Knackered old Porsche with loads of miles - 996 content

Discussion

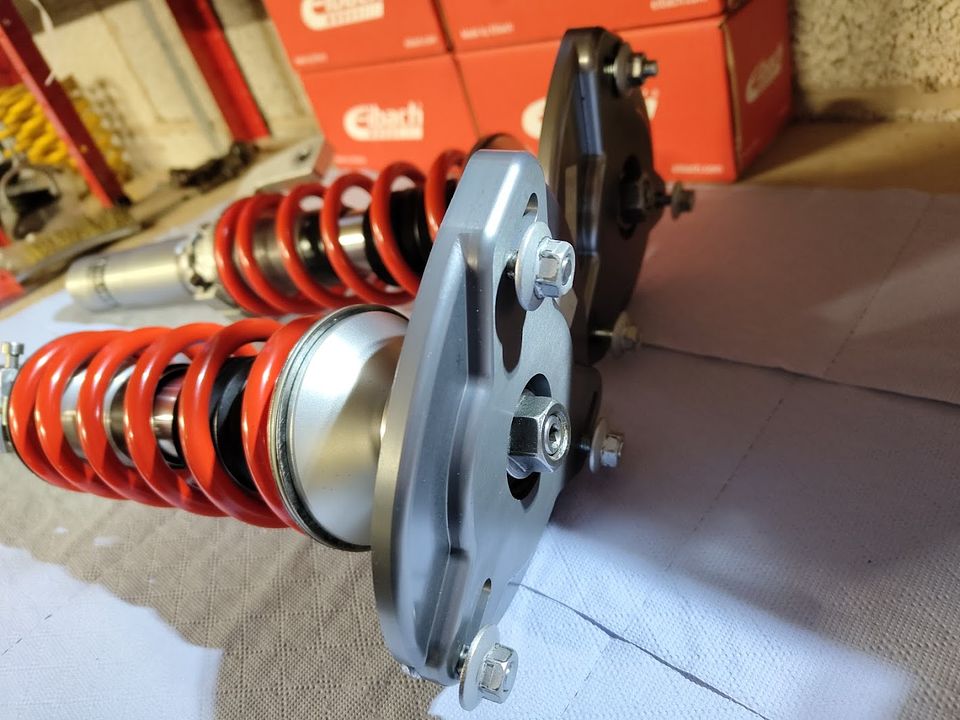

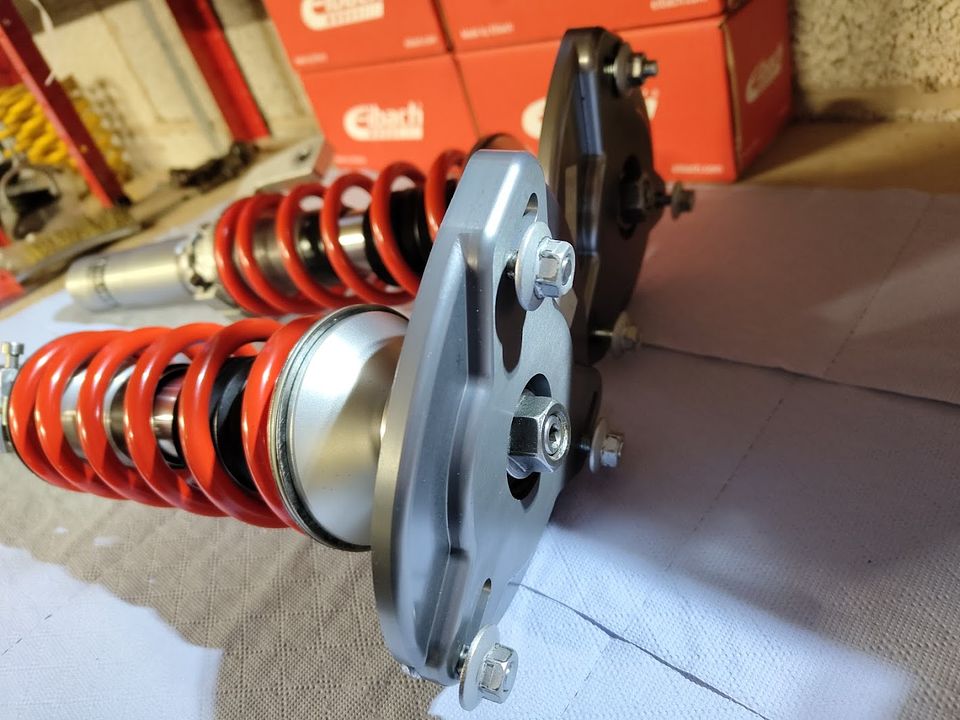

I suppose it's time for a bit of an update. Not a huge amount to report really, I've epically failed to get any proper mileage onto it over the last 18 months or so as there was very few places to actually go! I did lots of planned maintenance earlier this year as mentioned above with a front damper rebuild and brake line refresh (20+ years for a couple of the OEM hard lines is pretty good going!). During this I noticed the top mount sphericals were getting on to being done and due to them being an odd size they're on back order still, hence I've fitted some Elephant Racing mounts that I had kicking about as a stand in:

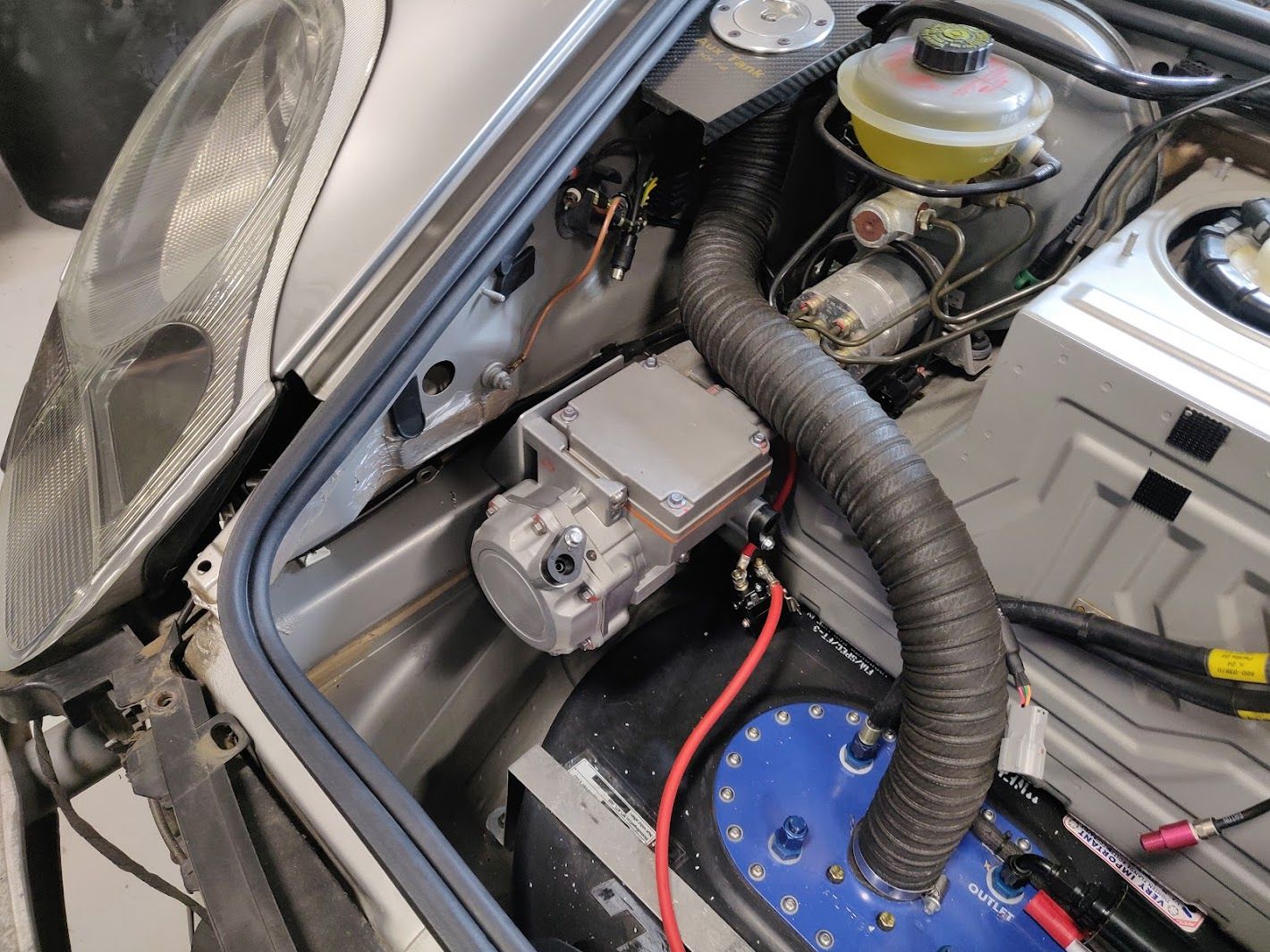

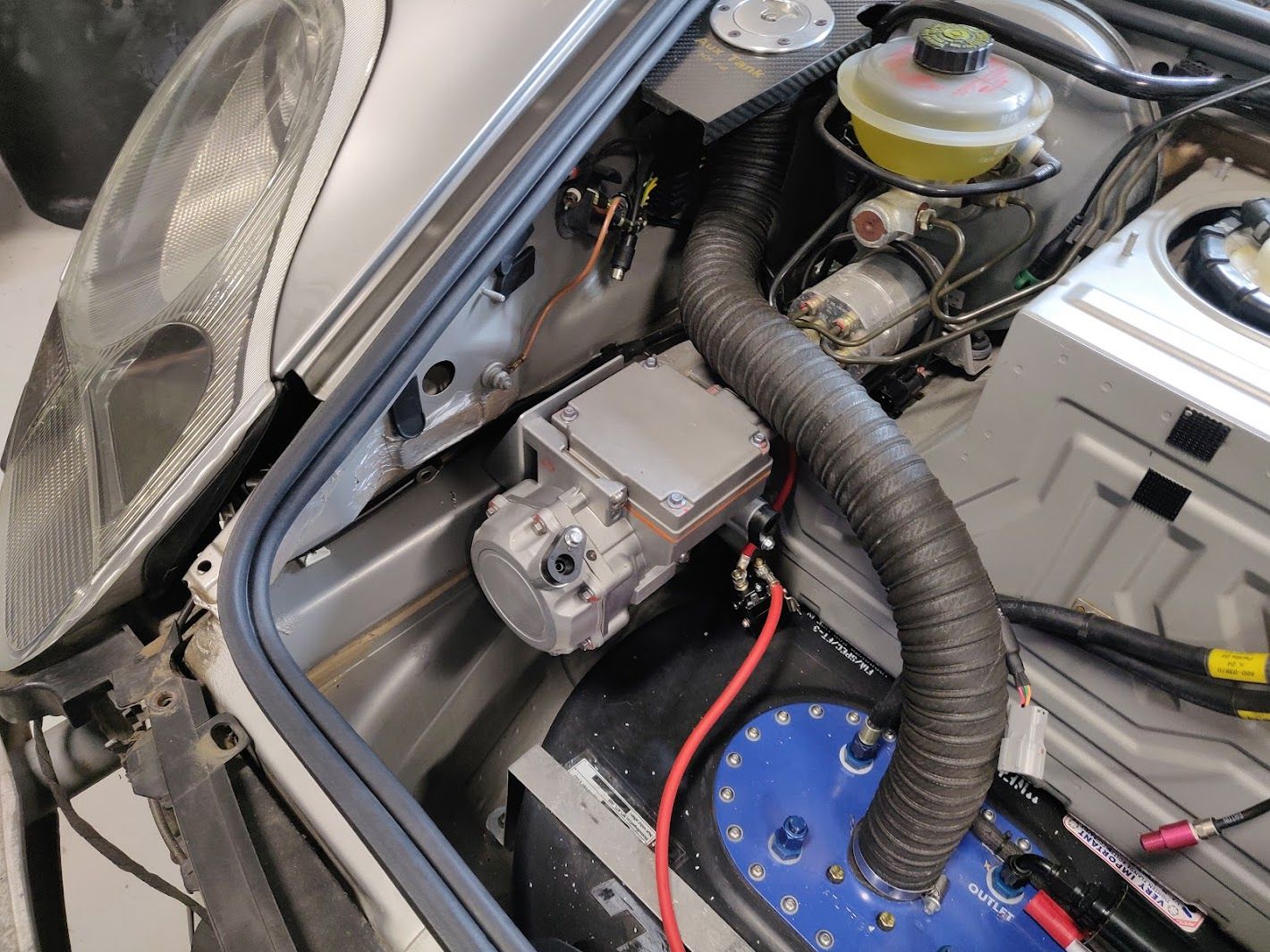

The winter mods are well under way with air-con going back on it in the form of e-AC as part of testing for another project I'm involved in, I've been considering re-airconing the car for a while as it's not like it mostly runs at night anymore! Aim with this is just to maintain ambient temperature inside the car (ACO style ) so just one heat exchanger is going in the nose - big props to the ally rads that went in many years ago and are still in great condition!

) so just one heat exchanger is going in the nose - big props to the ally rads that went in many years ago and are still in great condition!

E-AC compressor in the nose on the PAS side to balance the driver and move a little more mass forwards. There is quite a bit of HVH research required here so we'll see what its like on solid mounts first.

The system will use the standard 996 evaporator and expansion valve with a boggo aftermarket dryer. Lines are fabbed up to suit the install with one entering through the standard point in the arch and the other through a spare bung in the nose. Bit of wiring work to do but nothing too major due to the convenient battery location and the fact the car already has a SuperB fitted that is quite happy with big transient currents etc.

I'll be using the data system already on the car to monitor the inrush, temps and a few other bits whilst the compressor itself is commanded off the standard 996 climate control head unit.

I'm also aiming to finally get the composite front wings fitted over winter and I've got a load of broken floor studs to sort out.... to avoid welding bits and then having the same problems in ten years time I'm tempted to try DP490'ing some big heads onto the floor..... if it works on an LMP car.....

I've still got my Bose 996 Turbo sub floating about too..... it feels like a step too far to actually put a working stereo back in it as it's done ten years of hard work with a single working front speaker. This air-con lark might be a slippery slope to soft suspension and Radio 4!

The winter mods are well under way with air-con going back on it in the form of e-AC as part of testing for another project I'm involved in, I've been considering re-airconing the car for a while as it's not like it mostly runs at night anymore! Aim with this is just to maintain ambient temperature inside the car (ACO style

) so just one heat exchanger is going in the nose - big props to the ally rads that went in many years ago and are still in great condition!

) so just one heat exchanger is going in the nose - big props to the ally rads that went in many years ago and are still in great condition!

E-AC compressor in the nose on the PAS side to balance the driver and move a little more mass forwards. There is quite a bit of HVH research required here so we'll see what its like on solid mounts first.

The system will use the standard 996 evaporator and expansion valve with a boggo aftermarket dryer. Lines are fabbed up to suit the install with one entering through the standard point in the arch and the other through a spare bung in the nose. Bit of wiring work to do but nothing too major due to the convenient battery location and the fact the car already has a SuperB fitted that is quite happy with big transient currents etc.

I'll be using the data system already on the car to monitor the inrush, temps and a few other bits whilst the compressor itself is commanded off the standard 996 climate control head unit.

I'm also aiming to finally get the composite front wings fitted over winter and I've got a load of broken floor studs to sort out.... to avoid welding bits and then having the same problems in ten years time I'm tempted to try DP490'ing some big heads onto the floor..... if it works on an LMP car.....

I've still got my Bose 996 Turbo sub floating about too..... it feels like a step too far to actually put a working stereo back in it as it's done ten years of hard work with a single working front speaker. This air-con lark might be a slippery slope to soft suspension and Radio 4!

HughG said:

Great thread, thanks for all the insight into what you have done to the car. This thread and Jethro's video on his were major influences on getting mine.

Jethros car is my old one, I built it prior to this C4

HughG said:

A quick query on the photo above, presumable Ti exhaust studs and nuts have the benefit that they done corrode, and if the stud does corrode and sieze in the head it shouldn't matter. Do you have any issues between the Ti studs and manifold (assuming stainless - though I guess it may not be...)?

Don't use Ti nuts, it's far better to use a coated K-Nut (which is what is in the picture you posted) which is softer than the stud and therefore can be wound off no matter what the state it's in as there is no corrosive bond between the nut and stud. I guess what you are asking regarding the manifolds is related to galvanic corrosion and Ti being far more noble? If so it's just not a problem on the time scales and environment we are talking, the manifolds will fail from cracking upstream way before anything at the flange end is an issue. HughG said:

Now you mention it I recall having read that before. How standard was that car when you sold it?

Not that standard but not that modified either, Bilsteins, exhausts, 3.4 Autofarm motor, LSD, lobster claws etc. HughG said:

So with the exhaust manifolds, Ti studs, K nuts, and stainless manifold is optimal, and better than just replacing the standard bolts? Many thanks

You can use the standard manifolds if you're not seeking a performance improvement. The standard bolts will hold the manifolds on just as well as studs and nuts but once you've gone to the drama of removing them at 10+ years old it makes a lot of sense to replace them with something that won't give you the same faff next time around!darreni said:

Talking of k nuts - I’m in the process of replacing the discs on an AP big brake kit ( Ali bells/ performance friction discs) - the existing AP disc bolts and nuts are heavily corroded & need to be cut off, so I was thinking of using the AP bolts but replacing the supplied mild steel nuts with k nuts.

Worth while or a waste of time?

The disc to bell bolts and nuts (and washers if they are spec'd) should be single use only so if what you have lasted the life of the discs and aren't too much of a hassle to remove then running them again will be the cheapest option. You can use K-Nuts and benefit from the AV/Self locking they offer and most motorsport applications use K-Nuts but they are quite a lot more than a boggo nut Worth while or a waste of time?

ATM said:

My little Lithium Ion battery has arrived for my 996. Can I remove the standard heavy battery tray too or does it serve any other purpose?

On a C2 I think it covers the fuel tank top cover but you can remove it, or just hole cutter it to get the weight out and use it to bolt the retaining cage for the lithium too. That way you don't need to modify the scuttle or make a custom retaining cage. I'm not overly keen on that myself

This is mine:

Super B Andrena with the Super B supplied bracket

https://www.super-b.com/en/products/andrena-12v20a...

https://www.super-b.com/en/products/accessories/ba...

Great bit of kit and been on there for four years + faultlessly, slight downside is they're £800 a pop!

This is mine:

Super B Andrena with the Super B supplied bracket

https://www.super-b.com/en/products/andrena-12v20a...

https://www.super-b.com/en/products/accessories/ba...

Great bit of kit and been on there for four years + faultlessly, slight downside is they're £800 a pop!

Yes afraid they're out of production these days chaps - having had a couple of the Stomski jigs go AWOL and more than one set of studs "definitely not delivered" and claimed for via Paypal (despite them all being delivered via RM Special Delivery and being signed for) it just wasn't worth bothering with something that was more of a favour to other 996 owners than a money making exercise..... it definitely wasn't the latter as it cost me a good 300 quid in the end

Given the seats from the 996 are now a permanent fixture in the workshop, something is clearly afoot:

Quite a few have asked if I still have the car and if it is still in use, I do and it is indeed but is starting to show its age a little in some areas - which one can't really blame it for as it's done 21 winters of use as well as being a van for a good chunk of its life!

Over the past year I've been collating and planning various parts for the car, including a full carbon front end, and the car is in the process of coming apart ready for a big refresh. The use case has changed somewhat since it was first built and the target this time around is to keep its long range ability, modernise the general feel of the car, add some creature comforts (like air con) but keep it lean and lightweight where possible with a focus on getting it ready for the next 23 years of use.

This will be a multi-month project with the target of getting it back on the road around Feb 23. I'll post the odd update during the process

Oh and don't worry, it's not going EV and will retain its 3.7L

Quite a few have asked if I still have the car and if it is still in use, I do and it is indeed but is starting to show its age a little in some areas - which one can't really blame it for as it's done 21 winters of use as well as being a van for a good chunk of its life!

Over the past year I've been collating and planning various parts for the car, including a full carbon front end, and the car is in the process of coming apart ready for a big refresh. The use case has changed somewhat since it was first built and the target this time around is to keep its long range ability, modernise the general feel of the car, add some creature comforts (like air con) but keep it lean and lightweight where possible with a focus on getting it ready for the next 23 years of use.

This will be a multi-month project with the target of getting it back on the road around Feb 23. I'll post the odd update during the process

Oh and don't worry, it's not going EV and will retain its 3.7L

WojaWabbit said:

Just re-read the full thread, it's great stuff!

@PPBB - A few pages back you said that the 3.7 was a great engine "for a road car". If you were going to be tracking the car more frequently and spending fewer miles on the road would you change anything about the engine spec or ancillaries like cooling & lubrication?

A good track car is very far from a good road car with very different goals in terms of driveability, operating regime and life. Really a lot of a good track car is just as much in the gearbox as it is in the engine so if I was going to turn it into a track car the first thing to do would be convert it to 2WD and fit a sequential gearbox, probably not a Cup car Hollinger as I don't like several things about them like the use of a standard casing that requires the barrel position sensor to be driven off a secondary shaft making accurate barrel position sensing less reliable, something that's essential for paddle shift. I'd probably start with seeing how far off a Sadev SL-90 was from fitting (and if it minded being upside down!) and go from there. @PPBB - A few pages back you said that the 3.7 was a great engine "for a road car". If you were going to be tracking the car more frequently and spending fewer miles on the road would you change anything about the engine spec or ancillaries like cooling & lubrication?

Then it's all about inertia in the motor really. So the flywheel, clutch etc. would need to get very skinny along with anything else that rotates. With regards oiling and cooling, the latter is good for 400bhp in 40 degrees C at 100mph so over'spec for what the engine makes. For oiling I'd want to run some more scavenge on the heads but the existing sump (which is baffled and trap doored) would likely be good enough for my driving skills, if not the only sensible option would be to modify the sump to run with an external pressure stage and tank.

The engine itself would just need a change in cam profile to move the torque up the rev range, probably aiming for peak power around 7000RPM rather than 6600'ish, room for cam lift and intake allowing. Maybe a bit of exhaust manifold tuning as well but it's probably got another 25bhp or so in it with this at the expense of torque lower in the rev range. Or you'd just fit a 997 Cup Car motor

If you'd done all that then to take advantage of it all the road car uprights don't carry a big enough bearings or support brake cooling, the pickup points are in the wrong place and you'd probably want to make a proper floor, then dampers, fuel cell etc. etc.

As it is it is perfectly capable of doing track days, but if you wanted a quick track car you'd buy an ex Cup car and benefit from all the development and durability work Porsche spent a lot of money doing.... in kind of the same way you could road legal a Cup car and do Cannes to Calais in it, but you'd be much better off just doing that in mine and probably do it quicker- horses for courses and all that

When I say the 3.7 is a great road engine it's because it makes excellent torque through most of the rev range, the vast majority of which it is north of 300ftlbs. This makes it fantastic for mile munching and genuinely nippy for a 23 year old road car. The low rpm limit, big oil capacity and standard valve train and ancils also makes it pretty reliable and cheap to run whilst making a good increase in power over a standard 3.4.

I'd love to do a proper 996 track car, starting with a Cup car and a load of modern motorsport technology - paddles and KERS would be perfection. I'm a huge fan of the old 997 GT3 R Hybrid with the WAE flywheel KERS:

So doing "that" but with battery KERS and a few other bits would be a fantastic project, possibly with the V1 setup of driver controlled deploy and harvest to keep things interesting..... maybe next year once I've finished rebuilding the 996

Poor old thing is looking a bit sorry for itself sat on ramps for weeks on end:

But it's not bad in there for 23 years old, additional undersealing some years ago has really helped keep the inners and floor in good order!

Uprights have been treated to a clean, crack test and rebuild with new bearings and fasteners:

Calipers went for a holiday at Bigg Red and have come back looking well rested and refreshed:

And fresh discs, pads and fasteners in stock:

Healing shelf has done great work on the suspension bits :

:

997 brake ducts, new master cylinder, brake lines, few service bits etc. running out of room on the parts shelves now!

Supply chain is a challenge at the moment so I'm still waiting on radiator fans, exhaust manifolds, heat shields, a few random fasteners, springs, some sphericals for ARB drop links and toe arms but the ordering is almost at an end now.

A whole lot of work still to do but there is something really enjoyable about being able to rebuild this as an evenings and weekends gig as there is so much time to make it spot on rather than just sufficent to make next service

Once all the mechanicals are done it'll be into bodywork with fit of new skirts, front wings and bonnet before going off for paint. I'm aiming to have it all done sometime in Feb.....

Looking forward to making all this new stuff dirty and putting some stone chips in the new paint with some proper Euro trips next years. It's been too long since this has been sent across France at pace

But it's not bad in there for 23 years old, additional undersealing some years ago has really helped keep the inners and floor in good order!

Uprights have been treated to a clean, crack test and rebuild with new bearings and fasteners:

Calipers went for a holiday at Bigg Red and have come back looking well rested and refreshed:

And fresh discs, pads and fasteners in stock:

Healing shelf has done great work on the suspension bits

:

:

997 brake ducts, new master cylinder, brake lines, few service bits etc. running out of room on the parts shelves now!

Supply chain is a challenge at the moment so I'm still waiting on radiator fans, exhaust manifolds, heat shields, a few random fasteners, springs, some sphericals for ARB drop links and toe arms but the ordering is almost at an end now.

A whole lot of work still to do but there is something really enjoyable about being able to rebuild this as an evenings and weekends gig as there is so much time to make it spot on rather than just sufficent to make next service

Once all the mechanicals are done it'll be into bodywork with fit of new skirts, front wings and bonnet before going off for paint. I'm aiming to have it all done sometime in Feb.....

Looking forward to making all this new stuff dirty and putting some stone chips in the new paint with some proper Euro trips next years. It's been too long since this has been sent across France at pace

Edited by poppopbangbang on Thursday 15th December 20:29

M11rph said:

ATM said:

Did I miss this - what's going on with the CF there?

I'd guess it's to stop any cracks from starting/propogating on the casting? There's some "scotchbrite" and JB Weld in pic3 as you'd need to remove existing CF reinforcement for crack testing then clean up and bond the new CF patch.

The JB Weld in the pic is actually their high temp RTV product (which is really good!) which is used to fill the heads of cap heads which stops them corroding internally and makes things much easier to take apart again when the time comes. Crack test on these is just damper clamp, steering arm and caliper bosses area.

Few more bits done today, fasteners checked in - we're getting there now with nearly a cars worth. These are all the Porsche specific ones, lucky they're cheap right....

One I forgot to post earlier, the Ti wheel studs and nuts are still in fine fettle and crack tested all good. No sign of work hardening yet! They might have been the most expensive wheels studs ever but they're definitely holding in there and lets face it anything super lightweight in the unsprung area feels easily justifiable

Finally I built some new RARB drop links up, easy job as it's only three parts so "built up" is possible over egging things!

Still a lot to do before I can even think about beginning to put it back together and the recent cold has meant I've been less motivated to be in the garage rather than in front of the log burner drinking festive rum..... but it's warmed up now and I'd like to get most of the corners back together over winter break, which means I've got to work out how to get the rear toe adjuster inner sphericals out as I completely cocked up my material specs on that one and fitted some bare ally spacers either side of the rose joint on a steel bolt...... I vaguely remember past me not wanting to wait for them to be anodised and have well and truly created a PITA for future me in doing so, time to get the air saw fired up

A little more progress, although it feels like I'm deep in the part of a project where everything involves cleaning, measuring and working out how knackered something is

However there are some bits coming back together in serviceable order

Front dampers are built back up ready to refit:

Mild gravel rash on the damper bodies always shows willing

Cleaned up all the RARB hardware so once the next fastener order arrives these are ready to go back on:

And some replacement rear toe adjusters are here, went for a more agricultural option than the Cup car version to avoid having to change rose joints on a twice yearly basis, lets see how long these last!

Rear dampers up next and it's not far off the enjoyable job of building up the front suspension now! It'll be nice to see some bits going back on, although even at that it's way off halfway there!

It'll be nice to see some bits going back on, although even at that it's way off halfway there!

However there are some bits coming back together in serviceable order

Front dampers are built back up ready to refit:

Mild gravel rash on the damper bodies always shows willing

Cleaned up all the RARB hardware so once the next fastener order arrives these are ready to go back on:

And some replacement rear toe adjusters are here, went for a more agricultural option than the Cup car version to avoid having to change rose joints on a twice yearly basis, lets see how long these last!

Rear dampers up next and it's not far off the enjoyable job of building up the front suspension now!

It'll be nice to see some bits going back on, although even at that it's way off halfway there!

It'll be nice to see some bits going back on, although even at that it's way off halfway there!WojaWabbit said:

I must have missed this update last time I was on... cheers, good info

My C2 is awaiting the 3.7 upgrade with the Capricorn kit - can't wait for it to be finished!

It's a great kit and if the engine builder is experienced (which all the well known Porsche specialists are by now) it'll serve you very well!

My C2 is awaiting the 3.7 upgrade with the Capricorn kit - can't wait for it to be finished!

If the car is predominantly road use then all you need to do is ensure the cooling and oiling are to an acceptable level for any track work you do. If it's on standard suspension and road tyres then it all likelihood you are fine with the standard radiators if they are in good condition, I am a fan of the third radiator kit though as it gives a good chunk of useful rad area for very little weight and integrates well with the standard car. You can go to all aluminium rads (CSF produce drop ins which are very good) but if the standards are in good order it's of questionable benefit.

Remember the engine has a water/oil heat exchanger so on circuit or at sustained high RPM the cooling system will have to work harder to cool the additional oil temperature.

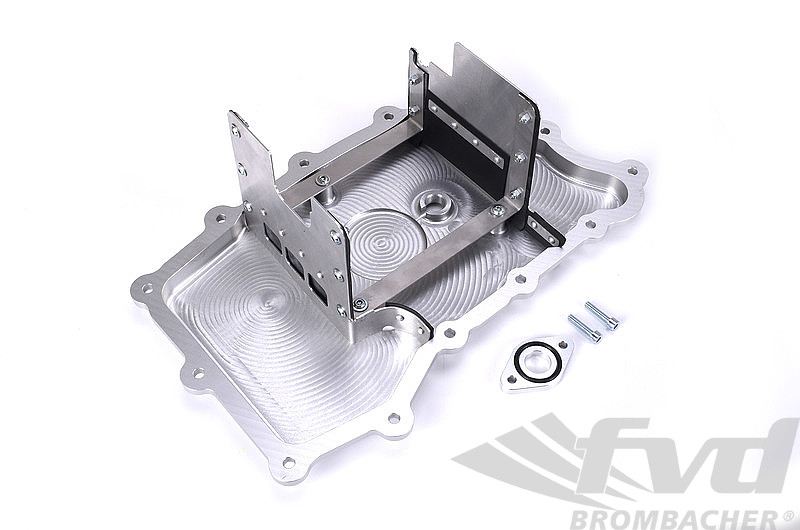

On the subject of oil a sump with a little extra oil capacity and some baffling is a very, very good shout on track even on standard tyres. I'm not a fan of the sump spacers and similar as you lose a lot of ground clearance from them but I do highly recommend the FVD billet sump as it has a very good copy of the X51 baffles in it, is machined from a single piece of billet so is plenty strong if you whack it and adds a little bit of extra oil capacity without much impact on ground clearance.

If I was doing mine again I wouldn't reuse the heads, I'd just buy two new ones from Porsche as they come built up with valves, springs, retainers etc. for way, way less than the parts cost of just those bits - I spent more on single piece aftermarket valves than two new heads from Porsche would have cost and don't use any where near the RPMs required to justify them

Only other things to consider are the oil pump drive, the standard is mild steel and if you are going to run much thicker oils it may be worth replacing it for one of the aftermarket shot peened and heat treated versions as they're only 50 quid or so. IMS is another thing to ponder, mine did 300K on the original dual row and if they were sourceable at the time I'd have used the same again when it was rebuilt. Your engine builder will have a preference for which IMS option is best, I used the EPS cylindrical bearing kit as I really liked how they had engineered the use of cylindrical pressure fed bearing in this application.

Finally find someone good to do the engine calibration work, it'll run fine on the standard cal if its DBW throttle but won't make anywhere near the performance it could. The calibration is torque based and I found that whilst it supports a little more torque target than the standard engine generally makes once this is exceeded (which it is with a 3.7 with GT3 throttle and tuned exhausts) the ECU will reduce throttle opening to maintain the calibrated torque target. Here's mine going dropping to 80% throttle in the mid range despite the pedal request being 100% !

It made a lot more mid range torque once I sorted that

I don't know what a cable throttle car will do but given the management on them is extremely ancient and can't do anything to influence inducted air mass once off idle I would expect it to go rather lean, which is never a good thing!

Well between Xmas and New Year I found a couple of days to lock myself in the garage with the telly on and the beer fridge stocked to make some progress.

Got the steam cleaner out and properly cleaned the arches, sub frames etc. It's amazing how well this comes up considering the age and mileage on the car!

I took this opportunity to clean up and treat the turret tops as whilst still in good order it's rude not to when the opportunity is there.

Once ship shape I moved onto building the front corners up:

New coffin arms, tuning forks, track rod ends and ARB drop links. I've moved to poly bushes on some of these bits so we'll see how good / bad that turns out to be...

Many suggest they make a positive difference to life and performance but I'm never that trusting of changing bushing shore on the off chance. Fingers crossed

Same on the rears and new flexible lines, I also made up a couple of new brake lines to replace the remaining originals that were looking a bit worse for wear.

New Sebro discs all round (I've always had good results with these) and whilst I toyed with the idea of moving to floating discs the cost/performance benefit along with future availability / lead time is such that sticking with the setup it's always ran of 997 Turbo 350mm front discs with 996 GT3 330mm rear discs seemed the best compromise:

Pads are standard spec Brembo all round, the pad sizes are pretty big for the weight of the car so using a road car pad compound on these works incredibly well, a lot of performance for a pretty minimal cost, good road manners, work well from cold etc. etc. The front brake setup is essentially off a Cayenne and the rear off the front of a 996 Carrera so unsurprisingly when you put brakes that passed OEM sign off on a 2.5T SUV on a 1.3T car the performance is acceptable I'm also very pleased with how the calipers came out following their refurb!

I'm also very pleased with how the calipers came out following their refurb!

I also fitted some 997 GT3 front brake ducts, these shift about the same amount of air to the brakes as the standard ones do but with a little bit less drag and a big more ground clearance.

Made a start on the E-HVAC as well, specifically moving the control and wiring of the compressor away from "will this actually work" to a more permanent install. I need to 3D print a few cover bits up etc. but I'll get the rest of it in properly first. I'm definitely going to be tight on alternator output on this - luckily there's a "standard" upgrade available that will do the trick

All of which leaves the old shed sat on the ramps in the garage still but looking a lot more cared for than it has for a few years

I'm waiting on a few fasteners so I can refit the rear ARB but the big hold up is going to be waiting on some spares from Ohlins which will likely take until the end of the month. In the meantime I need to pull the front and rear bumpers off to change rad fans, repair heat shields and generally give it a good sorting out under there before moving on to pulling the front wings off to test fit the carbon ones...... I almost know that's going to turn into a big job of flap wheels and panel gap stress

Hope everyone has had a wonderful Xmas break and new year. Here's to some proper mileage in 2023

Got the steam cleaner out and properly cleaned the arches, sub frames etc. It's amazing how well this comes up considering the age and mileage on the car!

I took this opportunity to clean up and treat the turret tops as whilst still in good order it's rude not to when the opportunity is there.

Once ship shape I moved onto building the front corners up:

New coffin arms, tuning forks, track rod ends and ARB drop links. I've moved to poly bushes on some of these bits so we'll see how good / bad that turns out to be...

Many suggest they make a positive difference to life and performance but I'm never that trusting of changing bushing shore on the off chance. Fingers crossed

Same on the rears and new flexible lines, I also made up a couple of new brake lines to replace the remaining originals that were looking a bit worse for wear.

New Sebro discs all round (I've always had good results with these) and whilst I toyed with the idea of moving to floating discs the cost/performance benefit along with future availability / lead time is such that sticking with the setup it's always ran of 997 Turbo 350mm front discs with 996 GT3 330mm rear discs seemed the best compromise:

Pads are standard spec Brembo all round, the pad sizes are pretty big for the weight of the car so using a road car pad compound on these works incredibly well, a lot of performance for a pretty minimal cost, good road manners, work well from cold etc. etc. The front brake setup is essentially off a Cayenne and the rear off the front of a 996 Carrera so unsurprisingly when you put brakes that passed OEM sign off on a 2.5T SUV on a 1.3T car the performance is acceptable

I'm also very pleased with how the calipers came out following their refurb!

I'm also very pleased with how the calipers came out following their refurb! I also fitted some 997 GT3 front brake ducts, these shift about the same amount of air to the brakes as the standard ones do but with a little bit less drag and a big more ground clearance.

Made a start on the E-HVAC as well, specifically moving the control and wiring of the compressor away from "will this actually work" to a more permanent install. I need to 3D print a few cover bits up etc. but I'll get the rest of it in properly first. I'm definitely going to be tight on alternator output on this - luckily there's a "standard" upgrade available that will do the trick

All of which leaves the old shed sat on the ramps in the garage still but looking a lot more cared for than it has for a few years

I'm waiting on a few fasteners so I can refit the rear ARB but the big hold up is going to be waiting on some spares from Ohlins which will likely take until the end of the month. In the meantime I need to pull the front and rear bumpers off to change rad fans, repair heat shields and generally give it a good sorting out under there before moving on to pulling the front wings off to test fit the carbon ones...... I almost know that's going to turn into a big job of flap wheels and panel gap stress

Hope everyone has had a wonderful Xmas break and new year. Here's to some proper mileage in 2023

Edited by poppopbangbang on Monday 2nd January 23:35

roboxm3 said:

Apologies if you've covered it before, PPBB but who's suspension components do you use/recommend, coffin arms, tuning forks etc.?

Cheers

In the past I've used TRW and Meyle with no issues, this time around I've used the Spyder Performance poly bushed ones. I've also used the EPS poly bushed control arms in the past but found they allowed a little too much deflection vs the ball jointed originals. Geometrically I've never had one that didn't measure up okay (but some are heavier than others!) and I think there are only two factories making these so anything of a known brand you should be fine with. TRW is technically the OE option and produced for Porsche originally but the days of being able to buy these with the Porsche logo machined off are gone it seems.Cheers

I'll report back on the Spyder ones but initial impressions are good!

Spring options have arrived:

Always good to have some tuning options.

As some will have guessed from the 996 seats on office chair bases earlier in the thread they aren't staying in the car - several hundred thousand miles have taken their toll on them . Having spent some time in a Cayman over the past year I was really impressed with how well the standard seats fit me - it always comes down to form vs function with these things as no once could say that a set of Recaro buckets don't look awesome but as this is a big mileage capable road car I'm focusing very much on comfort during this rebuild so I've got a set of half alcantara Cayman seats in there now.

. Having spent some time in a Cayman over the past year I was really impressed with how well the standard seats fit me - it always comes down to form vs function with these things as no once could say that a set of Recaro buckets don't look awesome but as this is a big mileage capable road car I'm focusing very much on comfort during this rebuild so I've got a set of half alcantara Cayman seats in there now.

The alcantara centres offer plenty of grip and the lack of "wings" fits my shoulders better than the 996 seats do! They also offer more adjustment than the 996 seats and go straight in on the standard runners:

Comparison:

Both in:

They only require a small wiring mod to fit and to avoid modifying the car side wiring loom I salvaged the connectors from the 996 seats to make the seat electrics plug and play and swapped the seat belt recepticles over from the 996 seats.

I'm not sure if I'll retrim these or not, the go to retro check isn't really my thing and I'm a big fan of alcantara so I may just do the bolsters.....

Always good to have some tuning options.

As some will have guessed from the 996 seats on office chair bases earlier in the thread they aren't staying in the car - several hundred thousand miles have taken their toll on them

. Having spent some time in a Cayman over the past year I was really impressed with how well the standard seats fit me - it always comes down to form vs function with these things as no once could say that a set of Recaro buckets don't look awesome but as this is a big mileage capable road car I'm focusing very much on comfort during this rebuild so I've got a set of half alcantara Cayman seats in there now.

. Having spent some time in a Cayman over the past year I was really impressed with how well the standard seats fit me - it always comes down to form vs function with these things as no once could say that a set of Recaro buckets don't look awesome but as this is a big mileage capable road car I'm focusing very much on comfort during this rebuild so I've got a set of half alcantara Cayman seats in there now. The alcantara centres offer plenty of grip and the lack of "wings" fits my shoulders better than the 996 seats do! They also offer more adjustment than the 996 seats and go straight in on the standard runners:

Comparison:

Both in:

They only require a small wiring mod to fit and to avoid modifying the car side wiring loom I salvaged the connectors from the 996 seats to make the seat electrics plug and play and swapped the seat belt recepticles over from the 996 seats.

I'm not sure if I'll retrim these or not, the go to retro check isn't really my thing and I'm a big fan of alcantara so I may just do the bolsters.....

Mikeeb said:

I assume you haven’t wired the side airbags. I’ve been looking at a set of these for mine.

I'm leaving that until I've decided if I'm retrimming the seats or not. If I am then I'm going to delete the seat bags as mine has door card bags already. If I'm not I'll look at swapping to some none airbag door cards and investigate the compatibility of the seat bag squab resistance vs the original door bag squab resistance. The bag deploy angle etc. should be all good as the door aperture vs seat position is the same as a 997 and I'm pretty sure the same as a Cayman bar the rear most position.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff