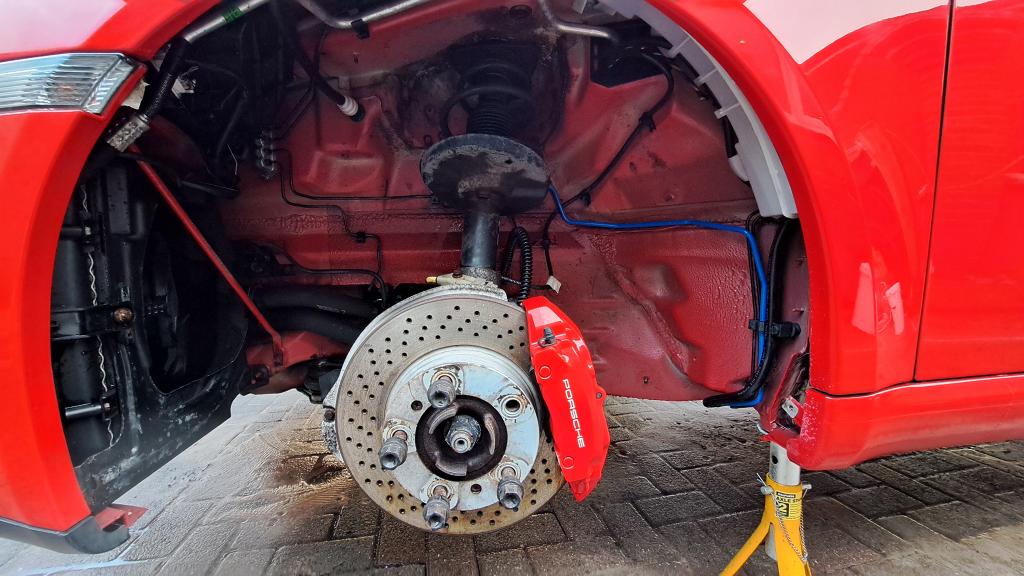

First thing was to get the car in the air and clean the underside, remove the arch liners and clean the lifetime of grime - decent enough body condition for a ~18 year old car.

Next was to strip it back to rolling shell, without the engine, gearbox, brakes, fluids, electrics, glass or anything else.

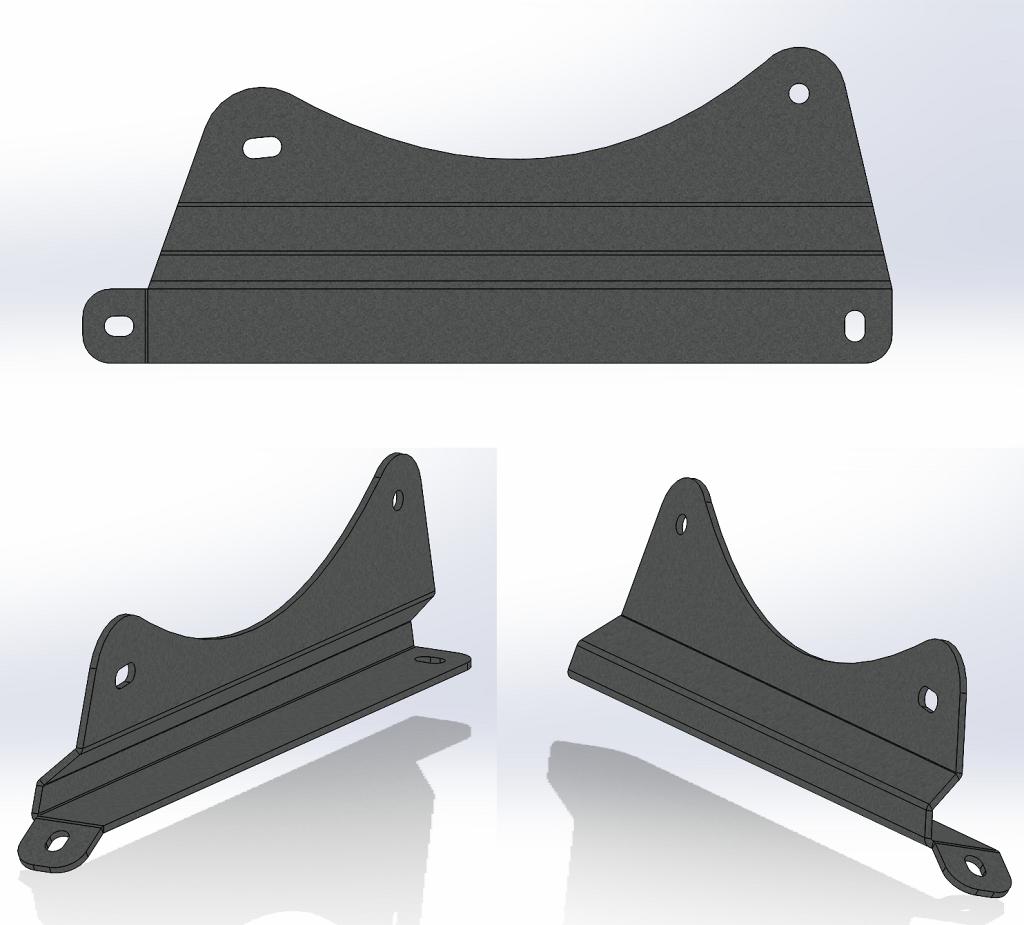

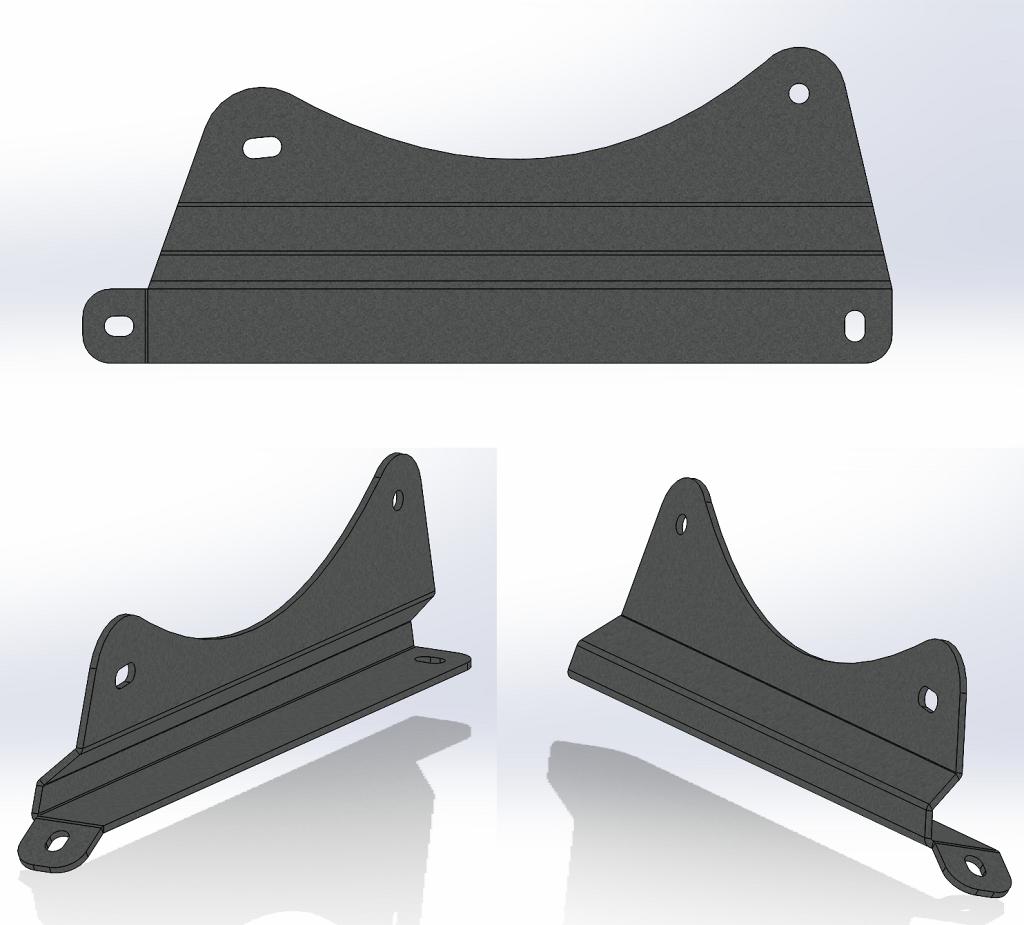

Between stripping the car back, some time was spent drawing up seat mounts to suit the seats I already had, and utilize the stock mounting points. I wanted it to go for a cage with the seat installed, to ensure everything would fit in relation to main hoop, roof diagonal and door bars with the 987 being quite narrow internally, at least when compared to an E36.

After a few variations I settled on a position, as close to the tunnel as possible so the seats wing cleared the window, and then laser cut/CNC folded the mounts from 4mm mild steel. I hate flimsy, wobbly seat mounts.

Any brackets that would be no longer required were removed, and the dash bar significantly cut down to only retain the steering column mount, which will be tied into the cage.

The shell could then be loaded up and dropped off...

It's final spec is listed in the video description if you are interested. The platform and interchangeability of the M5x engine parts will never go away, but fun was had and it was time to move on.

|

|  |

|  |

|

The remainder of 2023 went by, slowly stripping the E36, and after a few months going back and forth over options decided on a Cayman.

I wanted an un-modified 987.1 Base, for a couple of reasons - the 2.7s are less desirable and cheaper for that, secondly I wanted to go slower bringing the fun of track days back in line with the rest of the group for the time being. The E36 became too quick in comparison, and you would simply be driving round on your own. The track day fun factor had gone. In time I would realise you really do have to ring the neck of the 2.7 to make it work, and really think about the cars momentum round a lap - something that is easily overlooked when you have plenty of power like many modern cars do. The engine can always be changed and/or power added down the line...

In reality it's coming up to 2 years from when I started on this build, and many people have asked am I posting updates anywhere... In years gone by I did when there were a lot of active forums all over the internet, but now it seems PH is the only real one left, so here we are. There is a lot to deal with on an 18 year old Porsche to bring it to a level that I was happy with.

At the time of starting this thread, the car has done 15x track days since being built, and has gone through many improvements and changes... as you're about to find out.

December 2023

After looking at a few Caymans and them not being right for the plans I had, eventually one came up that fit the requirements. I wasn't set on colour, but did not want silver or black. This was mechanically standard, recently having waterpump and new crossover pipes, with decent history and an owner replacing it with a newer model. Deal was done and I brought it back on the trailer.

January 2024

First thing was to get the car in the air and clean the underside, remove the arch liners and clean the lifetime of grime - decent enough body condition for a ~18 year old car.

Next was to strip it back to rolling shell, without the engine, gearbox, brakes, fluids, electrics, glass or anything else.

Between stripping the car back, some time was spent drawing up seat mounts to suit the seats I already had, and utilize the stock mounting points. I wanted it to go for a cage with the seat installed, to ensure everything would fit in relation to main hoop, roof diagonal and door bars with the 987 being quite narrow internally, at least when compared to an E36.

After a few variations I settled on a position, as close to the tunnel as possible so the seats wing cleared the window, and then laser cut/CNC folded the mounts from 4mm mild steel. I hate flimsy, wobbly seat mounts.

Any brackets that would be no longer required were removed, and the dash bar significantly cut down to only retain the steering column mount, which will be tied into the cage.

The shell could then be loaded up and dropped off...

February 2024

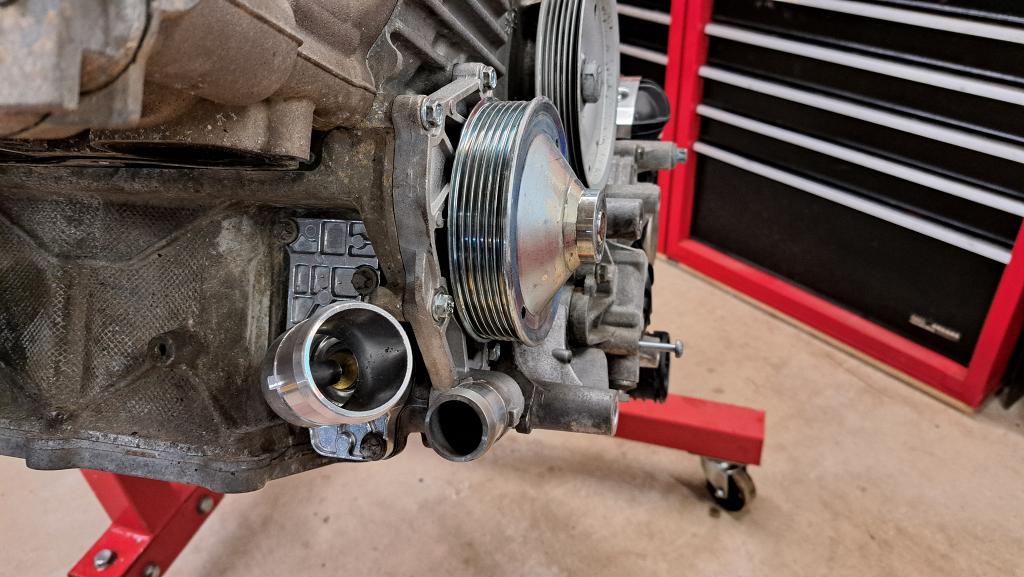

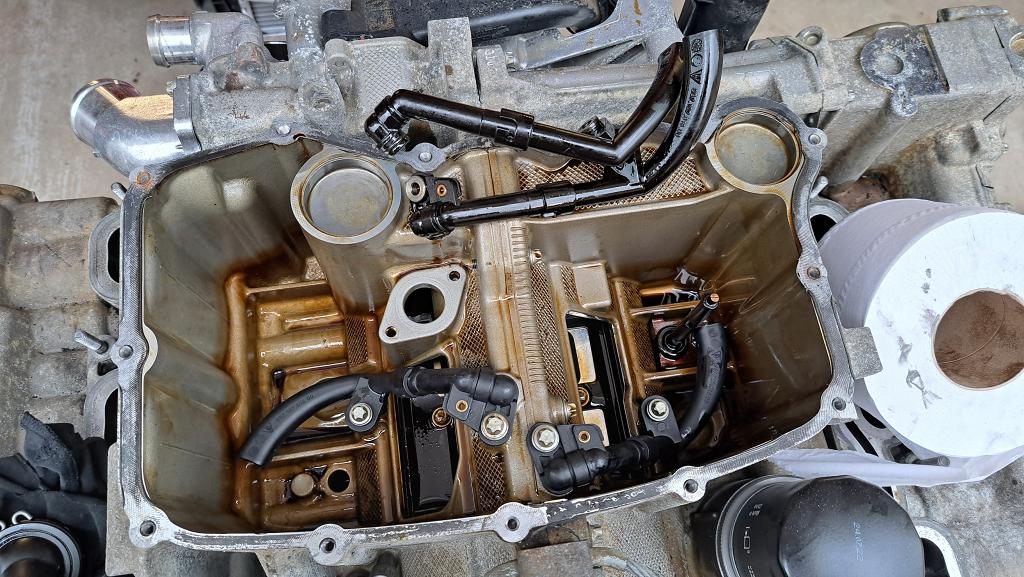

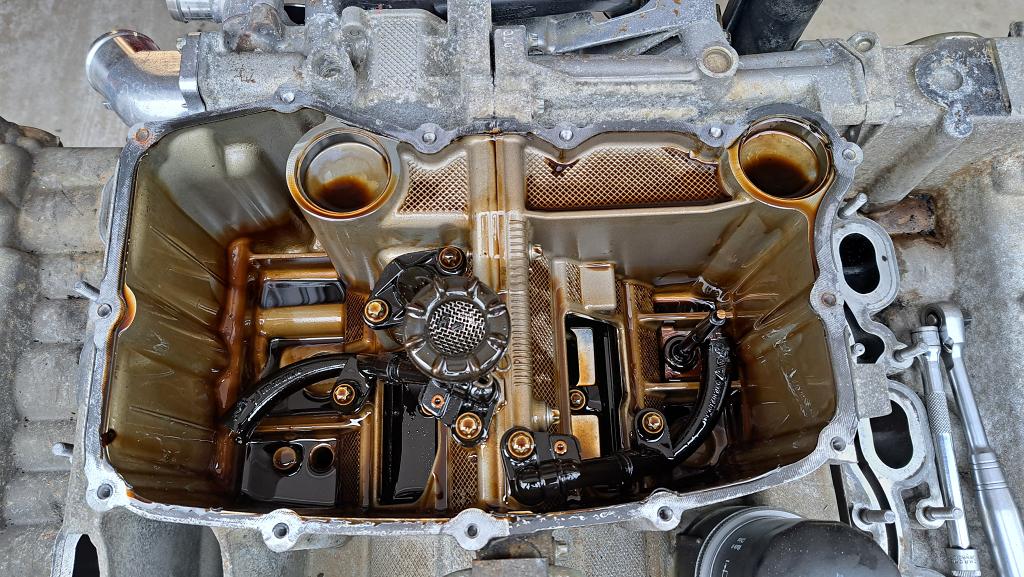

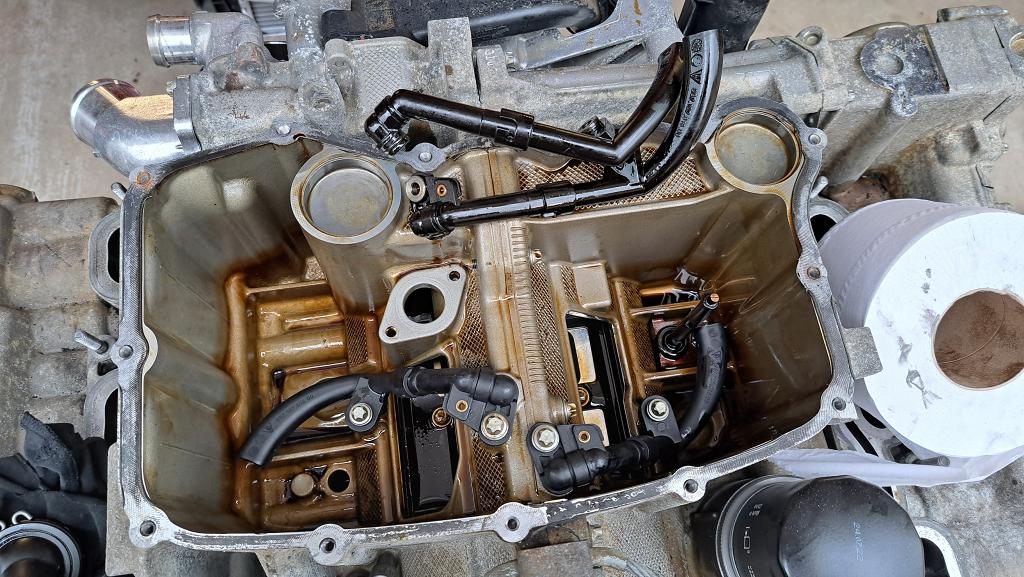

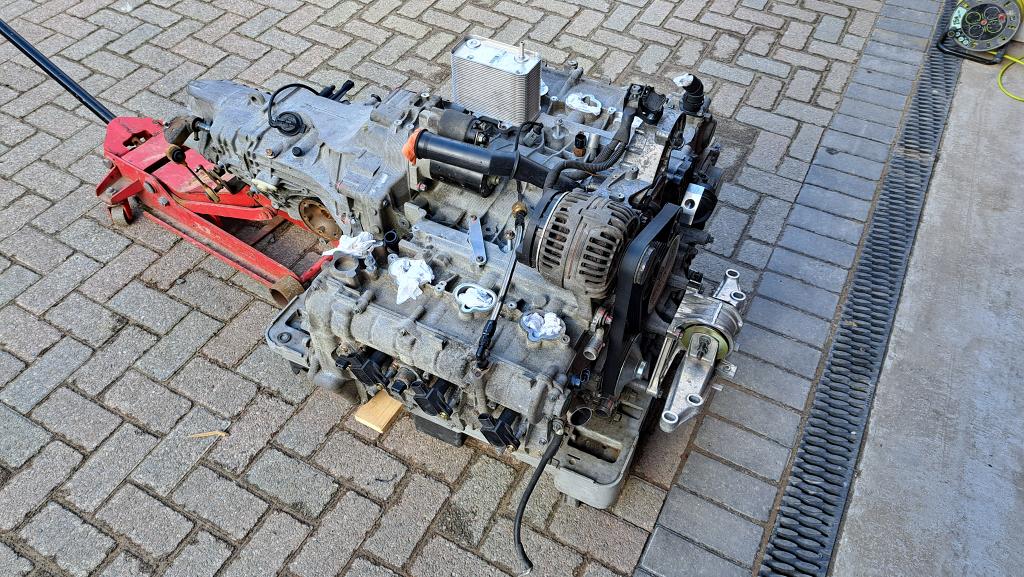

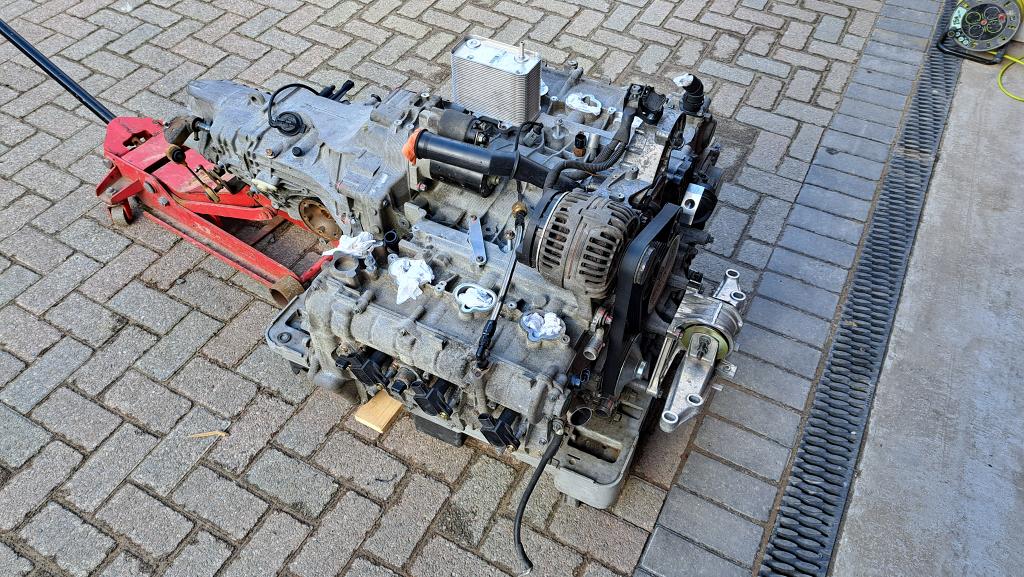

Attention was turned to cleaning up the un-touched 90k mile M97.20 engine whilst the shell was away.

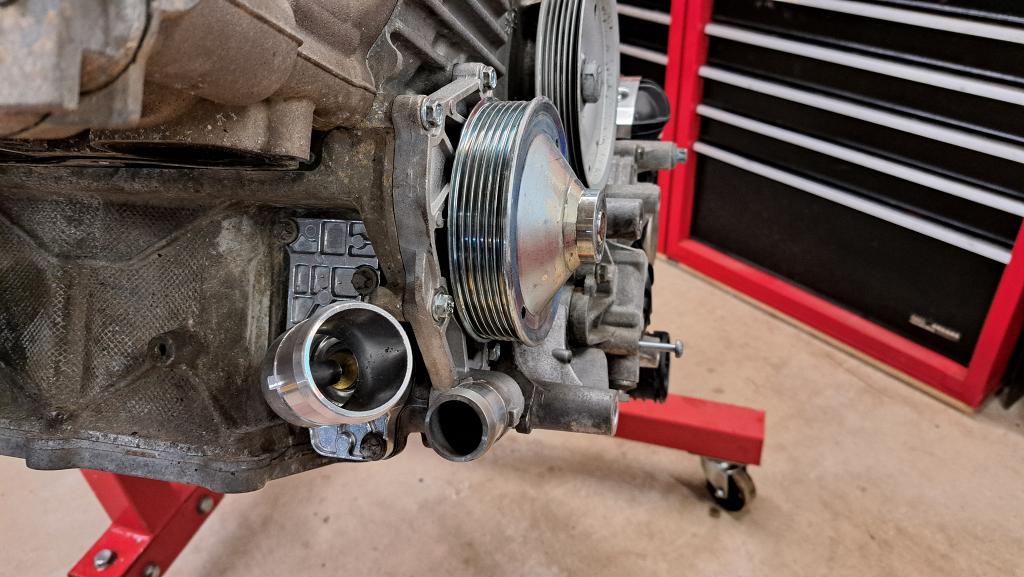

The AC compressor, original oil cooler and power steering pump would no longer be used. The secondary air pump was removed and blanked with new gaskets.

New low temperature thermostat installed, the waterpump had been recently replaced.

The engine will be ran with a standalone ECU, so the two VarioCam Plus solenoids were tested for approximate current draw just to be sure the ECU could drive them. No issues there.

The standard oil filter cartridge was replaced with a spin on filter adaptor. This was for two reasons, firstly the fact the standard filter setup does not have a non-return valve, and secondly I wanted to run a sandwich plate for additional sensors directly on the output side of the filter.

As many will know with M96/M97 engines, the exhaust bolts just snap off leaving an incredibly fun job in situ. However with the engine out, no such issue removing the 4x that snapped for me and replacing them all with studs.

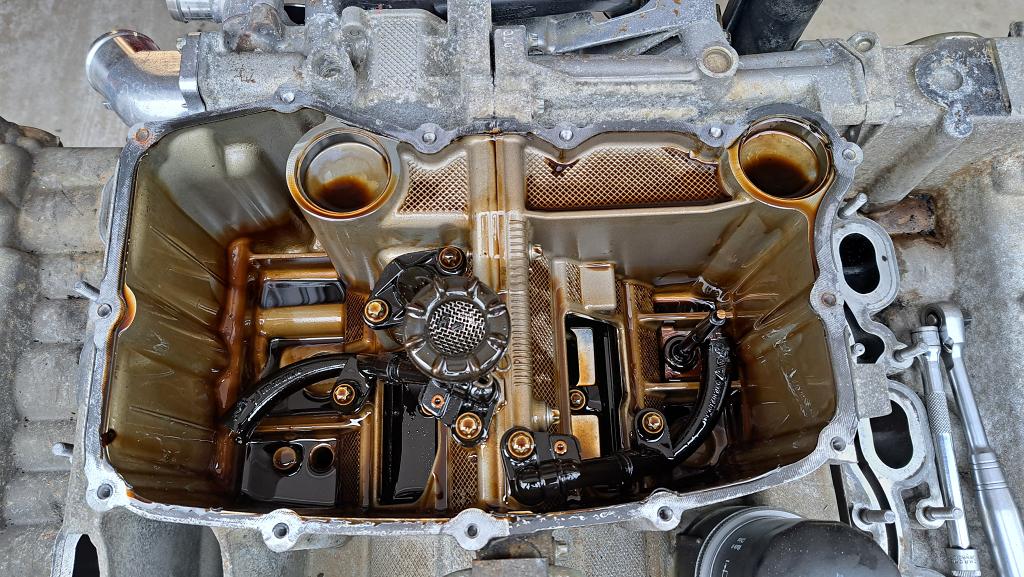

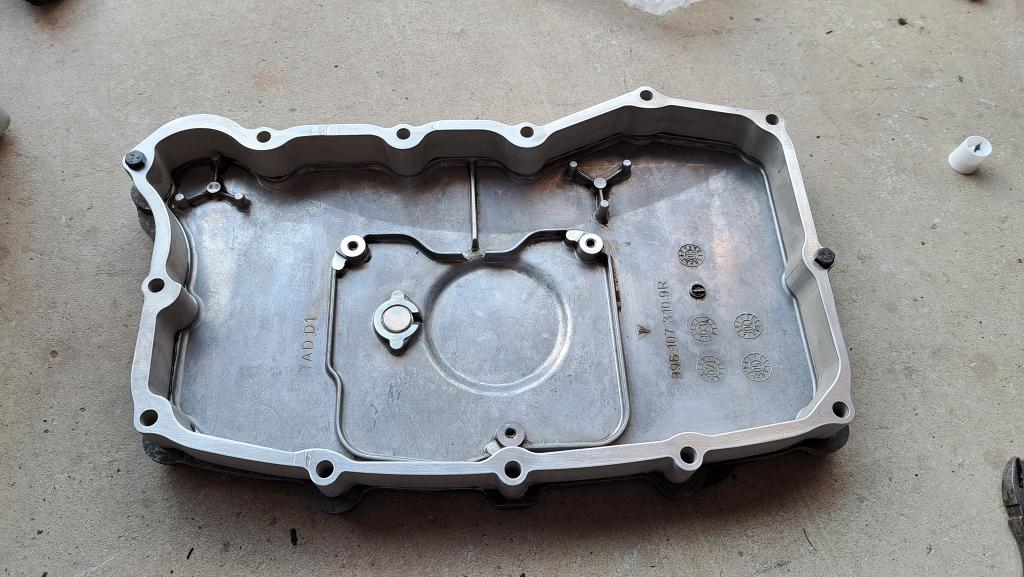

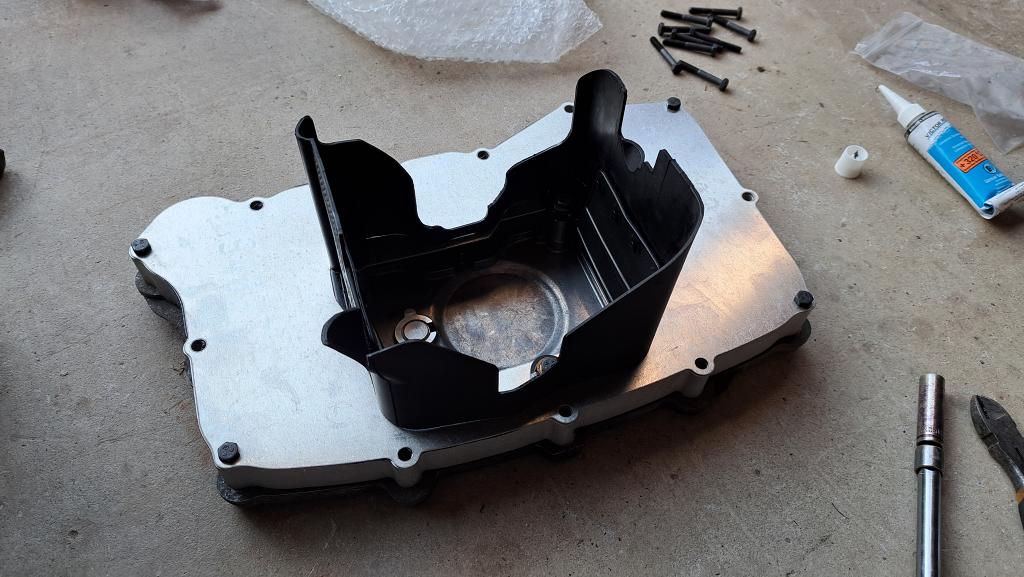

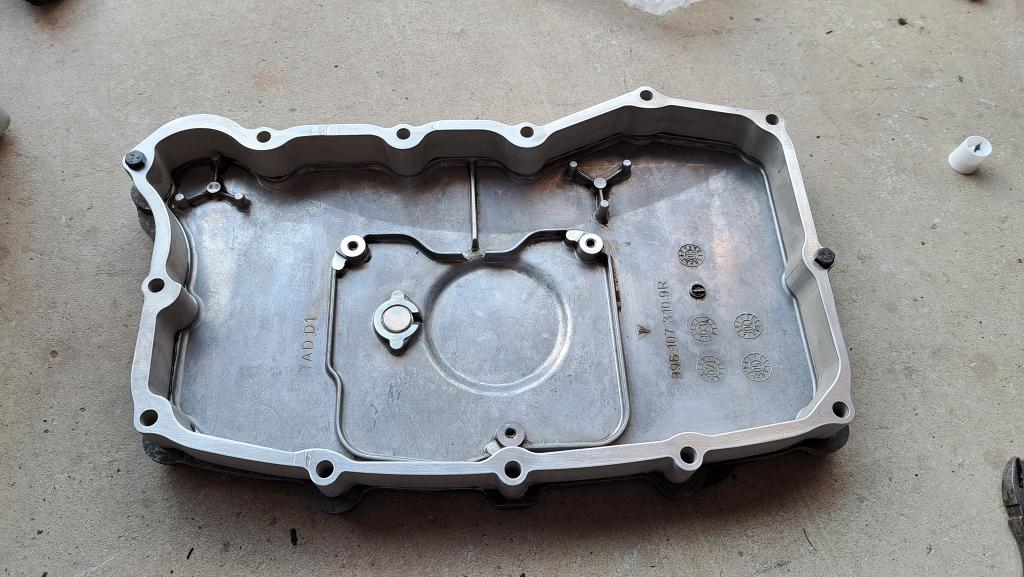

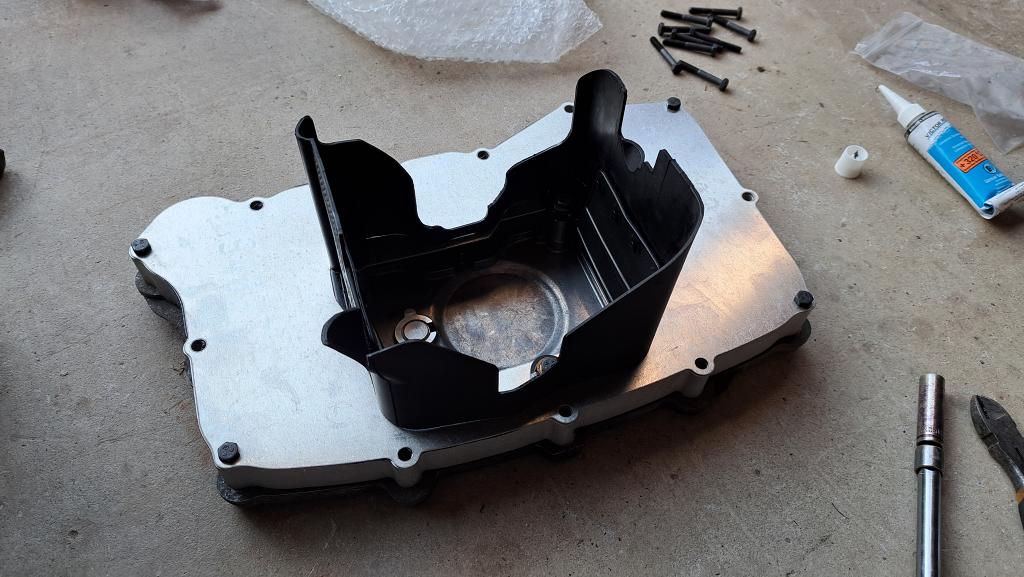

The original sump could then be removed and cleaned, new oil return tubes installed and deep sump extension fitted, sealed with Reinzosil.

Finally a Mahle CLC61000P (997 3.8) oil cooler was installed with new o-rings, the largest you can fit under the standard inlet manifold.

Attention was turned to cleaning up the un-touched 90k mile M97.20 engine whilst the shell was away.

The AC compressor, original oil cooler and power steering pump would no longer be used. The secondary air pump was removed and blanked with new gaskets.

New low temperature thermostat installed, the waterpump had been recently replaced.

The engine will be ran with a standalone ECU, so the two VarioCam Plus solenoids were tested for approximate current draw just to be sure the ECU could drive them. No issues there.

The standard oil filter cartridge was replaced with a spin on filter adaptor. This was for two reasons, firstly the fact the standard filter setup does not have a non-return valve, and secondly I wanted to run a sandwich plate for additional sensors directly on the output side of the filter.

As many will know with M96/M97 engines, the exhaust bolts just snap off leaving an incredibly fun job in situ. However with the engine out, no such issue removing the 4x that snapped for me and replacing them all with studs.

The original sump could then be removed and cleaned, new oil return tubes installed and deep sump extension fitted, sealed with Reinzosil.

Finally a Mahle CLC61000P (997 3.8) oil cooler was installed with new o-rings, the largest you can fit under the standard inlet manifold.

macron said:

You do not mess about!

Good effort, looking forward to more!

Considerable amount more to come yet!Good effort, looking forward to more!

Disintegrating coil packs seem to be the norm on the entire 996/986/997/987 era engines, the ones on this engine were quite bad, but it still ran without any sign of an issue before removal.

I had already decided to switch to Denso coil packs (as used on many Hondas) for a number of reasons before finding the above. They are cheap, super reliable and have excellent dwell characteristics when using standalone management.

Having ran them for years across E36/M5x engines I already had multiple sets, so when they lined up with the existing mounting point on the M97 head it was meant to be.

New spark plugs went in and the coil packs just needed a small stand off for the mounting depth difference, along with fresh hardware to replace any original rusty bolts.

The tired original front engine mount bushing was removed and a Powerflex Black insert installed.

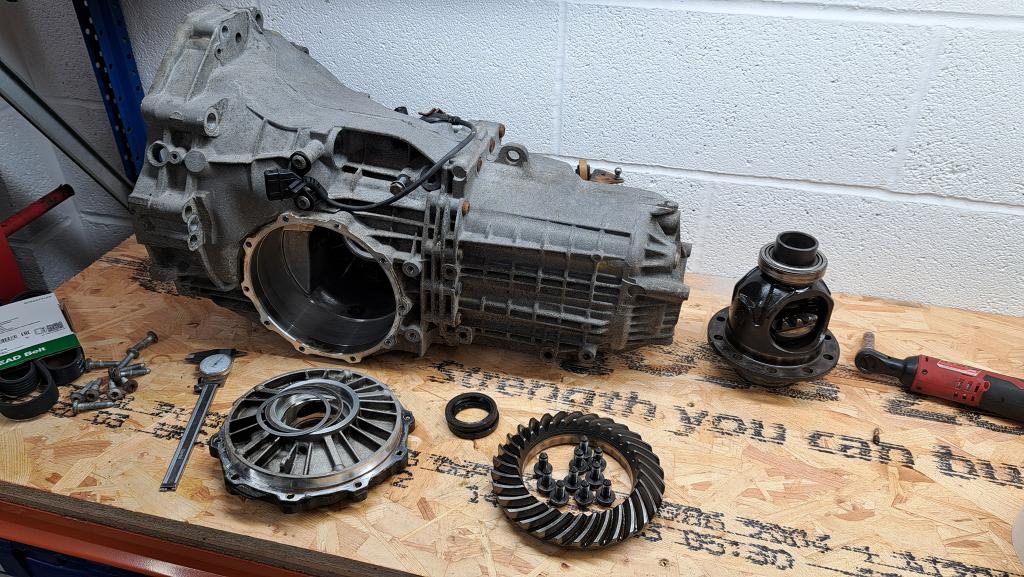

Up to this point everything was going smoothly. With the engine changes made, the gearbox was next. When looking for the right 987.1 base model, I had to decide between the standard 5 speed, or optional 6 speed gearbox. After some internet research I decided to go for the 5 speed, as it is essentially a VW/Audi transaxle and parts from other gearboxes of the same era (Passat, A4, etc) are compatible. In hindsight, this would come back to bite in a huge way down the line - both that compatability claim and the fact I event went for a 5 speed in the first place.

Considering this car will only ever be used on a circuit, an LSD was non-negotiable. In my E36 I used a Kaaz 1.5 Way Plate LSD, which was great for many years and had no issues. Unfortunately at the time, they were quoting a 5-6 month lead time, which would surpass the target for this car to be out on track pre-summer. I decided to go for a Gripper instead, as we have used them in the past on many different cars and had no issues. They list both a 5 speed and 6 speed Cayman variant. I ordered the 5 speed, with the specification I wanted and a few weeks later it arrived...

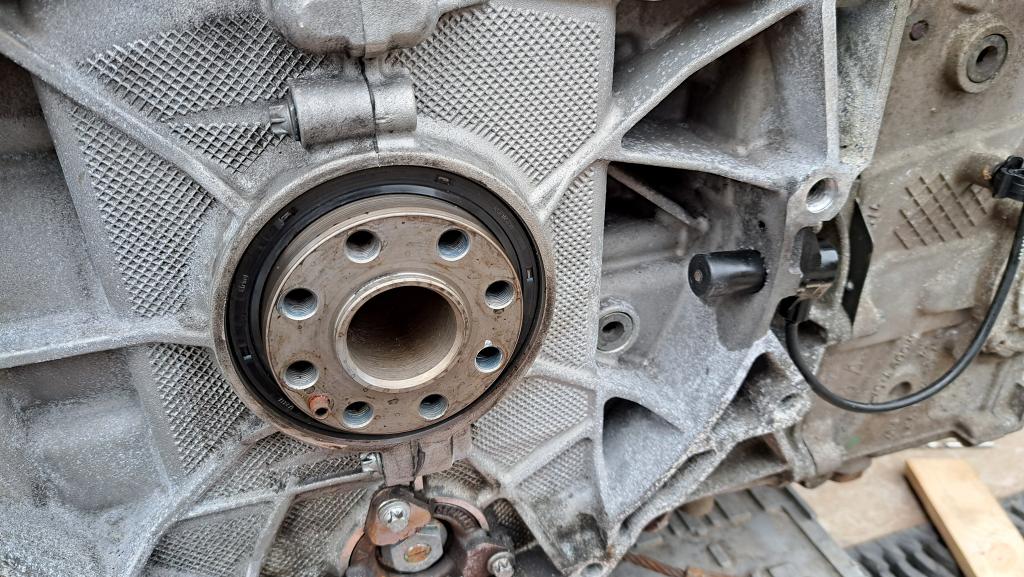

The original differential was stripped out of the gearbox, then bearings/crownwheel removed.

Putting the two differentials side by side, the first issue was apparent. The output flange internal diameters were completely different sizes...

Naturally, I thought you are meant to remove the original inner support bearing from the 5 speed output flange, as it looked to be about the right size for the bore.

No, that wont fit either.

After speaking with Gripper, I shipped them the LSD back, along with the original differential and the flanges. Maybe there was a manufacturing issue?

Around a week later everything arrived back. They explained the bores had been adjusted to the correct size for the flanges, and that the flanges had to be trimmed in length so they would fully snap in to the unit.

In hindsight, if this wasnt a red flag at the time I don't know what is...

I had new bearings for both sides of the case ready to go along with new seals. One bearing is only available from Porsche directly, which appears to be the same used in some DSG boxes, however the other can be purchased anywhere.

Replacement shims would be required to get the gear pattern correct, but initially the outer races were installed with the original shims so I could work out what thicknesses to order from Porsche.

Ring gear was baked in the oven for 15 minutes then dropped on to the unit, then torqued up.

The inner bearing races could then be pressed on...

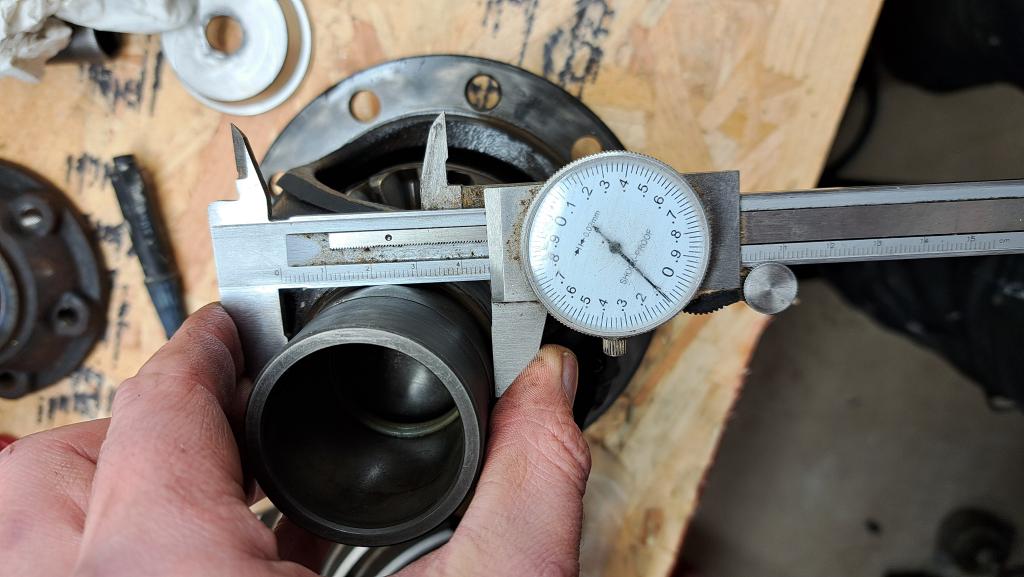

The other side, well? Initial thought, had I ordered the wrong bearing?

Check the basics, measure the original differential and compare. Gripper is the wrong size.

My immediate thought - they had both differentials (without bearings) and all parts to correct the first mistake, yet this somehow got missed.

I spent a few hours cross referencing all bearing part numbers and sizes from the Porsche/VAG parts system, and concluded that all 5 speeds had the same bearings, which is what I had ordered.

It still had not clicked, but the previous red flag with the flanges and now this, something wasn't right. I decided to have a look at what Quaife listed for the 987, as they also provide CAD drawings with dimensions for their products. Right there, in black and white, were two drawings of both 5 and 6 speed differentials showing considerable differences - one being the bearing size, and the other more critically being the offset of the ring gear in relation to the pinion. It was now crystal clear, Gripper had sold me a 6 speed unit, and not a 5 speed as they list in their catalog.

I put all this information together on an e-mail to Gripper, along with the Quaife drawings with the differences highlighted, the bearing part numbers and sizes. After a week with no response, phoning and leaving messages for a phone call back, I had no other choice but to drive to Coventry with all the parts, including the gearbox, to sort this once and for all. At this point it had been going on for nearly a month.

After turning up, and introducing myself, I still had no response to the e-mail clarification even though I was told it had been seen. After a short discussion, I simply don't think anyone has fitted one of their units to one of these 5 speeds before (would love to know if someone has!), with the 6 speed being so much more common. I left everything with them with the instruction to 'sort it' one way or another. Around a week later, I had a notification from DHL that a parcel was due from Gripper, which arrived. However, no contact from Gripper themselves with any explanation?

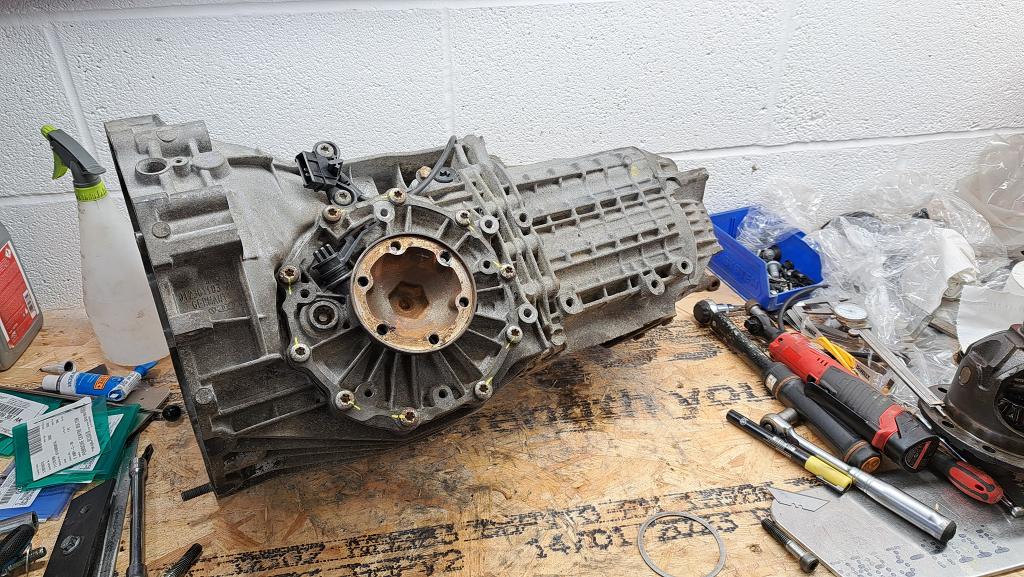

The ring gear face had been machined to correct the offset, matching the original unit. The incorrect bearing diameter had also been adjusted, along with both bearing seats, to correct the position of the unit inside the gearbox.

Take notice of the ring gear bolt markings too from where I previously torqued it down, and how they are not central on the drilled holes. Yes you got it, another issue is the ring gear PCD is different between the 5 and 6 speed!

Regardless, the ring gear went back on along with the inner bearings. I started working out what shims I needed from Porsche, ordered them and got to an acceptable gear pattern on both sides of the crown wheel, with backlash in spec.

The side case could then be sealed back on and torqued up, along with a new seal and passenger side output flange snapped in to place.

Flip the box over and install the new seal...

Finally install the drivers side flange - actually wait, sorry you can't do that. The flange hits the gearbox casing before it will snap in to the differential! Yes, another problem.

With the bearing seats and crownwheel offsets having material removed with its second visit to Gripper, the whole differential unit has moved over inside the gearbox by approximately 3mm. THere was absolutely no way this was coming apart to go back to them again, so the required amount was machined from the back of the flange ourselves to create enough clearance and allow the flange to snap in correctly.

Normally I probably wouldn't post about the issues like this, but I think it's only fair to publically state my experience so other people can avoid the same in this scenario, especially if you want an LSD for your 5 speed 986/7.

They are great products with excellent performance, but they simply do not manufacture a 5 speed LSD for the 987, even though it's listed for sale. The way this was dealt with was incomprehensible, compounded by the fact I had to go there in person to get a response after the initial issues. Things may have changed, but throughout the whole process the responses and discussions I had, it clearly felt like I was the issue and not the product, when in fact it was the product all along.

Super interested to see this progress, it sounds like a nightmare with the diff. I had a quaife diff fitted to the 6 speed on my 996 but I know these can be a little unpredictable on track. Good luck getting it resolved.

Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

Edited by shalmaneser on Saturday 18th October 08:01

shalmaneser said:

Super interested to see this progress, it sounds like a nightmare with the diff. I had a quaife diff fitted to the 6 speed on my 996 but I know these can be a little unpredictable on track. Good luck getting it resolved.

Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

After the initial build issues the diff has been fine and functioned as expected for the past 18 months, but yes for dedicated track use a plate diff will outperform a helical.Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

Edited by shalmaneser on Saturday 18th October 08:01

The 'Rohler' deep sump is installed as pictured and using the original baffle, nothing additional, just how it came. This was more of a 'install it and see what actually happens' in real terms on sticky tyres with good suspension. From the beginning I have logged oil pressure in three locations on the engine (filter and both cylinder heads), and over the 15x days there is some surge in specific conditions.

In my case it's usually only seen under very tight slower speed corners (Cadwell Park and the bus stop at Spa are good examples). It has not been enough to cause an issue (yet), and it is something I do keep an eye on. I have just made sure the oil level remains on the higher side at all times. The same problems exist with the E36/M5x platform even with a baffled sump, however it's usually under heavy braking and tight cornering with those.

Do you log anything to do with oil pressure on yours, or just have it on a gauge?

March 2024

The cage needed to allow access to both engine panels, but still have a double diagonal main hoop with harness bars to suit the seats I use. This was done along with all other requirements like the dash bar, roof diagonal, door bars and making the main hoop and a-pillar bars as tight as possible to the shell, being welded where possible. I could have taken it through to the front strut towers but when you consider the construction of the front firewall/tub/chassis I didn't think it was required for my use - added weight and expense I don't really need.

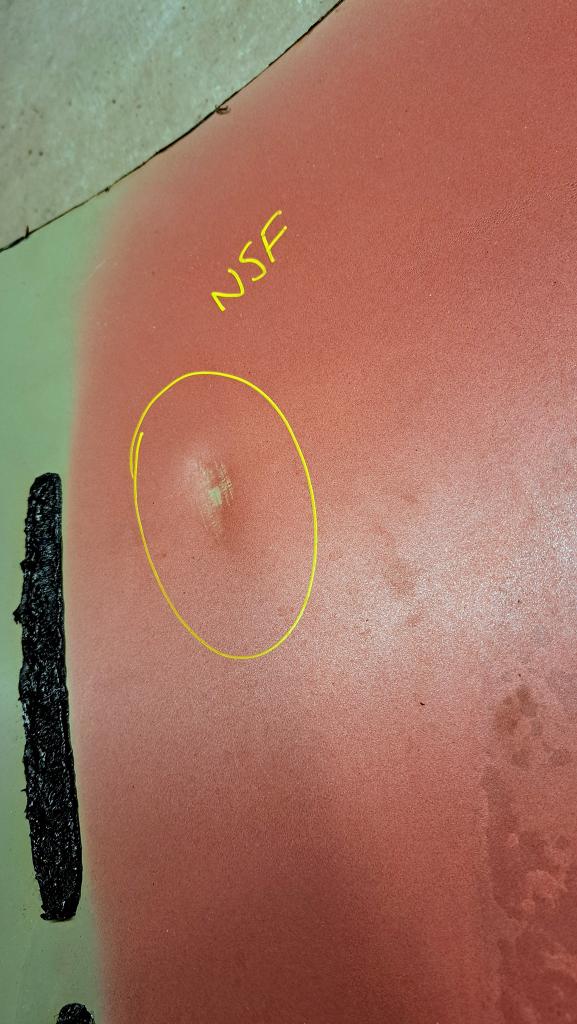

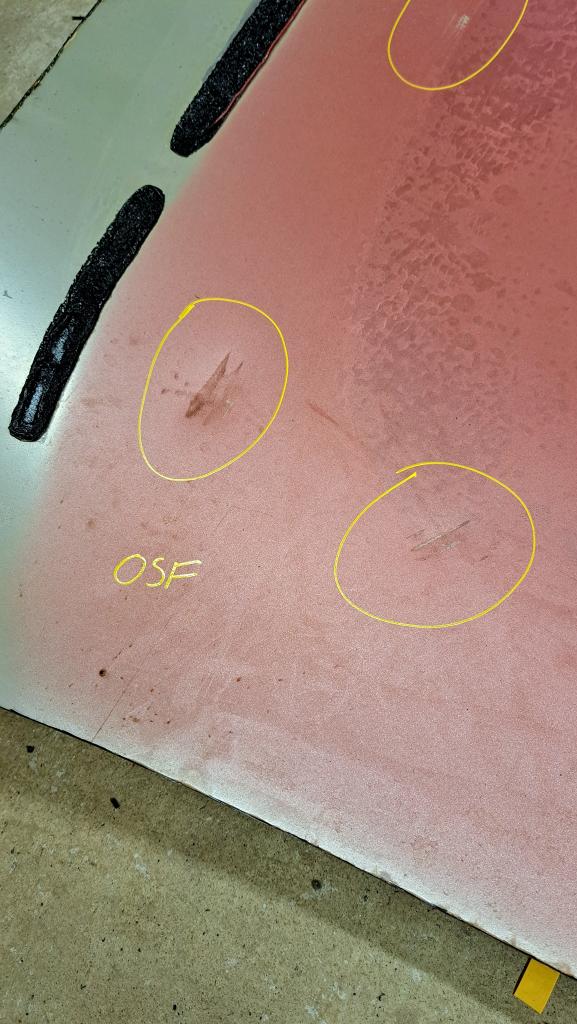

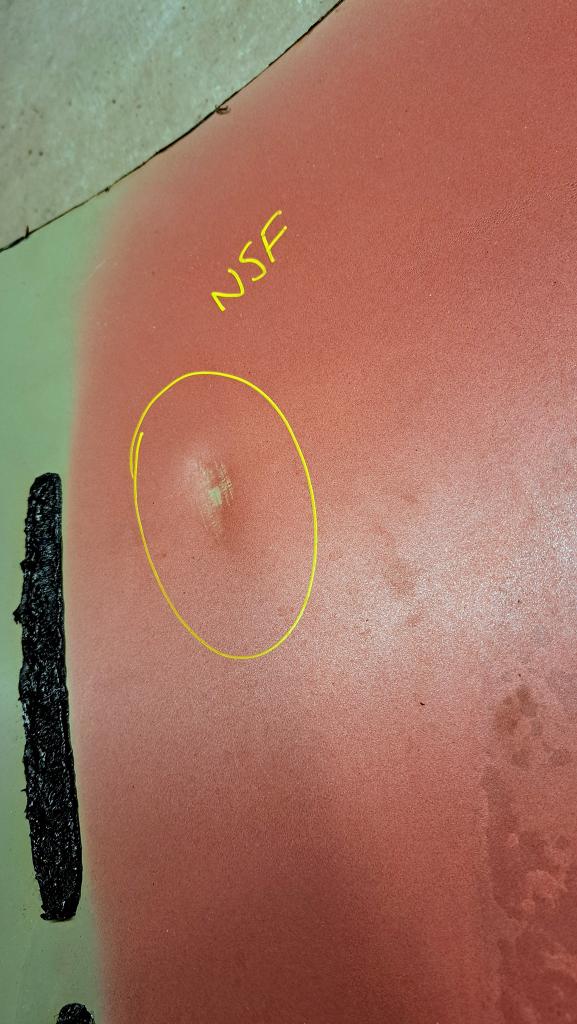

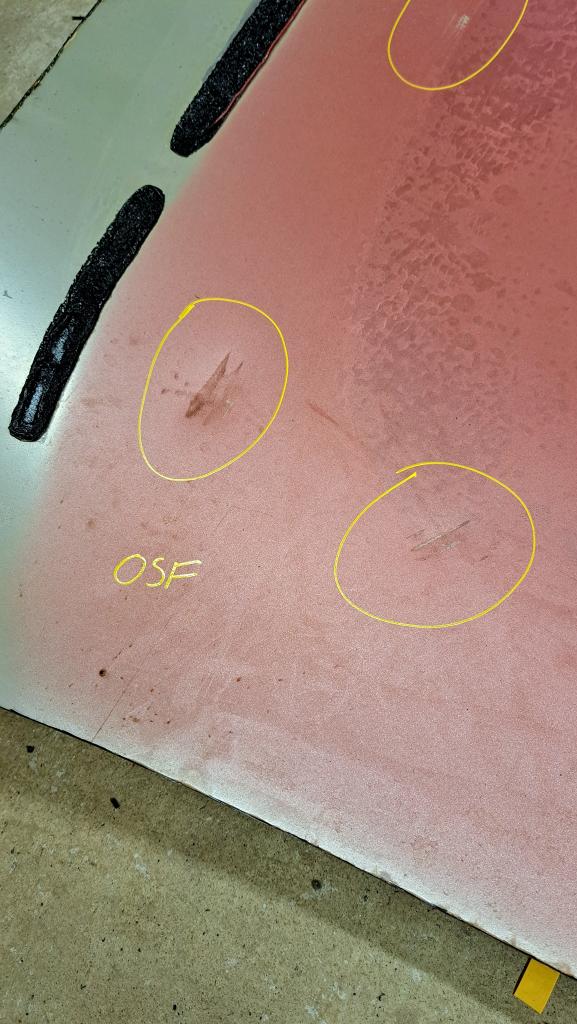

Picking the shell up covered in dust, and only really being interested in looking at the cage itself, I didn't notice the roof had been damaged until I got it back under the lights in the garage. Unfortunately it had been dented outwards in five places, during the process of the cage being constructed - I can only assume when the cage has been dropped down to weld the top bars and lifted back up into position. Someone was aware this had happened, as one of the dents had been rubbed marring the paint, however it was never mentioned on collection.

At this point I was at a loss with continual issues (mainly the differential), I knew that it would never be right again, even if a PDR could get it something like, which was unlikely as the cage was too high to allow the skin to be pushed back down.

The cage itself was exactly as requested and the quality of fabrication excellent, however let down by this basic mistake and what I assume the hope I wouldn't notice.

In a moment of madness, I decided to remove the roof skin instead.

Revealing the impact marks of the dents...

However if anything this made it easier to prepare the cage and interior. Seam sealer was applied where necessary and any required holes drilled before paint (harness eyelets, brackets, etc).

Then the next day got everything covered with some paint.

In the meantime I had ordered a replacement carbon roof skin, which (suprisingly) was in UK stock. This turned up very well packaged.

A few hours was spent trimming and getting the fit correct. It was then bonded in place and original body colour roof rail trims re-installed.

The cage needed to allow access to both engine panels, but still have a double diagonal main hoop with harness bars to suit the seats I use. This was done along with all other requirements like the dash bar, roof diagonal, door bars and making the main hoop and a-pillar bars as tight as possible to the shell, being welded where possible. I could have taken it through to the front strut towers but when you consider the construction of the front firewall/tub/chassis I didn't think it was required for my use - added weight and expense I don't really need.

Picking the shell up covered in dust, and only really being interested in looking at the cage itself, I didn't notice the roof had been damaged until I got it back under the lights in the garage. Unfortunately it had been dented outwards in five places, during the process of the cage being constructed - I can only assume when the cage has been dropped down to weld the top bars and lifted back up into position. Someone was aware this had happened, as one of the dents had been rubbed marring the paint, however it was never mentioned on collection.

At this point I was at a loss with continual issues (mainly the differential), I knew that it would never be right again, even if a PDR could get it something like, which was unlikely as the cage was too high to allow the skin to be pushed back down.

The cage itself was exactly as requested and the quality of fabrication excellent, however let down by this basic mistake and what I assume the hope I wouldn't notice.

In a moment of madness, I decided to remove the roof skin instead.

Revealing the impact marks of the dents...

However if anything this made it easier to prepare the cage and interior. Seam sealer was applied where necessary and any required holes drilled before paint (harness eyelets, brackets, etc).

Then the next day got everything covered with some paint.

In the meantime I had ordered a replacement carbon roof skin, which (suprisingly) was in UK stock. This turned up very well packaged.

A few hours was spent trimming and getting the fit correct. It was then bonded in place and original body colour roof rail trims re-installed.

f0xy said:

shalmaneser said:

Super interested to see this progress, it sounds like a nightmare with the diff. I had a quaife diff fitted to the 6 speed on my 996 but I know these can be a little unpredictable on track. Good luck getting it resolved.

Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

After the initial build issues the diff has been fine and functioned as expected for the past 18 months, but yes for dedicated track use a plate diff will outperform a helical.Regarding the deep sump have you fitted the appropriate baffle too? It looks like the original baffle which isn't super effective... The x51 version is better and even with that fitted I still see some surge on track, just make sure there aren't gaps for the oil to flow around with the dropped sump.

Edited by shalmaneser on Saturday 18th October 08:01

The 'Rohler' deep sump is installed as pictured and using the original baffle, nothing additional, just how it came. This was more of a 'install it and see what actually happens' in real terms on sticky tyres with good suspension. From the beginning I have logged oil pressure in three locations on the engine (filter and both cylinder heads), and over the 15x days there is some surge in specific conditions.

In my case it's usually only seen under very tight slower speed corners (Cadwell Park and the bus stop at Spa are good examples). It has not been enough to cause an issue (yet), and it is something I do keep an eye on. I have just made sure the oil level remains on the higher side at all times. The same problems exist with the E36/M5x platform even with a baffled sump, however it's usually under heavy braking and tight cornering with those.

Do you log anything to do with oil pressure on yours, or just have it on a gauge?

shalmaneser said:

Well the proof is very much in the pudding and if you're not seeing issues then is sounds like you're doing ok! I don't log oil pressures but I must admit it would be a pretty easy little electronics project to set up an Arduino connected to the sensor and log it on track. I have the x51 sump which is just an improved baffle and flaps, and run the oil slightly over max which is recommended on track also. No issues as such just some distracting movement out of the corner of my eye mid corner!

I'll look in to the X51 and different ones available - touch wood no issues with the current engine even in its current state. I have only ever ran at or slightly under max with Millers 5w50 since the start, normally stable 100-105C oil temperatures on a 30-40min outing. I started out using Arduino logging on previous projects, but with the work I had to do in relation to the 997/987 CAN during this build I went a little more custom, more details to come on that.Bright Halo said:

Looking really good!

The roof dent issue is annoying. Why can t people just own up to their errors?

Anyway the carbon roof looks great. So a good result (not for your wallet!) in a round about way.

I know, especially when the cage work itself was great. It wasn't too expensive, in stock and under £500 from D911 at the time. They do still list them, albeit slightly more expensive now.The roof dent issue is annoying. Why can t people just own up to their errors?

Anyway the carbon roof looks great. So a good result (not for your wallet!) in a round about way.

BertBert said:

definitely enjoying the build, what a project!

On the topic of OP data lagging what setup do you use to do that?

Cheers

Bert

In previous projects I would log using off the shelf products (RT Dash2Pro, ECUMaster EDL, etc), but there would always be something that didn't work when you needed it to, or log when you had an issue/failure... corrupt files, missing sessions, limited to number of channels (unless you pay for an additional licence?), and so on...On the topic of OP data lagging what setup do you use to do that?

Cheers

Bert

I decided to essentially build my own logging solution for this project, so now I'm a few revisions along on a custom PCB using an ESP32 SoC, I have no limitations and it has been ultra reliable for the past two years. I'll cover it in more detail as the thread goes on, and it will make sense why I've had to make new revisions along the way.

Edited by f0xy on Sunday 19th October 20:22

TV8 said:

Wow, that is some build you are doing there. I am wondering if I bought the 987 seats from you - they came out of a Cayman being converted for track use. Collected from a house near St Albans.

Unfortunately won't have been me! I'm around the Oulton Park area in the NW. The seats from this went to a local 996

williamp said:

great build!

what did you do with the parts you took off? trim etc?

I listed the majority of it on eBay, some has sold, some is still in the loft! Some parts I no longer required were worth a considerable amount, working cup holders being the most surprising!what did you do with the parts you took off? trim etc?

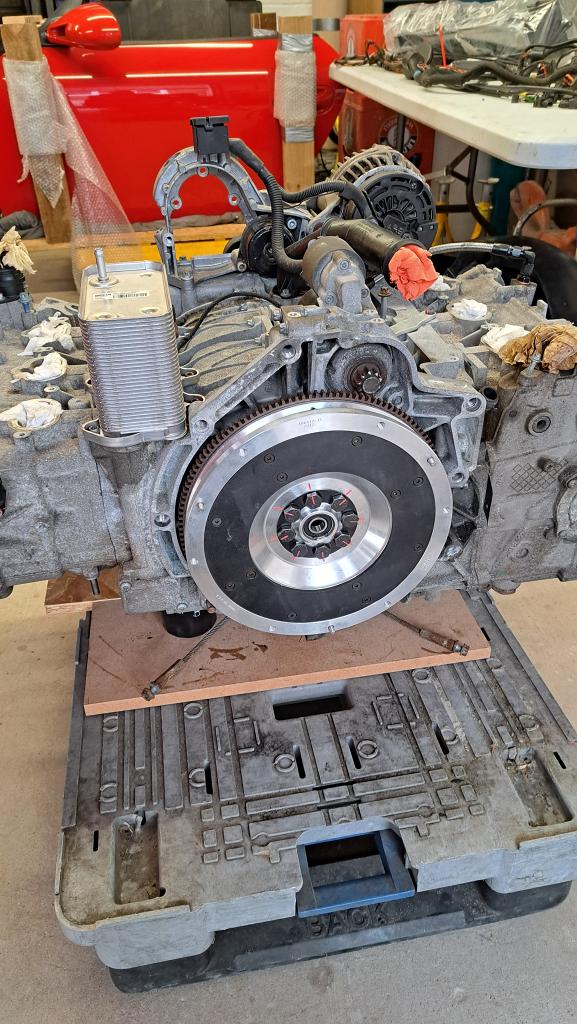

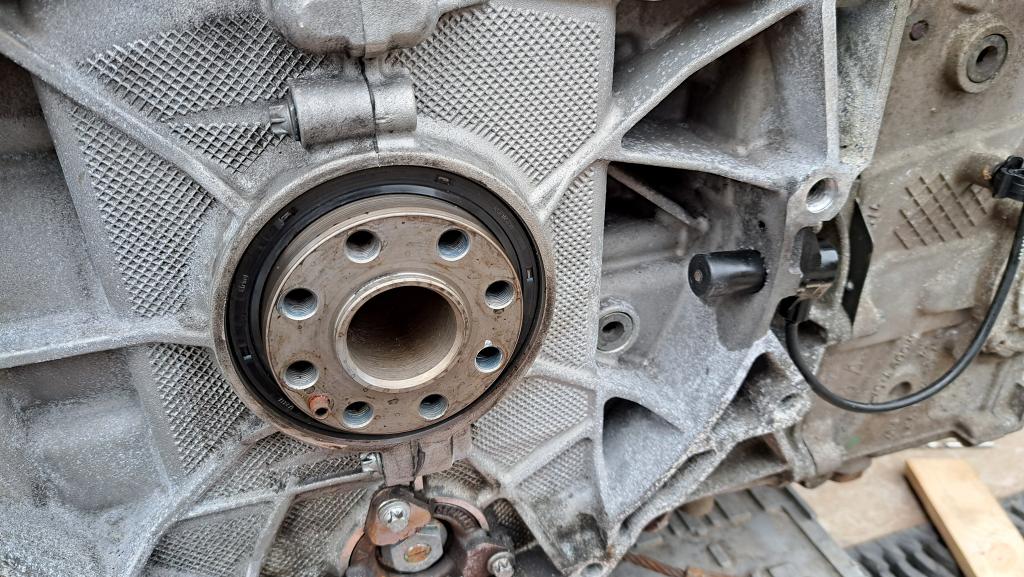

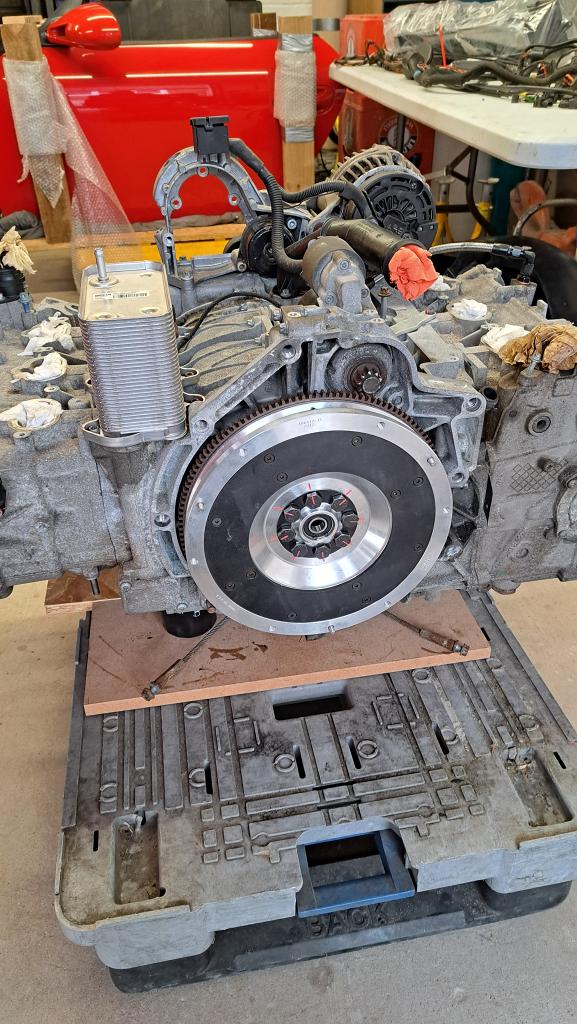

Between the car being prepared for paint the engine bay was stripped and cleaned.

The original dual mass flywheel was removed, crank seal replaced and a 6kg Aasco Motorsports item fitted with new bolts. The standard clutch and cover plate were re-installed.

Both camshaft position sensors and crank position sensor were replaced with OE Bosch items as they are very cheap, and I never used the car before taking it apart to see if it had any faults with these.

As mentioned previously the oil filter was converted to a spin on style so I could run a sandwich plate for sensors.

One port was tapped to M12x1.5 for a normal NTC temperature sensor, and the other an -4AN adaptor for an oil pressure sensor. The original oil pressure switch port on the cylinder head(s) were adapted to -4AN too. You can see this in the pictures of the engine above.

The engine and gearbox were then re-installed to make some space in the garage before painting the interior.

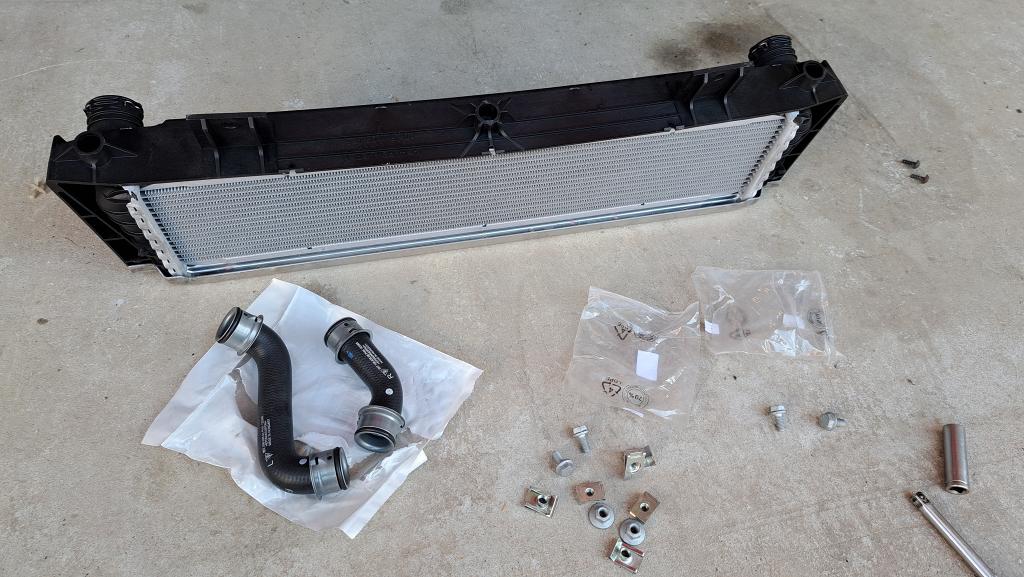

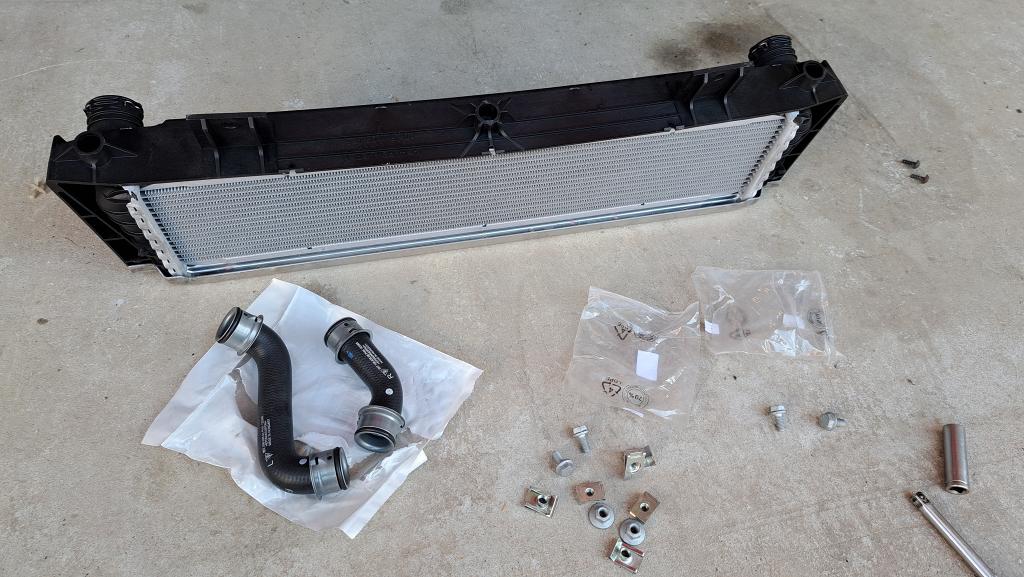

With the relatively cheap additional centre coolant radiator being a common trackday modification across the 997/987, I picked up an OE kit and got that installed.

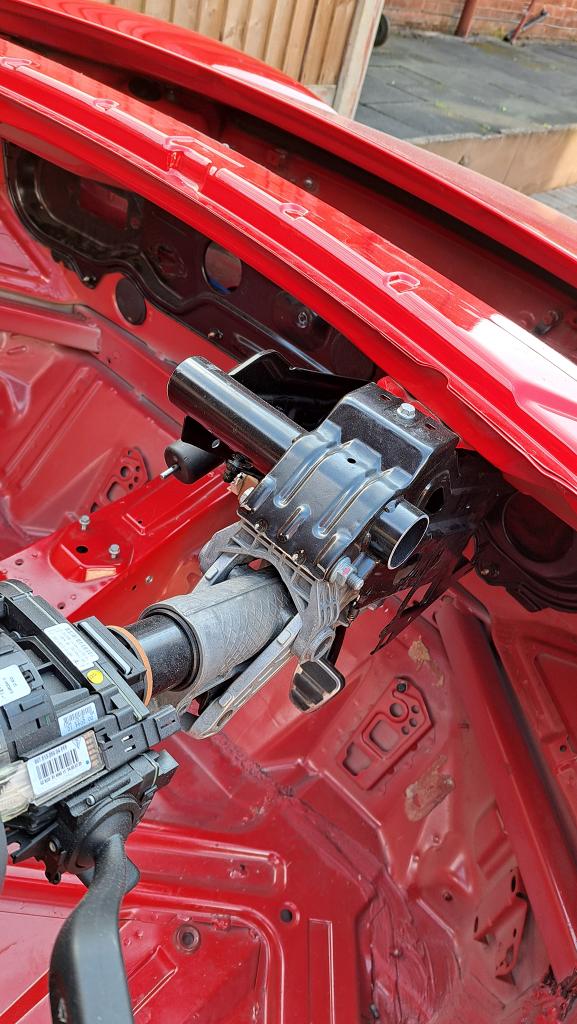

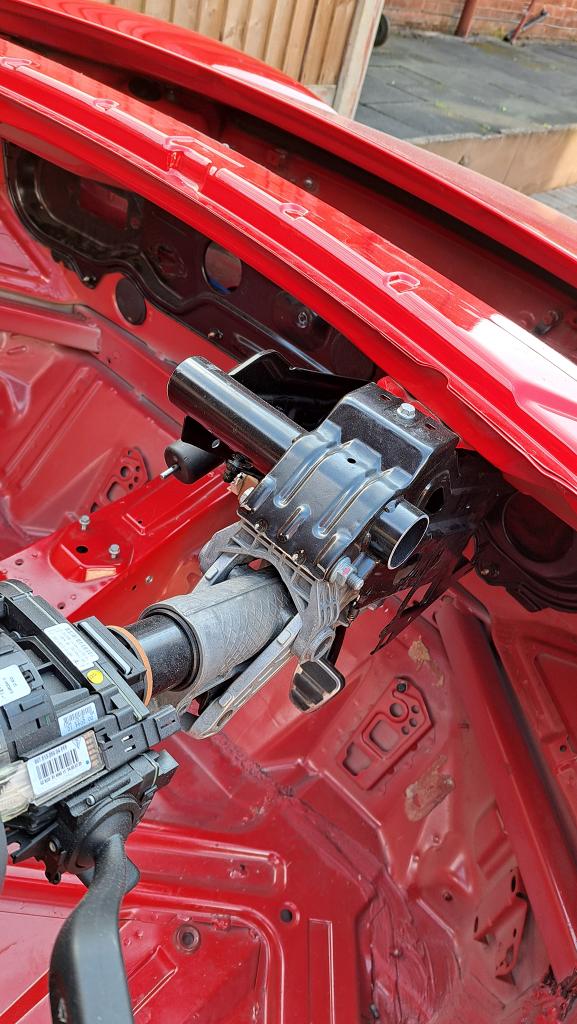

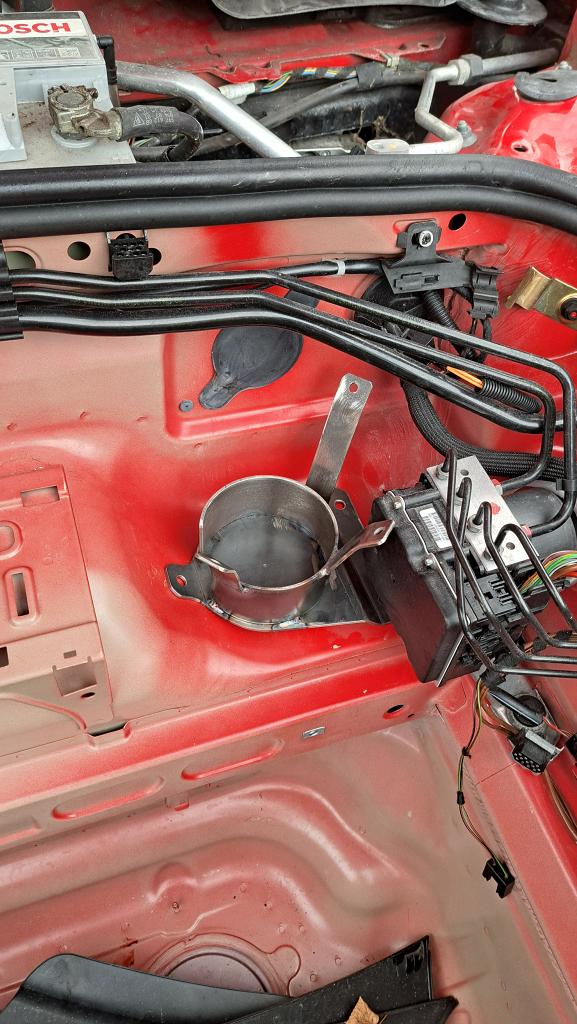

As the car is only going to be used on track, I did not want to use the original power steering pump for a number of reasons - location, length of pipework and how difficult it is to replace if you have an issue at a circuit.

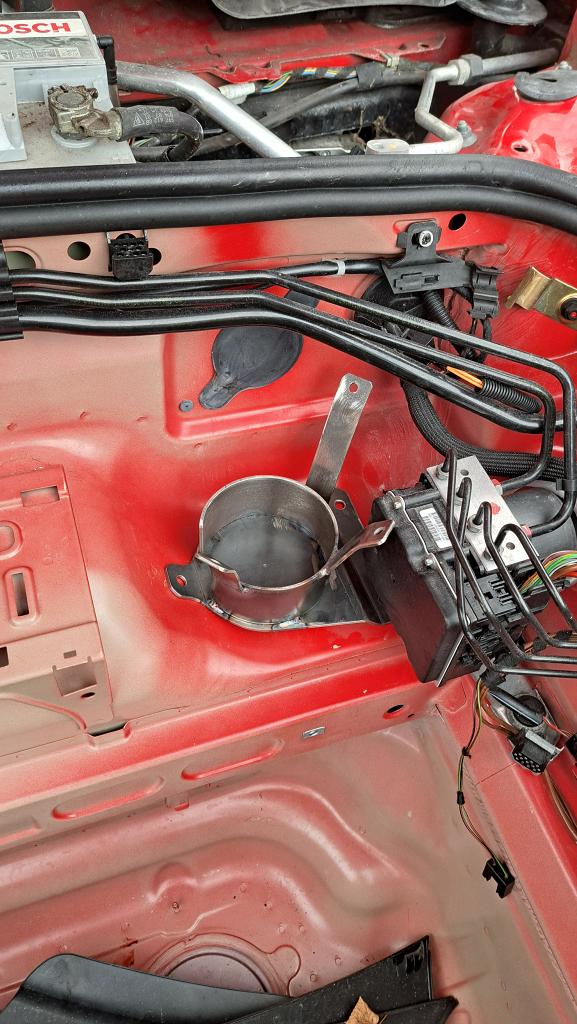

There was an era of the 996/997 Cup cars that use a TRW EPAS pump instead, mounted in the front tub. If you're in the 911 track space, you'll obviously know how common this is. They are reliable, really cheap (being from a Vauxhall Astra), use CHF like the Porsche does, and easy to control.

I wanted to mount it next to the ABS pump, so put together a bracket to suit.

It was then powdercoated along with the seat mounts and various other steel parts from the car that were looking a little tired.

The final install could only happen when the fuel tank was removed, which comes next. Just to note to anyone considering this, there is enough clearance behind the panel for a washer/nut, but nothing else. You will drill through the tank relatively quickly.

Something I forgot to mention when the car was stripped: The heater box, pollen filter, heater core pipework and air conditioning were also removed. These would not be re-installed, as the car would use a heated windscreen from now on.

With the 997/987 chassis practically being symmetrical side-to-side, there is a blanking plate on the drivers side where your pollen filter would be on the passenger side. I simply bought another one and fitted that, then cut a blanking plate from a piece of aluminium and bonded it into place.

The running gear, suspension, front subframe and fuel tank were then completely removed.

The original dual mass flywheel was removed, crank seal replaced and a 6kg Aasco Motorsports item fitted with new bolts. The standard clutch and cover plate were re-installed.

Both camshaft position sensors and crank position sensor were replaced with OE Bosch items as they are very cheap, and I never used the car before taking it apart to see if it had any faults with these.

As mentioned previously the oil filter was converted to a spin on style so I could run a sandwich plate for sensors.

One port was tapped to M12x1.5 for a normal NTC temperature sensor, and the other an -4AN adaptor for an oil pressure sensor. The original oil pressure switch port on the cylinder head(s) were adapted to -4AN too. You can see this in the pictures of the engine above.

The engine and gearbox were then re-installed to make some space in the garage before painting the interior.

With the relatively cheap additional centre coolant radiator being a common trackday modification across the 997/987, I picked up an OE kit and got that installed.

As the car is only going to be used on track, I did not want to use the original power steering pump for a number of reasons - location, length of pipework and how difficult it is to replace if you have an issue at a circuit.

There was an era of the 996/997 Cup cars that use a TRW EPAS pump instead, mounted in the front tub. If you're in the 911 track space, you'll obviously know how common this is. They are reliable, really cheap (being from a Vauxhall Astra), use CHF like the Porsche does, and easy to control.

I wanted to mount it next to the ABS pump, so put together a bracket to suit.

It was then powdercoated along with the seat mounts and various other steel parts from the car that were looking a little tired.

The final install could only happen when the fuel tank was removed, which comes next. Just to note to anyone considering this, there is enough clearance behind the panel for a washer/nut, but nothing else. You will drill through the tank relatively quickly.

Something I forgot to mention when the car was stripped: The heater box, pollen filter, heater core pipework and air conditioning were also removed. These would not be re-installed, as the car would use a heated windscreen from now on.

With the 997/987 chassis practically being symmetrical side-to-side, there is a blanking plate on the drivers side where your pollen filter would be on the passenger side. I simply bought another one and fitted that, then cut a blanking plate from a piece of aluminium and bonded it into place.

The running gear, suspension, front subframe and fuel tank were then completely removed.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff