Recommendations for GOOD machinists for engine bore

Discussion

Hi guys

I'm hoping that some engine builders amongst you can recommend a good place to get a block bored.

A good friend of mine has just had to set about buying new pistons for his forged re-build after his engineers failed to deliver what they promised.

The details with his pistons specify that "tolerance is .0002" from top/bottom and cylindrically".

After promising to deliver to these requirements, the place delivered his block back and after measuring he found that it was out on the tolerances. One of the bores was upto 1 thou out from diameter and all were undersize to some degree. In terms of tolerance down the bore, he found it ranged between 0.0004" and 0.0006" out in places.

They tried to correct it but seem to have been struggling to get pressure into the machine towards the bottom of the bores and have ended up boring oversize now.

This has been a huge blow to him as he was ready to begin re-assembly after this. He is now going to have to re-bore again and buy .25mm larger pistons to fit.

Understandably, he doesn't want to return to this company after they promised that they could confidently deliver on his request and have apparently been in this business for a long time. He's now in need of a company who can genuinely bore properly round and uniformly.

So can anyone offer suggestions? Preferably in the north west, but would consider anywhere if they can truly do a proper job.

Many thanks

Chris

I'm hoping that some engine builders amongst you can recommend a good place to get a block bored.

A good friend of mine has just had to set about buying new pistons for his forged re-build after his engineers failed to deliver what they promised.

The details with his pistons specify that "tolerance is .0002" from top/bottom and cylindrically".

After promising to deliver to these requirements, the place delivered his block back and after measuring he found that it was out on the tolerances. One of the bores was upto 1 thou out from diameter and all were undersize to some degree. In terms of tolerance down the bore, he found it ranged between 0.0004" and 0.0006" out in places.

They tried to correct it but seem to have been struggling to get pressure into the machine towards the bottom of the bores and have ended up boring oversize now.

This has been a huge blow to him as he was ready to begin re-assembly after this. He is now going to have to re-bore again and buy .25mm larger pistons to fit.

Understandably, he doesn't want to return to this company after they promised that they could confidently deliver on his request and have apparently been in this business for a long time. He's now in need of a company who can genuinely bore properly round and uniformly.

So can anyone offer suggestions? Preferably in the north west, but would consider anywhere if they can truly do a proper job.

Many thanks

Chris

Edited by bodhi808 on Saturday 25th July 01:04

http://www.scholarengines.co.uk/ not quite in the north west mind, but they are pretty good.

What engine and what make of pistons because frankly tolerances like this are bloody absurd and it sounds more like a misprint than anything the engine actually requires. Engine bore gauges don't even work reliably to that level of accuracy. In fact it's not that easy to use a micrometer to less than a couple of tenths.

Tolerances like that can only be measured properly or achieved in a temperature controlled metrology lab with specialised equipment. A change of just 5 degrees C will alter an average engine's bore size by that 2 tenths. The heat generated by honing itself can put half a thou or more into the bore. I used to let my blocks stabilise for 24 hours between each honing operation to make sure I was measuring actual size not something created by the heat of the last honing.

Go and measure the pistons. I bet they aren't accurate to 2 tenths unless this is F1 or something in which case you wouldn't posting in here. The pistons also obviously grow with temp rise and by a damn sight more than the block because aluminium has a higher coefficient of expansion so any tolerance down to tenths means setting a temperature for both components to measure the work at.

It's always hard to get the bottom of the bores to the exact same size as the top because you can't stroke the hone right through without hitting the main bearing saddles. Some blocks are therefore harder to do than others depending on that clearance. I even made a set of honing stones with the tops cut off just to be able to work the bottom of the bores in tricky engines when taper became an issue.

I used to try and work to a couple of tenths out of pride more than necessity but if a customer came along who was so analy retentive they thought they actually NEEDED an engine bore to that accuracy they'd be told to f**k off in very short order.

Bore a block on a cold rainy Tuesday and then have some dipsh*t customer measure it again on a sweltering Wednesday when it's half a thou bigger and come back and start whinging because he doesn't even understand what it takes to get the bullsh*t tolerances he demanded he needed and one of us would be leaving on a stretcher. How does your friend even know the equipment he used to "check" these poor sod's work with is any more accurate than theirs? Maybe he should buy his own honing gear and do it all himself if he thinks he can do better or needs 0.0002".

For a couple of hundred quid a bore I'm sure there's someone out there who can achieve tolerances like that, do the work in a metrology lab, certify the results and stand by them. It won't make a scrap of difference to how the engine runs but if it makes some idiot who's easily parted from his money happy then good luck to all concerned.

If this is a wind up then it's succeeded and I am. It's just reminded me of all the idiot customers through the years who thought they wanted something ridiculous and wouldn't be told and especially when you knew they'd do something stupid in another part of the engine and blow it up anyway.

I like engines but god I used to hate customers.

If these bores are still within -0/+0.001" then they're fine and the engine will run perfectly well. Buying new pistons and reboring again for anything less than that is so damn stupid I'm lost for words.

Tolerances like that can only be measured properly or achieved in a temperature controlled metrology lab with specialised equipment. A change of just 5 degrees C will alter an average engine's bore size by that 2 tenths. The heat generated by honing itself can put half a thou or more into the bore. I used to let my blocks stabilise for 24 hours between each honing operation to make sure I was measuring actual size not something created by the heat of the last honing.

Go and measure the pistons. I bet they aren't accurate to 2 tenths unless this is F1 or something in which case you wouldn't posting in here. The pistons also obviously grow with temp rise and by a damn sight more than the block because aluminium has a higher coefficient of expansion so any tolerance down to tenths means setting a temperature for both components to measure the work at.

It's always hard to get the bottom of the bores to the exact same size as the top because you can't stroke the hone right through without hitting the main bearing saddles. Some blocks are therefore harder to do than others depending on that clearance. I even made a set of honing stones with the tops cut off just to be able to work the bottom of the bores in tricky engines when taper became an issue.

I used to try and work to a couple of tenths out of pride more than necessity but if a customer came along who was so analy retentive they thought they actually NEEDED an engine bore to that accuracy they'd be told to f**k off in very short order.

Bore a block on a cold rainy Tuesday and then have some dipsh*t customer measure it again on a sweltering Wednesday when it's half a thou bigger and come back and start whinging because he doesn't even understand what it takes to get the bullsh*t tolerances he demanded he needed and one of us would be leaving on a stretcher. How does your friend even know the equipment he used to "check" these poor sod's work with is any more accurate than theirs? Maybe he should buy his own honing gear and do it all himself if he thinks he can do better or needs 0.0002".

For a couple of hundred quid a bore I'm sure there's someone out there who can achieve tolerances like that, do the work in a metrology lab, certify the results and stand by them. It won't make a scrap of difference to how the engine runs but if it makes some idiot who's easily parted from his money happy then good luck to all concerned.

If this is a wind up then it's succeeded and I am. It's just reminded me of all the idiot customers through the years who thought they wanted something ridiculous and wouldn't be told and especially when you knew they'd do something stupid in another part of the engine and blow it up anyway.

I like engines but god I used to hate customers.

If these bores are still within -0/+0.001" then they're fine and the engine will run perfectly well. Buying new pistons and reboring again for anything less than that is so damn stupid I'm lost for words.

Edited by Pumaracing on Saturday 25th July 13:19

Edited by Pumaracing on Saturday 25th July 13:30

You seem obsessed with the tolerance of the bore, yet no reference to squareness to the main journals!

As a time served toolmaker, I can only agree with Pumaracing.

I do know a place in the North West (Preston area), but if he didn't 'hit' the tolerance you state, you would fall out with him and him me.

Regards,

Chris.

As a time served toolmaker, I can only agree with Pumaracing.

I do know a place in the North West (Preston area), but if he didn't 'hit' the tolerance you state, you would fall out with him and him me.

Regards,

Chris.

I think you can place a pretty safe bet it wasn't 0.0002" on the side of the piston box in the first place. It was probably 0.02mm if they were continental made and some numpty who can't even convert mm into thou and understands even less about engines and machining has turned it into 0.0002" and tried to find someone who can work to that.

Anyway it certainly tells me the guy trying to build, or at least spec, his engine knows absolutely sweet FA about engines so he'll undoubtedly faff about trying to get all sorts of irrelevant things done to microscopic detail and totally ignore anything that's actually important like the valve seats and porting work.

I remember one of my very first customers many years ago who was building an engine for himself in the Fiesta XR2i Challenge. The class rules for head chamber volume was a minimum of 53.3cc. He'd already had one head done by a place who'd charged him a staggering £200 (this was 20 years ago when £200 was actually worth something) to set the chamber volumes which they'd done by measuring all four and just skimming the head until the smallest one was fairly close to 53.3cc. 20 minutes to cc the chambers, another half hour to skim, no other correction work to the other three chambers and that's £200 ta very much for not even getting it right.

Anyway so this pedantic little knownothing type 2 (see "Customer types" on my website) insisted he wanted exactly 53.3cc on ALL four chambers, whatever it took to get that even though you weren't allowed to remove metal from the chambers and even though it wouldn't have made a rat's arse worse of difference to the eventual CR or power output on an otherwise standard engine if they'd varied by 1cc or so.

So I CC'd everything down to a tenth of a CC, skimmed the head in tiny increments measuring again and again as I went, recut the valve seats and valve heads by a few thousandths of an inch at a time to create more volume to balance everything and after half a day's work finally got all four chambers to EXACTLY 53.3cc.

He ran the engine for a few races and then bought his own bloody burette!!!!

So next time the head comes off he decokes it, slaps his bit of perspex sheet with holes drilled in it on the head face, burettes each chamber and decides they're all 54.0cc and I've got it wrong and ripped him off. It's a perfectly round chamber on the CVH engine so nice and easy to work out how many cc per thou you get when you skim it. He takes it to another machine shop and asks them to skim exactly the 6 thou or whatever it was off it to get it back to EXACTLY 53.3cc.

He gets it back and measures the chamber volumes again. They're now 52.6cc and the head is illegal for its class. In fact it's exactly the 0.7cc UNDER the size I'd set it to that he'd thought it was OVER that to start with. He tears his hair out for ages and then finally swallows his pride and phones me.

"Why" he moans, "did I have exactly 6 thou skimmed off but it's removed twice as much metal as it ought to have done and it's now under size instead of right?"

Because it was right to a tenth of a cc in the bloody first place I told him and you shouldn't have f*cked about with it. He asked again how it could have happened that he measured it wrong but I was too pissed off to tell him. I just said I wasn't there watching him do it so how could I say. Instead I charged him very handsomely to recut the seats again and claw back enough volume to get it legal.

I never did tell him what he did wrong but it was this. When you take a head off an engine the miniscule dimples the gasket leaves in the face of the aluminium are sufficient to hold a perspex sheet a few thou proud of the true surface. You have to go over it all lightly with a fine oilstone to remove any dimples and burrs to achieve a proper flat surface to take really accurate measurements from. When he first cc'd the chambers without doing that he was measuring everything 0.7cc oversize. After it had been skimmed for this non-existant 0.7cc the surface was properly flat again so he now found out it had gone down to 0.7cc undersize.

A little bit of knowledge is a dangerous thing and on that basis god I've met some dangerous customers in my time. Even worse if they've got their own measuring equipment or tools and try and check things themselves and doubly worse when they're trying to do something which is pointless in the first place. Like boring a block to 2 tenths of a thou!

Anyway it certainly tells me the guy trying to build, or at least spec, his engine knows absolutely sweet FA about engines so he'll undoubtedly faff about trying to get all sorts of irrelevant things done to microscopic detail and totally ignore anything that's actually important like the valve seats and porting work.

I remember one of my very first customers many years ago who was building an engine for himself in the Fiesta XR2i Challenge. The class rules for head chamber volume was a minimum of 53.3cc. He'd already had one head done by a place who'd charged him a staggering £200 (this was 20 years ago when £200 was actually worth something) to set the chamber volumes which they'd done by measuring all four and just skimming the head until the smallest one was fairly close to 53.3cc. 20 minutes to cc the chambers, another half hour to skim, no other correction work to the other three chambers and that's £200 ta very much for not even getting it right.

Anyway so this pedantic little knownothing type 2 (see "Customer types" on my website) insisted he wanted exactly 53.3cc on ALL four chambers, whatever it took to get that even though you weren't allowed to remove metal from the chambers and even though it wouldn't have made a rat's arse worse of difference to the eventual CR or power output on an otherwise standard engine if they'd varied by 1cc or so.

So I CC'd everything down to a tenth of a CC, skimmed the head in tiny increments measuring again and again as I went, recut the valve seats and valve heads by a few thousandths of an inch at a time to create more volume to balance everything and after half a day's work finally got all four chambers to EXACTLY 53.3cc.

He ran the engine for a few races and then bought his own bloody burette!!!!

So next time the head comes off he decokes it, slaps his bit of perspex sheet with holes drilled in it on the head face, burettes each chamber and decides they're all 54.0cc and I've got it wrong and ripped him off. It's a perfectly round chamber on the CVH engine so nice and easy to work out how many cc per thou you get when you skim it. He takes it to another machine shop and asks them to skim exactly the 6 thou or whatever it was off it to get it back to EXACTLY 53.3cc.

He gets it back and measures the chamber volumes again. They're now 52.6cc and the head is illegal for its class. In fact it's exactly the 0.7cc UNDER the size I'd set it to that he'd thought it was OVER that to start with. He tears his hair out for ages and then finally swallows his pride and phones me.

"Why" he moans, "did I have exactly 6 thou skimmed off but it's removed twice as much metal as it ought to have done and it's now under size instead of right?"

Because it was right to a tenth of a cc in the bloody first place I told him and you shouldn't have f*cked about with it. He asked again how it could have happened that he measured it wrong but I was too pissed off to tell him. I just said I wasn't there watching him do it so how could I say. Instead I charged him very handsomely to recut the seats again and claw back enough volume to get it legal.

I never did tell him what he did wrong but it was this. When you take a head off an engine the miniscule dimples the gasket leaves in the face of the aluminium are sufficient to hold a perspex sheet a few thou proud of the true surface. You have to go over it all lightly with a fine oilstone to remove any dimples and burrs to achieve a proper flat surface to take really accurate measurements from. When he first cc'd the chambers without doing that he was measuring everything 0.7cc oversize. After it had been skimmed for this non-existant 0.7cc the surface was properly flat again so he now found out it had gone down to 0.7cc undersize.

A little bit of knowledge is a dangerous thing and on that basis god I've met some dangerous customers in my time. Even worse if they've got their own measuring equipment or tools and try and check things themselves and doubly worse when they're trying to do something which is pointless in the first place. Like boring a block to 2 tenths of a thou!

Edited by Pumaracing on Saturday 25th July 15:37

Those seem to be piston measurements, Ross record measurements to four digits. As for honing the bottom of the block, some boring bars can't do it properly due to obstructions interfering with the stones. The stones can't reach the very bottom of the bores. I had to get a block done using a portable Van Norman boring bar like this.

http://dallas.craigslist.org/dal/tls/1285487727.ht...

This did a cracking job and I had nice straight bores A lot of engineering firms don't have them but this may be a solution.

A lot of engineering firms don't have them but this may be a solution.

http://dallas.craigslist.org/dal/tls/1285487727.ht...

This did a cracking job and I had nice straight bores

A lot of engineering firms don't have them but this may be a solution.

A lot of engineering firms don't have them but this may be a solution.Hi guys thank you very much for the advice and comments.

This isn't a wind up by the way, but before you boil right over, I will add that you're correct in your assumptions that building a performance engine like this to small tolerances is new to my friend and nigh on completely alien to me. Apologies also if my post was written in a way that upset anyone, that was certainly not intended.

Whilst i'm not particularly knowledgable, I do understand the dynamics of metal expansion, but have never personally worked with tolerances like these before, so it's very new ground.

A bit of background. The engine is a toyota rev 3 3SGTE with yamaha cylinder head. The pistons are CP forged low expansion 86.25mm 8.5:1 compression ratio.

The 3sgte is not the best block for handling big power as it is prone to cracking between bores 2 & 3 and around the water pump, especially when bored out to 86.5 - 87mm hence my buddy wanting to keep it down to 86.25mm. I will double check the tolerance details that came with the pistons.

Yes he has measuring equipment and is very meticulous about this build hence checking the work afterwards. He had a torque plate made up to simulate the cylinder head during the boring process too. Incidentally, the head has been through extensive porting & polishing work and is to be fitted with 1mm oversized valves.

I'm certainly very interested to hear from you guys with performance engine experience, what sort of tolerances are realistic and acceptable in this sort of project. The intended goals of this engine are to be running likely in the region of 500-550bhp with better longevity than many 3sgte re-builds seem to achieve (15-20k miles). The parts have been spec'd to be suitable for considerably higher power with the intent to run below the engine's capability to achieve a good lifespan. Itis not intended to be a race car, but will likely be used for occasional track use.

Thanks again and apologies if I inadvertently offended anyone.

Cheers

Chris

This isn't a wind up by the way, but before you boil right over, I will add that you're correct in your assumptions that building a performance engine like this to small tolerances is new to my friend and nigh on completely alien to me. Apologies also if my post was written in a way that upset anyone, that was certainly not intended.

Whilst i'm not particularly knowledgable, I do understand the dynamics of metal expansion, but have never personally worked with tolerances like these before, so it's very new ground.

A bit of background. The engine is a toyota rev 3 3SGTE with yamaha cylinder head. The pistons are CP forged low expansion 86.25mm 8.5:1 compression ratio.

The 3sgte is not the best block for handling big power as it is prone to cracking between bores 2 & 3 and around the water pump, especially when bored out to 86.5 - 87mm hence my buddy wanting to keep it down to 86.25mm. I will double check the tolerance details that came with the pistons.

Yes he has measuring equipment and is very meticulous about this build hence checking the work afterwards. He had a torque plate made up to simulate the cylinder head during the boring process too. Incidentally, the head has been through extensive porting & polishing work and is to be fitted with 1mm oversized valves.

I'm certainly very interested to hear from you guys with performance engine experience, what sort of tolerances are realistic and acceptable in this sort of project. The intended goals of this engine are to be running likely in the region of 500-550bhp with better longevity than many 3sgte re-builds seem to achieve (15-20k miles). The parts have been spec'd to be suitable for considerably higher power with the intent to run below the engine's capability to achieve a good lifespan. Itis not intended to be a race car, but will likely be used for occasional track use.

Thanks again and apologies if I inadvertently offended anyone.

Cheers

Chris

Would just like to add that reading back my first post, does sound a bit like he's fallen out with the engineers, this is not the case, he was just dissapointed that he's hit another hurdle and feels that the the chap who ran the company may have been a bit bravo when talking about their capabilities. He was told that his tolerances were very easy to achieve by the owner, which is where his reluctance has come from to take it back there.

He has paid for the work and there has been no argument between them over this. Possibly lack of experience means that we are expecting too much or are aiming for the wrong results.

ETA i have not spoken to him about the bores in relation to the main journals, but I'll check this with him, thanks

He has paid for the work and there has been no argument between them over this. Possibly lack of experience means that we are expecting too much or are aiming for the wrong results.

ETA i have not spoken to him about the bores in relation to the main journals, but I'll check this with him, thanks

Well I've looked at their pdf catalogue for those pistons on their website

http://www.cppistons.com/Products/SportCompact/tab...

and indeed it does waffle on (page 18)about bores having to be round within 0.0002". It doesn't actually say anything about tolerances on taper or actual nominal size, only ovality as far as I can see.

It's very simple. It's complete bullsh*t designed I suspect to give them the maximum possible chance of a copout if their pistons fail. It's at the bitter limits of achievable machining and the piston and rings won't give a damn anyway. The bores will certainly move all over the place by much more than that once the engine is running and temperature gradients, thrust forces and compression forces start acting. On wet liner engines I've pulled old liners out where the piston thrust forces had pulled them 4 thou out of round and you wouldn't know a damn thing from either cranking tests or dyno results.

The tolerance limits on every other piston I've used are as I said above. -0.0/+0.001". It's easy to do better than that and half a thou would be nice but 2 tenths is just stupid.

Actually ovality is the easiest, and least important, thing to get right because proper honing equipment does that automatically. It's taper and barrelling that catch you out if you can't stroke the hone right through the bottom of the bore.

Your friend wants to go to a proper race engine builder who knows what he's doing and just take his advice or let him get on with it rather than trying to follow bullsh*t specs from a piston company when neither party knows why those specs are being specified or what's actually important.

Oh and yes the machinist should never have said they could easily achieve 2 tenths because no engine reconditioner with half a brain would think they could do that even if it was actually necessary.

http://www.cppistons.com/Products/SportCompact/tab...

and indeed it does waffle on (page 18)about bores having to be round within 0.0002". It doesn't actually say anything about tolerances on taper or actual nominal size, only ovality as far as I can see.

It's very simple. It's complete bullsh*t designed I suspect to give them the maximum possible chance of a copout if their pistons fail. It's at the bitter limits of achievable machining and the piston and rings won't give a damn anyway. The bores will certainly move all over the place by much more than that once the engine is running and temperature gradients, thrust forces and compression forces start acting. On wet liner engines I've pulled old liners out where the piston thrust forces had pulled them 4 thou out of round and you wouldn't know a damn thing from either cranking tests or dyno results.

The tolerance limits on every other piston I've used are as I said above. -0.0/+0.001". It's easy to do better than that and half a thou would be nice but 2 tenths is just stupid.

Actually ovality is the easiest, and least important, thing to get right because proper honing equipment does that automatically. It's taper and barrelling that catch you out if you can't stroke the hone right through the bottom of the bore.

Your friend wants to go to a proper race engine builder who knows what he's doing and just take his advice or let him get on with it rather than trying to follow bullsh*t specs from a piston company when neither party knows why those specs are being specified or what's actually important.

Oh and yes the machinist should never have said they could easily achieve 2 tenths because no engine reconditioner with half a brain would think they could do that even if it was actually necessary.

Edited by Pumaracing on Saturday 25th July 17:16

You want to read this.

http://www.circletrack.com/techarticles/cylinder_b...

Measurements of what happens to cylinder blocks when you hone them with the block cold, hot (hot water flowing through the coolant passages) and in both cases with and without torque plates. Look what happens when you introduce hot coolant into an engine that has been bored and honed at room temperature. The bores go several thou out of ovality at operating temperature. Not several tenths - several thou!

Like the article says, the effects of using torque plates which undoubtedly make a small difference to really high output engines are dwarfed by the effects of temperature which hardly anyone takes a scrap of notice of or has the equipment to do anything about.

Now you might realise just how very very far into the wind you're pissing worrying about 2 tenths of a thou ovality on a cold block that's going to be a COMPLETELY different shape anyway once it's hot and running.

You might also realise given how all this effort still only makes tiny differences to performance just how little piston rings really care about whether a bore is a bit oval or not. That's what they're designed to seal. Just like I said above about wet liner engines.

Enough said on this topic.

http://www.circletrack.com/techarticles/cylinder_b...

Measurements of what happens to cylinder blocks when you hone them with the block cold, hot (hot water flowing through the coolant passages) and in both cases with and without torque plates. Look what happens when you introduce hot coolant into an engine that has been bored and honed at room temperature. The bores go several thou out of ovality at operating temperature. Not several tenths - several thou!

Like the article says, the effects of using torque plates which undoubtedly make a small difference to really high output engines are dwarfed by the effects of temperature which hardly anyone takes a scrap of notice of or has the equipment to do anything about.

Now you might realise just how very very far into the wind you're pissing worrying about 2 tenths of a thou ovality on a cold block that's going to be a COMPLETELY different shape anyway once it's hot and running.

You might also realise given how all this effort still only makes tiny differences to performance just how little piston rings really care about whether a bore is a bit oval or not. That's what they're designed to seal. Just like I said above about wet liner engines.

Enough said on this topic.

3S-GTE blocks, especially 1994 on have well known issues with 2nd and 3rd bores. That's why they're known as "thin wall blocks".

We, and our peer businesses solve the problem on high powered engines by having them sleeved. Not expensive, and never had a failure.

PM me if you want more info or advice.

We, and our peer businesses solve the problem on high powered engines by having them sleeved. Not expensive, and never had a failure.

PM me if you want more info or advice.

Thanks again guys, really interesting feedback.

Having read more about this and taking comments on board from yourselves and some other sources, we're fast coming to the conclusion, as you've said, that our goals were unrealistic and uneccessary. Thanks pumaracing for taking the time to plough through the CP details too.

Well every day is a school day

I'm following and helping with his build closely as I will be doing a similar build in the not too distant future but with slightly more modest power goals.

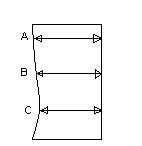

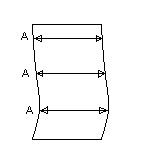

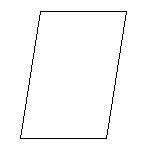

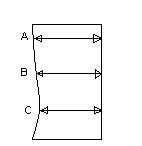

I drew up a few little images to help me discuss a few aspects of the tolerances. Like i said new to all this and pictures always help me

With regards ovality, on the basis that we're unlikely to get the engineering done with a temp controlled water jacket, is 0.0002" tolerance a pointless goal to work to, taking on board the changes when the block is upto working temps.

Moving onto the bore sides, i can see 3 scenarios for tolerances. I'm guessing that tolerances need to account for combinations of all the scenarios, hence the increduality at my initial expectations.

1. bore is uneven down the length where the maximum difference between measurements A, B & C is greater than desired Tolerance.

2. The tolerances appear to good (hence depicted as all being measurement A) but in reality the bore is not straight.

3. The bore is not perpendicular to the crank.

So if we could get the bores to around 0.001" tolerance or slightly better if possible, then we would be aiming for a realistic and useable result?

peterguk, thanks for mentioning liners. Although my friend is not a huge fan, I am actually quite interested in the idea. I've come across a couple of examples of the liners lifting the head though in our applications on GT4s rather than MR2s and was wondering if that might be a result of the additional stresses caused by 4wd or whether it was simply down to badly machined/fitted liners.

Many thanks

Chris

Having read more about this and taking comments on board from yourselves and some other sources, we're fast coming to the conclusion, as you've said, that our goals were unrealistic and uneccessary. Thanks pumaracing for taking the time to plough through the CP details too.

Well every day is a school day

I'm following and helping with his build closely as I will be doing a similar build in the not too distant future but with slightly more modest power goals.

I drew up a few little images to help me discuss a few aspects of the tolerances. Like i said new to all this and pictures always help me

With regards ovality, on the basis that we're unlikely to get the engineering done with a temp controlled water jacket, is 0.0002" tolerance a pointless goal to work to, taking on board the changes when the block is upto working temps.

Moving onto the bore sides, i can see 3 scenarios for tolerances. I'm guessing that tolerances need to account for combinations of all the scenarios, hence the increduality at my initial expectations.

1. bore is uneven down the length where the maximum difference between measurements A, B & C is greater than desired Tolerance.

2. The tolerances appear to good (hence depicted as all being measurement A) but in reality the bore is not straight.

3. The bore is not perpendicular to the crank.

So if we could get the bores to around 0.001" tolerance or slightly better if possible, then we would be aiming for a realistic and useable result?

peterguk, thanks for mentioning liners. Although my friend is not a huge fan, I am actually quite interested in the idea. I've come across a couple of examples of the liners lifting the head though in our applications on GT4s rather than MR2s and was wondering if that might be a result of the additional stresses caused by 4wd or whether it was simply down to badly machined/fitted liners.

Many thanks

Chris

Edited by bodhi808 on Thursday 30th July 10:58

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff