Caterham Superlight - Custom Tamiya 1/12

Discussion

where's the updates Angus - I even spent the weekend cleaning up and sorting the garage for upgrade time space (already in your design brief!) and bought some great LED rechargeable lights from Screwfix (they are awesome! -- except whilst flooring garage loft managed dropping a light that bounced and dented the side skin!!! AGGGHhh

Oh FFS!!! Send me a picture of the dent, and I'll add it in.... lol

lol

Doing a bit of sorting and tidying myself, but cracking on in the background - I made a list of all the things I have to draw up in 3D and then print etc....was much longer than I thought - now drawing up those handed floor mats you updated me on!! (and the bare ali-save-weight floor looked so good!)

(and the bare ali-save-weight floor looked so good!)

Oh, and the dash - total scratch build, as carbon - I think the light switches are the new 'smallest part' made!!!

lol

lolDoing a bit of sorting and tidying myself, but cracking on in the background - I made a list of all the things I have to draw up in 3D and then print etc....was much longer than I thought - now drawing up those handed floor mats you updated me on!!

(and the bare ali-save-weight floor looked so good!)

(and the bare ali-save-weight floor looked so good!)Oh, and the dash - total scratch build, as carbon - I think the light switches are the new 'smallest part' made!!!

Edited by caterhamnut on Wednesday 4th December 23:34

Right - where were we.....

It's been a while, but only in terms of an update - work has been progressing, inbetween a few foreign trips...FB has seen some picture dumps, but not here....

So although a lot has been done, there is still tons to do, with almost every aspect of the car having to be either drawn up in CAD and printed, or scratch built. Very easy to under estimate how much work will be involved - and time....jeez!

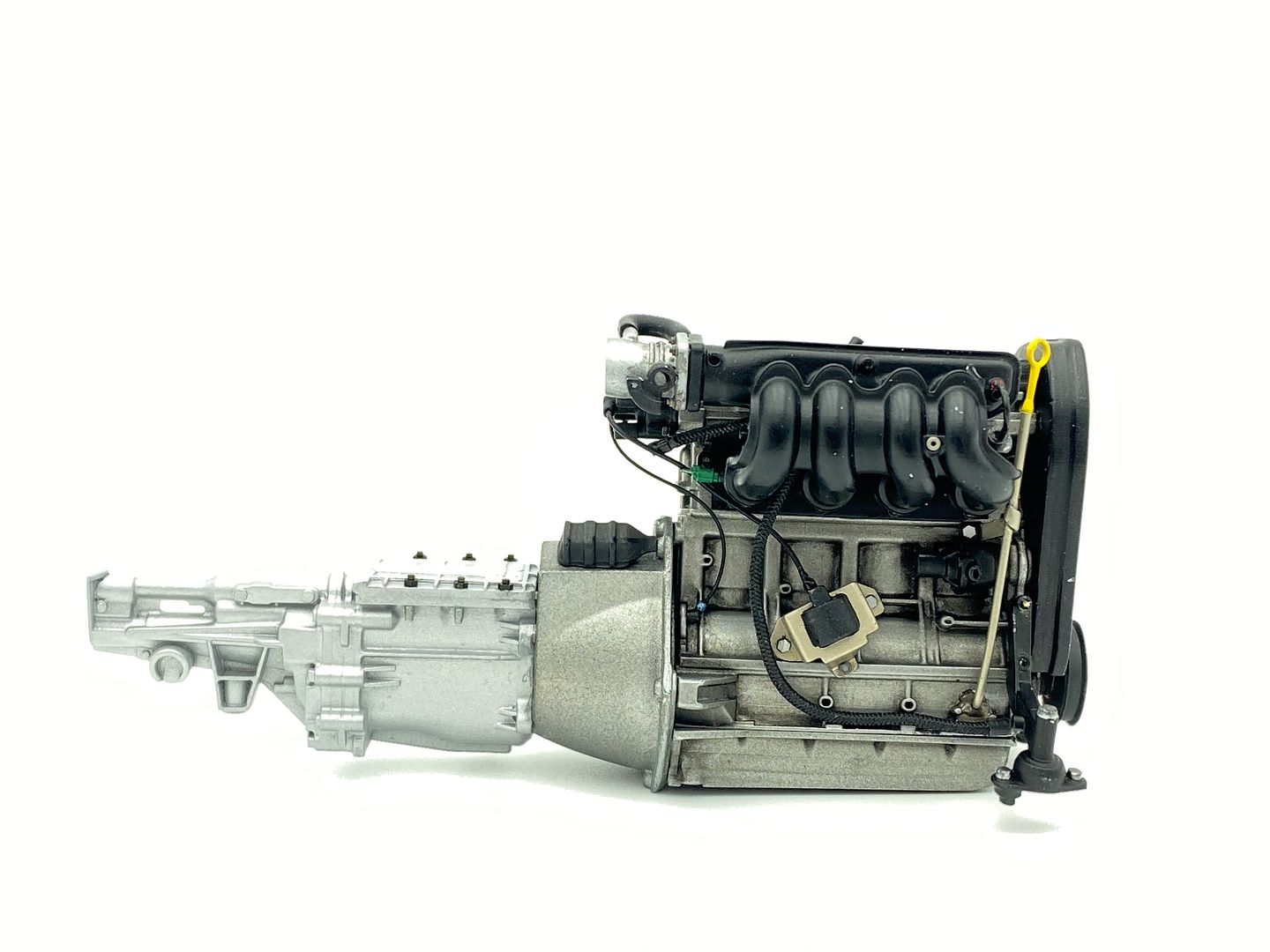

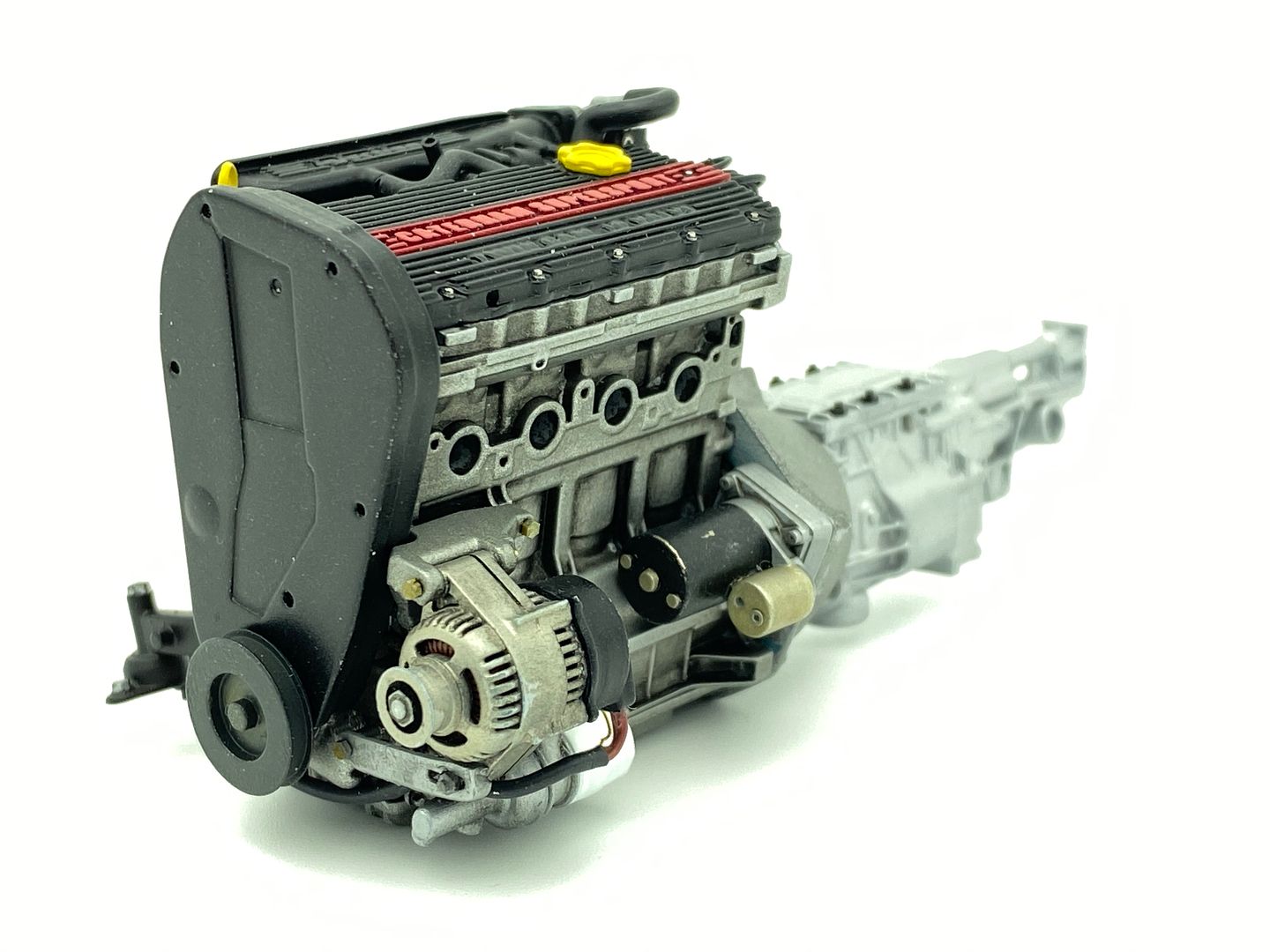

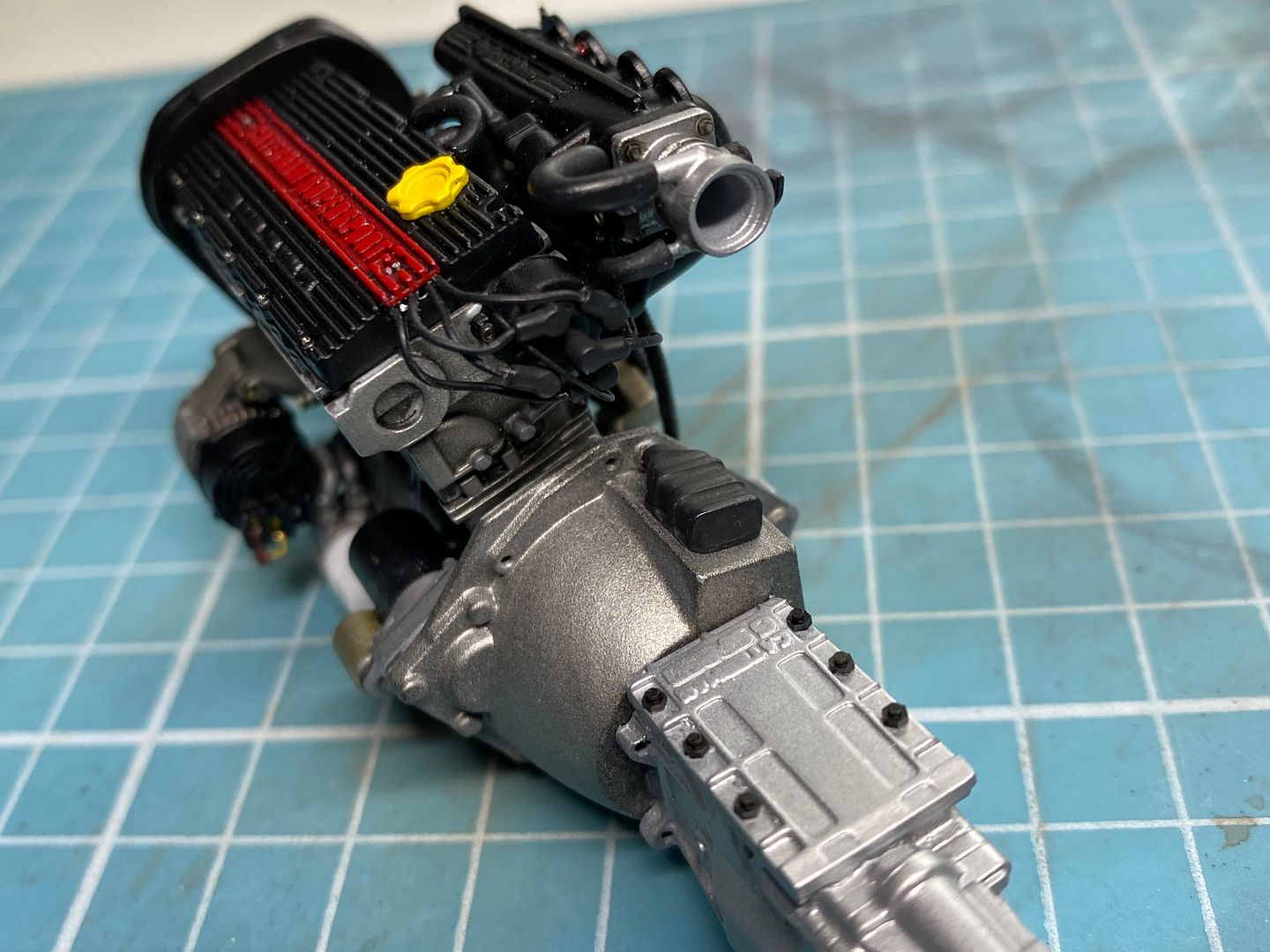

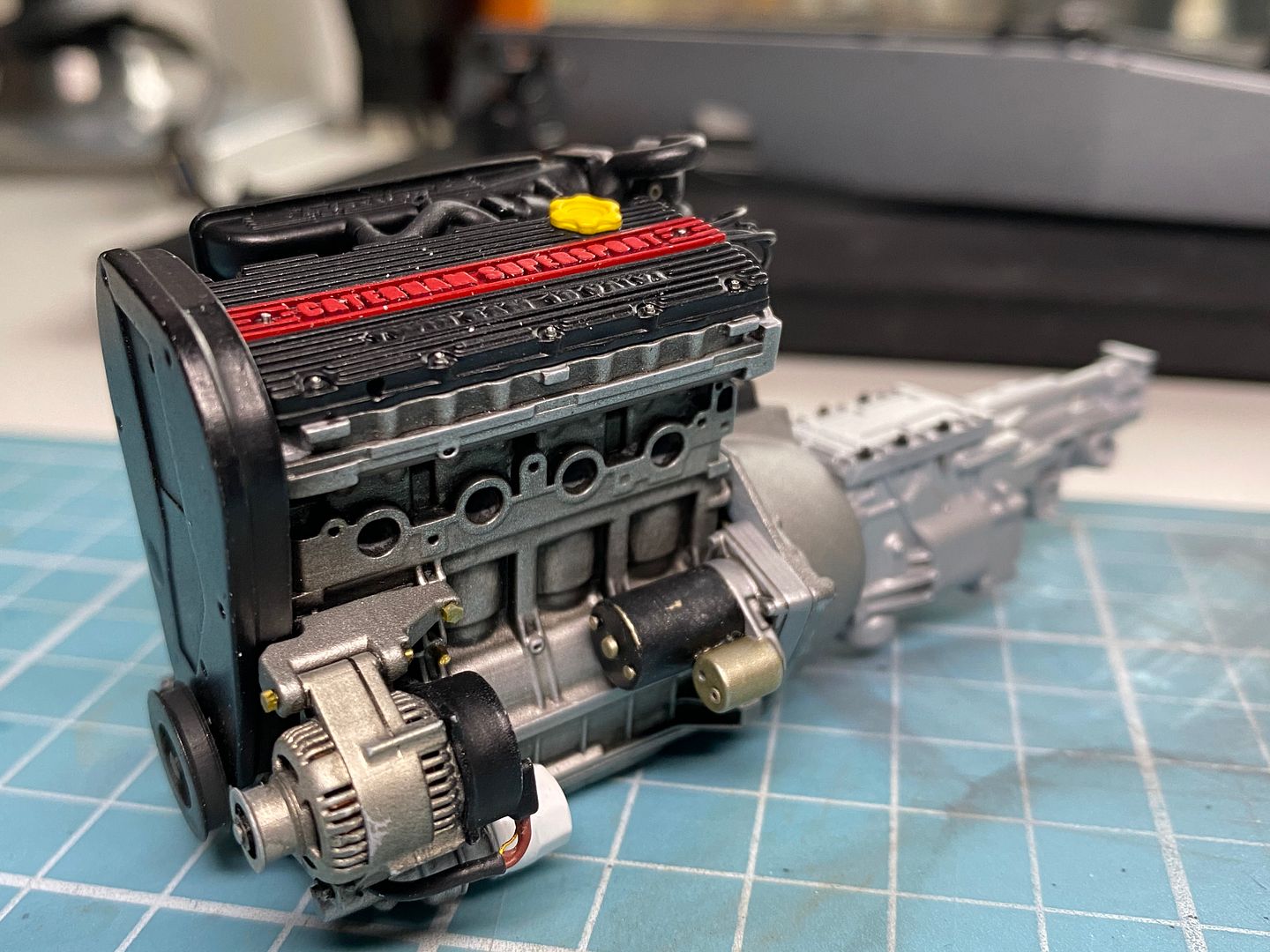

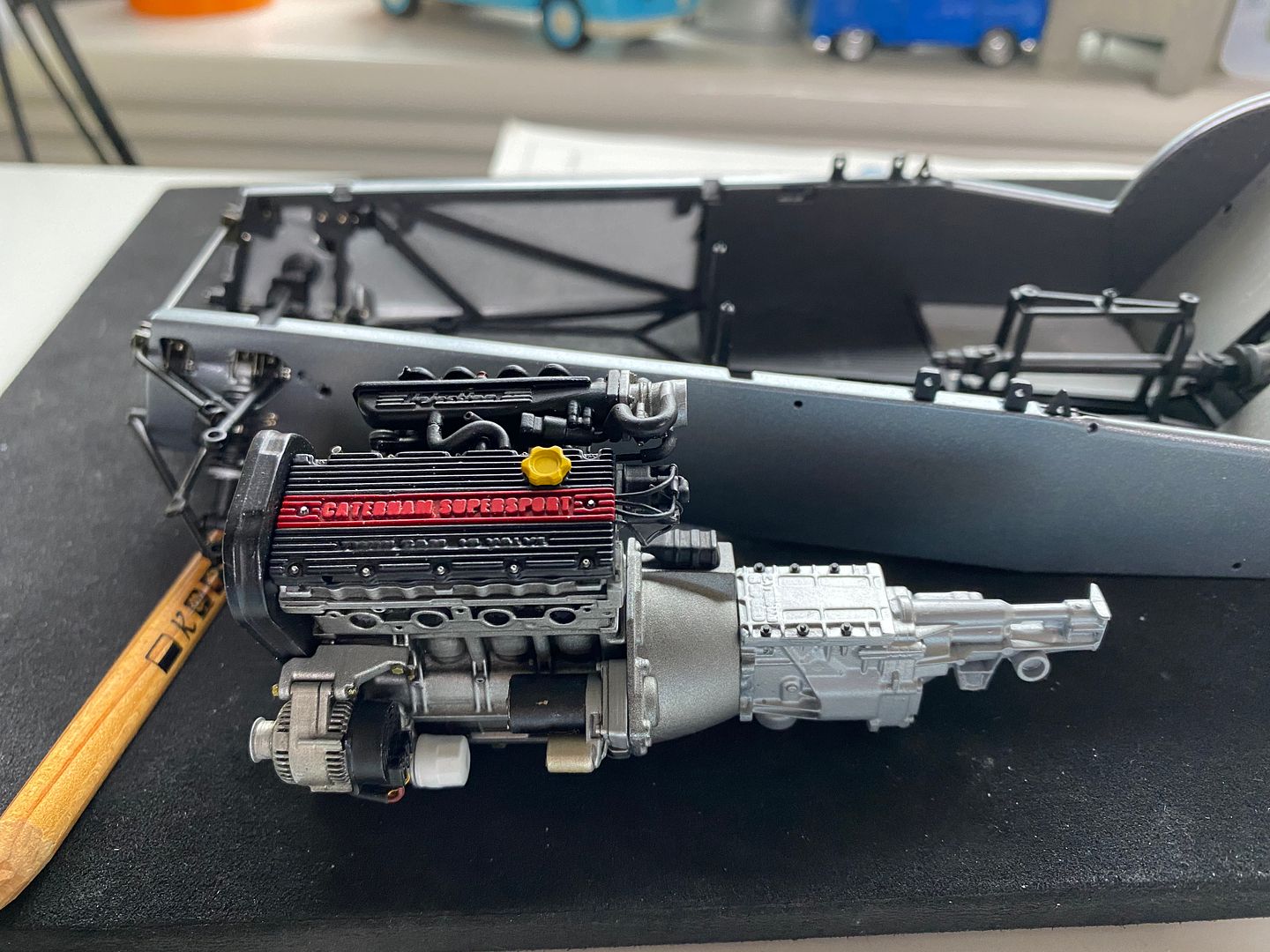

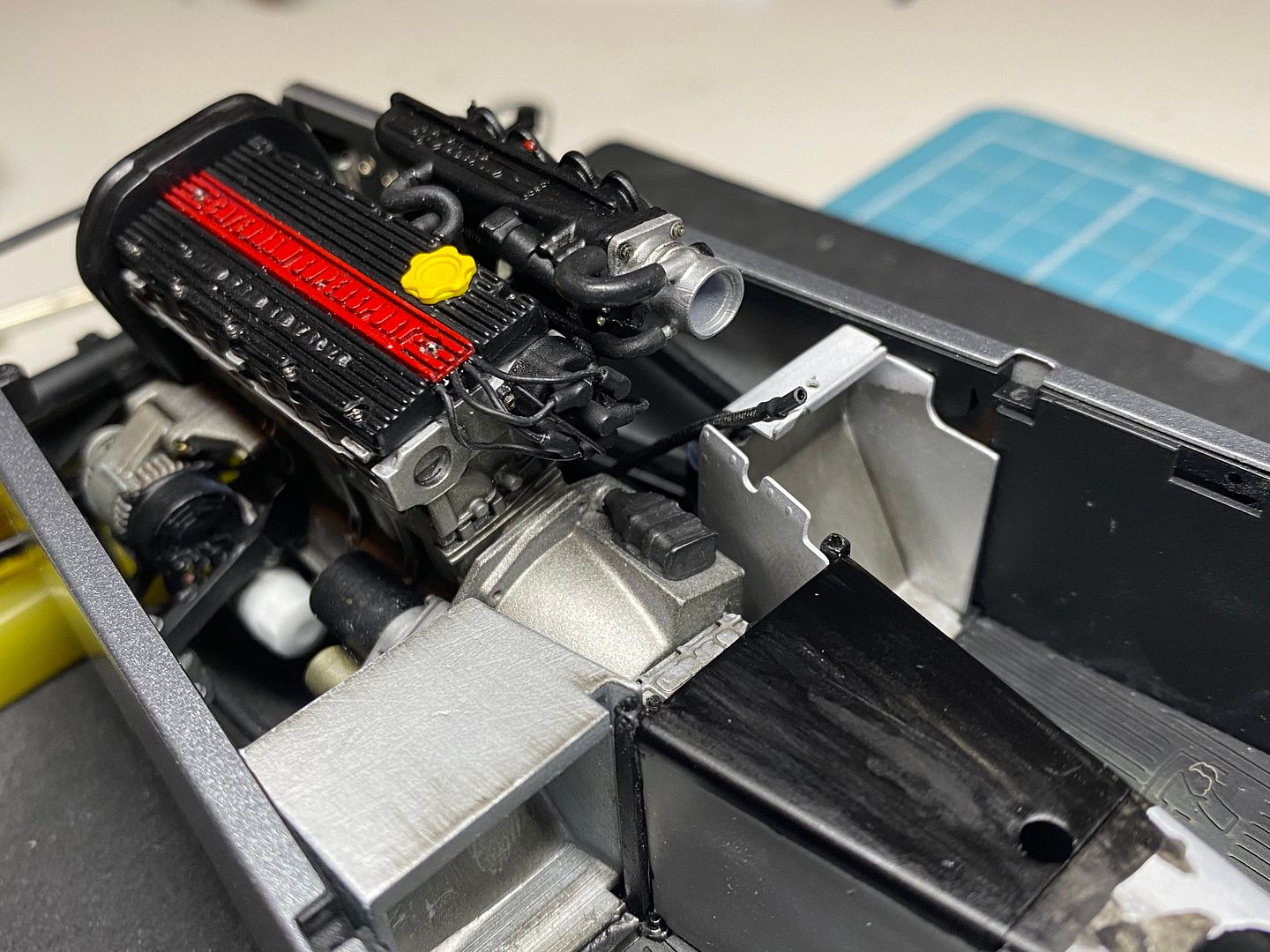

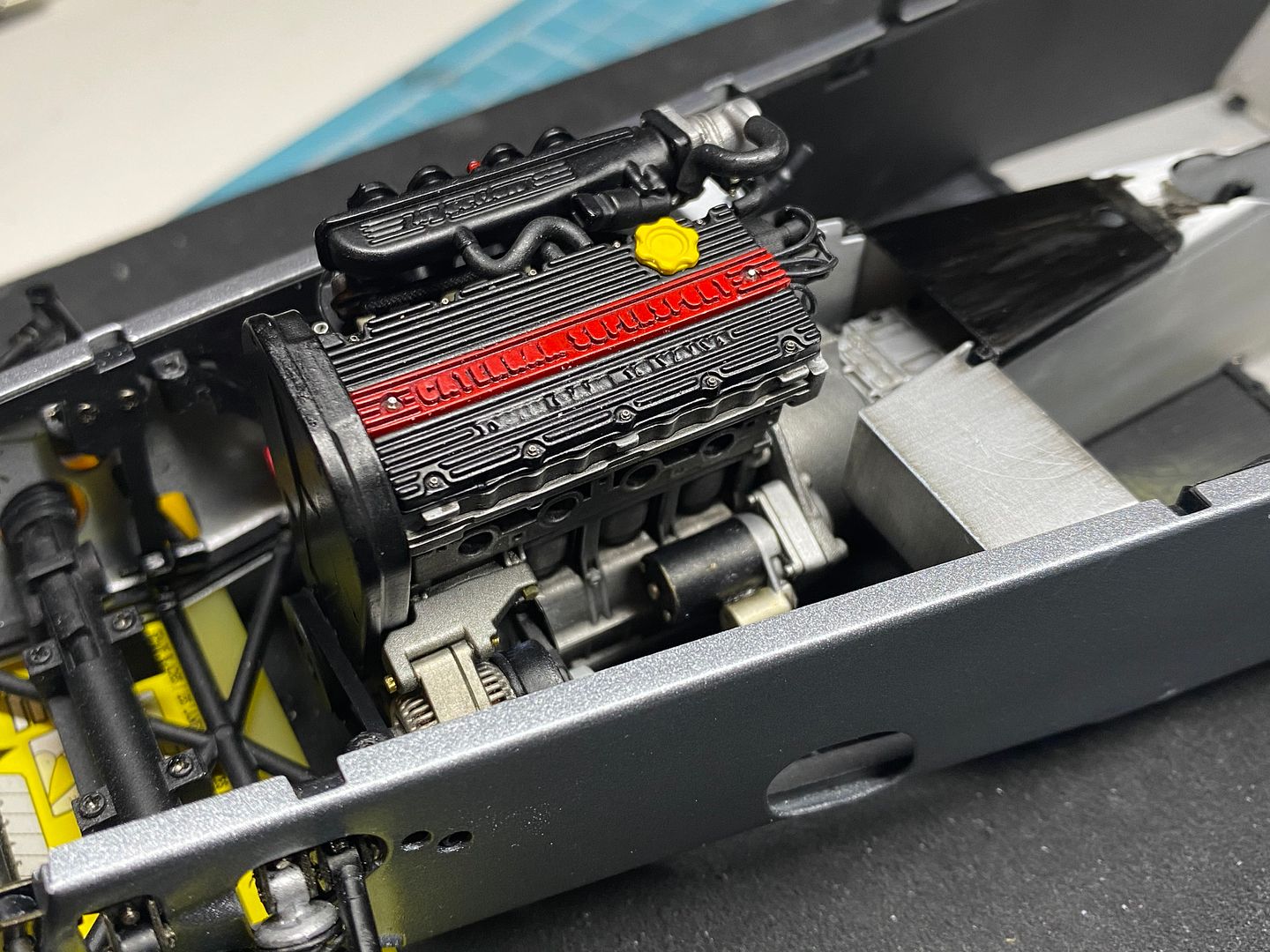

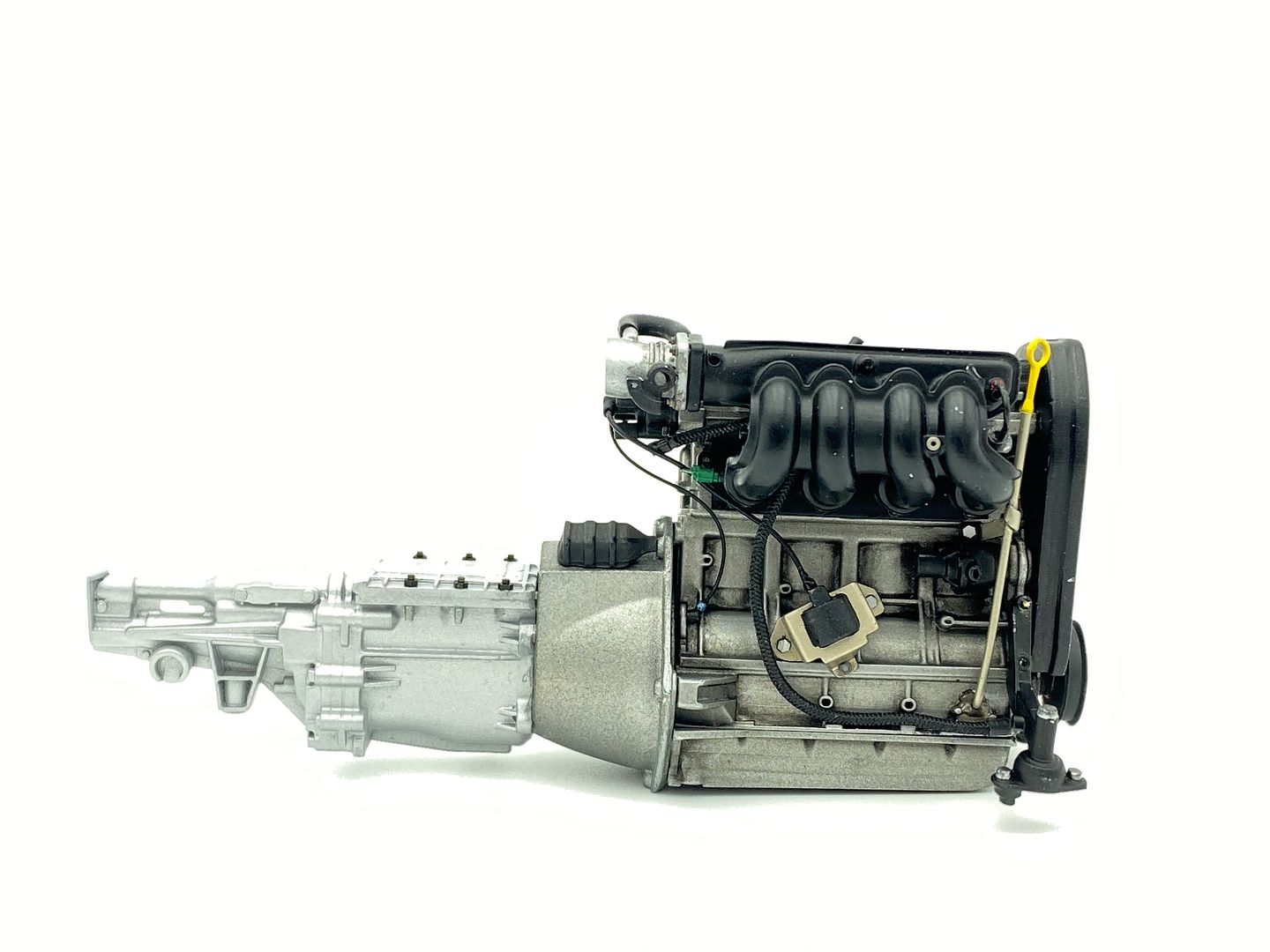

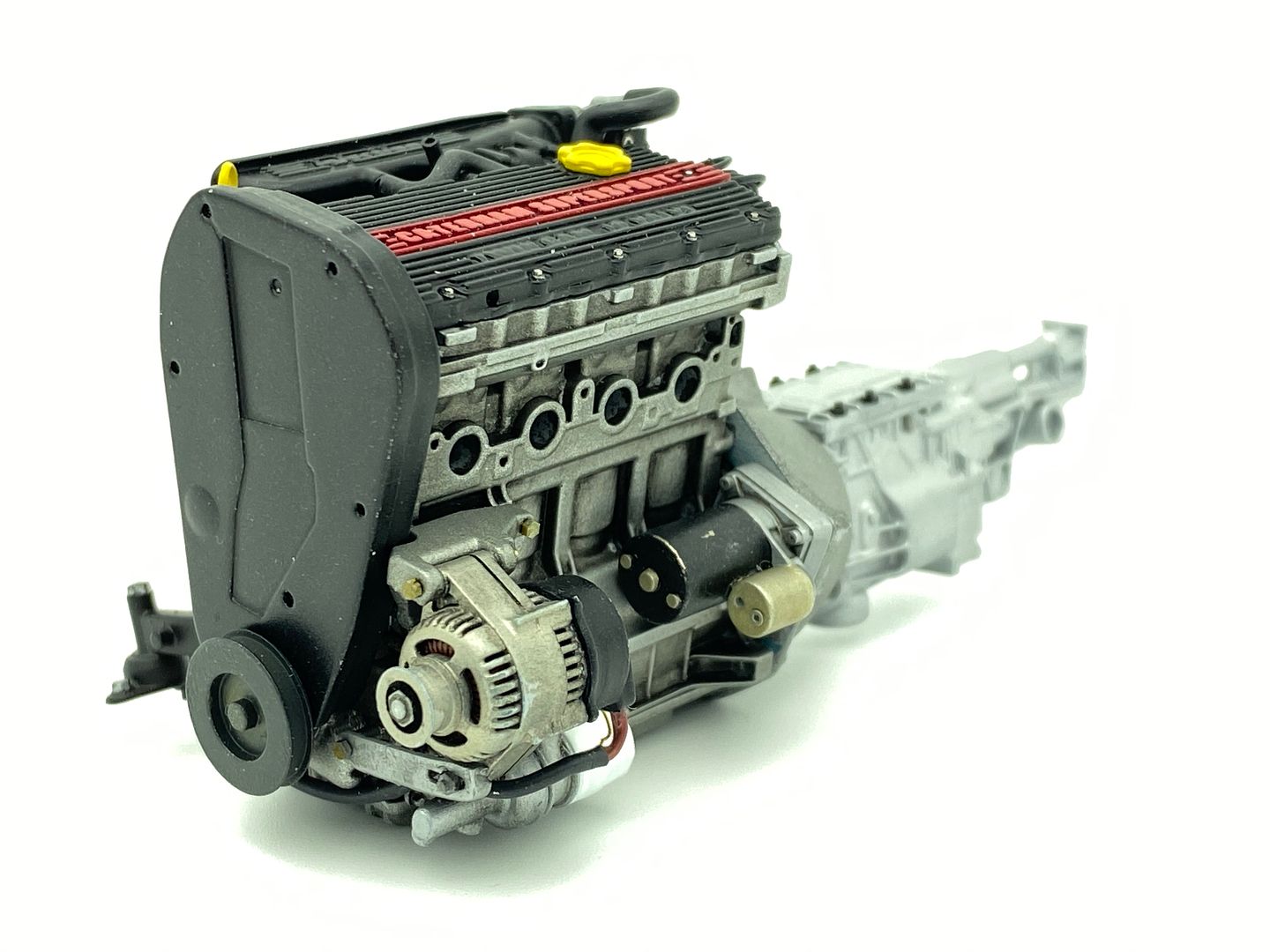

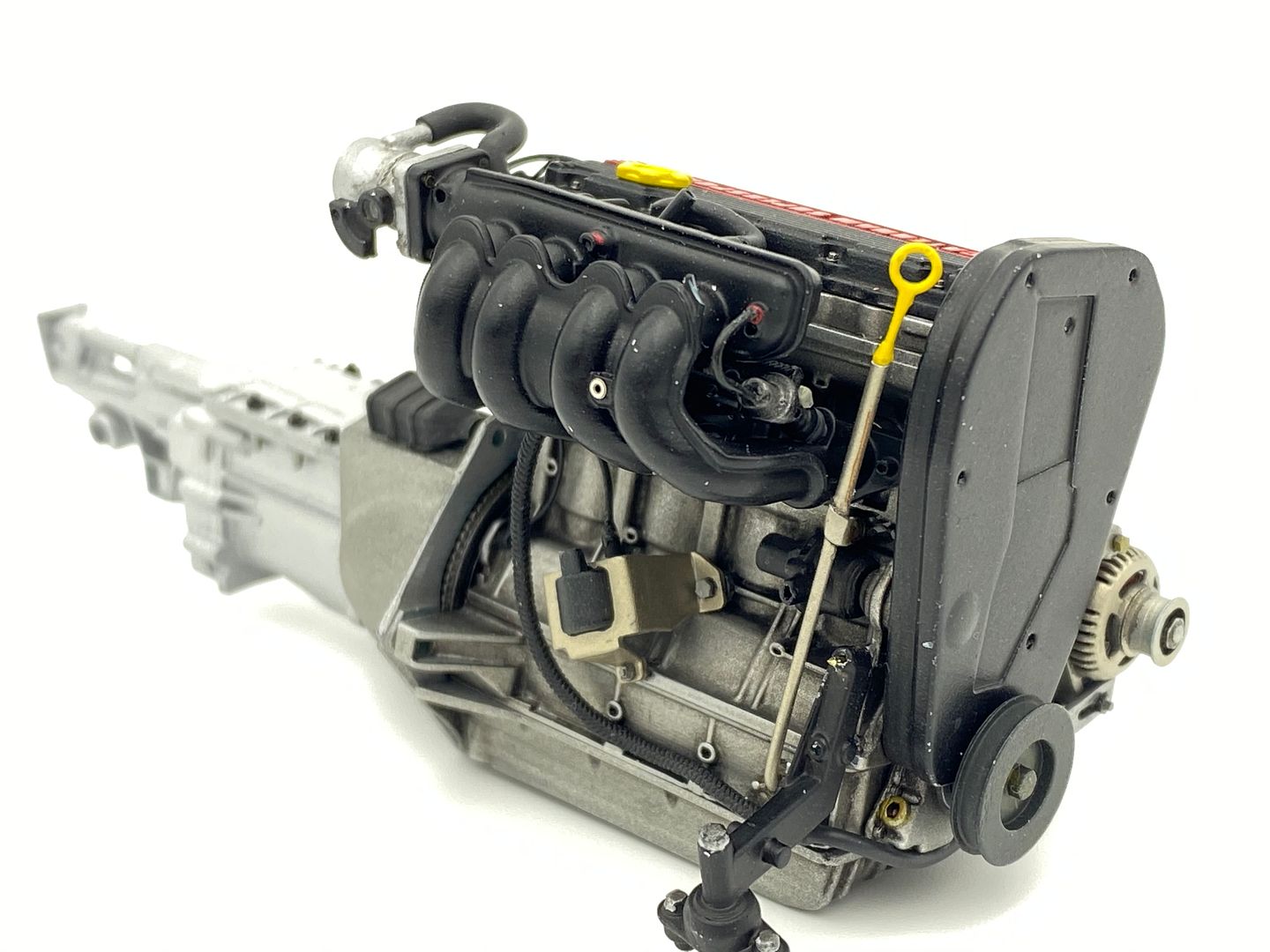

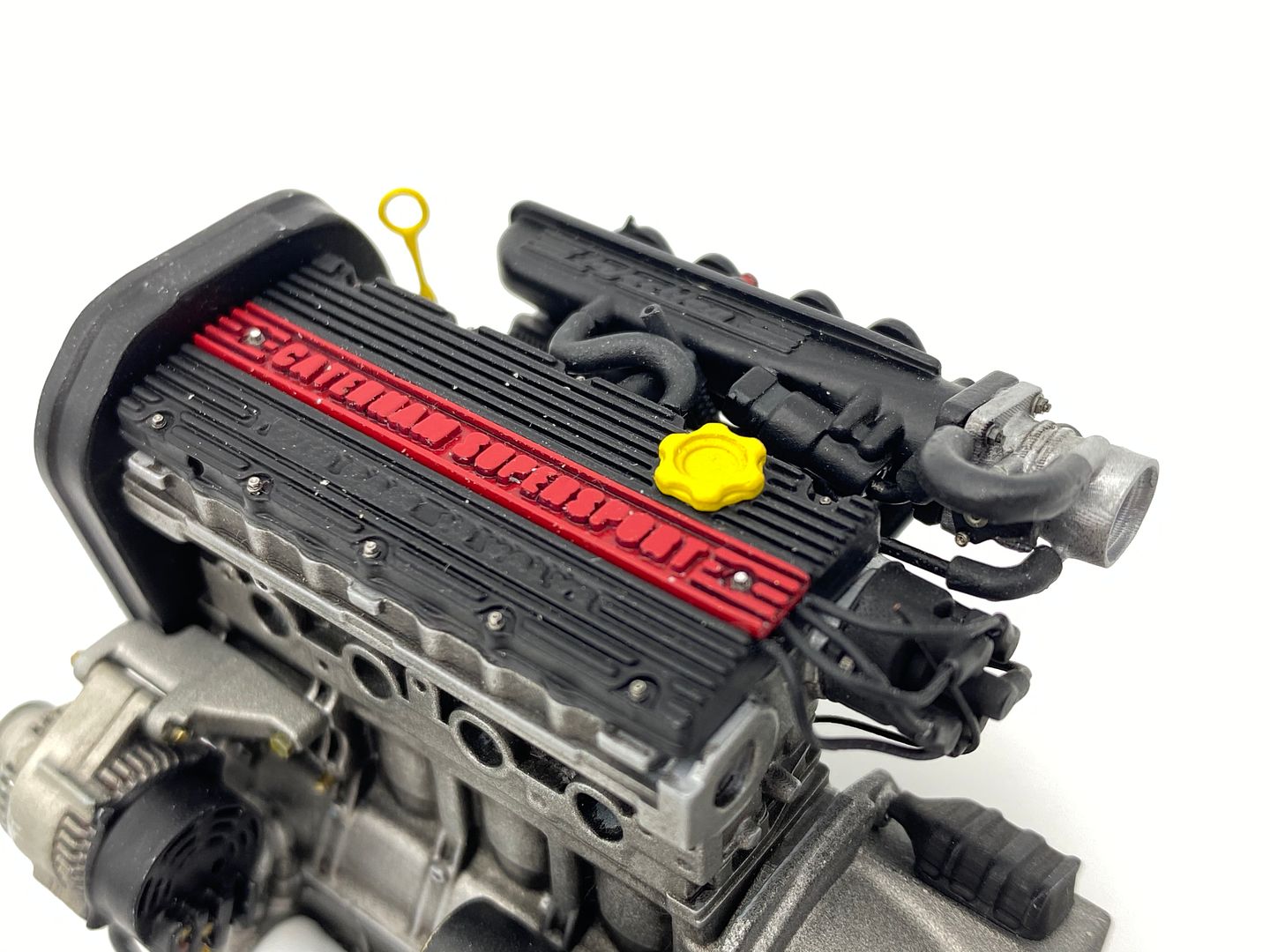

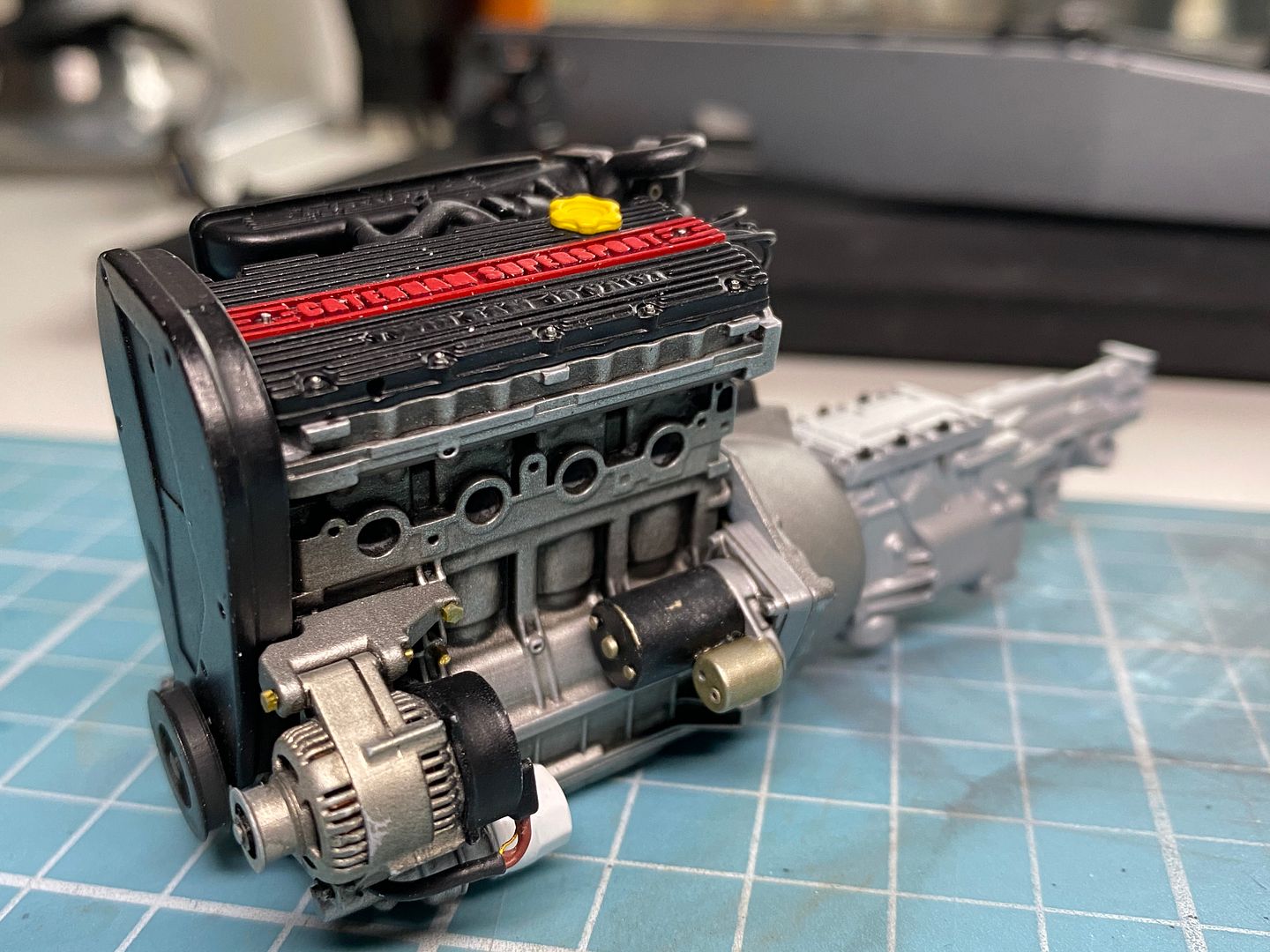

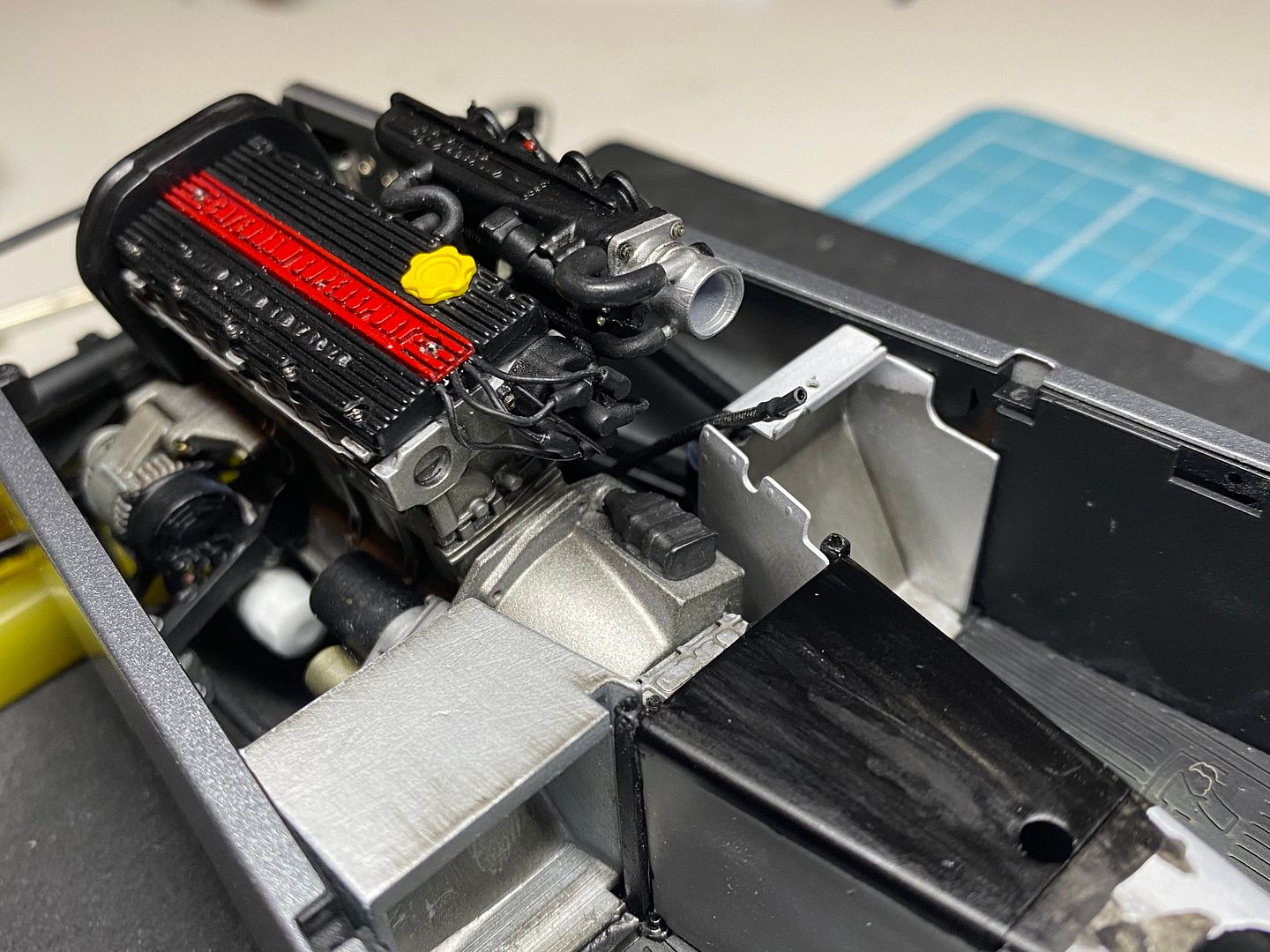

So I had completed the 'core' of the engine - that is, most of the components were assembled OUT of the car. Things like exhausts have to be fixed to the block AFTER the engine is in the chassis - just like the real thing of course.

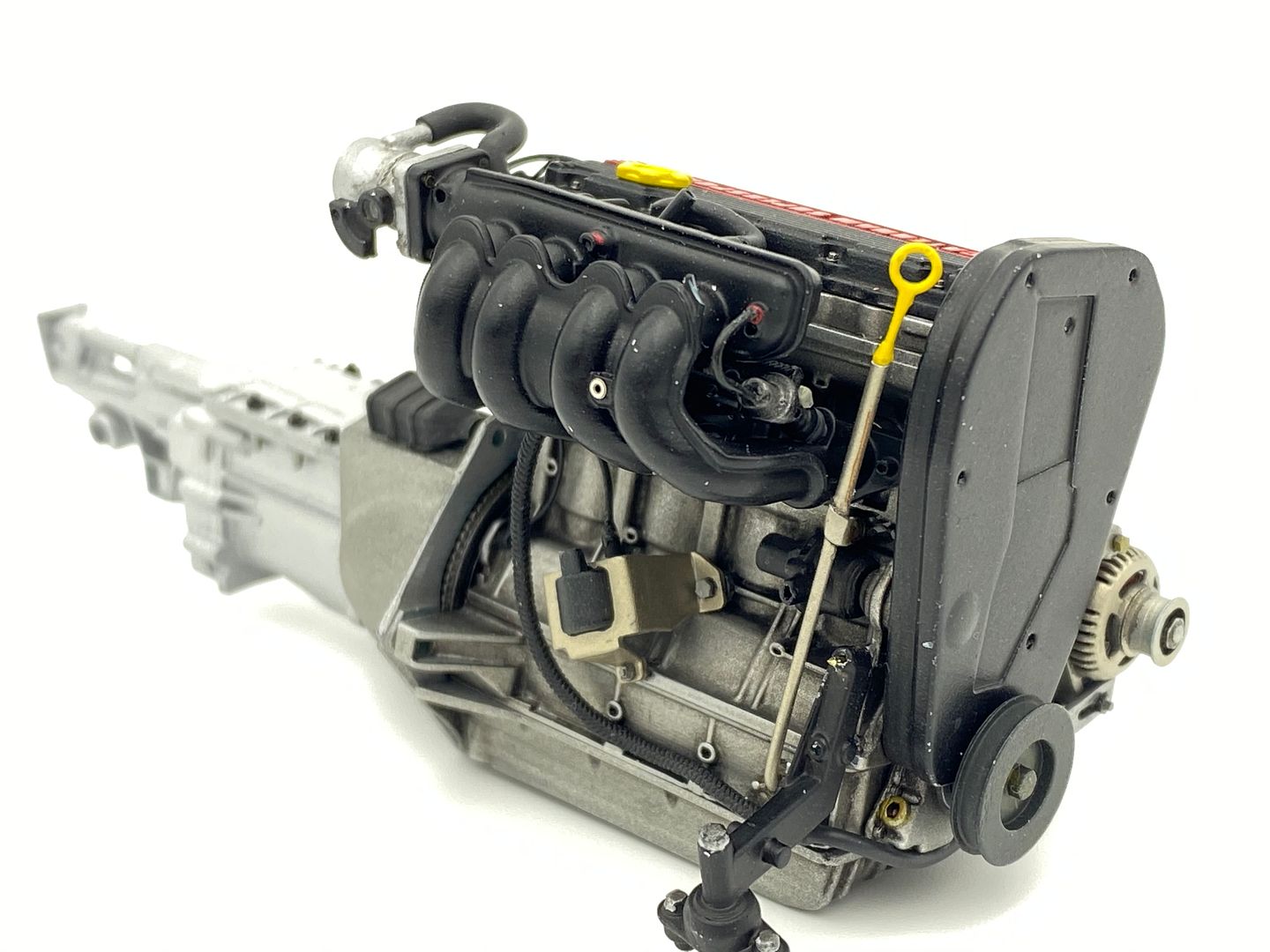

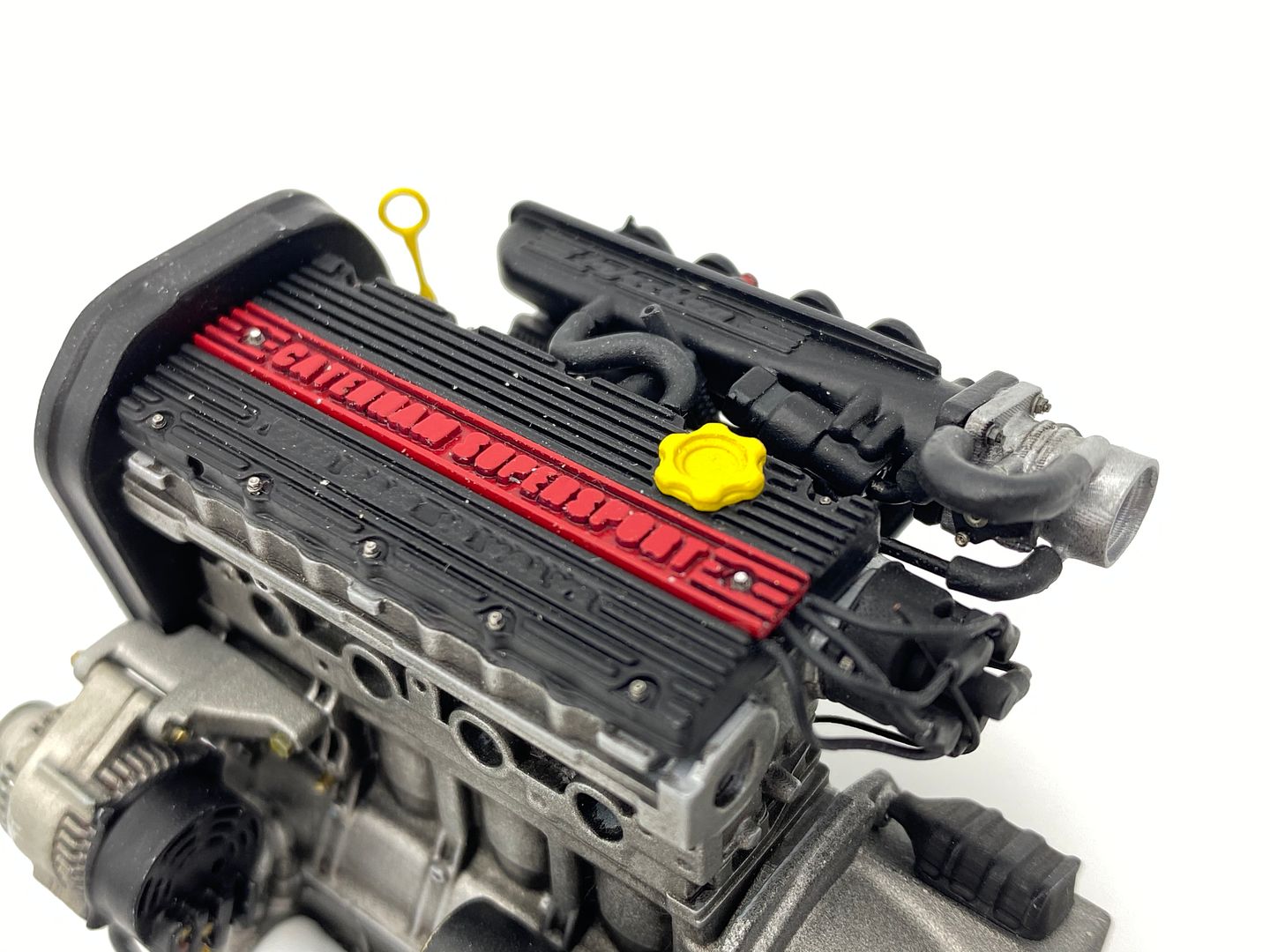

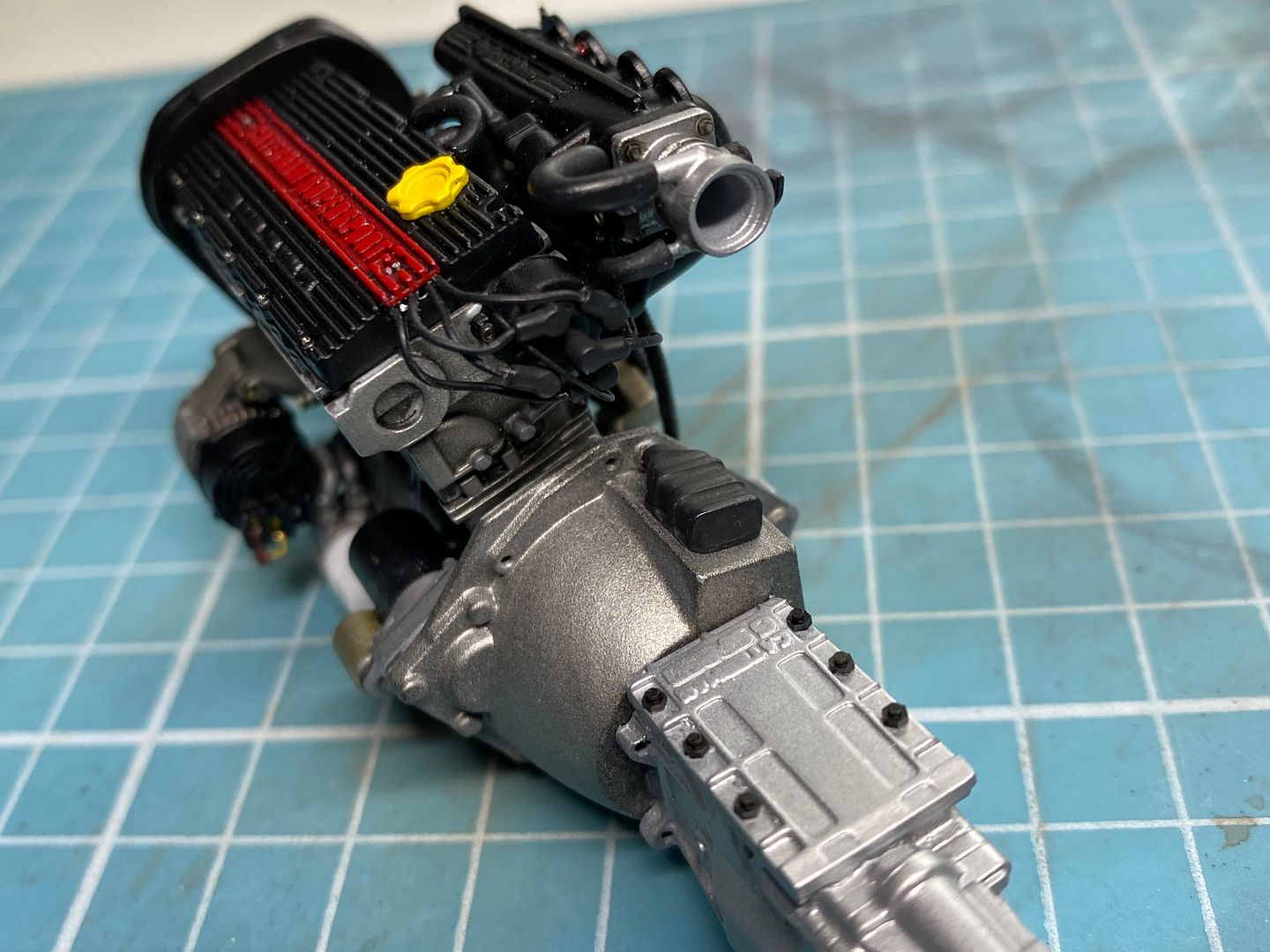

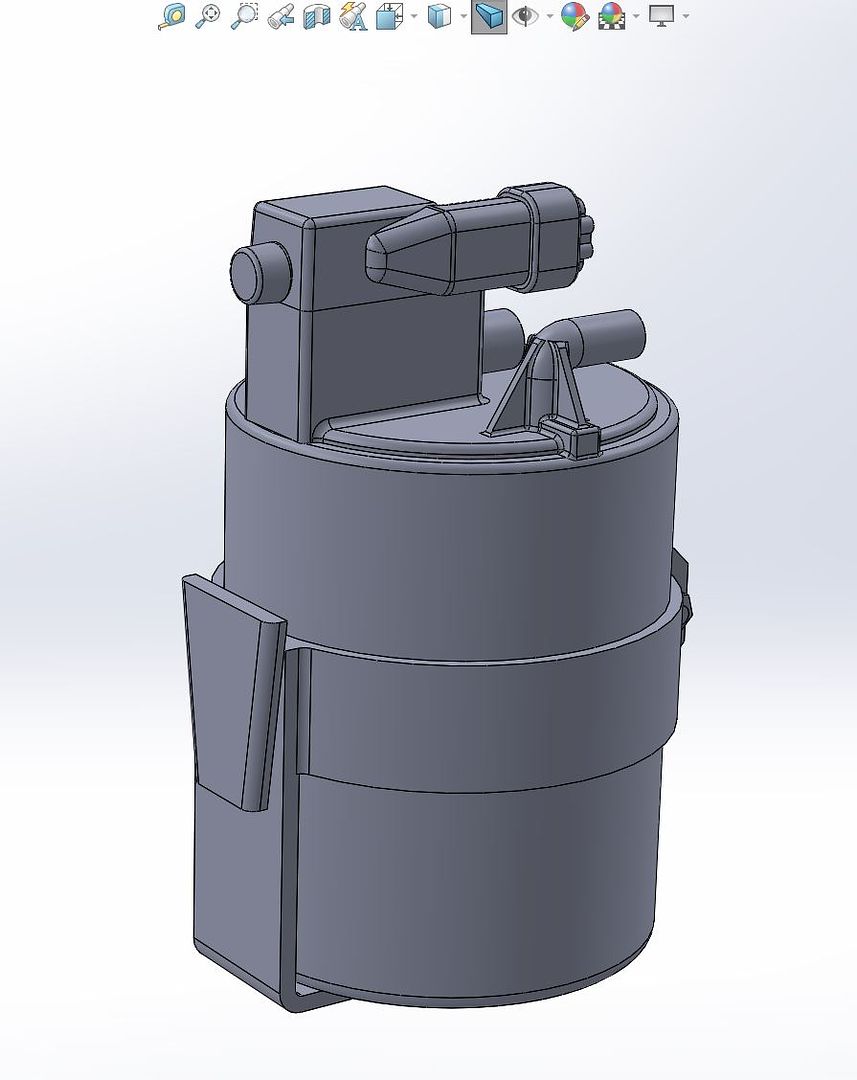

So I have to determine what needs to be done to the engine AND the engine bay before the engine can be located. I also have to design and model the engine mounts. But without doubt the biggest pain is the exhaust manifolds - despite lots of photos, there is no easy way to get each manifold the correct shape in CAD, other than visually and trial and error - so after learning how to actually draw these up (3D sketches in Solidworks) I started printing off samples. I actually got it pretty close first go, so it all comes together quite well - of course I cannot use the exhaust can from the R500 models - so a new one is drawn up! (I modeled the manifolds on the R500 models with thick solder wire - long before the CAD/3D printing process, so could not use any parts from those...)

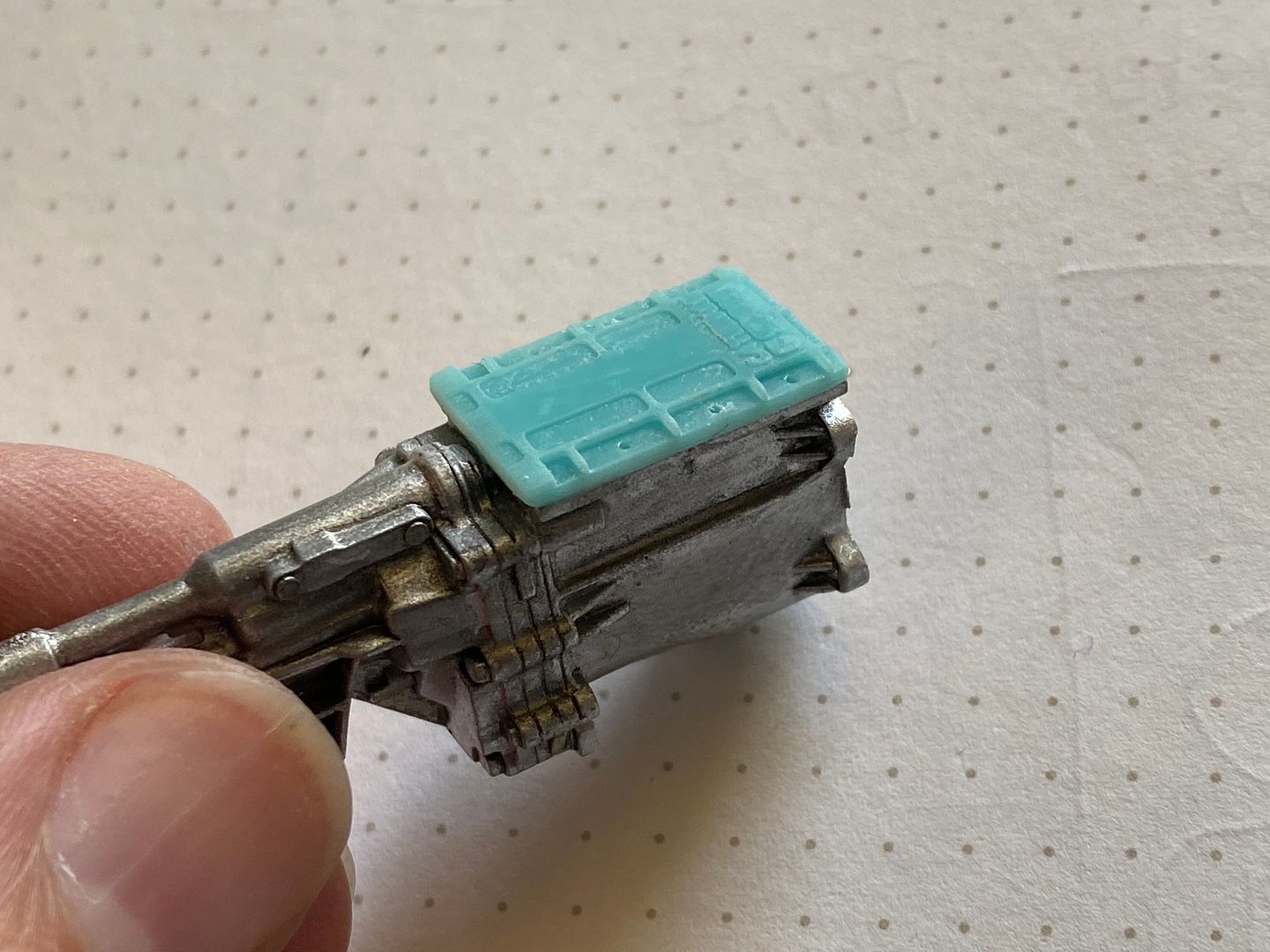

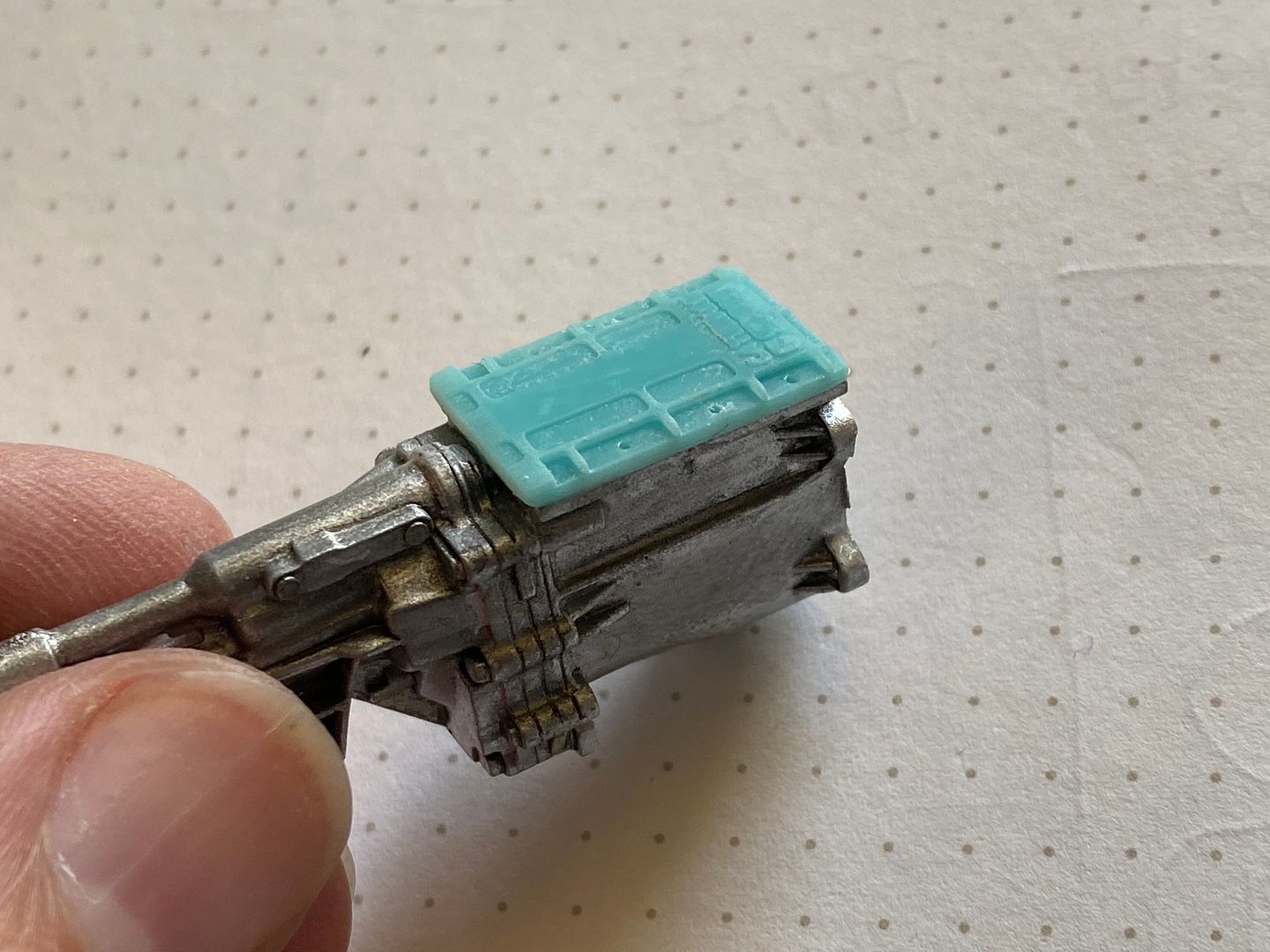

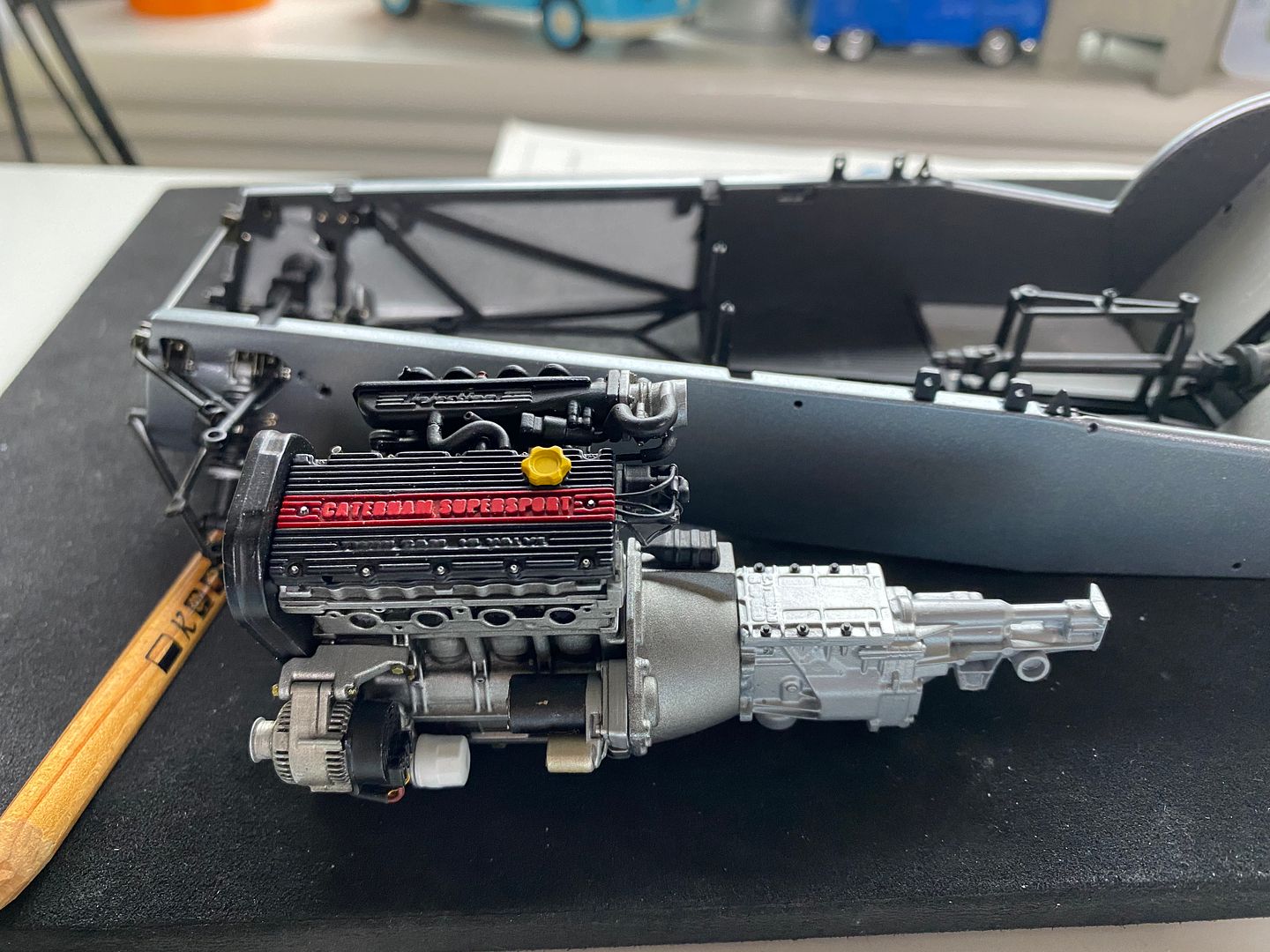

Before I could work on the exhaust, I had to fit the gearbox (in order to locate the engine in the engine bay correctly) This Superlight has the Caterham 6-speed box fitted, so I made the top plate that will be SLIGHTLY visible from within the engine bay.

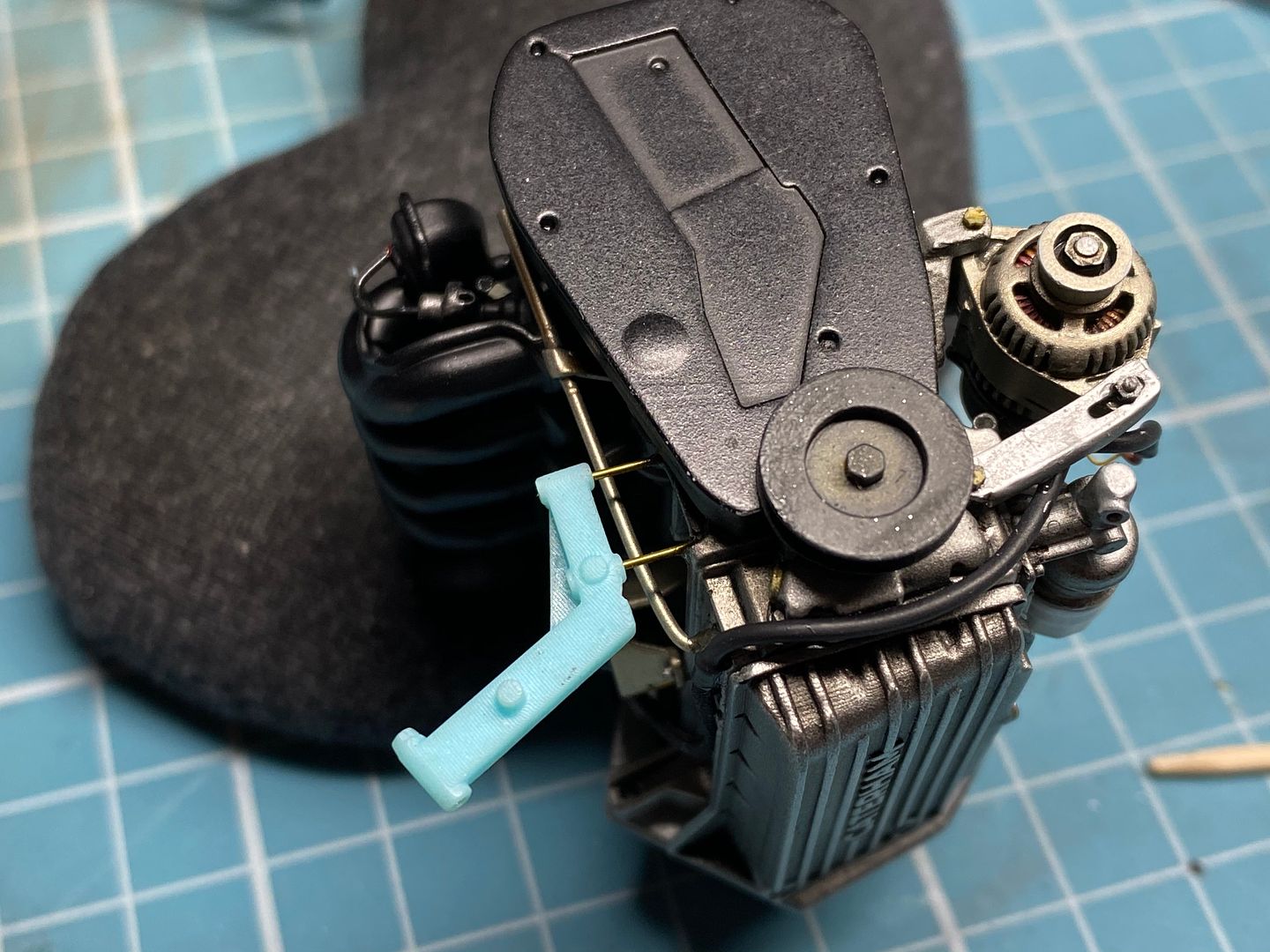

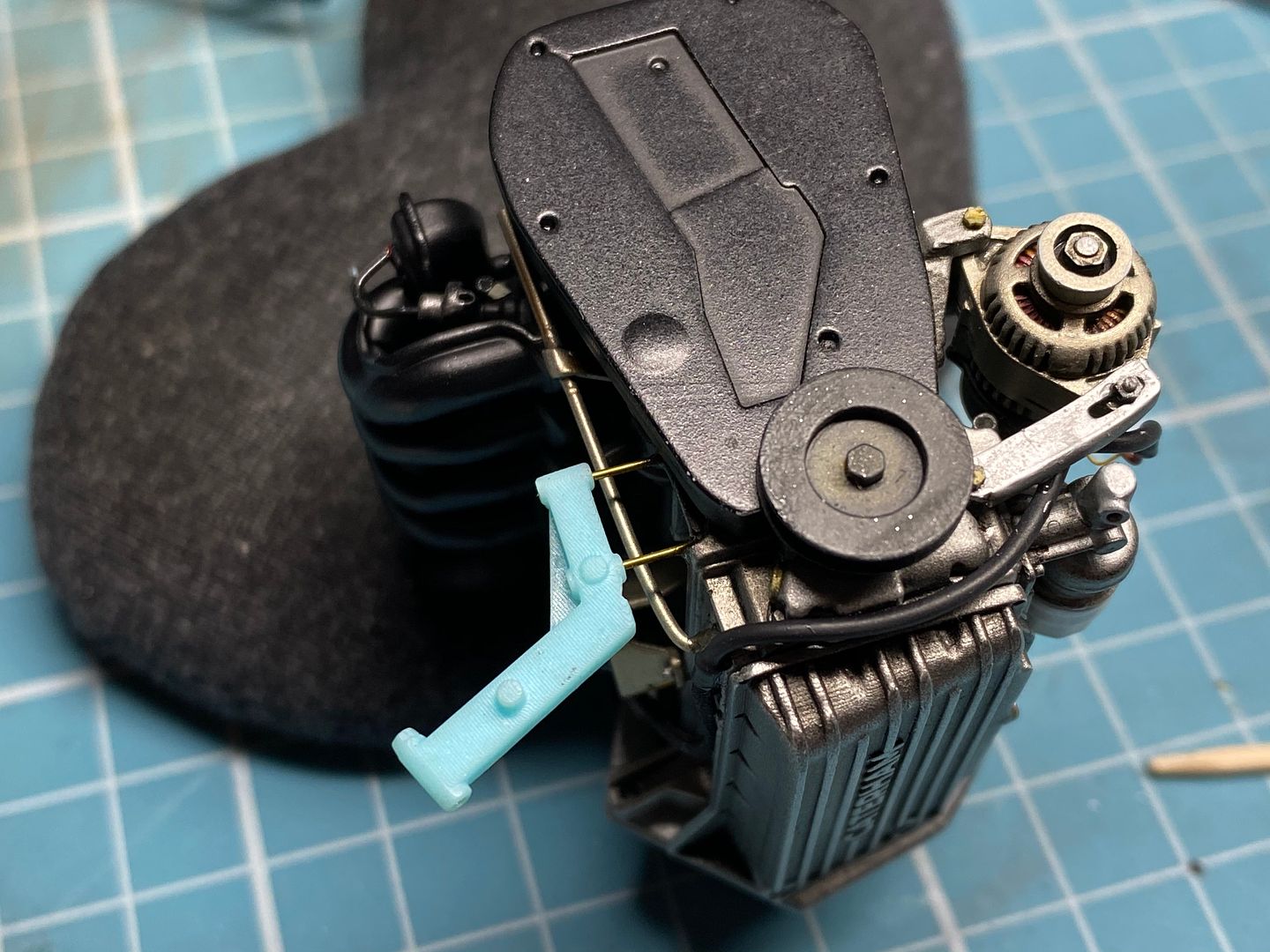

This now gave me the correct fore/aft fitting of the engine, so I could work on the engine mounts. True to the real ones, these are a very tight fit around the components, such as the exhaust and particularly the alternator.

They locate into corresponding mounting points in the chassis rails.

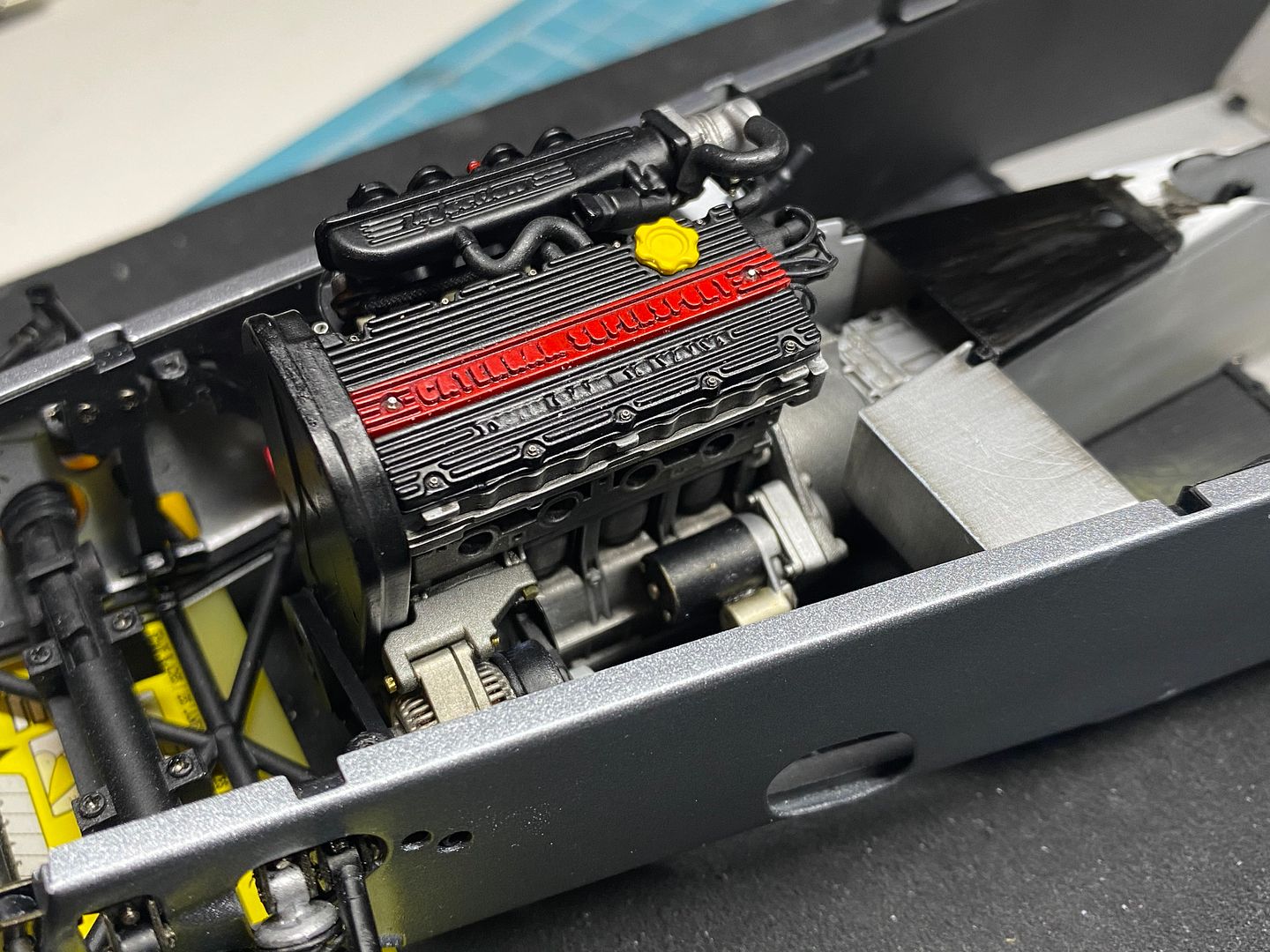

So at this point I have the engine location fixed. Now I have to figure out what has to be designed, made and fixed in place BEFORE the engine can be actually located permanently. The exhaust is a 'floating' fit - by that I mean I have to partially insert the engine, then thread the manifolds through the gaps, and bring everything into place as the engine is lowered - just like in 1:1 scale - a right pain in the arrrse.

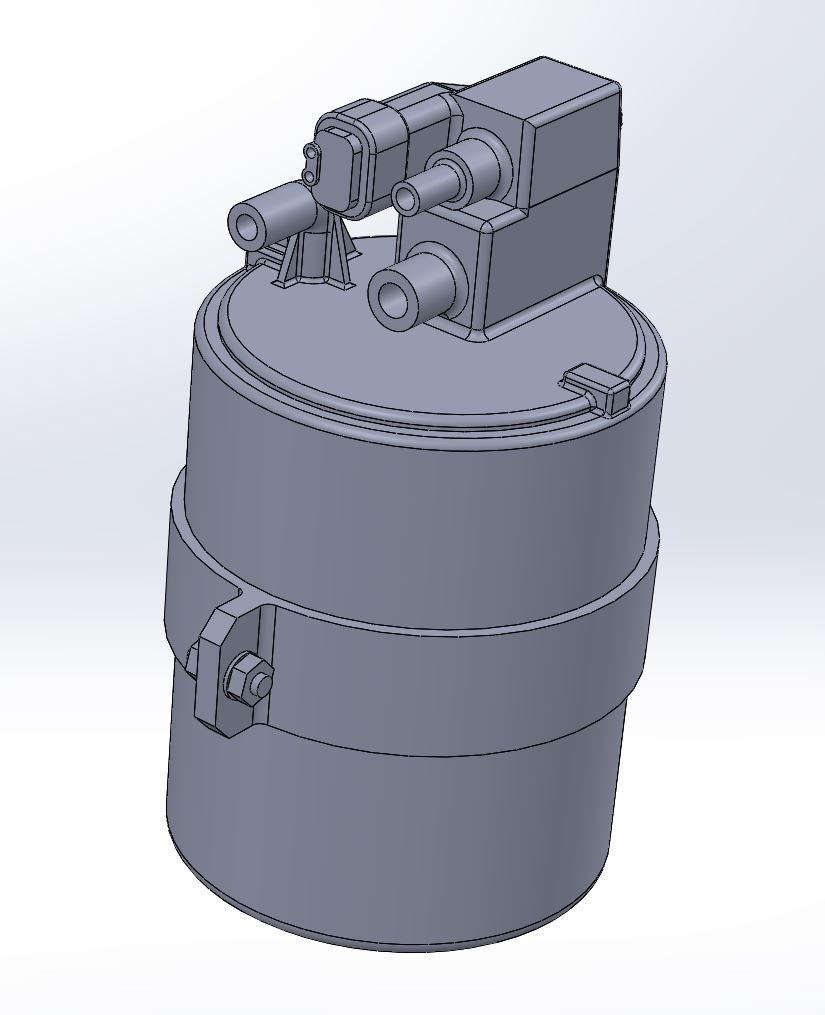

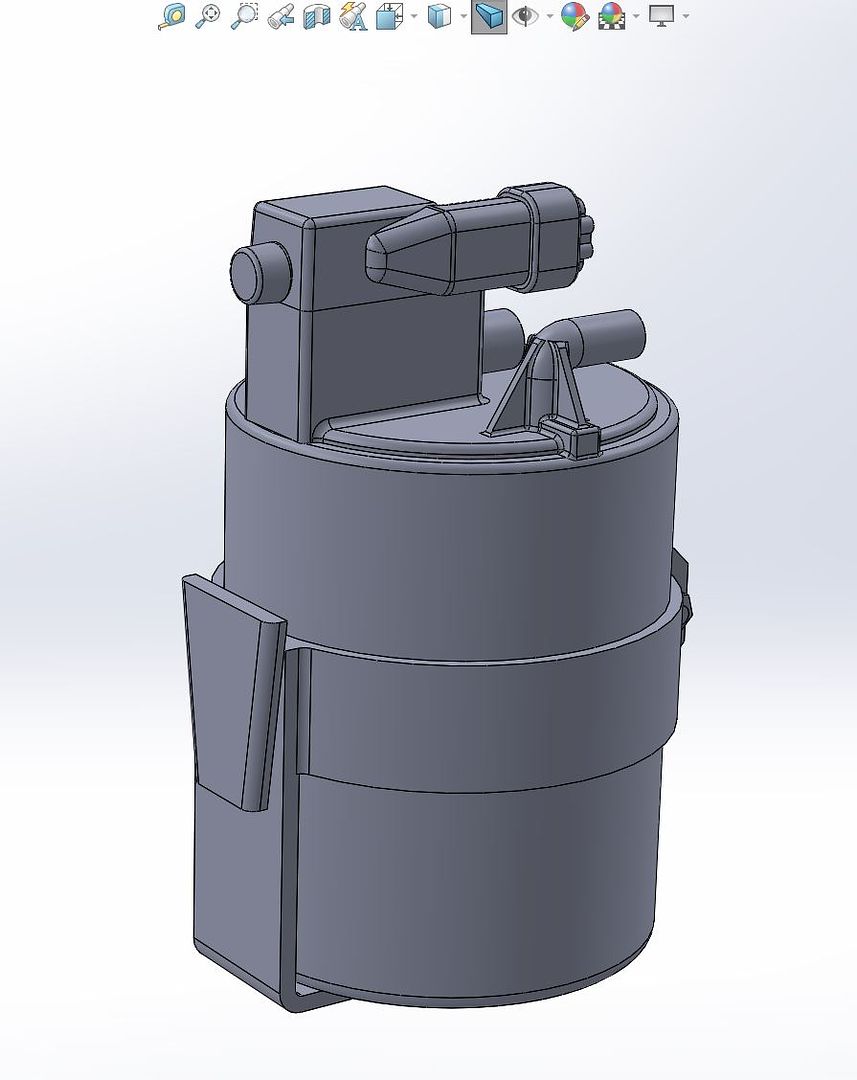

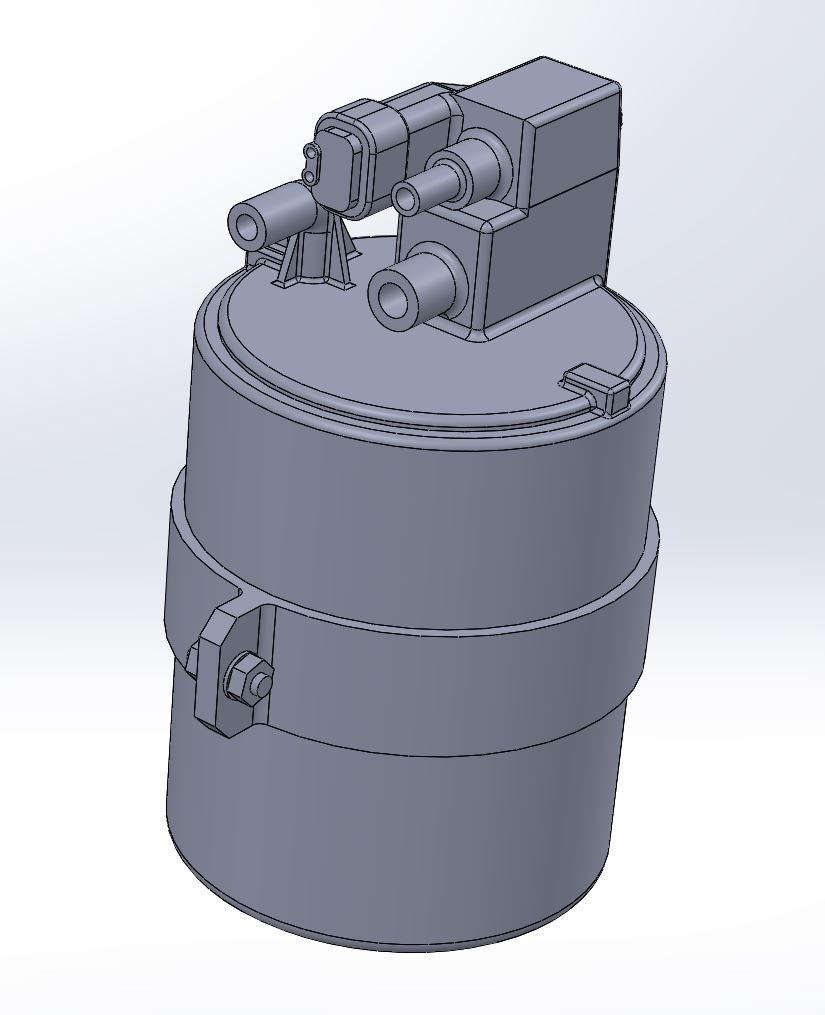

But before that I have some other things to fix in place. Any wiring that may be hard to get too later. A carbon filter on this car (usually removed) sits in the engine bay on the side skin - I drew this up in CAD and printed it - I'll add piping before fitting...

You can see the black canister next to the dash in this pic.

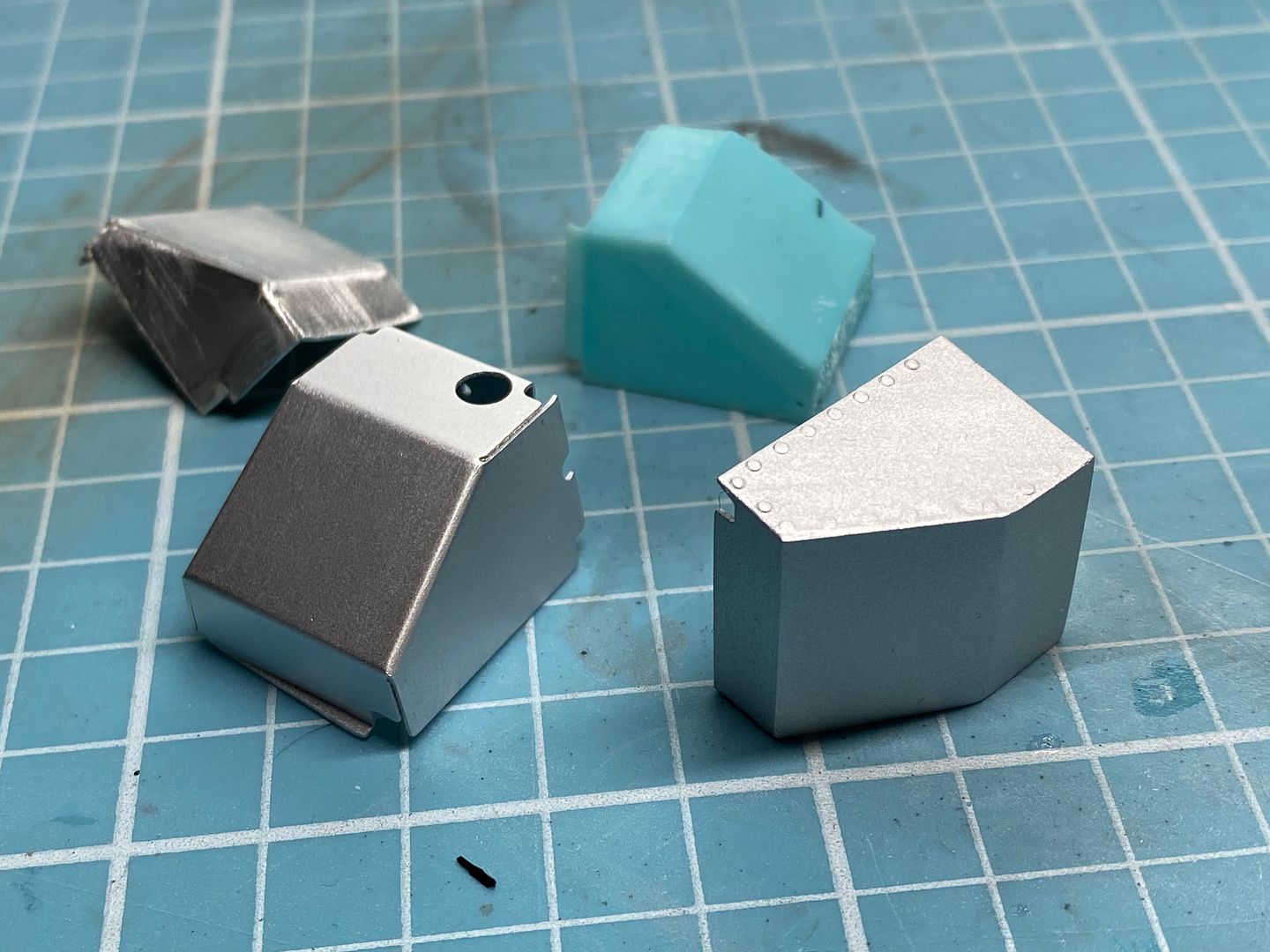

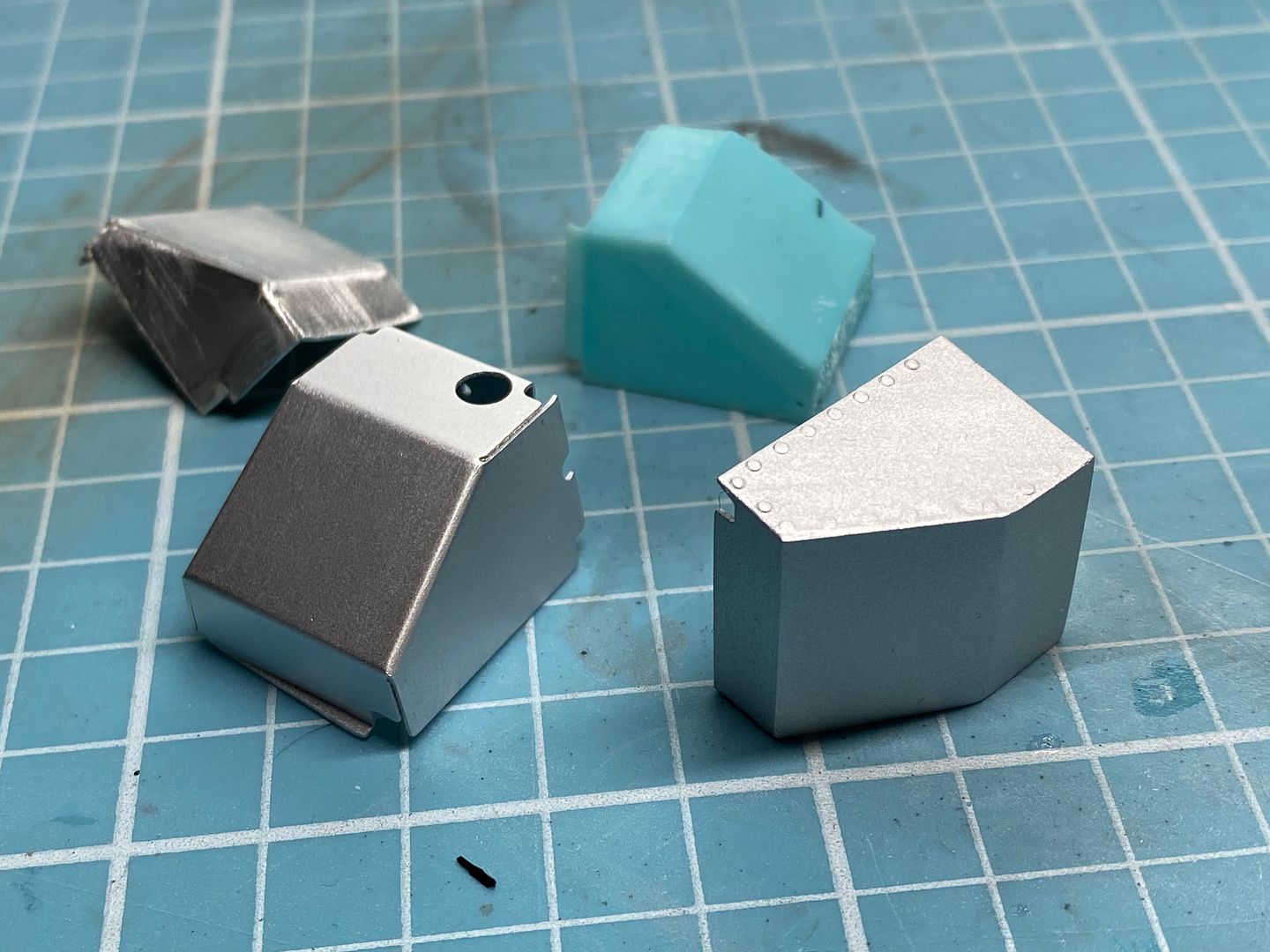

Quite a big job has been the footwells. The Tamiya kit is based on an older Caterham, which had a short passenger footwell (where your legs stretch out under the dash) - later models have an 'extended' version, which gives more room and usually holds some electrical boxes - in the case the battery - on top. It brings the footwell out to the same place as the pedal box on the drivers side. I had to make this, as the kit has a short version. I tried different methods - plasti-card, folder ali-sheet and in the end a 3D printed version - it was just easier to draw up the awkward shape in CAD than try origami with ali sheet. A few attempts here:

The box with the hole in it is the ali kit version, and the hole is for the steering column. I sprayed both boxes to match the rest of the aluminium interior panels. I haven't got a picture of these in situ yet because it requires 5 hands to hold them in place with the bulkhead above, chassis rails etc etc - it is going to be a one-hit fitting process with the engine and engine bay chassis rails!

Oh hang on - I have...

On to the exhaust....

It's been a while, but only in terms of an update - work has been progressing, inbetween a few foreign trips...FB has seen some picture dumps, but not here....

So although a lot has been done, there is still tons to do, with almost every aspect of the car having to be either drawn up in CAD and printed, or scratch built. Very easy to under estimate how much work will be involved - and time....jeez!

So I had completed the 'core' of the engine - that is, most of the components were assembled OUT of the car. Things like exhausts have to be fixed to the block AFTER the engine is in the chassis - just like the real thing of course.

So I have to determine what needs to be done to the engine AND the engine bay before the engine can be located. I also have to design and model the engine mounts. But without doubt the biggest pain is the exhaust manifolds - despite lots of photos, there is no easy way to get each manifold the correct shape in CAD, other than visually and trial and error - so after learning how to actually draw these up (3D sketches in Solidworks) I started printing off samples. I actually got it pretty close first go, so it all comes together quite well - of course I cannot use the exhaust can from the R500 models - so a new one is drawn up! (I modeled the manifolds on the R500 models with thick solder wire - long before the CAD/3D printing process, so could not use any parts from those...)

Before I could work on the exhaust, I had to fit the gearbox (in order to locate the engine in the engine bay correctly) This Superlight has the Caterham 6-speed box fitted, so I made the top plate that will be SLIGHTLY visible from within the engine bay.

This now gave me the correct fore/aft fitting of the engine, so I could work on the engine mounts. True to the real ones, these are a very tight fit around the components, such as the exhaust and particularly the alternator.

They locate into corresponding mounting points in the chassis rails.

So at this point I have the engine location fixed. Now I have to figure out what has to be designed, made and fixed in place BEFORE the engine can be actually located permanently. The exhaust is a 'floating' fit - by that I mean I have to partially insert the engine, then thread the manifolds through the gaps, and bring everything into place as the engine is lowered - just like in 1:1 scale - a right pain in the arrrse.

But before that I have some other things to fix in place. Any wiring that may be hard to get too later. A carbon filter on this car (usually removed) sits in the engine bay on the side skin - I drew this up in CAD and printed it - I'll add piping before fitting...

You can see the black canister next to the dash in this pic.

Quite a big job has been the footwells. The Tamiya kit is based on an older Caterham, which had a short passenger footwell (where your legs stretch out under the dash) - later models have an 'extended' version, which gives more room and usually holds some electrical boxes - in the case the battery - on top. It brings the footwell out to the same place as the pedal box on the drivers side. I had to make this, as the kit has a short version. I tried different methods - plasti-card, folder ali-sheet and in the end a 3D printed version - it was just easier to draw up the awkward shape in CAD than try origami with ali sheet. A few attempts here:

The box with the hole in it is the ali kit version, and the hole is for the steering column. I sprayed both boxes to match the rest of the aluminium interior panels. I haven't got a picture of these in situ yet because it requires 5 hands to hold them in place with the bulkhead above, chassis rails etc etc - it is going to be a one-hit fitting process with the engine and engine bay chassis rails!

Oh hang on - I have...

On to the exhaust....

Edited by caterhamnut on Wednesday 18th March 22:47

Did the real one in 1 week - literally!

Started mine today after a few weeks away - need to fit a mechanical oil pressure gauge tomorrow (if it arrives) - the 'electrical' one is not reading anything - I am 95% sure it is the sender, but....

My rear pads are also....not there! lol

For anyone interested, here is a video of us taking our real car apart (properly apart!!) before a rebuild - this is from about 12 years ago now - but you can see how good the model is in terms of chassis etc etc...

https://youtu.be/6t-ieuDABuI

https://youtu.be/olfz079ZrG4

Started mine today after a few weeks away - need to fit a mechanical oil pressure gauge tomorrow (if it arrives) - the 'electrical' one is not reading anything - I am 95% sure it is the sender, but....

My rear pads are also....not there! lol

For anyone interested, here is a video of us taking our real car apart (properly apart!!) before a rebuild - this is from about 12 years ago now - but you can see how good the model is in terms of chassis etc etc...

https://youtu.be/6t-ieuDABuI

https://youtu.be/olfz079ZrG4

Edited by caterhamnut on Wednesday 18th March 22:36

After quite a bit of effort....

...and figuring out how to support the model...

The manifold will attach to the block with bolts, as everything lines up - thanks to the solidworks model!

But I have not modeled the chassis or panels, so getting all those hard points to line up is a challenge!

It did take a few attempts...

Once I selected the parts, I added some detail - in this case the lamda sensor...

Once I had the fit ok, I painted the exhaust. The main exhaust can will be covered by a heat shield.

In these photos nothing is fixed into place yet....just test fitting.

...and figuring out how to support the model...

The manifold will attach to the block with bolts, as everything lines up - thanks to the solidworks model!

But I have not modeled the chassis or panels, so getting all those hard points to line up is a challenge!

It did take a few attempts...

Once I selected the parts, I added some detail - in this case the lamda sensor...

Once I had the fit ok, I painted the exhaust. The main exhaust can will be covered by a heat shield.

In these photos nothing is fixed into place yet....just test fitting.

caterhamnut said:

Did the real one in 1 week - literally!

Started mine today after a few weeks away - need to fit a mechanical oil pressure gauge tomorrow (if it arrives) - the 'electrical' one is not reading anything - I am 95% sure it is the sender, but....

My rear pads are also....not there! lol

For anyone interested, here is a video of us taking our real car apart (properly apart!!) before a rebuild - this is from about 12 years ago now - but you can see how good the model is in terms of chassis etc etc...

https://youtu.be/6t-ieuDABuI

https://youtu.be/olfz079ZrG4

My engine temperature gauge fell out of the dashboard. It's currently on my bench being mended. Hopefully, I'll re-install it tomorrow,.

Started mine today after a few weeks away - need to fit a mechanical oil pressure gauge tomorrow (if it arrives) - the 'electrical' one is not reading anything - I am 95% sure it is the sender, but....

My rear pads are also....not there! lol

For anyone interested, here is a video of us taking our real car apart (properly apart!!) before a rebuild - this is from about 12 years ago now - but you can see how good the model is in terms of chassis etc etc...

https://youtu.be/6t-ieuDABuI

https://youtu.be/olfz079ZrG4

Edited by caterhamnut on Wednesday 18th March 22:36

Fingers crossed...

Dash - although the dash in the kit is the same layout as this model, the Superlight has a carbon dash - the texture on the dash would have to be removed to cover the dash in a carbon decal - but this would be very difficult to do around all the instruments and switches - so of course it requires drawing up and printing....

I covered the dash in the carbon decal, and then set about the switches and dials, which I elected to make all separately.

I coloured and cut tiny pieces of foil to represent the lights within the rocker switches.

I drew up the instrument gauges...

Still work to do on this - and these parts are just placed, not fixed yet...

Dash - although the dash in the kit is the same layout as this model, the Superlight has a carbon dash - the texture on the dash would have to be removed to cover the dash in a carbon decal - but this would be very difficult to do around all the instruments and switches - so of course it requires drawing up and printing....

I covered the dash in the carbon decal, and then set about the switches and dials, which I elected to make all separately.

I coloured and cut tiny pieces of foil to represent the lights within the rocker switches.

I drew up the instrument gauges...

Still work to do on this - and these parts are just placed, not fixed yet...

This car has an FIA roll bar fitted - the kit comes with an old style roll bar you often see on Japanese cars for some reason - and of course the R500's had full cages.

I printed this using a slightly different support method for the printed parts - usually you place many small supports, but these can lead to a lot of marks that need to be removed, or worse, 'sagging' of the resin around the parts. So for these thin 'rods' I instead drew a thing 'fin' in the solidworks model - this would provide support all along the length of the bar, and be easy to sand off once printed - it worked well.

Test fitting...

So that is where I am as of now...the photos below show most of the parts so far started 'assembled' loosely - nothing is fixed into position here, so it all looks a bit wonky! Next stage is probably to aim to fix the engine into place, once I am sure everything else has been done that will be much harder to access once the engine is in.

I printed this using a slightly different support method for the printed parts - usually you place many small supports, but these can lead to a lot of marks that need to be removed, or worse, 'sagging' of the resin around the parts. So for these thin 'rods' I instead drew a thing 'fin' in the solidworks model - this would provide support all along the length of the bar, and be easy to sand off once printed - it worked well.

Test fitting...

So that is where I am as of now...the photos below show most of the parts so far started 'assembled' loosely - nothing is fixed into position here, so it all looks a bit wonky! Next stage is probably to aim to fix the engine into place, once I am sure everything else has been done that will be much harder to access once the engine is in.

Gassing Station | Scale Models | Top of Page | What's New | My Stuff