My project: Renault F7P 704 engine rebuild

Discussion

Well today i decided to go out and start building the 19's Normally aspiriated engine, I've got alot to do!

I have already stripped down the engine, discovered what went wrong with it originally!(http://clubclio.co.uk/forums2/index.php?showtopic=59

Today, I rehoned the bores, and checked the diameter of all of them. Rehoning is basically making a cross hatch patern, as this will prevent a suction caused by oil between the piston and the bore,this will make it rev freely.

Before:

After:

Not very clear, but you can make out the crosshatching scores.

I also started measuring up the pistons, to see which ones fit the bores best:

I still have 10 more pistons from other F7P engines to measure!

I cleaned up the block-to-head surface

you can see the crosshatching in the furthest bores.

I then started weighing up the componants.

I have only managed to get round to weighing 2 pistons.rods etc:

Pistons

(weight on its own/weight with pin)

1) 331g/434g

2) 333g/435g

Con-Rods

(on its own/with big end cap)

1) 439g/683g

2) 437g/680g

Big end caps

1) 198g

2) 200g

Combined weight (Piston,Con-rod with bolts and caps,Pin,2 Circlips)

1) 1117g

2) 1117g

Big end weight with caps, no bolts

1) 377g

2) 373g

Small end weight

1) 214g

2) 206g

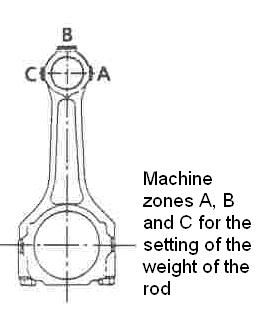

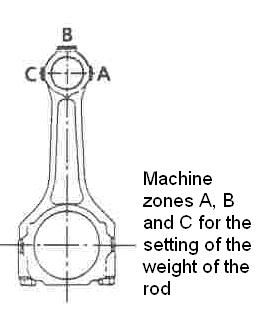

There is alot of improvement to be done, this here is for lightening and balencing, what i am doing is Static balencing as i dont have the equipment for dynamic balencing.

I will also be machining the big ends, as the lower weight of the moving componant, the more freely it will rev, down the sides of the rod also allows roughly 1g to be taken off and they are very poorly finished.

I have already stripped down the engine, discovered what went wrong with it originally!(http://clubclio.co.uk/forums2/index.php?showtopic=59

Today, I rehoned the bores, and checked the diameter of all of them. Rehoning is basically making a cross hatch patern, as this will prevent a suction caused by oil between the piston and the bore,this will make it rev freely.

Before:

After:

Not very clear, but you can make out the crosshatching scores.

I also started measuring up the pistons, to see which ones fit the bores best:

I still have 10 more pistons from other F7P engines to measure!

I cleaned up the block-to-head surface

you can see the crosshatching in the furthest bores.

I then started weighing up the componants.

I have only managed to get round to weighing 2 pistons.rods etc:

Pistons

(weight on its own/weight with pin)

1) 331g/434g

2) 333g/435g

Con-Rods

(on its own/with big end cap)

1) 439g/683g

2) 437g/680g

Big end caps

1) 198g

2) 200g

Combined weight (Piston,Con-rod with bolts and caps,Pin,2 Circlips)

1) 1117g

2) 1117g

Big end weight with caps, no bolts

1) 377g

2) 373g

Small end weight

1) 214g

2) 206g

There is alot of improvement to be done, this here is for lightening and balencing, what i am doing is Static balencing as i dont have the equipment for dynamic balencing.

I will also be machining the big ends, as the lower weight of the moving componant, the more freely it will rev, down the sides of the rod also allows roughly 1g to be taken off and they are very poorly finished.

Well today i set about lightening the conrods

Before:

I am doing this with a dremel and a sand paper attachment.

The basics of doing this is taking away any excess material from manufactor.

I was given the example if it was left on a beach for 10 odd years, it'll be all smooth, this is what you want to take off.

This is how i have started(no where near finished, and yet it has still lost 5g!):

BEFORE

AFTER

SIDE BY SIDE:

Before:

I am doing this with a dremel and a sand paper attachment.

The basics of doing this is taking away any excess material from manufactor.

I was given the example if it was left on a beach for 10 odd years, it'll be all smooth, this is what you want to take off.

This is how i have started(no where near finished, and yet it has still lost 5g!):

BEFORE

AFTER

SIDE BY SIDE:

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff