Classic mini 16V turbo A series, 6 speed seqential

Discussion

Hi, this is my mini that I have owned for about 14 years now. It's now on its 3rd complete rebuild and 6th/7th engine rebuild. 😂 I took it apart about 4 years ago for an engine refresh and ended up rebuild the entire car in the quest for more power, less weight...more speed!

The shell and generally everything else has been lightened where it can be. I still have plenty to do, but it's sub 500kgs which was the main aim 4 years ago.

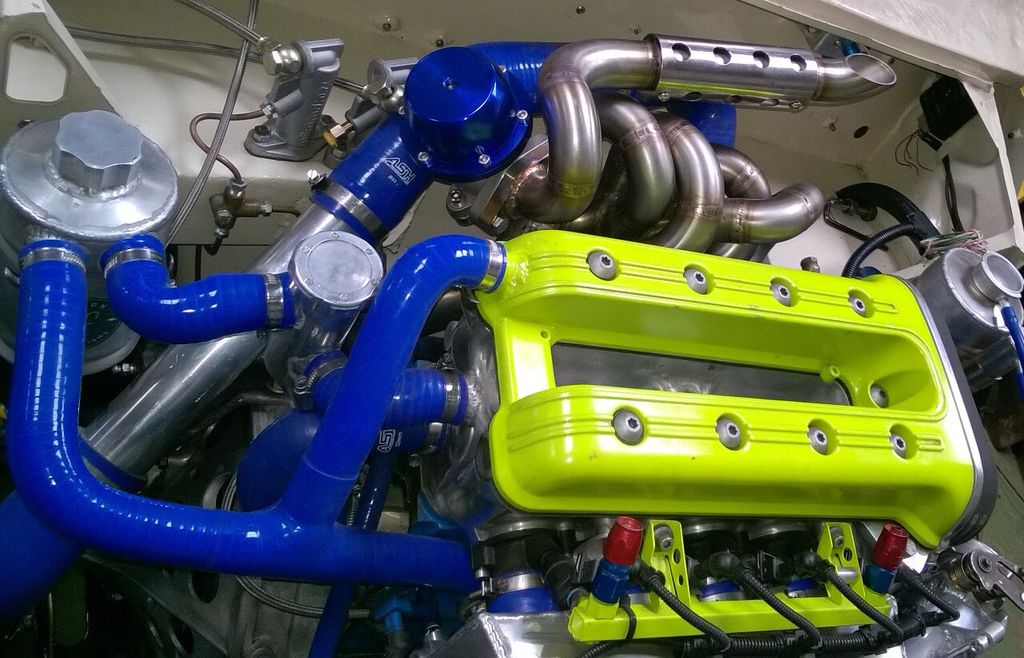

The engine is an A series block, with a BMW K1100 16V head, running EFI, turbo.

The gearbox is an A Series casting modified to take a Honda VFR 6 speed gear set.

I still have plenty of bits to finish off, but it is slowly but surely getting closer to being finished.

The shell and generally everything else has been lightened where it can be. I still have plenty to do, but it's sub 500kgs which was the main aim 4 years ago.

The engine is an A series block, with a BMW K1100 16V head, running EFI, turbo.

The gearbox is an A Series casting modified to take a Honda VFR 6 speed gear set.

I still have plenty of bits to finish off, but it is slowly but surely getting closer to being finished.

57Ford said:

Looks like incredible fun! This was a dream when I was 13 / 14 years old. Unfortunately I've never had space to do it yet but there's time yet... Well done

Thanks, yeah it is good fun to drive and surprises a few people. After 4 yeas of not driving it, it's going to be a bit of shock after driving a Diesel van everyday.Sf_Manta said:

How much is it making?! Given the high flow head and turbo.. must be what? 160-180bhp or there abouts.

Must be like having a bike engine and a stuggle to get the power down once the boost winds up Top work!

fttm said:

Nice work but looks scary as hell , what have you done to the shell ?

The shell has had rear bins removed and rear bench, battery box removed and every unused bracket removed. It's got ally skinned doors, fibreglass front, and fibreglass boot lid. The bulkhead has been remade and dash rails removed. Rear subframe replaced with beam, front subframe lightened. Pretty much everything that bolts on to the shell has had weight removed from it.vrooom said:

Bloody hell. how well does the VFR gearbox hold up? have you found the limitation ?

The gearbox is the latest modification, it has been bench testing and run through heat cycles to check runnign clearances etc, but not put under power yet....it's going to a nervous moment! I have been told that these boxes are good for over 400bhp on the turbo'd drag bikes.dom9 said:

Would love to hear more about the gearbox conversion; how you worked out it could be done, why the VFR gears, what youv done with the diff etc!

I will post some pictures up later on. I saw some pictures of someone in Aus that had done the conversion, and thought I'd have a go basically, just as a bit of an engineering exercise.It ended up a lot more complex than I originally thought, but I got there eventually.

Matty... said:

I will post some pictures up later on. I saw some pictures of someone in Aus that had done the conversion, and thought I'd have a go basically, just as a bit of an engineering exercise.

It ended up a lot more complex than I originally thought, but I got there eventually.

Looking forward to hearing/seeing more as this sounds very interesting indeed!It ended up a lot more complex than I originally thought, but I got there eventually.

Did you need a different pitch crown wheel or anything for the diff?

Could you do a list/ instructions of you went about it? I'd love something like this in my 106 XSi project car!

I'll just be over here clicking the 'watch' button if anyone needs me!

Looks ace. I had a Mini pickup shell and all the bits for a while. Taught myself to weld while patching it up but never got round to rebuilding the Metro turbo engine I bought before I split up with the ex and had to get rid of it all at speed.

Looking forward to seeing more updates.

Looks ace. I had a Mini pickup shell and all the bits for a while. Taught myself to weld while patching it up but never got round to rebuilding the Metro turbo engine I bought before I split up with the ex and had to get rid of it all at speed.

Looking forward to seeing more updates.

Matty... said:

The shell has had rear bins removed and rear bench, battery box removed and every unused bracket removed. It's got ally skinned doors, fibreglass front, and fibreglass boot lid. The bulkhead has been remade and dash rails removed. Rear subframe replaced with beam, front subframe lightened. Pretty much everything that bolts on to the shell has had weight removed from it.

Triggers broom.But in a good way. In a very VERY good way!

I'm looking forward to following the updates with this one.

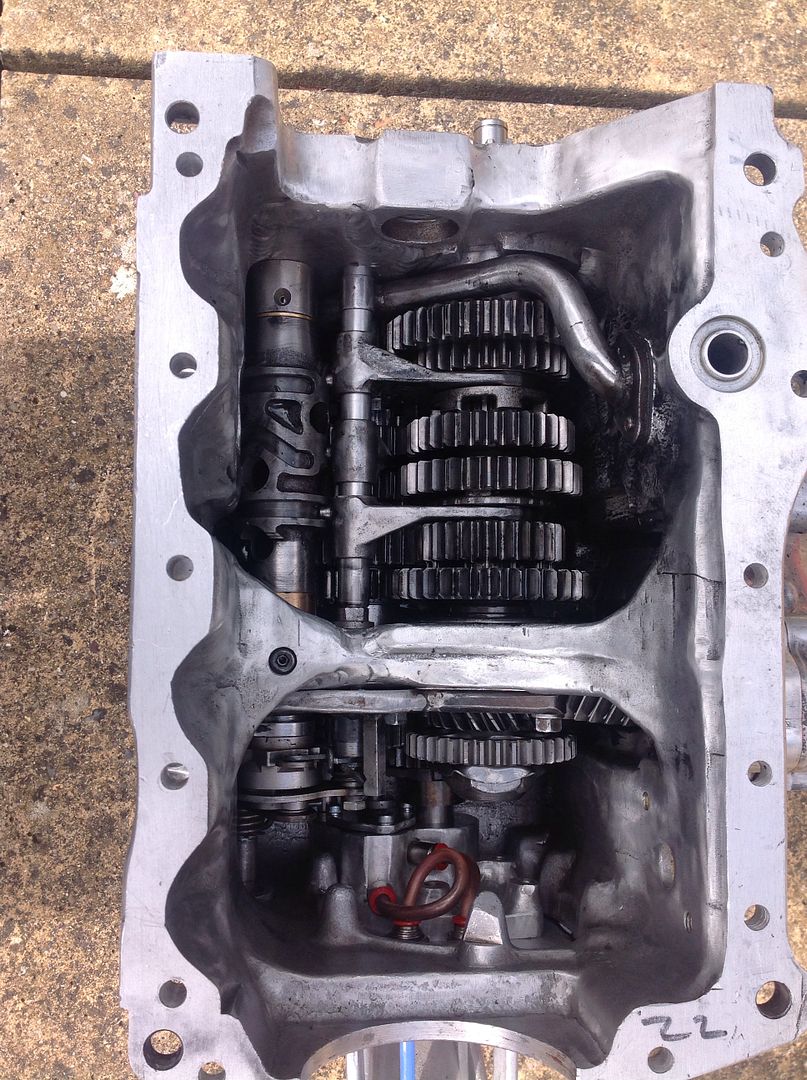

Thanks for the comments. It could take a while to write up the whole gearbox build, but here are the main mods done to the casing etc...

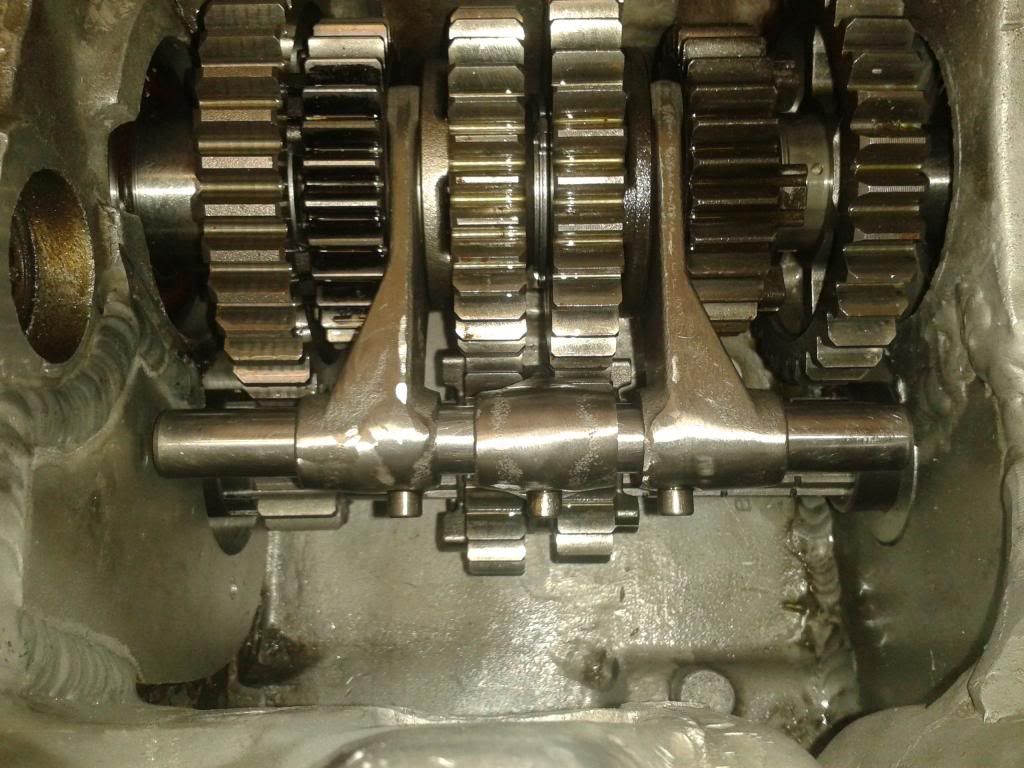

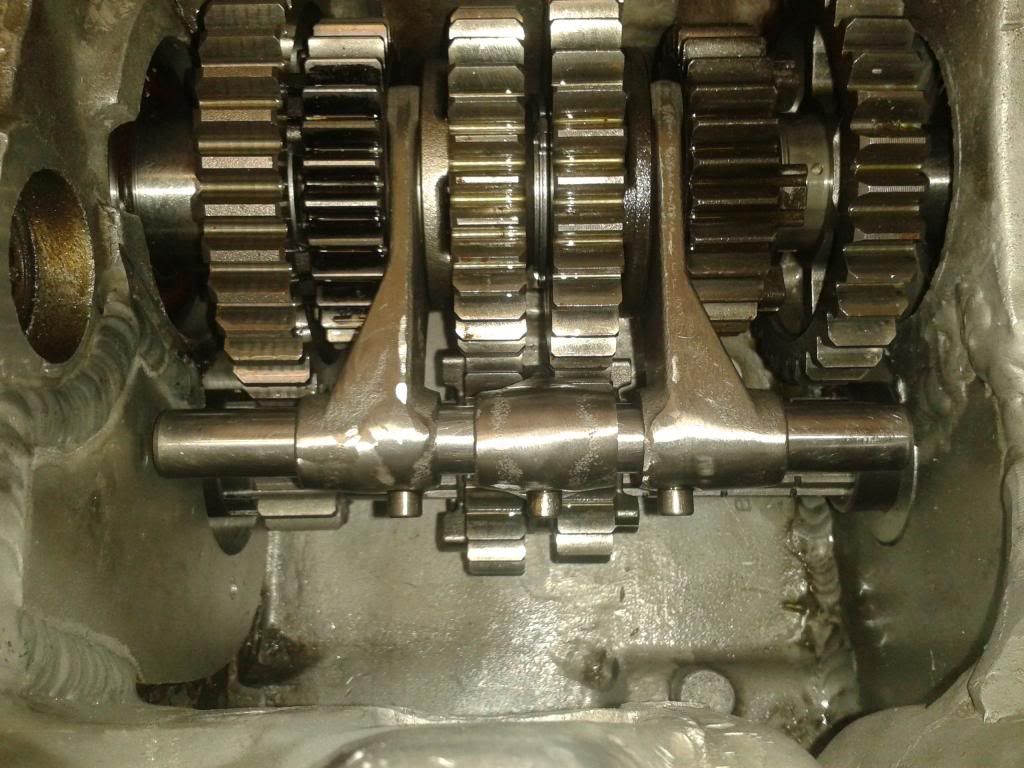

I started comparing the two gearsets, and measuring shaft centres to see where the input shaft one align in the casing. The 3rd motion shaft was always going to stay in the stay position as I used this as the datum point. It also allowed me to keep the standard CWP and allowed standard mesh of the drops gears also.

The case was then chopped to allow for new blank plates to be welded in for new shaft locations.

New plates welded in place.

A Jig was then made and a pointer for the selector fork shaft to work out that shaft centre in comparison to the others.

I started comparing the two gearsets, and measuring shaft centres to see where the input shaft one align in the casing. The 3rd motion shaft was always going to stay in the stay position as I used this as the datum point. It also allowed me to keep the standard CWP and allowed standard mesh of the drops gears also.

The case was then chopped to allow for new blank plates to be welded in for new shaft locations.

New plates welded in place.

A Jig was then made and a pointer for the selector fork shaft to work out that shaft centre in comparison to the others.

The casing was the bored to the correct shaft centres. To check clearances on the machine to ensure correct backlash clearance, I made some bungs for the bearings inserted two shafts, then two discs machined to the same OD and use a feeler to measure the backlash.

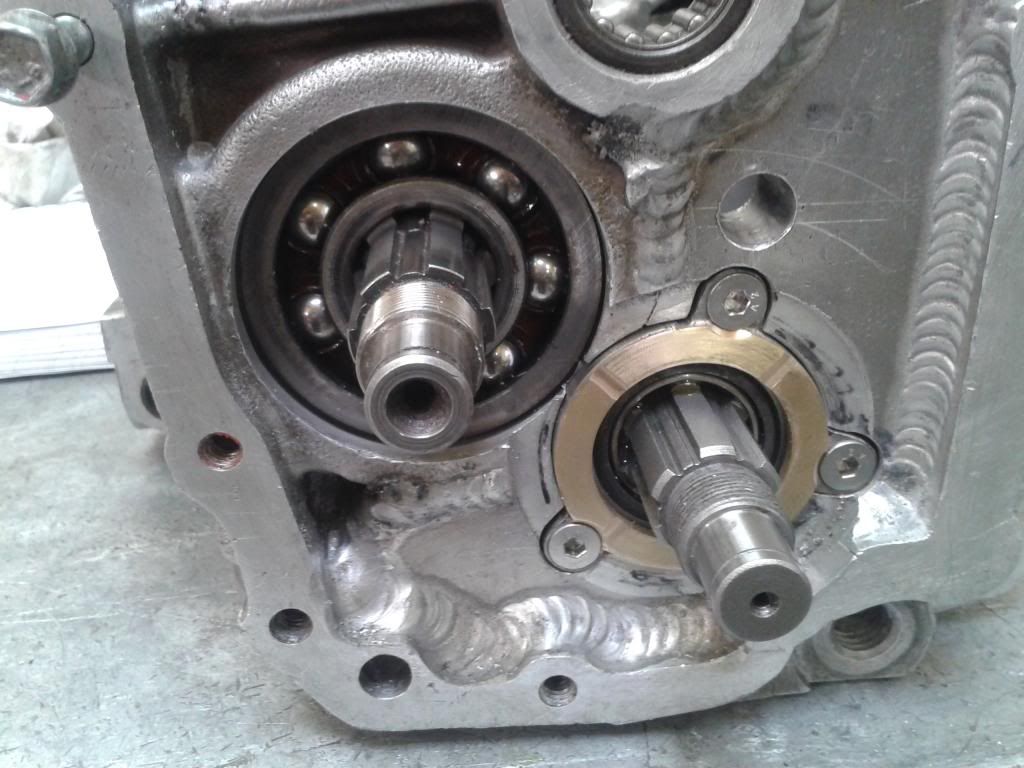

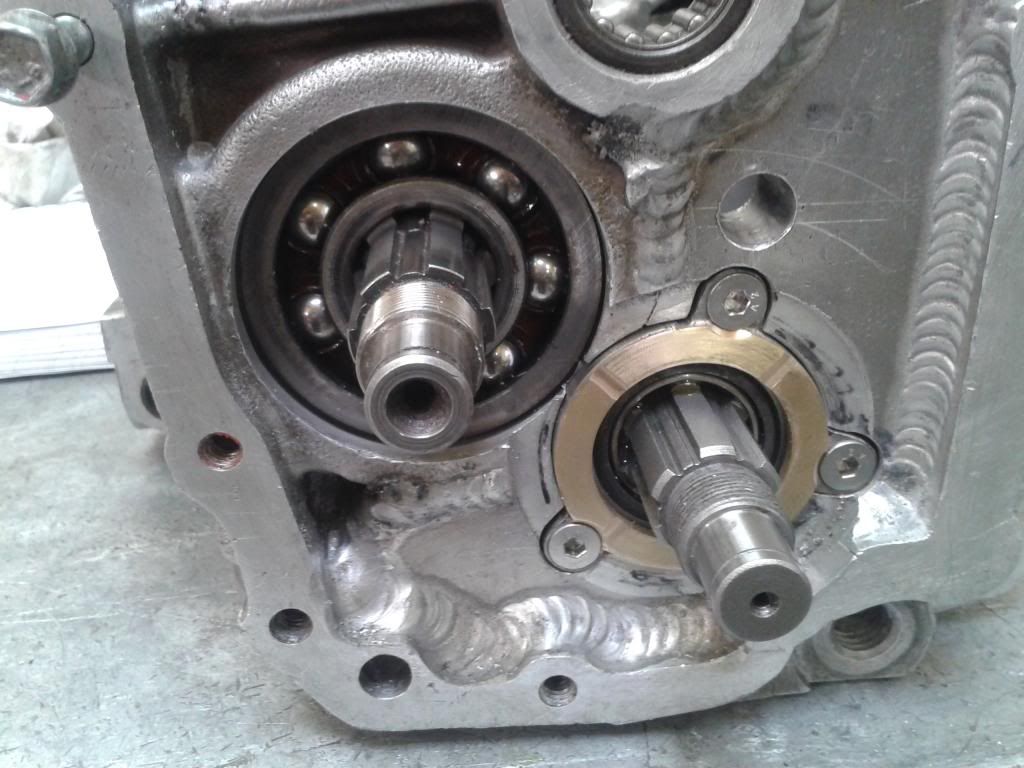

A removable bearing carrier was then machined up. It had to be removable to allow the shaft to be fitted from the end and gears assembled in situ. The was EN36 main body Phosphor bronze bush silver soldered onto carrier.

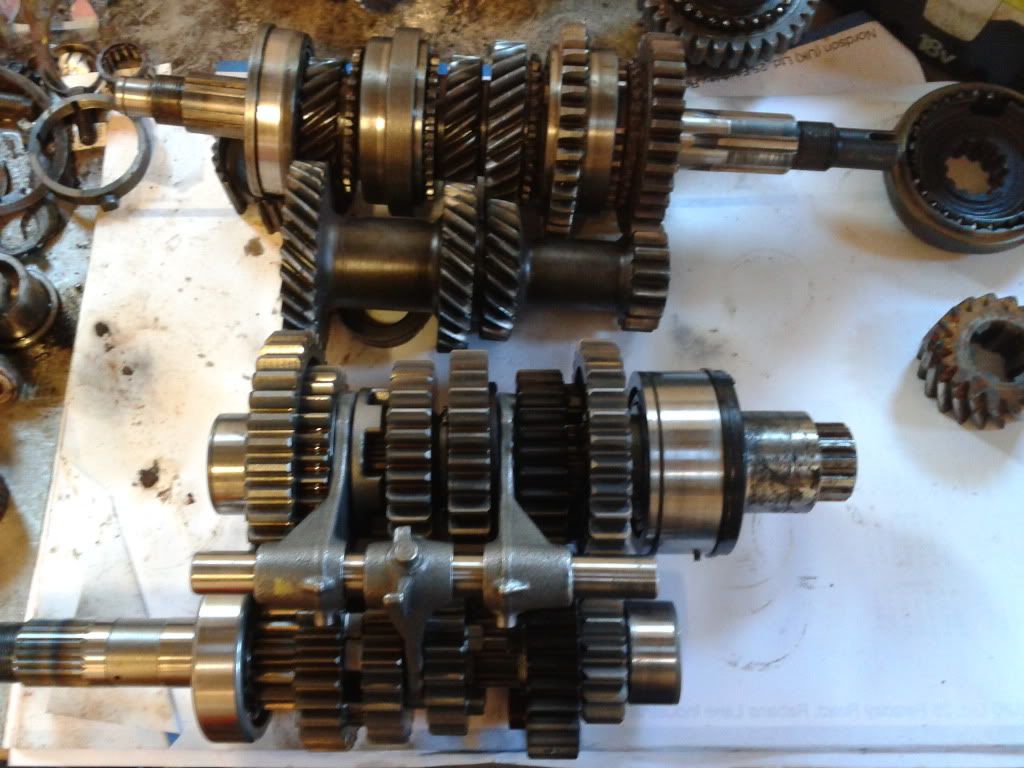

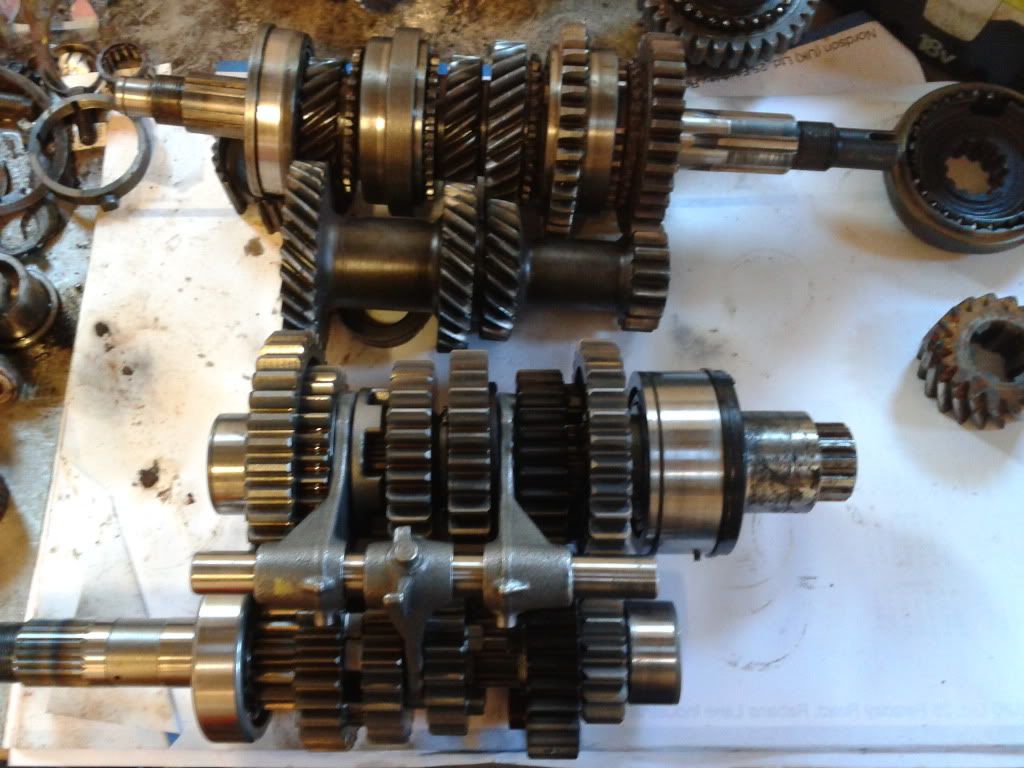

This is the standard mini 3rd motion and VFr output shaft, so I need to make a bike shaft that had the mini pinion spline, and mini 1st motion bearing surface on the end, so I designed a shaft and had this made.

A removable bearing carrier was then machined up. It had to be removable to allow the shaft to be fitted from the end and gears assembled in situ. The was EN36 main body Phosphor bronze bush silver soldered onto carrier.

This is the standard mini 3rd motion and VFr output shaft, so I need to make a bike shaft that had the mini pinion spline, and mini 1st motion bearing surface on the end, so I designed a shaft and had this made.

Edited by Matty... on Tuesday 15th November 21:30

I then designed the second shaft to be made, this time the input shaft. This was VFR spline and fixed gear. And was extended on the input end for an additional drop gear to reverse the gears to make them rotate the correct way.

The 1st motion shaft was then modified by removing the standard gear and selector ring as these are no longer needed.

This is them roughly in position.

The next part to modify was the selector fork pins. As the standard selector drum position wouldn't work. I made a jig and re drilled the new pin positions. The new pins were made from silver steel and hardened.

They are now in the correct position for selector.

The 1st motion shaft was then modified by removing the standard gear and selector ring as these are no longer needed.

This is them roughly in position.

The next part to modify was the selector fork pins. As the standard selector drum position wouldn't work. I made a jig and re drilled the new pin positions. The new pins were made from silver steel and hardened.

They are now in the correct position for selector.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff