Knackered old Porsche with loads of natural light - Boxster!

Discussion

Mikeeb said:

I guess from your work you have experience of doing this. I can’t imagine the cost won’t be insignificant!

I'm building this in the same double garage that I rebuilt the 996 in, whilst it's a very nice double garage with a good amount of kit nothing I'm doing can't be done by someone else in a similar double garage and these certainly aren't limitless budget builds! We're not talking a full emissions calibration program here but rather validation that the details on the COC for a 2004 Golf GTI are still valid for that engine in this chassis - that's not "easy" but it's a job where most of the work is on me to get right way before it goes on the emissions dyno - assuming I haven't already cocked it up with the piston choice but time will tell

Surely it would just be easier to gain ulez approval on the current engine if the paperwork is available from Porsche. Is the ulez system that sophisticated that it flags up if an engine change has been carried out? I would have thought once the registration is cleared in the system you'd be good to go.

Or are you wanting to carry out getting the pukka approval purely as an engineering project?

Or are you wanting to carry out getting the pukka approval purely as an engineering project?

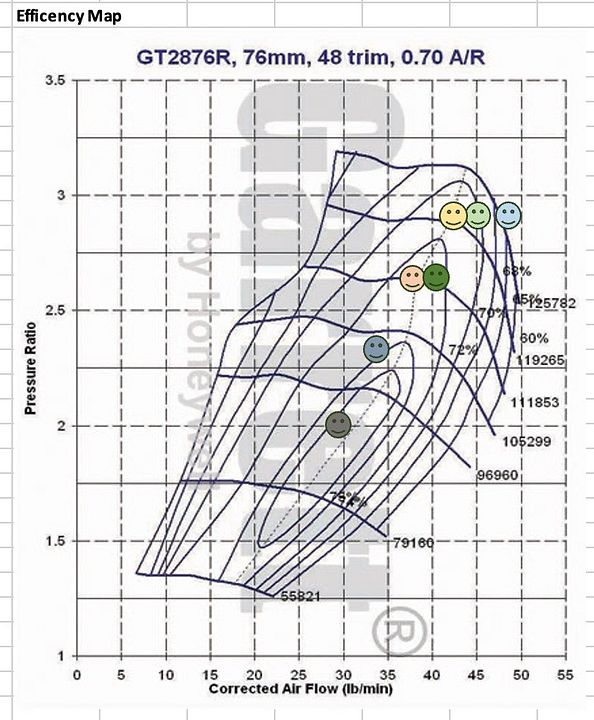

As thought it's a bit tight on that turbo for 500bhp but it'll do 475 just and is very happy at 400 - 425bhp so we'll put it in the good starting point box

I've about finished all the working out on this now, well as much as I'm going to do to sense check the basics so one the block is back from machining I'll get that into CAD and start building an engine. There's no rush on this project as it's purely an evenings and weekends job but lets see how much this escalates

Dr.Hellno said:

470 been done on standard cams; apparently that’s pretty much their limit. Over 100 been added with just better cams though.

I’m hoping for full escalation on this

To get that sort of gain they must have been reving to at least 8000RPM and have had a big enough turbo on there to deliver the additional airmass required for another 100bhp odd when they swapped cams.....it's never quite as simple as just swapping cam profiles I’m hoping for full escalation on this

The standard cams are all done by around 7200RPM but you can hang things in with a bit more boost (making up for the reducing valve open time with more air density) to 7500RPM which on a 76MM compressor wheel Garrett is 475bhp or so. You can make more than this with more boost but that needs a larger turbo and now you're not making that boost until later in the rev range with the same 7500RPM limit so the power band is ever shrinking (unless you're now getting into high flow low inertia turbo chargers, ALS etc.).... it's all a balancing act

The standard cams are arguably a bit sporty for the standard power and turbo size but there will have been a reason for that... maybe the little inlet valves keep the gas flow speed up at higher lift / lower RPM so it's worth it for the benefit in using less boost around those RPMS.

The standard cams are arguably a bit sporty for the standard power and turbo size but there will have been a reason for that... maybe the little inlet valves keep the gas flow speed up at higher lift / lower RPM so it's worth it for the benefit in using less boost around those RPMS. As power = torque X rpm / 5252 the same torque at more RPM will always give more power hence why moving to a cam profile with lift optimised for higher RPM will make a big difference in power.

This works the other way too, for example the FIA F2 race cars (which were 1.8 20V powered) rev'd to 8500RPM with a GT30 derrived turbo and made 425bhp with another 50bhp or so more in push to pass but torque was always below 300ftlbs to keep the gearbox nice, light and reliable. They made this power using more revs rather than more torque.

Basically if you know the torque limit of the drivetrain (and you're not RPM limited in terms of input shaft speed) then this determines how high you're going to need to rev to make the target power and therefore what cams/turbo is required to achieve a good power band and response. As revs have far more impact on engine life than boost quite often to achieve the reliability target you end up boxed into a corner on how high you can rev it but that's all part of the game

P.S. The light green smiley face on the compressor map above is 475 bhp, at this we're still in a decent efficency island but right up there in compressor speed but it also brings us into another challenge, charge cooling.

At a pressure ratio of 2.9 or so and a 20 degree ambient we're going to be outputting air from the turbo at around 165 degrees C which means we need a really good charge cooling solution, we also need to minimise the pressure drop as much as possible to keep that boost pressure up post cooler. To do this I'm going to use a PWR barrel type charge cooler which is naturally very low pressure drop and with a decent diameter will give the cooling performance required achieving 85% efficency or so with a reasonably cool water loop (lets not dwell on that or we're now getting into deltas to ambient etc. ) which gives us a plenum intake temp of 42 degrees or so - pretty acceptable

) which gives us a plenum intake temp of 42 degrees or so - pretty acceptable

At a pressure ratio of 2.9 or so and a 20 degree ambient we're going to be outputting air from the turbo at around 165 degrees C which means we need a really good charge cooling solution, we also need to minimise the pressure drop as much as possible to keep that boost pressure up post cooler. To do this I'm going to use a PWR barrel type charge cooler which is naturally very low pressure drop and with a decent diameter will give the cooling performance required achieving 85% efficency or so with a reasonably cool water loop (lets not dwell on that or we're now getting into deltas to ambient etc.

) which gives us a plenum intake temp of 42 degrees or so - pretty acceptable

) which gives us a plenum intake temp of 42 degrees or so - pretty acceptable

Dr.Hellno said:

Been to see these guys today and what a helpful and genuinely nice lot they are! We had a great chat and they introduced me to an ECU option that I wasn't aware of. Lovely location overlooking the airfield too and a mega dyno!

Dr.Hellno said:

Nice!

I guess you’re referring to Ignitron!? Mine runs on an Emerald but may swap over at some point.

Look forward to updates!

Yes, I'm hugely impressed with it. Having spent the early part of my career on "proper" pro-motorsport engine control I never thought I'd see the day where an aftermarket ECU came close to OE engine control in some areas but aside from catalyst control and a few other emissions strategies this really is pretty close. It's leagues ahead of the various basic ECUs that have been common for the last couple of decades like Emerald, Omex, DTA etc. and features some really impressive stuff like weight of air calibration, MAF signal filtering, real proper knock control with adaption of windowing etc., boost control with proper configurable PIDs and none linear P support, anti-stall throttle and a full OBD2 integration (even though it's obviously not homologated). I guess you’re referring to Ignitron!? Mine runs on an Emerald but may swap over at some point.

Look forward to updates!

Okay we live in a world now where you can buy a Motec that has Simulink integration and write all that yourself but the Ignitron box is less than a Matlab licence alone

So let's pretend I understood none of your previous post. Although that's not true because I understand loads, obviously. Can one of these modern aftermarket ECU solve my problem of fitting a modern pork engine in a 986. Like a 981 engine maybe even with the - controversial - PDK box?

ATM said:

So let's pretend I understood none of your previous post. Although that's not true because I understand loads, obviously. Can one of these modern aftermarket ECU solve my problem of fitting a modern pork engine in a 986. Like a 981 engine maybe even with the - controversial - PDK box?

Yes and No, the ECU we're talking about here that I may end up using has been designed to directly replace the Bosch ME 7.5 controller and a lot of the strategies etc. are heavily inspired by the function of ME7.5 as a result. However it's still a unit designed to run port injectors, single cam VVT etc. etc. so of little use if you want to fit something from a 981 with a PDK box. For that you're going to need something with a bit more IO, which supports direct injection, multi cam VVT and of course the PDK box. Luckily for you Syvecs (which is a distant relation to Life Racing which in turn is a relation to Pectel/Cosworth) do a plug and play for the 981 and PDK box support:

https://www.syvecs.com/product/porsche-cayman-987-...

If you took the engine, box, looms etc. from a 981 then with some dedicated work you get these powered up and working in the 986 - the nice thing about an aftermarket ECU is that there is no immobilisers etc. to mess with and the ECU is easily communicated with so it's entirely possible to achieve these sorts of engine transplants. The big fly in the ointment though is calibration - OEMs spend millions on ECU calibration and it's the reason why road cars drive like they do now, you can absolutely get close to this on an aftermarket (especially in terms of actual driveability, engine performance etc.) but you just won't have covered all the edge cases that an OEM will have done so you'll have to accept these edge cases won't be perfect in the end car.

.... but the short answer is yes there's a box of sparks that'll run a 981 motor and PDK gearbox

poppopbangbang said:

Dr.Hellno said:

470 been done on standard cams; apparently that’s pretty much their limit. Over 100 been added with just better cams though.

I’m hoping for full escalation on this

To get that sort of gain they must have been reving to at least 8000RPM and have had a big enough turbo on there to deliver the additional airmass required for another 100bhp odd when they swapped cams.....it's never quite as simple as just swapping cam profiles I’m hoping for full escalation on this

The standard cams are all done by around 7200RPM but you can hang things in with a bit more boost (making up for the reducing valve open time with more air density) to 7500RPM which on a 76MM compressor wheel Garrett is 475bhp or so. You can make more than this with more boost but that needs a larger turbo and now you're not making that boost until later in the rev range with the same 7500RPM limit so the power band is ever shrinking (unless you're now getting into high flow low inertia turbo chargers, ALS etc.).... it's all a balancing act

The standard cams are arguably a bit sporty for the standard power and turbo size but there will have been a reason for that... maybe the little inlet valves keep the gas flow speed up at higher lift / lower RPM so it's worth it for the benefit in using less boost around those RPMS.

The standard cams are arguably a bit sporty for the standard power and turbo size but there will have been a reason for that... maybe the little inlet valves keep the gas flow speed up at higher lift / lower RPM so it's worth it for the benefit in using less boost around those RPMS. As power = torque X rpm / 5252 the same torque at more RPM will always give more power hence why moving to a cam profile with lift optimised for higher RPM will make a big difference in power.

This works the other way too, for example the FIA F2 race cars (which were 1.8 20V powered) rev'd to 8500RPM with a GT30 derrived turbo and made 425bhp with another 50bhp or so more in push to pass but torque was always below 300ftlbs to keep the gearbox nice, light and reliable. They made this power using more revs rather than more torque.

Basically if you know the torque limit of the drivetrain (and you're not RPM limited in terms of input shaft speed) then this determines how high you're going to need to rev to make the target power and therefore what cams/turbo is required to achieve a good power band and response. As revs have far more impact on engine life than boost quite often to achieve the reliability target you end up boxed into a corner on how high you can rev it but that's all part of the game

and having worked for many teams, then and now, it was nice not to have to change engines all the time, unlike some endurance engine builders i could name, think a elms lmp2 needing 5 in one weekend lol

richhead said:

I worked as a contractor with the old f2 palmer cars for a few years, one of the great engine heros of motorsport imo,

I could not agree more! I worked on the tail end of Mountune / MSVRs 20V engine program for a different applicaiton where with minimal component changes the same engines which had done three seasons of F2 were making nearly 600bhp! It was a fantastic engine package..... as was the whole car, I don't think anything quicker has been run for those sort of costs a mile before or after

The engine spec for this project is heavily inspired by the F2 spec as a result of just how reliable they were at those power figures. The only difference is I've gone for a cast exhaust manifold and sacrified some weight and response for durability.

So last bits and bobs validating this idea done today, thermals will be the limiting factor as first thought but the green light is well and truly lit and project "Booster" is on

Time scales will be fairly slow on this due to lots of other stuff going on at the moment but roughly:

- CAD Complete M9.5

- Engine build complete M10

- Outsource Manufacture complete M11

- Build it over Xmas break

- Map it January and start the process of integration, emissions etc. etc.

Engine out During December means the Boxster will stay on the road until then and if I've got all the CAD correct it should all bolt in without too much of a drama....... let's check back on that statement during December

Time scales will be fairly slow on this due to lots of other stuff going on at the moment but roughly:

- CAD Complete M9.5

- Engine build complete M10

- Outsource Manufacture complete M11

- Build it over Xmas break

- Map it January and start the process of integration, emissions etc. etc.

Engine out During December means the Boxster will stay on the road until then and if I've got all the CAD correct it should all bolt in without too much of a drama....... let's check back on that statement during December

Edited by poppopbangbang on Monday 4th September 00:27

Your planning is impressive for such a major transplant, hoping all goes well. And here's me just starting to pull a cylinder head for overhaul and planning to have it all finished early next year! I need a reality check...or slap on the back of the head.

Really like the ''Booster'' name, spot on.

Really like the ''Booster'' name, spot on.

eltax91 said:

"Progress will be slow" and "done over xmas". Oxymoron.

I started the strip and rebuild of a Range Rover. Had it 2 months now. The interior's out.... that's it.

Done is a strong word!

I started the strip and rebuild of a Range Rover. Had it 2 months now. The interior's out.... that's it.

It'll be in and running but that's only really the end of part 1 and the start of a load of calibration, integration and general messing around to get it all to work really nicely. Probably another 2 - 3 months worth there!

It'll be in and running but that's only really the end of part 1 and the start of a load of calibration, integration and general messing around to get it all to work really nicely. Probably another 2 - 3 months worth there! Good news is the CAD is coming together reasonably well with most of the large bits now in there so I can start looking at how to nicely do a front mount etc.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff