Mounting this vice on a work bench

Discussion

OK folks I have what might be a dumb question but some collective PH wisdom would be appreciated.

I'm revamping my workshop space in the garage and want to replace a fairly feeble vice with a nice old chunky Record vice like the one in the picture below.

My understanding is that the vice mounts under the bench using 4 coach bolts, the back plate being flush with edge of the bench and the base plate being flush with the underside of the bench. Makes perfect sense.

However the vice in the first picture has what I guess are reinforcing sections between the back plate and the base plate (see red arrows) and these will prevent the vice being mounted flat against the side of the work bench.

I have seen basically the same vice without these reinforcing elements - and so it would mount flush against the side of the bench - but the version pictured seems to be more common.

So to my question. How the hell do you mount this vice on to the bench? Are you supposed to cut slots in to the edge of the bench to accommodate these vertical reinforcing walls? It just seems like a really odd design vs the second picture where the vice can be mounted flush against the side of the bench without any interference.

What am I missing?

I'm revamping my workshop space in the garage and want to replace a fairly feeble vice with a nice old chunky Record vice like the one in the picture below.

My understanding is that the vice mounts under the bench using 4 coach bolts, the back plate being flush with edge of the bench and the base plate being flush with the underside of the bench. Makes perfect sense.

However the vice in the first picture has what I guess are reinforcing sections between the back plate and the base plate (see red arrows) and these will prevent the vice being mounted flat against the side of the work bench.

I have seen basically the same vice without these reinforcing elements - and so it would mount flush against the side of the bench - but the version pictured seems to be more common.

So to my question. How the hell do you mount this vice on to the bench? Are you supposed to cut slots in to the edge of the bench to accommodate these vertical reinforcing walls? It just seems like a really odd design vs the second picture where the vice can be mounted flush against the side of the bench without any interference.

What am I missing?

Edited by TorqueDirty on Wednesday 3rd December 06:18

chrismoose91 said:

Notch the workbench where the webs will interfere? Multitool or circular saw to the required depth.

Yes that would seem to be the obvious solution but that would weaken the bench which just seems daft.However............. maybe these old vices were made back in the days when workbenches were made of bloody great solid slabs of oak, so a coupe of notches in the edge would make bugger all difference to the integrity of bench. Unlike my bench which is homemade and has a 95 x 45mm C16 pine frame with a 18mm plywood top!

Perhaps I am beginning to answer my own question here.

If you want to play with a big boy's vice you need a big boy's workbench.

Yup, two slots in your bench to receive the re-forcing webs, I had to do the same on my bench. The post 1963 model did away with them as well as making the the forward two mounting holes slots, this enabled you to fix two coach bolts to the underside of the bench and slide the slots over them to take the weight whilst you faffed around fitting the other two rearward bolts.

One tip to make things easier to fit your vice, clamp a piece of timber in the vice jaws to hold it at the correct height and so take the weight.

Cutting slots in the front of your bench isn’t the end of the world, as some people cut a recess anyway so as to have the rear jaw flush with the front edge of the bench.

One tip to make things easier to fit your vice, clamp a piece of timber in the vice jaws to hold it at the correct height and so take the weight.

Cutting slots in the front of your bench isn’t the end of the world, as some people cut a recess anyway so as to have the rear jaw flush with the front edge of the bench.

wolfracesonic said:

Yup, two slots in your bench to receive the re-forcing webs, I had to do the same on my bench. The post 1963 model did away with them as well as making the the forward two mounting holes slots, this enabled you to fix two coach bolts to the underside of the bench and slide the slots over them to take the weight whilst you faffed around fitting the other two rearward bolts.

One tip to make things easier to fit your vice, clamp a piece of timber in the vice jaws to hold it at the correct height and so take the weight.

Cutting slots in the front of your bench isn t the end of the world, as some people cut a recess anyway so as to have the rear jaw flush with the front edge of the bench.

Thank for this info - and I'm glad I'm not going nuts.One tip to make things easier to fit your vice, clamp a piece of timber in the vice jaws to hold it at the correct height and so take the weight.

Cutting slots in the front of your bench isn t the end of the world, as some people cut a recess anyway so as to have the rear jaw flush with the front edge of the bench.

I'm planning to reinforce the bench frame where the vice will go anyway so cutting the slots wont be a big issue if I go for a pre 1960's version.

Good tip on mounting the vice.

Yes you cut the notches out, then bolt it to the framework before fitting the bench top.

You can do what loughan above says and bring it forward or just notch your bench like I have with mine.

I have used hard wood pattresses in the jaws and the far end one still has them but now I generally use 18mm ply as it’s less prone to split like hardwood ones have in the past.

IMO there is no better bench vice than an original record from 1920-1960. Before Irwin.

You can do what loughan above says and bring it forward or just notch your bench like I have with mine.

I have used hard wood pattresses in the jaws and the far end one still has them but now I generally use 18mm ply as it’s less prone to split like hardwood ones have in the past.

IMO there is no better bench vice than an original record from 1920-1960. Before Irwin.

I also have the same/a similar vice and as said above, just cut the notches into the workbench. If your bench is beefy enough it won't make any difference. I also did the method of clamping a piece of wood to act as a support leg to hold the vice whilst measuring and fitting. It's a really great vice.

Thanks guys.

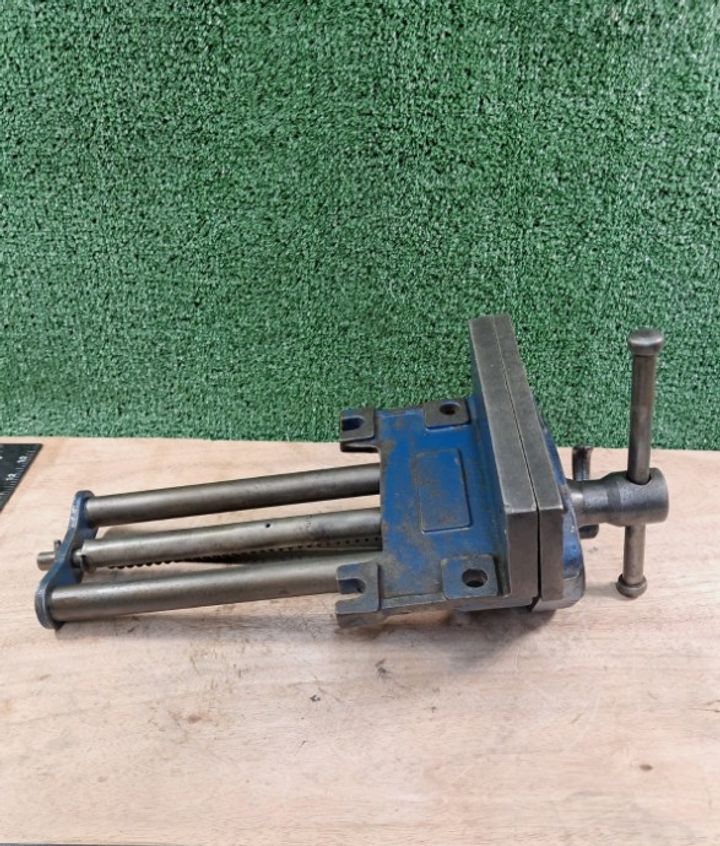

Well things have moved quickly today. I placed a bid on a nice 1940's (I think) Record 52 1/2 with a quick release and managed to pay only £21 for it.

Ebay advert says it is in fully working order. Time will tell. I'm quite keen to give it a sympathetic restoration but I'll decide when it gets here.

This is the offending item.

Well things have moved quickly today. I placed a bid on a nice 1940's (I think) Record 52 1/2 with a quick release and managed to pay only £21 for it.

Ebay advert says it is in fully working order. Time will tell. I'm quite keen to give it a sympathetic restoration but I'll decide when it gets here.

This is the offending item.

TorqueDirty said:

Thanks guys.

Well things have moved quickly today. I placed a bid on a nice 1940's (I think) Record 52 1/2 with a quick release and managed to pay only £21 for it.

Ebay advert says it is in fully working order. Time will tell. I'm quite keen to give it a sympathetic restoration but I'll decide when it gets here.

This is the offending item.

That is correct, anywhere between 1940-1960 for that type, the first ones had the RD number stamped on the vice, then the removed the number but kept the recessed area it was stamped in, then they changed the front and yours is the result.Well things have moved quickly today. I placed a bid on a nice 1940's (I think) Record 52 1/2 with a quick release and managed to pay only £21 for it.

Ebay advert says it is in fully working order. Time will tell. I'm quite keen to give it a sympathetic restoration but I'll decide when it gets here.

This is the offending item.

52 1/2 is a very good vice, quick release as well. I have one, and a 53 the larger model and the 3 52 s fitted on my benches.

The 52 on the left has the RD number stamped at the top you can just see, this predates the 52 fitted to my bench as no RD number, then the middle one is like yours a 52 1/2, the far right is the larger 53 but made after 1960.

Being a bit geeky it s quite an interesting topic to read about.

https://smallworkshop.co.uk/2018/04/17/record-vice...

Promised Land said:

That is correct, anywhere between 1940-1960 for that type, the first ones had the RD number stamped on the vice, then the removed the number but kept the recessed area it was stamped in, then they changed the front and yours is the result.

52 1/2 is a very good vice, quick release as well. I have one, and a 53 the larger model and the 3 52 s fitted on my benches.

The 52 on the left has the RD number stamped at the top you can just see, this predates the 52 fitted to my bench as no RD number, then the middle one is like yours a 52 1/2, the far right is the larger 53 but made after 1960.

Being a bit geeky it s quite an interesting topic to read about.

https://smallworkshop.co.uk/2018/04/17/record-vice...

Oh I know! I spent most of yesterday way down the Record 52 1/2 rabbit hole. 52 1/2 is a very good vice, quick release as well. I have one, and a 53 the larger model and the 3 52 s fitted on my benches.

The 52 on the left has the RD number stamped at the top you can just see, this predates the 52 fitted to my bench as no RD number, then the middle one is like yours a 52 1/2, the far right is the larger 53 but made after 1960.

Being a bit geeky it s quite an interesting topic to read about.

https://smallworkshop.co.uk/2018/04/17/record-vice...

I tend to get rather obsessed about these things. You know you are in trouble when you find yourself watching a full 30 min youtube video of someone comparing and contrasting each iteration, and spending more than a few minutes discussing the relative merits and aesthetics of the knobs on each of the veersions. The verdict was that the 1940's has a vey nice knob!

Nice collection BTW.

TorqueDirty said:

Oh I know! I spent most of yesterday way down the Record 52 1/2 rabbit hole.

I tend to get rather obsessed about these things. You know you are in trouble when you find yourself watching a full 30 min youtube video of someone comparing and contrasting each iteration, and spending more than a few minutes discussing the relative merits and aesthetics of the knobs on each of the veersions. The verdict was that the 1940's has a vey nice knob!

Nice collection BTW.

Yes it’s a bit geeky but it’s my trade, I started with one 52, then bought another pair, (3 matching is better for holding longer stock) then the 52 1/2, 53 and 3 engineers vice, a 00,0 and a 1. I tend to get rather obsessed about these things. You know you are in trouble when you find yourself watching a full 30 min youtube video of someone comparing and contrasting each iteration, and spending more than a few minutes discussing the relative merits and aesthetics of the knobs on each of the veersions. The verdict was that the 1940's has a vey nice knob!

Nice collection BTW.

I’ve not bought a 2-6 yet but there is still time!

Pre 1960 for any vice is far better in original patina as well, I hate ones that have been repainted.

Well it is here and now temporarily mounted to the new workbench I built last week. It is currently held in place with some random coach screws I had lying around but I have some more grown up coach bolts arriving tomorrow which ought to make it solid as a rock.

What a thing. It weights a ton and the mechanism is lovely and smooth. The quick release is fantastic.

Not bad for something that must be getting on for 90 years old. I have a cheaper modern vice at the other end of the bench and it is junk by comparison.

And all this for about £40 including £20 delivery.

I'm happy, even if I'm not entirely sure what I am going to do with it!

What a thing. It weights a ton and the mechanism is lovely and smooth. The quick release is fantastic.

Not bad for something that must be getting on for 90 years old. I have a cheaper modern vice at the other end of the bench and it is junk by comparison.

And all this for about £40 including £20 delivery.

I'm happy, even if I'm not entirely sure what I am going to do with it!

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff