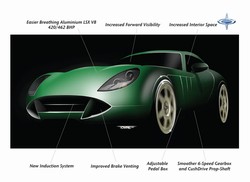

Marcos GTC

Ted gets the skinny behind today's launch of a brand new car

Later today Marcos will reveal the final evolution of its TSO GT car -- and we'll be bringing you pictures the moment they're available.

Just to confuse matters the car’s moniker is now ‘GTC’ rather than GT2. Marcos boss Tony Stelliga explained that the new handle is to emphasise the fact that the car has undergone such radical changes (149 of them) that he considers it worthy of a new handle.

So what’s changed from the previous prototypes? One of the most significant changes – largely in response to feedback from potential customers – is that the interior space has been improved. Laterally, Marcos has provided an extra 4.5 inches while a windscreen redesign and tweaking of the seats adds an extra 2.5 inches of headroom, and better visibility.

Chassis

Under the body, further work has been done by Marcos’s design partner Prodrive. Chassi stiffness is improved and weight is down: the kerb weight of the car is now an impressive 1,125kg.

Bolted to that chassis is a new prefabricated roll cage to provide more rigidity and of course a high level of protection for the occupants in the case of a serious crash.

On the drivetrain front, Marcos is using a six-litre LSX V8 as fitted to the Monaro and Corvette. Monaro emissions hardware has been used to ensure compliance at a reasonable cost. Use of this ECU also paves the way for future enhancements like traction control and ABS.

A redesign of the front of the car has allowed the team to ram more air through the front aperture, improving the breathing of the engine, allowing more cool air to enter the engine bay and resulting in a ‘Ram Air’ effect too.

We’ve obtained the power run that Marcos did at WRC Technologies last week. (see it here as a PDF file). The flat curves should be a good indication of how easy the motor will be to live with. Power for the standard car will be 420bhp whilst the performance pack will take that up to a quoted 462bhp. Marcos is confident that there’s more to be had but wants to ensure its quoted figures are conservative and accurate. It's also achieved its goal of a power to weight ratio exceeding that of a Caterham R400!

Other changes include the gearbox (Monaro spec) and a ‘Cush Drive’ prop shaft which helps buffer some of the drivetrain shunt that can be experienced with such torquey motors.

Exhaust

Conscious of how owners want their cars to sound, Marcos has spent what appears to be an inordinate amount of time tweaking the exhaust tone. The company has varied the point at which the two pipes join in order to get the right exhaust pulses winging their way to the rear of the car. The result is one that Stelliga describes as “Aston-like” but with a good dose of Aussie V8 racer.

The car is built from three outsourced modules: chassis, drivetrain and bodywork. Stelliga is keen to advance production techniques for this type of car. After all, production of spaceframed chassis and GRP bodied cars hasn’t advanced much for some decades.

Revisiting the Build Process

As part of that review, Marcos has adopted a dual gelcoat foam cored version of GRP which it claims is perfect – “as good as metal” - straight out of the box and requires no sanding or filling. The final product is 38 per cent stiffer than their prototypes and 14 per cent lighter. There have also been several hints from Marcos that a targa version of the car might be available in due course.

The largest change to existing practices is that rather than slapping a body on a chassis, screwing it together and then fitting the running gear, Marcos has adopted a production system that sees the chassis fully fitted (and therefore fully stressed) before a body it lowered on. Most significantly, the body comes prefitted with 58 threaded brass pickups which should align to the stressed chassis. If they don’t line up, the body is rejected. The fitting of the body later in the production process ensures fewer scratches and scrapes during other fitting and allows the body to be fitted to a properly stressed car, and should avoid flexing and cracking as the car is loaded up.

The car has been designed using the latest in CAD/CAM technology, something Stelliga is very proud of. “It’s self documenting” he told us. Each component is designed in-house and generates the appropriate tooling data for the component manufacturers. This removes the need for subcontractors to design their own tooling -- and more significantly means that Marcos could switch suppliers if necessary without significant delays.

Dealers

Production is underway with dealer cars arriving in August and the first customer cars soon after.

The dealer network has some familiar names in it. Giles Cooper (TVR Centre, Noble London) will provide the outlet in London. Mole Valley Motor Group (formerly TVR dealers, now Noble dealers) will service the Surrey and surrounding areas. David Gerald Sportscars will service the West Country and Champ Cars at Silverstone will look after the Midlands. A further dealer is to be appointed in the North.

Stelliga’s plans are conservative. When we quizzed him about making the whole project work financially (he’s obviously invested significantly in the design and build), he was reserved. “We don’t plan to build thousands of cars each year”, he told us. One per week, rising to two per week in due course fits his business plan. What we do know is that the modular approach to building the cars should ensure there’s scope to ramp up production if required.

The GTC will be unveiled at 1pm today – we’ll be there to grab some pictures for you and Marcos has also provided us with some studio shots which we’ll be allowed to release early this afternoon.

Links

Gassing Station | Marcos | Top of Page | What's New | My Stuff