Knackered old Porsche with loads of natural light - Boxster!

Discussion

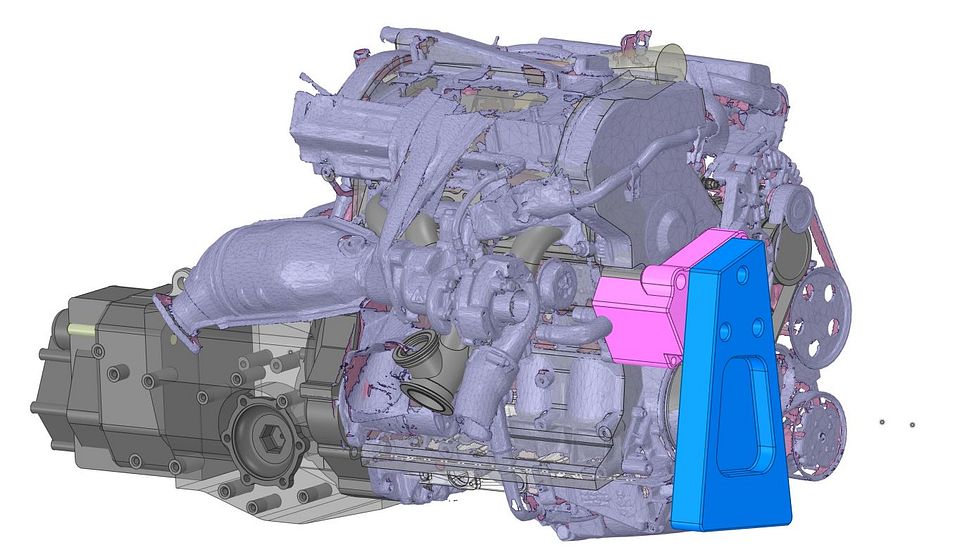

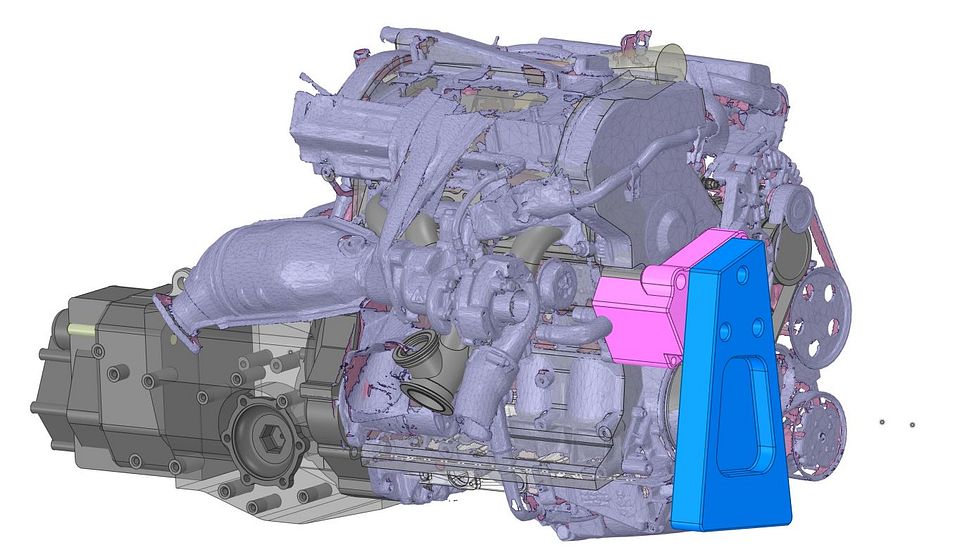

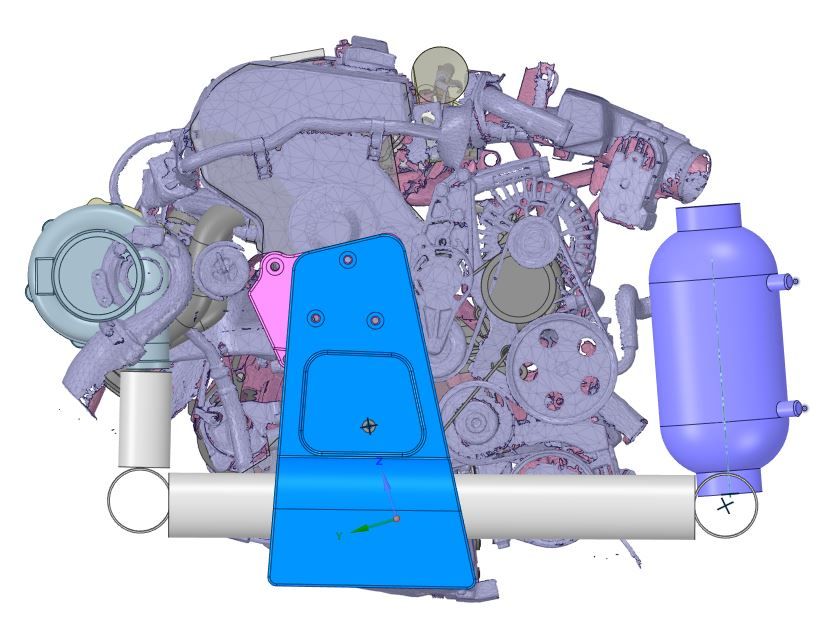

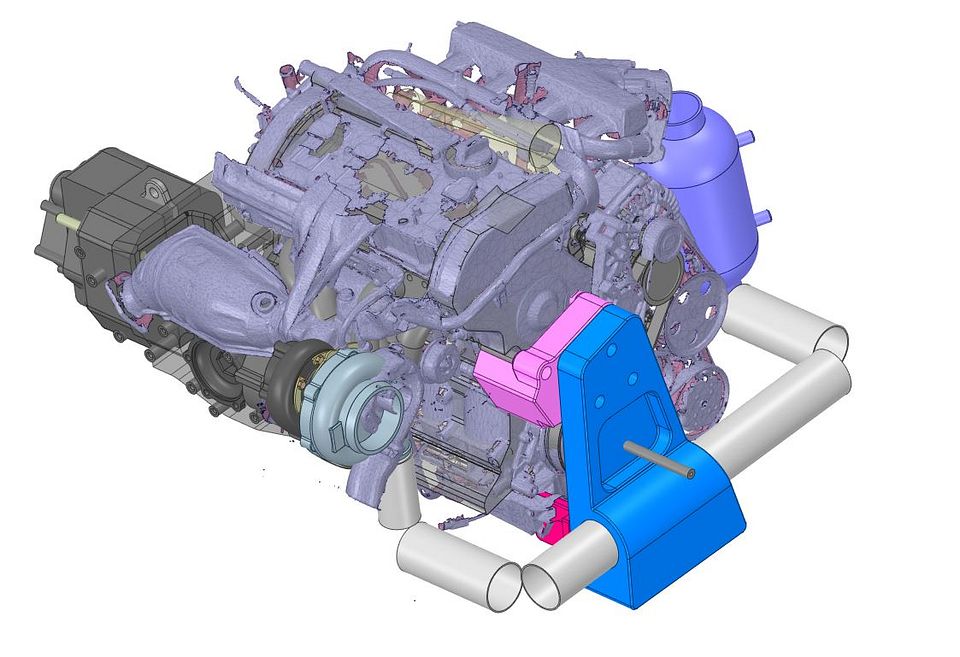

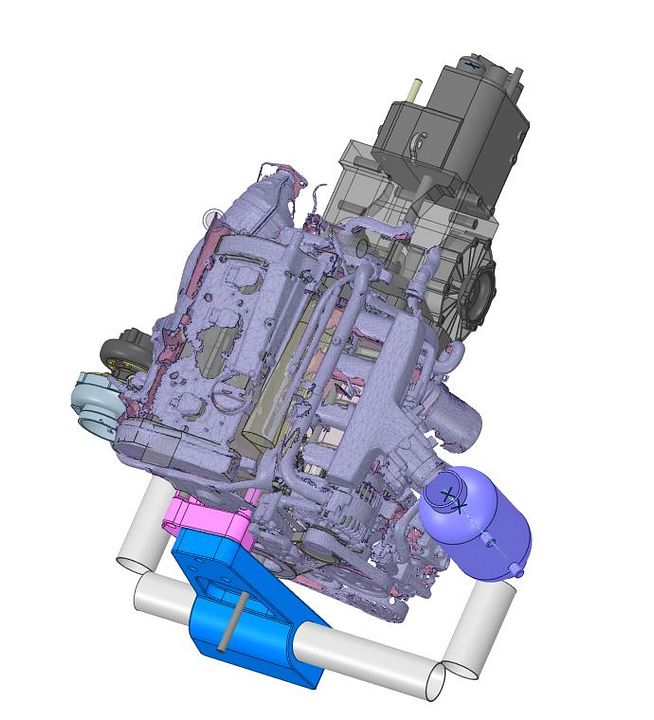

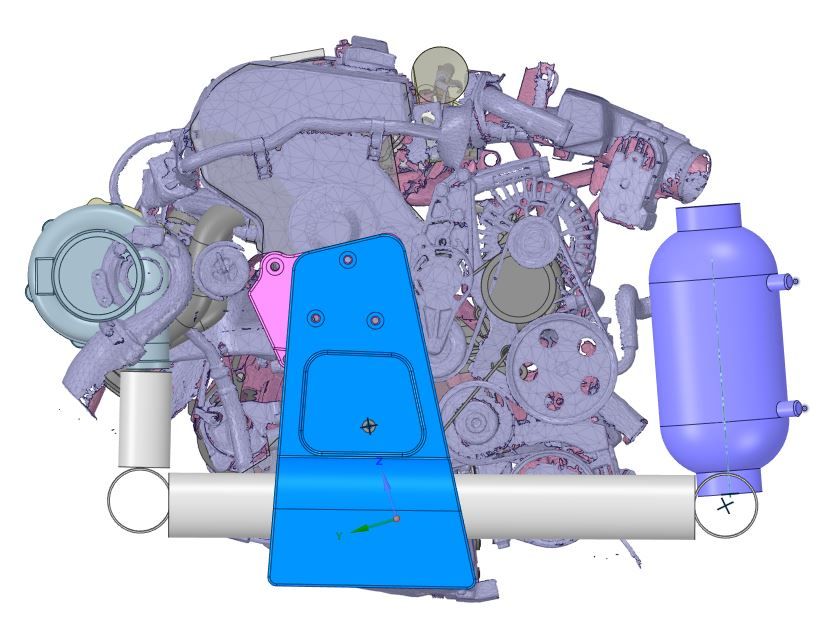

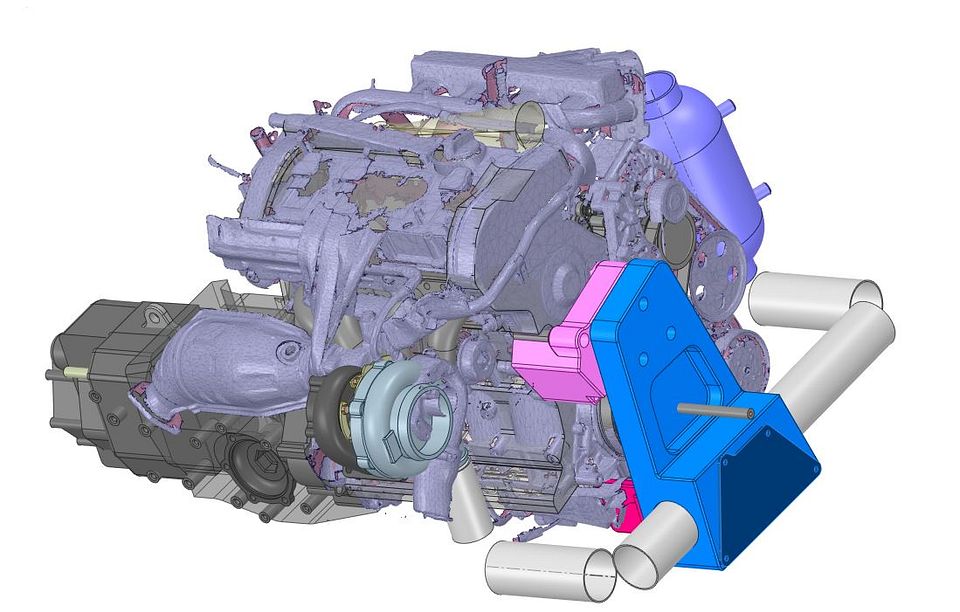

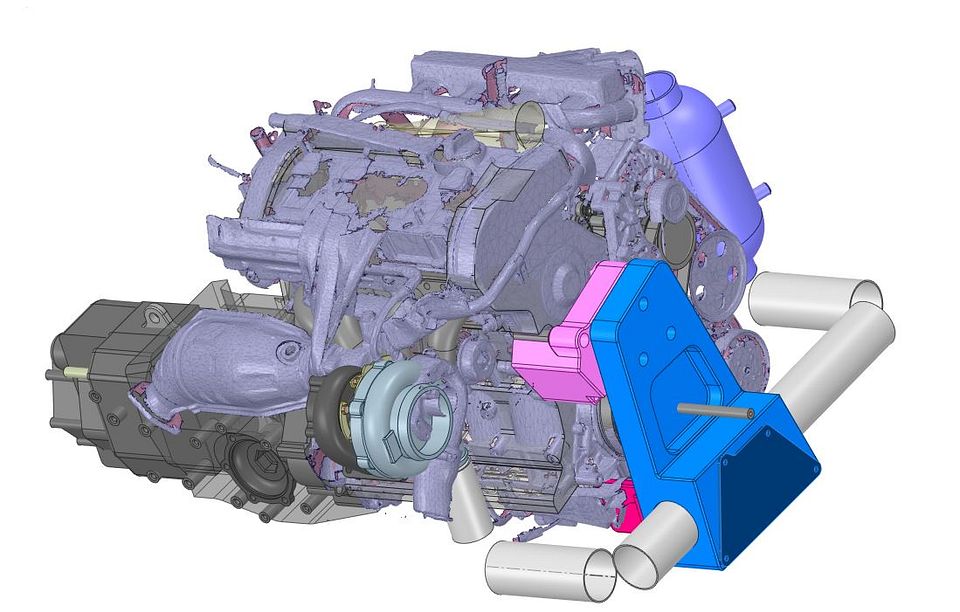

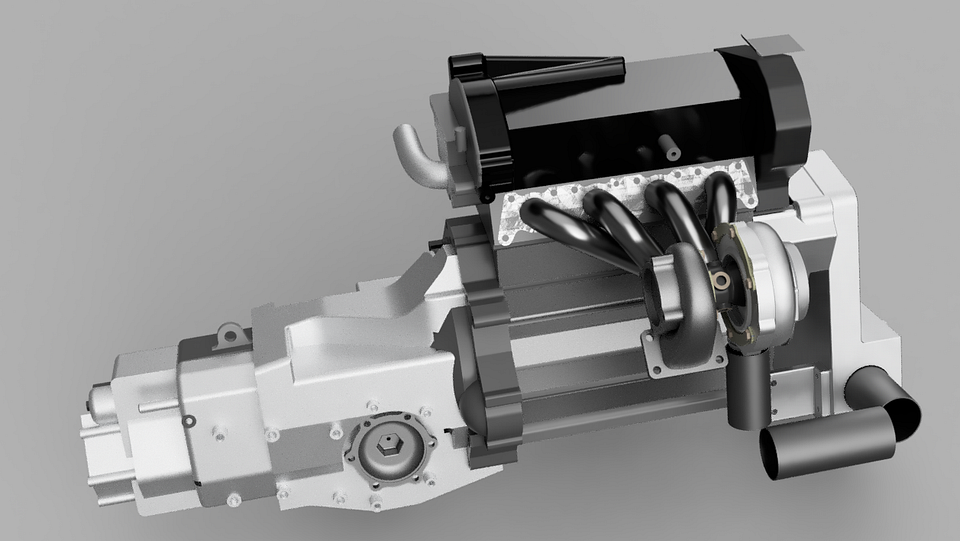

It's all a space claim at the moment using the dirtiest 3D scan ever (of actually the wrong engine) but it fits, two piece billet front engine mount that picks up on the original threaded holes in the block that carried the original upper mount in a Golf and translates that to pick up the standard Boxster front mount.

Waiting on a Boxster mount now so I can draw that up and once that's done I'll put some actual effort into making the mount nicer and somewhat lighter

As always it's critical to avoid falling foul of the DVLA "Radically Modified Vehicles" rules so this has to go in with zero modification to the monocoque i.e no brackets welded on, no holes drilled etc. etc.

Waiting on a Boxster mount now so I can draw that up and once that's done I'll put some actual effort into making the mount nicer and somewhat lighter

As always it's critical to avoid falling foul of the DVLA "Radically Modified Vehicles" rules so this has to go in with zero modification to the monocoque i.e no brackets welded on, no holes drilled etc. etc.

poppopbangbang said:

Yes, I'm hugely impressed with it. Having spent the early part of my career on "proper" pro-motorsport engine control I never thought I'd see the day where an aftermarket ECU came close to OE engine control in some areas but aside from catalyst control and a few other emissions strategies this really is pretty close. It's leagues ahead of the various basic ECUs that have been common for the last couple of decades like Emerald, Omex, DTA etc. and features some really impressive stuff like weight of air calibration, MAF signal filtering, real proper knock control with adaption of windowing etc., boost control with proper configurable PIDs and none linear P support, anti-stall throttle and a full OBD2 integration (even though it's obviously not homologated).

Okay we live in a world now where you can buy a Motec that has Simulink integration and write all that yourself but the Ignitron box is less than a Matlab licence alone

Apologies in advance for the tangential query on a product you are just getting familiar with, but do you think a engine of a similar generation running an ME7.1 could be made to work (e.g. with 8-cyl, and 40v..)? I guess this may not have sufficient I/O..Okay we live in a world now where you can buy a Motec that has Simulink integration and write all that yourself but the Ignitron box is less than a Matlab licence alone

My other (unrelated) car operates a modified OEM ECU that allows a similar (but less comprehensive) range of configuration. For me it just allows update mapping files dependent on pulley size (SC), and I think its certainly a more attractive set up then a full replacement unit.

gofasterrosssco said:

Apologies in advance for the tangential query on a product you are just getting familiar with, but do you think a engine of a similar generation running an ME7.1 could be made to work (e.g. with 8-cyl, and 40v..)? I guess this may not have sufficient I/O..

My other (unrelated) car operates a modified OEM ECU that allows a similar (but less comprehensive) range of configuration. For me it just allows update mapping files dependent on pulley size (SC), and I think its certainly a more attractive set up then a full replacement unit.

Not enough coil drivers on this one to run that and the software doesn't appear to have 8 cylinder support (max 6 for VR6/R32). My other (unrelated) car operates a modified OEM ECU that allows a similar (but less comprehensive) range of configuration. For me it just allows update mapping files dependent on pulley size (SC), and I think its certainly a more attractive set up then a full replacement unit.

Regardless it's not just the hardware, that's the easy bit, it's the calibration of the ECU which is the complex and costly part of the job. Yes you can get a WOT power run in a day on a rolling road but all the subtleties of cold start, catalyst control, knock control etc. are significant work to get to an acceptable standard. In nearly all applications you're better off running an OE ECU with an OE based calibration if at all possible unless there is a hugely well developed option to replace it as the standard of aftermarket plug and play calibrations etc. can vary greatly even if the hardware physically plugs and goes.

poppopbangbang said:

Not enough coil drivers on this one to run that and the software doesn't appear to have 8 cylinder support (max 6 for VR6/R32).

Regardless it's not just the hardware, that's the easy bit, it's the calibration of the ECU which is the complex and costly part of the job. Yes you can get a WOT power run in a day on a rolling road but all the subtleties of cold start, catalyst control, knock control etc. are significant work to get to an acceptable standard. In nearly all applications you're better off running an OE ECU with an OE based calibration if at all possible unless there is a hugely well developed option to replace it as the standard of aftermarket plug and play calibrations etc. can vary greatly even if the hardware physically plugs and goes.

Thanks for the comprehensive response, and pretty much the basis I was working on hence the interest in this particular solutionRegardless it's not just the hardware, that's the easy bit, it's the calibration of the ECU which is the complex and costly part of the job. Yes you can get a WOT power run in a day on a rolling road but all the subtleties of cold start, catalyst control, knock control etc. are significant work to get to an acceptable standard. In nearly all applications you're better off running an OE ECU with an OE based calibration if at all possible unless there is a hugely well developed option to replace it as the standard of aftermarket plug and play calibrations etc. can vary greatly even if the hardware physically plugs and goes.

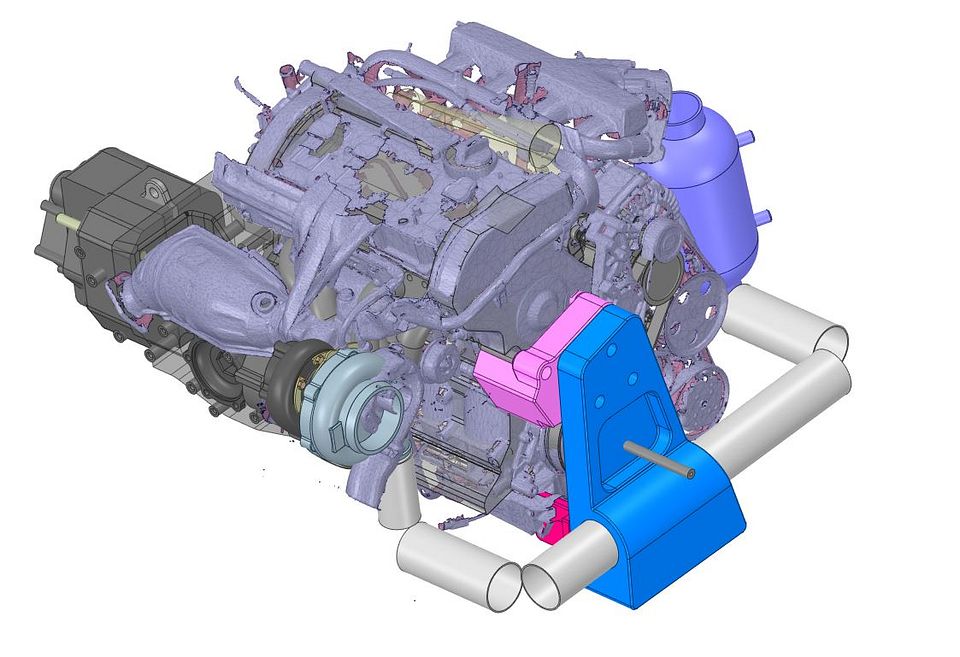

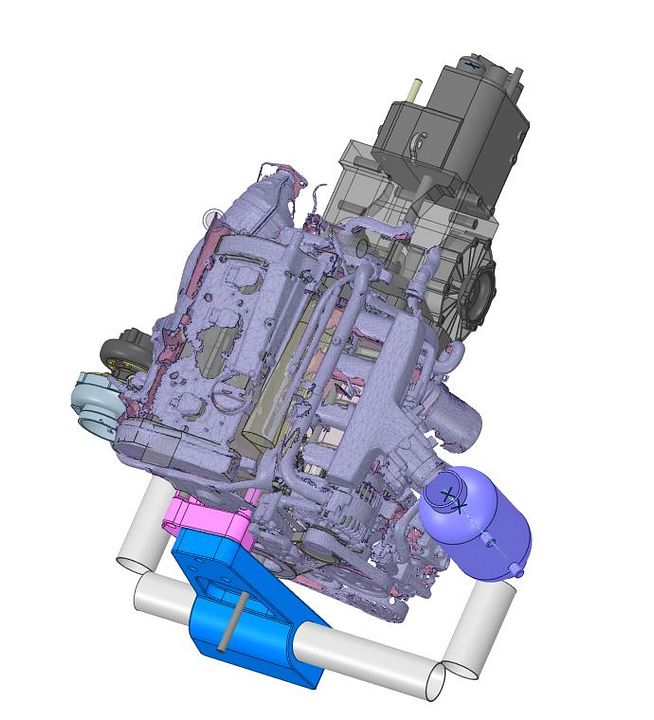

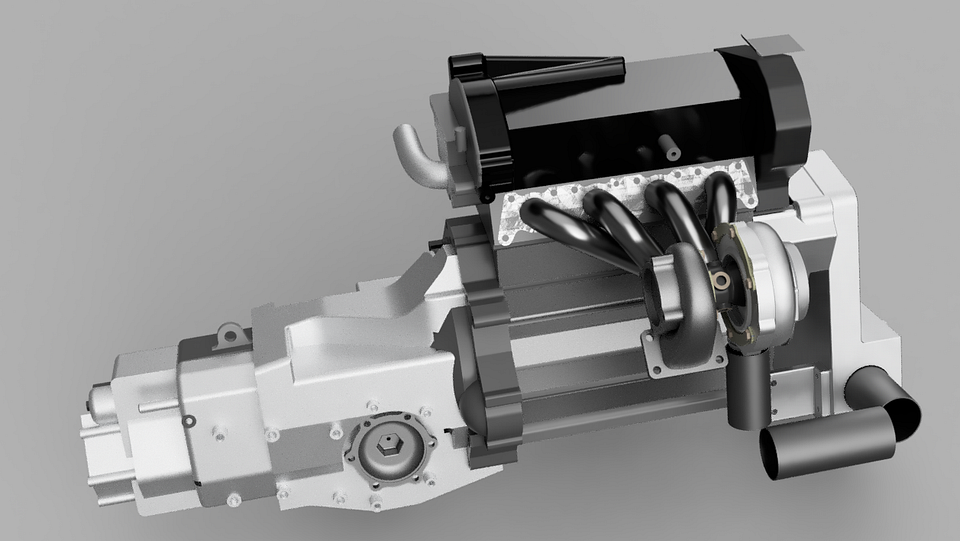

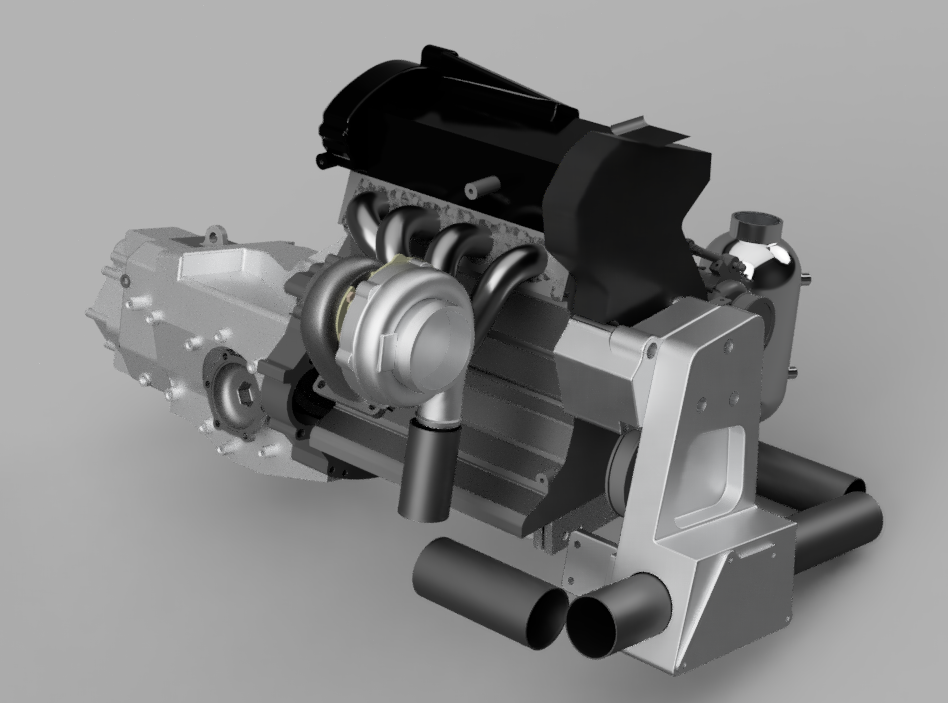

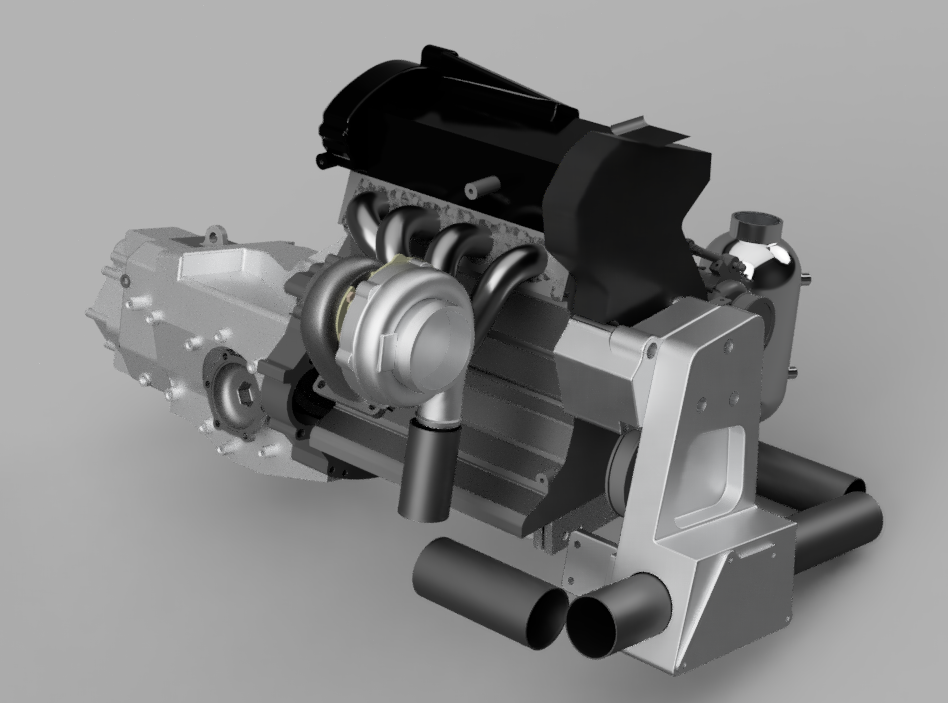

CAD is going pretty well, all the big bits fit and of course as we know if it fits on CAD it'll definitely fit on the car

Lots of FEA to do on the front mount to get some weight out but it's looking the part now, it was rude not to run the boost transfer pipe through the engine mount really when it packages so well like that and I need the extra reach to pickup the standard front mounting point anyway. I added a small anti deflection mount on the lower mount inline with the load path to the original engine mount as the A4 sump has bosses here that carried the original anti-deflection mount on the OE installation so pretty certain the sump won't mind a bit of load going in here. The vertical of the front mount is so stiff at the moment it doesn't need it but best to give some options to reduce the mass in the front mount!

The turbo fits in a really nice position with lots of room for downpipe, CAT and a decent sized air filter in the side intake vent.

And the air delivery path is pretty short, I need to do some maths and see how small I can make them (they're all 3" at the moment so the mount FEA is done worst case) to get the volume down without impairing flow. Also some working out on which bends can be hard piped and just how much can be made as one piece as I want the minimum joins possible in this as there is nothing worse than a joiner buried in the bottom of the car as it's always that one which'll make a bid for freedom and a load of silicone and 27 hose clips just looks a mess. At the moment I think I can get this done with four joiners but might be able to get it down to three with a transfer pipe that loads into the car already in the engine mount.

Charge cooler packages nicely too, a PWR 6" X 6" one made the most packaging sense directly under the intake manifold, the big diameter and short length will help pressure drop but still provides plenty of cooling capacity but over 400 beans will likely need WI for sustained use unless the charge cooler rad works really, really well. I'll mount this to the engine with a couple of weld on mounts on the charge cooler so that way the entire system is retained on and moves with the engine which will help durability no end.

Onto exhaust packaging next, I really want to retain the standard Boxster silencer as 1) It's really well engineered onto the car in terms of mounts and packaging, 2) it's super quite so track legal and 3) there are a load of aftermarket exhausts that are a direct fit if greater flow is required. The problem with this idea is that they all have two entrances to the silencer box due to the pair of heads on the original flat six. There is just enough room to squeeze a transfer pipe of a Y pipe setup under the gearbox but now we're in to how bad would that be for the gearbox oil temps! Time to work that out as adding some gearbox cooling because you're cooking the gearbox with the exhaust seems a little counter productive.

Finally the rest of the engine build bits are currently waiting for UK Customs to pull their finger out and issue a duty invoice but they should be here by the end of next week with a bit of luck and then we can get into building a motor up.

This quick project has turned into a bit of a job now...... it better be bloomin quick once done

Lots of FEA to do on the front mount to get some weight out but it's looking the part now, it was rude not to run the boost transfer pipe through the engine mount really when it packages so well like that and I need the extra reach to pickup the standard front mounting point anyway. I added a small anti deflection mount on the lower mount inline with the load path to the original engine mount as the A4 sump has bosses here that carried the original anti-deflection mount on the OE installation so pretty certain the sump won't mind a bit of load going in here. The vertical of the front mount is so stiff at the moment it doesn't need it but best to give some options to reduce the mass in the front mount!

The turbo fits in a really nice position with lots of room for downpipe, CAT and a decent sized air filter in the side intake vent.

And the air delivery path is pretty short, I need to do some maths and see how small I can make them (they're all 3" at the moment so the mount FEA is done worst case) to get the volume down without impairing flow. Also some working out on which bends can be hard piped and just how much can be made as one piece as I want the minimum joins possible in this as there is nothing worse than a joiner buried in the bottom of the car as it's always that one which'll make a bid for freedom and a load of silicone and 27 hose clips just looks a mess. At the moment I think I can get this done with four joiners but might be able to get it down to three with a transfer pipe that loads into the car already in the engine mount.

Charge cooler packages nicely too, a PWR 6" X 6" one made the most packaging sense directly under the intake manifold, the big diameter and short length will help pressure drop but still provides plenty of cooling capacity but over 400 beans will likely need WI for sustained use unless the charge cooler rad works really, really well. I'll mount this to the engine with a couple of weld on mounts on the charge cooler so that way the entire system is retained on and moves with the engine which will help durability no end.

Onto exhaust packaging next, I really want to retain the standard Boxster silencer as 1) It's really well engineered onto the car in terms of mounts and packaging, 2) it's super quite so track legal and 3) there are a load of aftermarket exhausts that are a direct fit if greater flow is required. The problem with this idea is that they all have two entrances to the silencer box due to the pair of heads on the original flat six. There is just enough room to squeeze a transfer pipe of a Y pipe setup under the gearbox but now we're in to how bad would that be for the gearbox oil temps! Time to work that out as adding some gearbox cooling because you're cooking the gearbox with the exhaust seems a little counter productive.

Finally the rest of the engine build bits are currently waiting for UK Customs to pull their finger out and issue a duty invoice but they should be here by the end of next week with a bit of luck and then we can get into building a motor up.

This quick project has turned into a bit of a job now...... it better be bloomin quick once done

Luther Blissett said:

Why use a GT2876R? It's a 20 year old design at this point. I'm sure you can find much better these days.

Because 1) I have one, 2) I have an accurate simulation model of the 76mm compressor on the front of it and 3) It's almost what was run on the F2 cars so I have bags of real world data. Turbo's are easy to change at a later date if required but the wins available by going into something with solid data cannot be underestimated.

Magnum 475 said:

Beautifully done but very big - you have to give it to the Boxster platform though, there isn't much that won't fit in the back! I did toy with the idea of a big naturally aspirated motor but I have that in the 996 with the 3.7 and given I don't have a turbo car in the fleet and have a lot of boosted applications in my past the idea of building what is essentially the F2 motor for the back of it appealed greatly. Pop

Slightly off topic but 986 related - I promise. I'm trying to use a 986 16 inch rear on my 3.2S and it doesn't fit. Same problem I had with the 996 if you remember. Fouls on the toe arm. So I'm wandering if there are any non OEM type arms which might have a lower profile ball joint link or mounting. Can you think of any please?

Slightly off topic but 986 related - I promise. I'm trying to use a 986 16 inch rear on my 3.2S and it doesn't fit. Same problem I had with the 996 if you remember. Fouls on the toe arm. So I'm wandering if there are any non OEM type arms which might have a lower profile ball joint link or mounting. Can you think of any please?

ATM said:

Pop

Slightly off topic but 986 related - I promise. I'm trying to use a 986 16 inch rear on my 3.2S and it doesn't fit. Same problem I had with the 996 if you remember. Fouls on the toe arm. So I'm wandering if there are any non OEM type arms which might have a lower profile ball joint link or mounting. Can you think of any please?

That's tight! Something with a rose joint as the outer link will likely be your best bet as the joint body is pretty skinning in Z and you've got plenty of room for the fastener: Slightly off topic but 986 related - I promise. I'm trying to use a 986 16 inch rear on my 3.2S and it doesn't fit. Same problem I had with the 996 if you remember. Fouls on the toe arm. So I'm wandering if there are any non OEM type arms which might have a lower profile ball joint link or mounting. Can you think of any please?

https://suspensionsecrets.co.uk/product/suspension...

You could modify the stake collar to bring the joint up close to the upright (as there is very little misalighnment to compensate for there) but in doing so you will also be impacting the bump steer.... how much is calculatable once you know the reduction but it'll be pretty small given the short distance we're talking about here.

As a package check I'd probably order a cheap joint from McGill and mock it up with a bolt and washers to look at the maximum packaging height available - remember wheels move about on the hubs so a fag paper/blonde one is not going to be sufficent clearance as it's good practice to allow for an amount of wheel bearing failure/aging etc.

Hi PPBB

Sorry to side track the thread. You mentioned LIFE engine management earlier in the thread.

Do you have any experience with it? I look after an 2001 Reynard LMP2 car which runs in Masters MEL and we are looking for someone to help with getting the best from it.

Would you or do you know anyone who might be interested in some engine management setup work? I’f so can you PM me?

Thanks

Mike

Sorry to side track the thread. You mentioned LIFE engine management earlier in the thread.

Do you have any experience with it? I look after an 2001 Reynard LMP2 car which runs in Masters MEL and we are looking for someone to help with getting the best from it.

Would you or do you know anyone who might be interested in some engine management setup work? I’f so can you PM me?

Thanks

Mike

Bit of an update on the "Booster". CAD is done as far as it's getting done at this point, I need to get the car up in the air to confirm some overall lengths but it's all in a form where this can be accounted for in a few minutes in CAD so happy to say that'll do for now:

One of the last jobs to do before it goes out for machining will be a bit of prettying up but we'll get round to that once the overall package length is 100% known

Looking good to kick engine build off at the end of this month too with a fairly vast array of bits turning up including a load of plumbing and general bits and bobs as well as all the major bits. Very much looking forward to putting it together now!

Still to do is:

- Measure up and design the exhaust Y pipe.

- Measure up and design the downpipe.

- Finish working out which wires will need to go where, although I've hashed out all the loom drawings from the ME7.5 Golf and the Boxster so that's not too much of a job.

- Make a test rig up to work out where the standard Boxster oil level sensor needs to go to get an accurate oil level on the dash.

- Decide how much of the standard fillers/dip stick I'm going to use and how best to plumb those.

Still it's getting there at a reasonable pace

One of the last jobs to do before it goes out for machining will be a bit of prettying up but we'll get round to that once the overall package length is 100% known

Looking good to kick engine build off at the end of this month too with a fairly vast array of bits turning up including a load of plumbing and general bits and bobs as well as all the major bits. Very much looking forward to putting it together now!

Still to do is:

- Measure up and design the exhaust Y pipe.

- Measure up and design the downpipe.

- Finish working out which wires will need to go where, although I've hashed out all the loom drawings from the ME7.5 Golf and the Boxster so that's not too much of a job.

- Make a test rig up to work out where the standard Boxster oil level sensor needs to go to get an accurate oil level on the dash.

- Decide how much of the standard fillers/dip stick I'm going to use and how best to plumb those.

Still it's getting there at a reasonable pace

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff