AWD Civic Coupe Turbo Build

Discussion

This is the best thing I've read on PH for some time!

What an absolutely amazing project, not to mention the talent needed to do this .

.

Casually making computers for everything as if it's easy ha ha!

I love the dash, work of art IMO.

And I think Garrett is a great name for an awesome looking dog .

.

What an absolutely amazing project, not to mention the talent needed to do this

.

.Casually making computers for everything as if it's easy ha ha!

I love the dash, work of art IMO.

And I think Garrett is a great name for an awesome looking dog

.

.purplecivicturbo said:

People actually do double take when they ask his name.. Well, those that arent clued up on their turbo makes lol

Yeah, i do make all sorts of items and sell them.. I try to keep it quiet on here though because im not a trader or anything on PH, I dont want to get in trouble..

A lot of business owners have the url of their business in their profile. If someone's interested in your stuff they'll find it when they go to send you a PM. Yeah, i do make all sorts of items and sell them.. I try to keep it quiet on here though because im not a trader or anything on PH, I dont want to get in trouble..

The car seems like a CV to me. As in "This is what I can do at home, now pay me lots of money to work for you".

Thanks for the compliments chaps.. It really does mean a lot..

I know what you mean, but id still find it a little underhanded to taint a build thread with business stuff.. Plus i set the business up in order to fund the build, and thats it lol..

Its hopefully going to be a time attack car, but at least a trackday car.. Obviously the entrance fee for TA would probably require sponsorship.. And better tyres lol

I was offered a job by Williams F1.. But i unfortunately couldnt relocate so it wasnt affordable, im not dwelling on it and to be honest i hold on to it as it proves that i could have done it.. Id love at some point to do this sort of thing for a living but this is probably as close as im going to get lol

I know what you mean, but id still find it a little underhanded to taint a build thread with business stuff.. Plus i set the business up in order to fund the build, and thats it lol..

Its hopefully going to be a time attack car, but at least a trackday car.. Obviously the entrance fee for TA would probably require sponsorship.. And better tyres lol

I was offered a job by Williams F1.. But i unfortunately couldnt relocate so it wasnt affordable, im not dwelling on it and to be honest i hold on to it as it proves that i could have done it.. Id love at some point to do this sort of thing for a living but this is probably as close as im going to get lol

purplecivicturbo said:

Thanks for the compliments chaps.. It really does mean a lot..

I know what you mean, but id still find it a little underhanded to taint a build thread with business stuff.. Plus i set the business up in order to fund the build, and thats it lol..

Its hopefully going to be a time attack car, but at least a trackday car.. Obviously the entrance fee for TA would probably require sponsorship.. And better tyres lol

I was offered a job by Williams F1.. But i unfortunately couldnt relocate so it wasnt affordable, im not dwelling on it and to be honest i hold on to it as it proves that i could have done it.. Id love at some point to do this sort of thing for a living but this is probably as close as im going to get lol

The way things are going at Williams, your car, when finished, may well be faster I know what you mean, but id still find it a little underhanded to taint a build thread with business stuff.. Plus i set the business up in order to fund the build, and thats it lol..

Its hopefully going to be a time attack car, but at least a trackday car.. Obviously the entrance fee for TA would probably require sponsorship.. And better tyres lol

I was offered a job by Williams F1.. But i unfortunately couldnt relocate so it wasnt affordable, im not dwelling on it and to be honest i hold on to it as it proves that i could have done it.. Id love at some point to do this sort of thing for a living but this is probably as close as im going to get lol

oooh ouch lol...

No not very many updates at the moment..

I bought this;

for my business, so im using it to make PCBs and small aluminium parts.. Not a bad little thing, its exceeded my expectations..

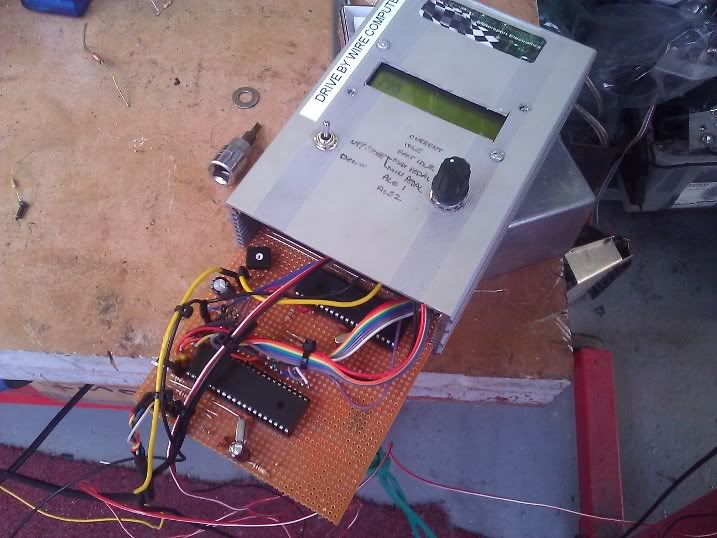

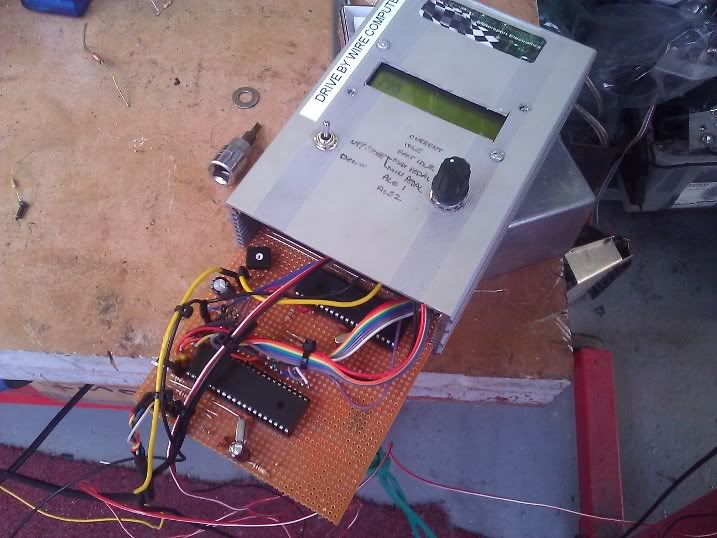

i finished the final DBW, i wasnt happy with some jitter it had so i redesigned it from scratch..

(connected to a function generator so it was opening and closing fully for 2 hours)

Ive figured out how to attach my arch flares properly, so they wont flex and yet remain separate. So i have ordered some extra wide ones, they should be here soon.

Thats it really

No not very many updates at the moment..

I bought this;

for my business, so im using it to make PCBs and small aluminium parts.. Not a bad little thing, its exceeded my expectations..

i finished the final DBW, i wasnt happy with some jitter it had so i redesigned it from scratch..

(connected to a function generator so it was opening and closing fully for 2 hours)

Ive figured out how to attach my arch flares properly, so they wont flex and yet remain separate. So i have ordered some extra wide ones, they should be here soon.

Thats it really

Great to see some more progress, but without trying to sound negative, please hear a few comments about your DBW system:

1) Ensure it has a mechical spring bias to the shut position. I can't see clearly from the pic, but it looks like you are using an RC servo to drive the throttle plate, these, if not sprung, will simply remain in there current position in case of a failure. That is unacceptable for a throttle system imo

2) Is their any secondary position feed back to the controller, or do you just push a 1ms - 2ms pulse out to the servo and rely on the PI loop controller within the servo to supply the final position. For reliability reasons a second shaft position sensor (mounted prefferably directly on the throttle shaft) should be used to validate the true throttle position. Sme systems go as far as having two totally seperate uC to control safety critical items such as the throttle (even with one uC deliberately injecting a fault into the 2nd one to check it gets picked up!)

3) As a minimum have a large "power off" estop button prominent within easy reach of the driver (whilst in belt/harness!) This should kill power to both the throttle system and ideally the ignition system to give a secondary "safe torque off" protection.

4) Consider allowing the system to kill the sparks itself if a large negative (plate too far open) error exisits for too long (typically 100ms)

5) whilst 2hrs of test cycles proves the basic integrity of the linkages etc, in reality, the conditions on a running engine are far harsher. Temps over 100degC, vibrations, possibly as much as 40g on a poorly supported plenum, not to mention dust, water, and voltage fluctuations (or worse load dump!). In reality, the confidence in your systems robustness will accumulate during the early running periods and then mature after significant running hrs under all conditions has taken place. For this very reason, the E-stop is a must !

I'm all for people experimenting and pushing the boundaries for control electronics at a DIY level, but i'm also very much in favour of doing it in a safe and preemptive fashion!!

1) Ensure it has a mechical spring bias to the shut position. I can't see clearly from the pic, but it looks like you are using an RC servo to drive the throttle plate, these, if not sprung, will simply remain in there current position in case of a failure. That is unacceptable for a throttle system imo

2) Is their any secondary position feed back to the controller, or do you just push a 1ms - 2ms pulse out to the servo and rely on the PI loop controller within the servo to supply the final position. For reliability reasons a second shaft position sensor (mounted prefferably directly on the throttle shaft) should be used to validate the true throttle position. Sme systems go as far as having two totally seperate uC to control safety critical items such as the throttle (even with one uC deliberately injecting a fault into the 2nd one to check it gets picked up!)

3) As a minimum have a large "power off" estop button prominent within easy reach of the driver (whilst in belt/harness!) This should kill power to both the throttle system and ideally the ignition system to give a secondary "safe torque off" protection.

4) Consider allowing the system to kill the sparks itself if a large negative (plate too far open) error exisits for too long (typically 100ms)

5) whilst 2hrs of test cycles proves the basic integrity of the linkages etc, in reality, the conditions on a running engine are far harsher. Temps over 100degC, vibrations, possibly as much as 40g on a poorly supported plenum, not to mention dust, water, and voltage fluctuations (or worse load dump!). In reality, the confidence in your systems robustness will accumulate during the early running periods and then mature after significant running hrs under all conditions has taken place. For this very reason, the E-stop is a must !

I'm all for people experimenting and pushing the boundaries for control electronics at a DIY level, but i'm also very much in favour of doing it in a safe and preemptive fashion!!

i couldnt agree more mate- and im always open to suggestions..

i have a few backups in the system..

1) youre correct, im using a high spec hobby servo. And youre correct, as standard there is no spring return, however the mechanism ive designed incorporates an idle return spring.

2) Estop, already covered. As the car uses electro-hydraulic power steering and electric vacuum brakes, i have a switch on the dash for shutting down the servo / engine. Flicking the switch terminates power to both the ecu and the drive by wire controller. The engine will obviously stop and the throttle will close on the spring.

3) i have provisioned- as i still have the old TPS, a crude feedback loop on the output micro. This chip drives the position of the servo, and is aware of its physical positioning. The TPS is to be wired in and provide a basic limiting system, if the throttle position is too different to the real position (obviously within a field of delay during the seek time) it reports an error and will disable the servo (so the spring will shut it).

This isnt installed yet, the software isnt ready. I dont want to overload the new system with safety protocols until i can ensure it works as standard on the engine. Once im happy, then i can develop it. But the hardware will all be ready.

As you say, im all for playing with this, but having been trained in the aerospace industry i cant help but have picked up a real safe working mentality. I wont do anything that puts passengers or other road users at risk. If there is a system im not sure about, i will either have a redundancy, shut off or at least a self check.

i have a few backups in the system..

1) youre correct, im using a high spec hobby servo. And youre correct, as standard there is no spring return, however the mechanism ive designed incorporates an idle return spring.

2) Estop, already covered. As the car uses electro-hydraulic power steering and electric vacuum brakes, i have a switch on the dash for shutting down the servo / engine. Flicking the switch terminates power to both the ecu and the drive by wire controller. The engine will obviously stop and the throttle will close on the spring.

3) i have provisioned- as i still have the old TPS, a crude feedback loop on the output micro. This chip drives the position of the servo, and is aware of its physical positioning. The TPS is to be wired in and provide a basic limiting system, if the throttle position is too different to the real position (obviously within a field of delay during the seek time) it reports an error and will disable the servo (so the spring will shut it).

This isnt installed yet, the software isnt ready. I dont want to overload the new system with safety protocols until i can ensure it works as standard on the engine. Once im happy, then i can develop it. But the hardware will all be ready.

As you say, im all for playing with this, but having been trained in the aerospace industry i cant help but have picked up a real safe working mentality. I wont do anything that puts passengers or other road users at risk. If there is a system im not sure about, i will either have a redundancy, shut off or at least a self check.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff