Knackered old Porsche with loads of natural light - Boxster!

Discussion

Decided to have a quick sniff around the back of the engine with the borescope to see if I could find my coolant weep, spotted where the gearbox was wet on top and a likely looking silicone above it and got two turns on the hoseclip holding it. If it's solved that easily then I'm off to buy a lottery ticket as it's avoided dropping the engine down to access it!

Chargecooler rad design is over with PWR who are busy making that, they've offered to do a Booster charge cooler kit as a part number so if anyone else should be crazy enough to build one at least you can order that fairly off the shelf and it'll just bolt on.

Very excited to get it on the dyno now and see what it makes, as always dyno time goes one of two ways - either smiles all round or crushing disappointment so I'm hoping for the former!

so I'm hoping for the former!

Chargecooler rad design is over with PWR who are busy making that, they've offered to do a Booster charge cooler kit as a part number so if anyone else should be crazy enough to build one at least you can order that fairly off the shelf and it'll just bolt on.

Very excited to get it on the dyno now and see what it makes, as always dyno time goes one of two ways - either smiles all round or crushing disappointment

so I'm hoping for the former!

so I'm hoping for the former! If everything works and it doesn't vomit a driveshaft out then rather boringly it will make about 400bhp @ 7000rpm and 300 ftlbs everywhere over the boost threshold..... as that's what we're calibrating to  It's on standard cams so will be running a lot of boost higher up to hold the torque figure up as it will be over the top of the cams by 6K but it should make that power without too much trouble as it's well within the limits of the turbo.

It's on standard cams so will be running a lot of boost higher up to hold the torque figure up as it will be over the top of the cams by 6K but it should make that power without too much trouble as it's well within the limits of the turbo.

I'll run at that for a bit and get everything about right in terms of systems, charge cooling etc. and then decide what the next development steps are..... I could fit an NA inlet cam, a G25-660 on a suitable manifold and some water/meth and see how long the gearbox lasts or look at a G25-550 and see how much lower we can make the boost threshold. Sensible cams for the power would probably help charge temps too as it'll need less boost to make the power, I suspect on the boost button it's going to run out of charge cooling really quickly so maybe just some water/meth and 500 on the button will do the trick.

or look at a G25-550 and see how much lower we can make the boost threshold. Sensible cams for the power would probably help charge temps too as it'll need less boost to make the power, I suspect on the boost button it's going to run out of charge cooling really quickly so maybe just some water/meth and 500 on the button will do the trick.

Either way keeping it as reliable as possible with good driveability is the name of the game on this one really as 400 beans in a 1200KG Boxster is going to be pretty nippy regardless!

It's on standard cams so will be running a lot of boost higher up to hold the torque figure up as it will be over the top of the cams by 6K but it should make that power without too much trouble as it's well within the limits of the turbo.

It's on standard cams so will be running a lot of boost higher up to hold the torque figure up as it will be over the top of the cams by 6K but it should make that power without too much trouble as it's well within the limits of the turbo. I'll run at that for a bit and get everything about right in terms of systems, charge cooling etc. and then decide what the next development steps are..... I could fit an NA inlet cam, a G25-660 on a suitable manifold and some water/meth and see how long the gearbox lasts

or look at a G25-550 and see how much lower we can make the boost threshold. Sensible cams for the power would probably help charge temps too as it'll need less boost to make the power, I suspect on the boost button it's going to run out of charge cooling really quickly so maybe just some water/meth and 500 on the button will do the trick.

or look at a G25-550 and see how much lower we can make the boost threshold. Sensible cams for the power would probably help charge temps too as it'll need less boost to make the power, I suspect on the boost button it's going to run out of charge cooling really quickly so maybe just some water/meth and 500 on the button will do the trick.Either way keeping it as reliable as possible with good driveability is the name of the game on this one really as 400 beans in a 1200KG Boxster is going to be pretty nippy regardless!

braddo said:

What kind of cost do ECUs start from that can handle this kind of arrangement? I find it really interesting how the torque can be managed into the curve shape you want and how boost can be added as the revs go beyond the cams.

I'm thinking of how a big turbo and good ECU could improve something like a 1960s fuel injected Benz (strong engine, low compression, FI inlet manifold) ....

Really most things now have workable boost control and a good 50% support DBW throttle so you can do this sort of thing with a wide range of ECU's at varying cost points. I'm thinking of how a big turbo and good ECU could improve something like a 1960s fuel injected Benz (strong engine, low compression, FI inlet manifold) ....

The strategies that the ECU runs becomes more important the finer the control you want and to a point driveability and performance is directly related to the complexity of these strategies. You can run an engine on two sensors (crank position and load) but it won't be very nice when compared to something modern and it also won't cold start very well. On some of the more serious engine control platforms you're paying more for access to the strategies than you are for the hardware.

Torque is essentially just air mass i.e. the more air mass you have, the larger the combustion event can be in terms of gas generation and the greater the useful work on the piston crown i.e. there's more torque on the end of the crank shaft. Two things impact the air mass availability to the cylinder, one is the throttle and the other is boost pressure so with a combination of those two things you can directly impact what the torque curve looks like. This is the reason why if you plot boost pressure on a turbo charged engine the torque curve looks a very similar shape to the boost pressure plot.

Boost control can be achieved in several ways, modern production engines use electrically actuated wastegates where they can be driven to an exact position for bypass but there's nothing wrong with a decent mechanical gate. Pressure bleed off or bleed on is used via a PWM driven valve to allow boost pressures greater than the mechanical gate is sprung for. Most aftermarket ECUs will support PWM based boost control via a single solenoid valve.

If you're looking to do this on a 1960's engine though then the key challenge will be getting accurate and reliable crank position sensing in there and ideally some sort of phase sensor too. If you've got those then you can run the engine on something many decades more modern than the engine itself is.

Big thanks to Mike for donating this to the project:

Cruise control stalk

I've been tinkering with it today and it's straightforward to pass the analogues from this to the dash and then CAN them to the ECU for boost preset select. Means I can tap it forward or backwards for the desired boost pressure and use the button on the end to quick select "race mode".

Cruise control stalk

I've been tinkering with it today and it's straightforward to pass the analogues from this to the dash and then CAN them to the ECU for boost preset select. Means I can tap it forward or backwards for the desired boost pressure and use the button on the end to quick select "race mode".

Perhaps walking the tightrope of no commercial posts here so keeping my fingers crossed this is okay and I don't get a telling off.... it has been a bit of an open secret that this project became a "kit" about halfway through the project afterall and I'm pretty sure this will be of interest to a few people on here. Afterall it became a fit-kit project off the back of this thread and the people who messaged wanting to do the same thing...

Earlier this evening I did an online presentation on the kit to a few interested parties, it covers a lot of the engineering ethos behind the project and how it's come together as a repower option. I've snipped anything with a web address etc. out of it so fingers crossed it passes PH scruiteneering

Fair warning, it's nearly 40 minutes of me droning on about the contents of this thread - for those who are having trouble getting to sleep this may just do the trick

Earlier this evening I did an online presentation on the kit to a few interested parties, it covers a lot of the engineering ethos behind the project and how it's come together as a repower option. I've snipped anything with a web address etc. out of it so fingers crossed it passes PH scruiteneering

Fair warning, it's nearly 40 minutes of me droning on about the contents of this thread - for those who are having trouble getting to sleep this may just do the trick

Beautiful day today and absolutely rude not to put more miles on the car, so I glued a go-pro to the rear bumper to get some exhaust noise captured:

Full throttle at 1bar boost to 6500RPM at 35 seconds in

This is on the standard Boxster silencer which has been split in half and had a 3" system built inside it. I'm pretty pleased with how sporty it sounds considering that as the only goals here were as quite as the standard car when meandering about and looks totally stock from outside. Definitely achieved the latter:

Full throttle at 1bar boost to 6500RPM at 35 seconds in

This is on the standard Boxster silencer which has been split in half and had a 3" system built inside it. I'm pretty pleased with how sporty it sounds considering that as the only goals here were as quite as the standard car when meandering about and looks totally stock from outside. Definitely achieved the latter:

Escy said:

I watched the 40 minute YouTube earlier today. Nicely done, all very professional.

Have you got a solution to the engine cover?

Thank you! Really do appreciate the compliment! Have you got a solution to the engine cover?

Solution currently is a cut template for the standard engine cover based around clearing a none breather rocker cover and a bond in section - this is WIP but will go in the kit shortly, although I know at least one person is planning on binning the roof off and running some sort of taller cover with a window in it and a hard top. I'd really like to do a single piece carbon one as getting ten off blue block tooling is pretty cost effective but I'm not sure anyone else wants one, especially given cost compared to ten minutes with a hole saw and a 330 kit

So next job post dyno etc. is to build a gearbox for it, the one that's on there has covered just under 100K behind the original M96 so I suspect it is not going to have a 1) Good Time or 2) Long Time with the 20V attached to it

Question is do I build another "Porsche" box for it or a lower ratio Audi box....

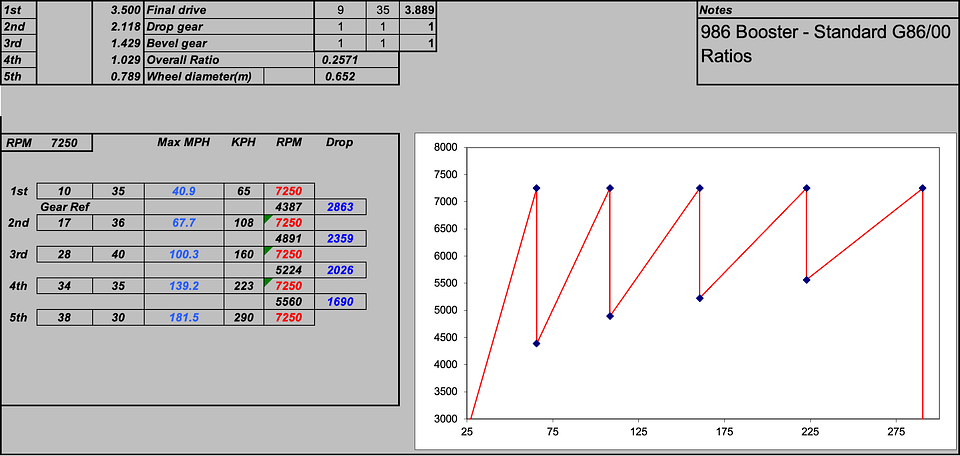

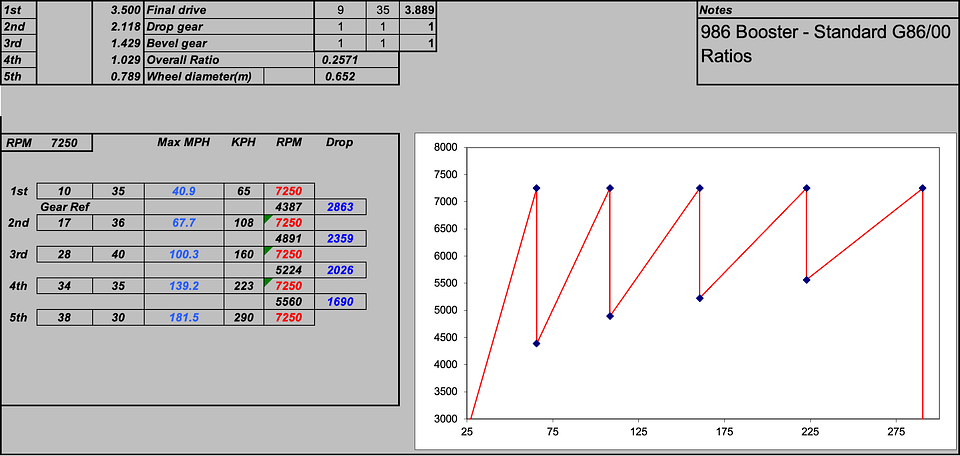

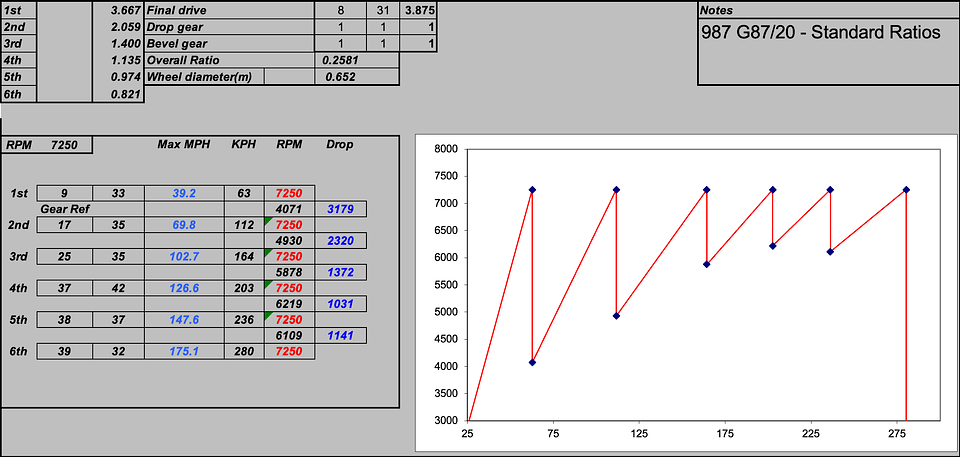

Standard ratios look like this:

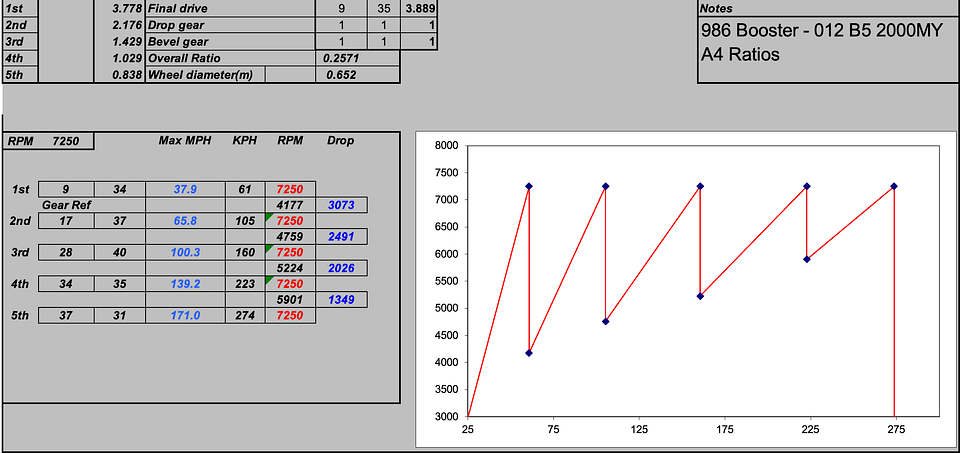

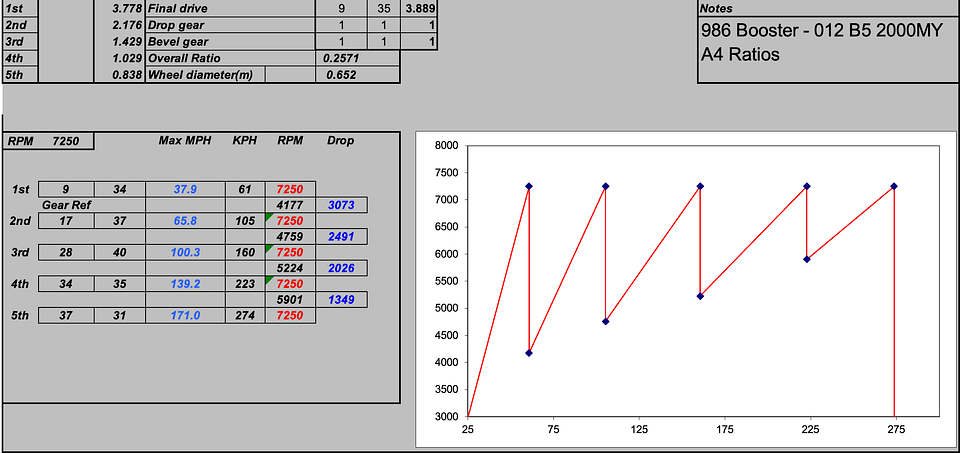

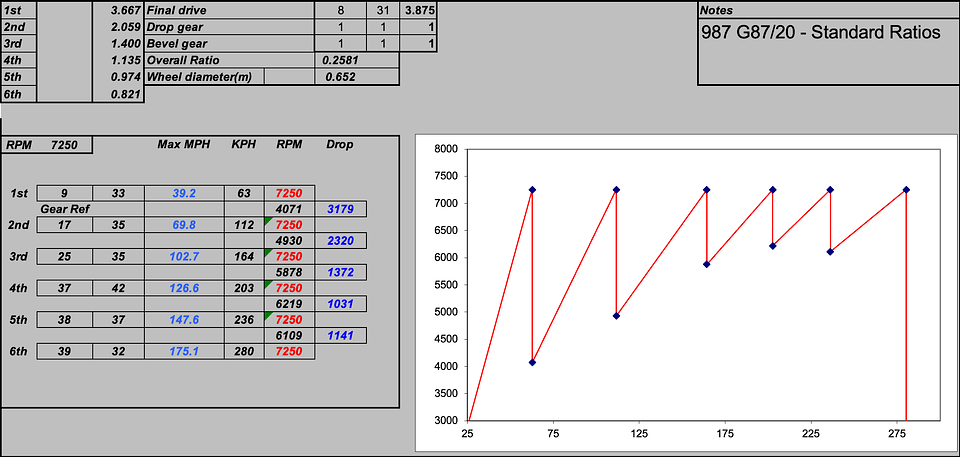

Audi ratios look like this:

Both assuming a 7250RPM limit. The Audi has a shorter 1st, 2nd and 5th and arguably a ratio stack that looks nicer than the Boxster one does for a sporty car. 1st and 2nd being longer in the Boxster box makes sense as the rev limit is pretty low and the engine intertia pretty high (plus its got 50% more firings than a 4 cyl!).

I'll decide shortly but a more useful 5th is quite tempting, even if it does mean it's turning a few more revs at motorway speeds.

Either way it will be getting an ATB diff

Question is do I build another "Porsche" box for it or a lower ratio Audi box....

Standard ratios look like this:

Audi ratios look like this:

Both assuming a 7250RPM limit. The Audi has a shorter 1st, 2nd and 5th and arguably a ratio stack that looks nicer than the Boxster one does for a sporty car. 1st and 2nd being longer in the Boxster box makes sense as the rev limit is pretty low and the engine intertia pretty high (plus its got 50% more firings than a 4 cyl!).

I'll decide shortly but a more useful 5th is quite tempting, even if it does mean it's turning a few more revs at motorway speeds.

Either way it will be getting an ATB diff

There definitely is a 6 speed box that will fit, Escy has done just this with his 2.7T 987 and I believe is using the 987 6 speed box with a mod to shafts to suit the flanges.

The ratios for this box plot like this:

(Note I've guessed the tooth counts to get the ratios as I didn't have counts to hand)

So it's actually a bit shorter than the Boxster 5 speed 5th and a bit longer than the A4 5 speed 5th.... but with another cog in the middle.

In reality the 5 speed is just fine behind the 20V as it's got a boat load of torque once it's up on boost and due to the higher rev limit a set of cogs which are a bit shorter work well with it (like the A4 ones), it has circa another 1000RPM vs the M96 so even though the A4 ratios are shorter the max speed per gear is really similar.

What I'm really pondering here with regards A4 vs Boxster ratios on the 5 speed is do I gear it to suit the high revs the 20V offers or do I keep the slightly longer ratios which arguably are a bit long but likely not a problem due to another 100 ftlbs of torque vs the M96.

Or I could finish making it all work before worrying too much about ratios but I do want another box built up ready to go for when this one cries enough (which of course if you have a spare ready it never will!).

but I do want another box built up ready to go for when this one cries enough (which of course if you have a spare ready it never will!).

The ratios for this box plot like this:

(Note I've guessed the tooth counts to get the ratios as I didn't have counts to hand)

So it's actually a bit shorter than the Boxster 5 speed 5th and a bit longer than the A4 5 speed 5th.... but with another cog in the middle.

In reality the 5 speed is just fine behind the 20V as it's got a boat load of torque once it's up on boost and due to the higher rev limit a set of cogs which are a bit shorter work well with it (like the A4 ones), it has circa another 1000RPM vs the M96 so even though the A4 ratios are shorter the max speed per gear is really similar.

What I'm really pondering here with regards A4 vs Boxster ratios on the 5 speed is do I gear it to suit the high revs the 20V offers or do I keep the slightly longer ratios which arguably are a bit long but likely not a problem due to another 100 ftlbs of torque vs the M96.

Or I could finish making it all work before worrying too much about ratios

but I do want another box built up ready to go for when this one cries enough (which of course if you have a spare ready it never will!).

but I do want another box built up ready to go for when this one cries enough (which of course if you have a spare ready it never will!).3 miles a minute is always nice..... but I do also have a 996 which was pretty much built for that sort of thing  the Boxster/Booster is all about being a bit more raw and revvy with a Group B sountrack

the Boxster/Booster is all about being a bit more raw and revvy with a Group B sountrack

I remain undecided though, well not totally it's staying 5 speed so that it remains kit parts (we'll revisit 6 speed or 981 PDK at some point in the future), but just to have some gearbox spares I've ordered a used box from an A4 1.8T, I'll need to change a few bolt on bits to work in place of the original but the basic box is the same:

I sourced this from Southern Spain as it is an amazing source of uncorroded and generally mint casings and castings due to the complete lack of salt, mostly bone dry conditions and the fact it never really gets much below 8 degrees C! Shipping isn't even that expensive if you aren't in a rush. The box above is 24 years old, try finding one like that in the UK

This gives me both sets of ratios, a mint casing and shafts and a few other bits. I've got to order an ATB next but we'll get dyno and dampers out the way first along with a bit more running!

the Boxster/Booster is all about being a bit more raw and revvy with a Group B sountrack

the Boxster/Booster is all about being a bit more raw and revvy with a Group B sountrack

I remain undecided though, well not totally it's staying 5 speed so that it remains kit parts (we'll revisit 6 speed or 981 PDK at some point in the future), but just to have some gearbox spares I've ordered a used box from an A4 1.8T, I'll need to change a few bolt on bits to work in place of the original but the basic box is the same:

I sourced this from Southern Spain as it is an amazing source of uncorroded and generally mint casings and castings due to the complete lack of salt, mostly bone dry conditions and the fact it never really gets much below 8 degrees C! Shipping isn't even that expensive if you aren't in a rush. The box above is 24 years old, try finding one like that in the UK

This gives me both sets of ratios, a mint casing and shafts and a few other bits. I've got to order an ATB next but we'll get dyno and dampers out the way first along with a bit more running!

Bright Halo said:

I hear what you say about the torque but I still think I would go with the six speeder.

You can play about with the final Drive ratio to get the ideal set up.

I'm not kicking off Booster Evo or anything but the ratios in the 981 PDK look nicer than those in the six speed..... the driveshaft flanges are less than ideally positioned though.You can play about with the final Drive ratio to get the ideal set up.

I should have opportunity for some time on the dyno later this week so with that in mind it was time for a dyno bodge:

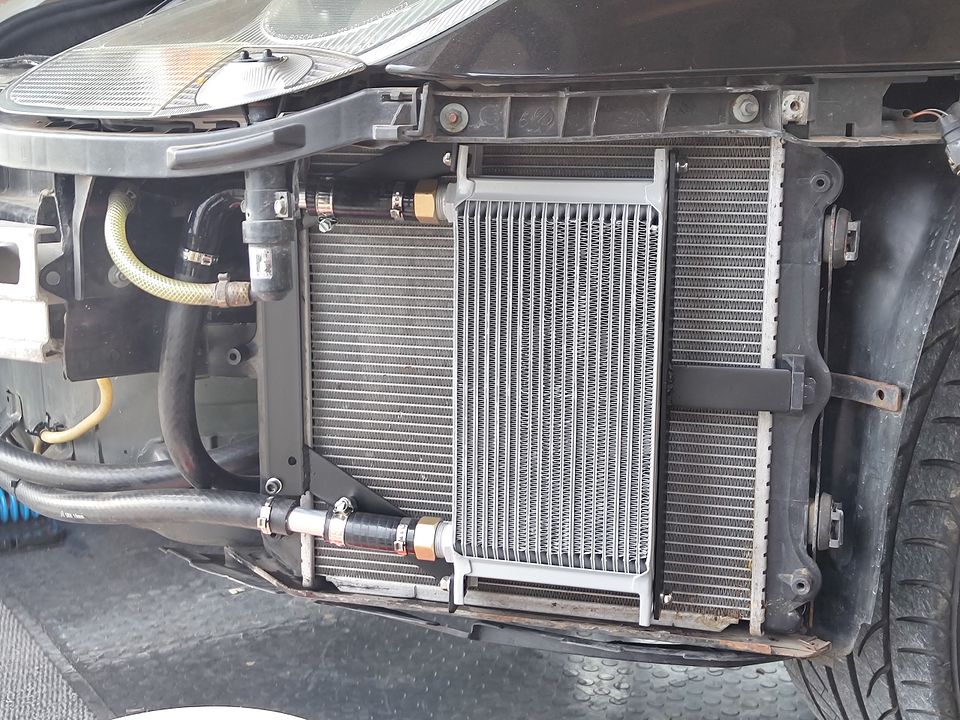

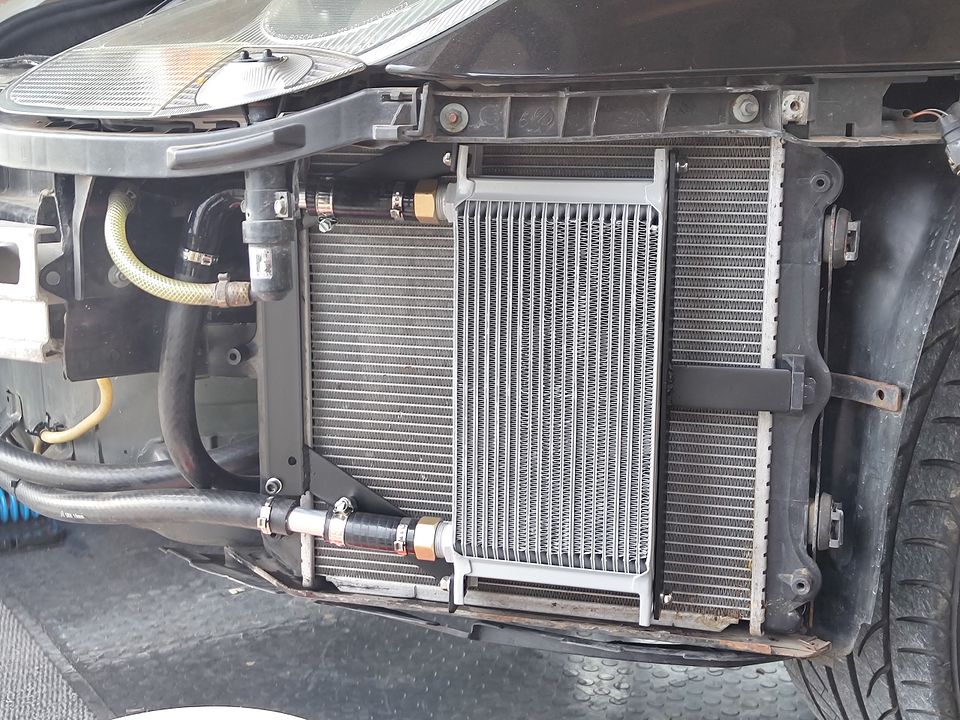

PWR are a couple of weeks off having the charge cooler heat exchanger finished and the flow that the modified air-con rad could manage was way below optimal so it was time for a good dyno bodge. A quick call to Think (who are awesome and generally a top bunch) had an old stock NLA oil cooler on the way which I promptly modified to be a charge cooler rad by gluing some push ons to the top of it and welding a frame up to carry it in the rad duct off the mounts on the standard rad. This is completely the wrong thing to be using as a water heat exchanger as it's designed for oil, which is much more viscous, much higher pressure and generally has a much higher temperature delta to atmosphere - basically this couldn't be more wrong....

However for the dyno, which is a controlled environment where you can manage if it takes three minutes to chill off between runs pretty effectivly it'll be just fine. As always you end up building a car for testing, or rather the test environment you have available to you and the timescale you're working to and if you've targetted the right data/things in that environment you can turn that into the actual car later. So in this case I just want to see if with the most amount of flow possible the chargecooler barrel can do the do at 400bhp, getting the heat out the chargecooler coolant can be dealt with later. I have positioned it as far back in the rad duct as space allows and it's sealed to the coolant rad so I've at least given it a fighting change of doing something useful

I'm also going to do yet another thermostat change as I've found one which is in the middle of the two temperatures I've tried to date, one which was too hot and one which was too cold so at this point I'm hoping we've three bears'd it succesfully and how have one that's just right.... or somewhere between 78 and 88 degrees C

Finally all the trays need to come off ready for dyno and I better clean it as it's got 800 miles of road grime, mud and dead flies on it at the moment!

I just need to decide now if I'm going to be sensible and take it on the trailer or show full confidence in my engineering and drive it down

PWR are a couple of weeks off having the charge cooler heat exchanger finished and the flow that the modified air-con rad could manage was way below optimal so it was time for a good dyno bodge. A quick call to Think (who are awesome and generally a top bunch) had an old stock NLA oil cooler on the way which I promptly modified to be a charge cooler rad by gluing some push ons to the top of it and welding a frame up to carry it in the rad duct off the mounts on the standard rad. This is completely the wrong thing to be using as a water heat exchanger as it's designed for oil, which is much more viscous, much higher pressure and generally has a much higher temperature delta to atmosphere - basically this couldn't be more wrong....

However for the dyno, which is a controlled environment where you can manage if it takes three minutes to chill off between runs pretty effectivly it'll be just fine. As always you end up building a car for testing, or rather the test environment you have available to you and the timescale you're working to and if you've targetted the right data/things in that environment you can turn that into the actual car later. So in this case I just want to see if with the most amount of flow possible the chargecooler barrel can do the do at 400bhp, getting the heat out the chargecooler coolant can be dealt with later. I have positioned it as far back in the rad duct as space allows and it's sealed to the coolant rad so I've at least given it a fighting change of doing something useful

I'm also going to do yet another thermostat change as I've found one which is in the middle of the two temperatures I've tried to date, one which was too hot and one which was too cold so at this point I'm hoping we've three bears'd it succesfully and how have one that's just right.... or somewhere between 78 and 88 degrees C

Finally all the trays need to come off ready for dyno and I better clean it as it's got 800 miles of road grime, mud and dead flies on it at the moment!

I just need to decide now if I'm going to be sensible and take it on the trailer or show full confidence in my engineering and drive it down

Edited by poppopbangbang on Monday 6th May 00:11

OK Chaps, message recieved  I'll drive it down. YOLO as the kids say

I'll drive it down. YOLO as the kids say

I've finished the dyno prep today and am very excited to see what it makes and more importantly how it drives once I can lay into it a little. All I really want to achieve from the dyno is a calibration that drives nice and a list of performance limiters identified and understood - at that point I can decide what the first EVO of this car looks like

I'll drive it down. YOLO as the kids say

I'll drive it down. YOLO as the kids say

I've finished the dyno prep today and am very excited to see what it makes and more importantly how it drives once I can lay into it a little. All I really want to achieve from the dyno is a calibration that drives nice and a list of performance limiters identified and understood - at that point I can decide what the first EVO of this car looks like

Well I'm back from the dyno..... and I drove the car home too!

Super succesful day today, well aside from the run down to Badger 5 which took three hours rather than two due to traffic - but good chance to test the idle drive, cooling etc. out!

The key things I wanted to achieve were to run the car at gate pressure, ensure all was healthy and doing what it should with regards strategies, actuators and general engine bits and if it made the circa 300bhp I thought it should with a 1bar spring in the gate push on and see what stopped it. Along the way testing how well the boost control worked, if we had good mechanical function etc. etc.

Very happy that it nailed 296bhp at 1bar so that showed we were pretty much in the ballpark with regards the expected engine efficiency etc. The engine responded very well to 1.2bar picking up another 40bhp or so (and hitting the 300ftlb self imposed limit for gearbox happiness/survivability) but made very little additional power at 1.4bar and took a load of gate duty cycle to get it there. What that showed was the exhaust flow was insufficient to go much further, which isn't too surprising as the silencer on the car was designed for 200bhp and I hacked it up and welded some bigger tube into it.... it wasn't exactly meant to be on the back of this engine

Charge temps were as expected, i.e. pretty sporty at mid 50's at 1.4bar. Some of that is due to my terrible placement of the air filter, some is due to the coolant aleady being fairly warm and some is due to being on a dyno where everything is minging hot even with massive fans.

It's also pretty clear it will need some sportier cams to make 500bhp as it's over the top of the standard ones at 6K RPM and the torque curve is only really being held up by the boost at that point. We're only running a 7250RPM rev limit in the video as there's just no point using all 8K available.

But regardless of all that I'm over the moon . The big thing was nailing 300bhp at a bar (because if it does that then all the powers are there with some fairly basic additions/component changes) and getting a proper systems test done (especially on things like boost and knock control). It was also very nice that the car behaved absolutely impeccably, no misfires or system dramas, no boost pipes popping off, sensible engine coolant temps, good fuel pressure, great oil pressure, drove on and drove off and didn't even drop any fluids.

. The big thing was nailing 300bhp at a bar (because if it does that then all the powers are there with some fairly basic additions/component changes) and getting a proper systems test done (especially on things like boost and knock control). It was also very nice that the car behaved absolutely impeccably, no misfires or system dramas, no boost pipes popping off, sensible engine coolant temps, good fuel pressure, great oil pressure, drove on and drove off and didn't even drop any fluids.

With all that said I need to have a bit of a think now about next steps. I could leave it as it is and have a bombproof car with similar power to weight as a 997 Turbo and just use and abuse it. I could make a new exhaust system, fit the proper PWR chargecooler rad with a larger resoirvoir to up the system thermal mass along with some water/meth and have a probably as bombproof car at a sniff over 400bhp or absolutely go bonkers - chuck some cams in it, go massive on the chargecooler core or build an inlet manifold with an integrated one, even more water/meth and send it to 8250RPM (or a bit more) with all the boost the turbo will make...... somewhere in the middle of that is probably the right option, but the right options power figure doesn't start with a 5 and I have a reputation to uphold

Huge thanks to the guys at Badger 5 too, they've been a great help on the engine build supplying various bits (coils, injectors, ECU, engine bearings etc.) and doing the calibration work today. They're also bloody nice chaps and a pleasure to spend some time chatting cars with

Super succesful day today, well aside from the run down to Badger 5 which took three hours rather than two due to traffic - but good chance to test the idle drive, cooling etc. out!

The key things I wanted to achieve were to run the car at gate pressure, ensure all was healthy and doing what it should with regards strategies, actuators and general engine bits and if it made the circa 300bhp I thought it should with a 1bar spring in the gate push on and see what stopped it. Along the way testing how well the boost control worked, if we had good mechanical function etc. etc.

Very happy that it nailed 296bhp at 1bar so that showed we were pretty much in the ballpark with regards the expected engine efficiency etc. The engine responded very well to 1.2bar picking up another 40bhp or so (and hitting the 300ftlb self imposed limit for gearbox happiness/survivability) but made very little additional power at 1.4bar and took a load of gate duty cycle to get it there. What that showed was the exhaust flow was insufficient to go much further, which isn't too surprising as the silencer on the car was designed for 200bhp and I hacked it up and welded some bigger tube into it.... it wasn't exactly meant to be on the back of this engine

Charge temps were as expected, i.e. pretty sporty at mid 50's at 1.4bar. Some of that is due to my terrible placement of the air filter, some is due to the coolant aleady being fairly warm and some is due to being on a dyno where everything is minging hot even with massive fans.

It's also pretty clear it will need some sportier cams to make 500bhp as it's over the top of the standard ones at 6K RPM and the torque curve is only really being held up by the boost at that point. We're only running a 7250RPM rev limit in the video as there's just no point using all 8K available.

But regardless of all that I'm over the moon

. The big thing was nailing 300bhp at a bar (because if it does that then all the powers are there with some fairly basic additions/component changes) and getting a proper systems test done (especially on things like boost and knock control). It was also very nice that the car behaved absolutely impeccably, no misfires or system dramas, no boost pipes popping off, sensible engine coolant temps, good fuel pressure, great oil pressure, drove on and drove off and didn't even drop any fluids.

. The big thing was nailing 300bhp at a bar (because if it does that then all the powers are there with some fairly basic additions/component changes) and getting a proper systems test done (especially on things like boost and knock control). It was also very nice that the car behaved absolutely impeccably, no misfires or system dramas, no boost pipes popping off, sensible engine coolant temps, good fuel pressure, great oil pressure, drove on and drove off and didn't even drop any fluids.With all that said I need to have a bit of a think now about next steps. I could leave it as it is and have a bombproof car with similar power to weight as a 997 Turbo and just use and abuse it. I could make a new exhaust system, fit the proper PWR chargecooler rad with a larger resoirvoir to up the system thermal mass along with some water/meth and have a probably as bombproof car at a sniff over 400bhp or absolutely go bonkers - chuck some cams in it, go massive on the chargecooler core or build an inlet manifold with an integrated one, even more water/meth and send it to 8250RPM (or a bit more) with all the boost the turbo will make...... somewhere in the middle of that is probably the right option, but the right options power figure doesn't start with a 5 and I have a reputation to uphold

Huge thanks to the guys at Badger 5 too, they've been a great help on the engine build supplying various bits (coils, injectors, ECU, engine bearings etc.) and doing the calibration work today. They're also bloody nice chaps and a pleasure to spend some time chatting cars with

Heaveho said:

In my limited experience, torque is what makes for a nice road car. If you hit the limits of the gearbox at 300 ft/lbs, which in itself is a nice number, and you're already making 340 brake, and it drives well and reliably, is there much point in chasing numbers at the potential expense of reliability? Or would you make changes to the box specifically to allow it to handle more torque? I get the impression the engine itself is good for a fair bit more as is? Genuine question, interested to know where you see this finishing.

Power = Torque X RPM / 5252 - essentially you can make more power at the same torque if there is more opportunity (RPM) to do work, as power is a just a measure of work done. At the moment it makes 300ftlbs but drops off above 6200RPM, the engine will rev to 8250RPM quite happily so by adding some cam suitable for higher RPM use we can pick this up massively, even at the same boost pressure, without increasing the torque.... we just hold it up longer in the rev range. Ideally this will make 300ftlbs all the way past 8K RPM at which point it's making 500'ish or so near it doesn't matter. To support that we'll need an exhaust that flows much better so the extra gas from that extra work can exit and a way to keep the charge air cool as the pressure rise at more boost will result in more heat.

The engine was built with bits that have done 650bhp+ in other peoples engines with the aim of 500bhp reliably, as I'm not making big torque I don't need to worry too much about the main caps as the rod loadings are pretty low, they're just going round faster.

The gearbox should be okay at 8000RPM for short periods, it's only splash lubricated and not pressure fed bearings etc. so it won't like much more than that, but 8K is enough and I have a spare box on the way.

At the moment I'm feeling like a plan is fit the proper chargecooling bits and some W/MI and see what it makes at that (likely to pick up 15bhp or so from the lower charge temps), then make a nicer exhaust and test again before finally fitting some cams. Somewhere along the way I may decide the turbo is too big and more response / lower boost threshold is more important but we'll burn that bridge when we come to it

Escy said:

It looks good on the dyno.

I think the very well presented dyno cell helps too!

Escy said:

What's the plan on the cams, can you run n/a ones or will you go aftermarket?

What are your IAT's like on the road?

I've left it with the guys at Badgers to come up with some options for cams, my engine is none VVT (because it won't package) and I think most of the cam profiles out there are designed around VVT. They've got so much experience with the 20V it's foolish not to try and benefit from it. What are your IAT's like on the road?

IAT's on the road are just about acceptable, at a bar they're high 40's/low 50's, at 1.4bar mid 50's. Pretty amazing given the charge cooler core is only 150mm long! It's pretty clear that I need to improve this for higher boost levels but package space is pretty tight, I only have about 400mm total length to fit something into but I'm not that limited on width so could do something short and wide.

There's nothing OTS that looks like it would be an improvement bar the Hanon coolers that are on the Mclaren P13 which are a pretty compatible shape, these seem to be decent on the tuned 570S cars I've seen that are doing about 320bhp a side at very sensible charge temps. That still might not be enough though as we get up towards the top of the turbos efficiency island though. Really it wants a big core in the intake manifold as that would package really nicely and provide a load of performance but to do that nicely is quite a bit of work, next best is to design something bespoke and get PWR to make it.

Escy said:

Does no VVT have much impact on the boost threshold?

Are you wanting to develop a solution to offer with the kit or just a one off for yourself?

As a one off, I wonder if something like this would be the answer? It would need a water jacket making for it but apparently Secan is as good as it gets. I'm sure you'll know better than me from your day job. Just thought I'd post it as it might be a bargain for the right person.

https://www.ebay.co.uk/itm/305301915262?itmmeta=01...

Yes it's about 500RPM down on where a VVT car could spool the turbo to a useful RPM, however I somewhat compensated for this in the engine build by putting all the valvetrain bits in there for a reliable 8K RPM so even with the higher boost threshold I would still have a very similar width of powerband.Are you wanting to develop a solution to offer with the kit or just a one off for yourself?

As a one off, I wonder if something like this would be the answer? It would need a water jacket making for it but apparently Secan is as good as it gets. I'm sure you'll know better than me from your day job. Just thought I'd post it as it might be a bargain for the right person.

https://www.ebay.co.uk/itm/305301915262?itmmeta=01...

I'd like to do something which could be documented at the least and ideally supplied by a third party for those wanting to do this, PWR are keen to support so all I need to do is sort fit and volumetric etc. and they'll keep the drawings on file to make another should anyone want one. I'm tempted to acquire a P13 LH charge cooler assembly as the core is pretty much perfect and the end tank dimms are close enough to work well, it's a cheap way of testing the core size and I know the availability of a very similar performing core so a quick and dirty validation on that may be the order of the day.

Secan stuff is very, very good however. They supplied an awful lot of F1 teams over the years. These days a lot have gone to Microtube stuff like this - https://reactionengines.co.uk/products/charge-air-... the performance of this stuff is unreal but is far beyond the cost that one could justify for modified road cars. It's actual rocker scientist stuff

Megaflow said:

I’m normally in the ‘’you can’t have too much power category’. But on this occasion, at double the original power, I’d be inclined to leave it as for a bit, to work out if there is anything else that could be improved at the same time as making it good for 500bhp.

I'm occupying myself at the moment by tidying up all the bits that were done "to get it on the dyno" but it does seem a bit rude not to at least turn it up to 400 - especially as with the bits required to do that the engine will likely be in a more comfortable place than it is at the moment with regards post turbine back pressure, EGT etc. This evening I have clearanced the original engine cover ready to 3D scan so I can draw up some bond on blisters:

It doesn't actually need a lot, with the FPR being the main culprit of clash so a fairly easy job to make nice.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff