2 Door Range Rover project

Discussion

vjj said:

none - the 24 ecu talks to the gems and bosch engine ecus

the 22/24 - stage 2 - hybrid is not electronic in any way and used the combination of speed sensor and kickdown cable tightness/throttle linkage position to decide which gear to be in.

if you want some adjustability you will have to go with the 4HP24EH and the compushift from Ashcroft

Yup. This is why I'm currently planning to use the high torque Ashcroft box but in non electronic form. the 22/24 - stage 2 - hybrid is not electronic in any way and used the combination of speed sensor and kickdown cable tightness/throttle linkage position to decide which gear to be in.

if you want some adjustability you will have to go with the 4HP24EH and the compushift from Ashcroft

Looks like the next stage of the project will be getting underway in the next couple of weeks.

First tasks are:

Remove current gearbox housing and fit the later version so that the uprated ZF unit will fit.

Change lower section of dash to the factory aircon spec.

Install later seating.

So in terms of drivetrain it will initially be running a 1989+ set up plus seating.

First tasks are:

Remove current gearbox housing and fit the later version so that the uprated ZF unit will fit.

Change lower section of dash to the factory aircon spec.

Install later seating.

So in terms of drivetrain it will initially be running a 1989+ set up plus seating.

Previous owner who restored the car and fully galvanised it also invested quite a bit on a full Nationwide teddy bear trim. All now removed and about to go into Ebay.

Dash removed, interior removed. Trans tunnel is also off.

Waiting to prep the replacement trans tunnel and prepare to install the uprated auto box and LT230 with 1:1.

Interestingly, on closer inspection of the engine the previous owner really went to town on it. Sports exhaust, wrapped, bespoke manifolds, webers. By all accounts it is quite a pokey engine and has only done a few hundred miles since being installed around 12 years ago.

Dash removed, interior removed. Trans tunnel is also off.

Waiting to prep the replacement trans tunnel and prepare to install the uprated auto box and LT230 with 1:1.

Interestingly, on closer inspection of the engine the previous owner really went to town on it. Sports exhaust, wrapped, bespoke manifolds, webers. By all accounts it is quite a pokey engine and has only done a few hundred miles since being installed around 12 years ago.

A bit of an update 12 months on.

I've removed and rebuilt the 4L engine that was in the donor Disco I bought. It was in amazing condition to start with with fantastic compression on all cylinders but as the aim is to fit a Rotrex it has been refreshed with a new cam, followers, shells, chain etc. It is currently mated to the updated Ashcroft auto box and the LT230 from the disco ready for installation. I've gone for the LT230 instead of the BW purely for the reason it gives me the option to change the ratio at a later date from 1.2 to 1 if desired.

Interestingly, the engine that was in the 2 door when I bought it has revealed a bit of additional information on close inspection. The engine was built specifically for this car on behalf of the previous owner and I always assumed it was a 3.5 albeit the smoothest one of ever run and quite a bit more pokey than a standard 3.5. However, we noticed it was cross bolted and so picked up the phone to RPI who I knew had been involved. They supplied a short engine in 4.0 along with the edelbrock carb and piper cam. Once the engine is out and I've removed the performance manifolds I'll be able to see if the heads have been ported at all.

In short, it is a brand new 4.0 engine that was built 10 years ago with pre serp running gear and has covered less than 500 miles so I'll need to have a rethink as to what to do with it. It's far too good to job out on eBay.

I've removed and rebuilt the 4L engine that was in the donor Disco I bought. It was in amazing condition to start with with fantastic compression on all cylinders but as the aim is to fit a Rotrex it has been refreshed with a new cam, followers, shells, chain etc. It is currently mated to the updated Ashcroft auto box and the LT230 from the disco ready for installation. I've gone for the LT230 instead of the BW purely for the reason it gives me the option to change the ratio at a later date from 1.2 to 1 if desired.

Interestingly, the engine that was in the 2 door when I bought it has revealed a bit of additional information on close inspection. The engine was built specifically for this car on behalf of the previous owner and I always assumed it was a 3.5 albeit the smoothest one of ever run and quite a bit more pokey than a standard 3.5. However, we noticed it was cross bolted and so picked up the phone to RPI who I knew had been involved. They supplied a short engine in 4.0 along with the edelbrock carb and piper cam. Once the engine is out and I've removed the performance manifolds I'll be able to see if the heads have been ported at all.

In short, it is a brand new 4.0 engine that was built 10 years ago with pre serp running gear and has covered less than 500 miles so I'll need to have a rethink as to what to do with it. It's far too good to job out on eBay.

NomduJour said:

What happened to the AMG engine?

Lack of a gearbox solution combined with the realisation that the majority of people involved in the Mercedes side of the market are just buffoons who know nothing other than the price of wrapping a car or how to chip the ECU had made it too much of a hurdle for this project. The updated ZF is 15mm longer than the standard unit and once you fit an adaptor plate for the Merc engine you are having to relocate every aspect of the drive train. Given the amount of time I have spare for the project it would mean at least another year of work. Plus, the ZF really can't handle the power.

No one has yet cracked how to map and control a modern auto box in a retro fit meant for smooth road use which is what I really wanted to fit and that meant I was left with only being able to use a manual box but I need this car to be an auto.

However, rather conveniently, I have another Rangie sitting here which is missing a drivetrain so the Merc with a manual box is still going to happen but not for this two door. It will be my pet project once I've got this one completed.

NomduJour said:

An LS/6L80 is a direct bolt-in solution nowadays - straight to an LT230, with engine and accessory mounts all available - I'm sort-of looking for a suitable drivetrain. Insuring it in town is possibly the biggest issue.

It's still not as bolt in as they claim. The 6L after market TCUs are all for drag racing and make for very harsh changes for normal driving and weird change points etc. Mapping a system for road use and dropping the line pressures back down is a huge amount of work. The engine brackets are from Marks Adapters and unless they have changed very recently they are for LS1/2 mounts so you have to fudge them to the 3 bolt LS3. And the adaptor plate for the 4L and 6L to the LT230 shoves it back a long way meaning new shafts and remote mounting etc.

In engineering terms by far the best box is the NAG1 from Chrysler which is the 5G-tronic from Merc. The box is much shorter than the GM units so allows for Adapters without having to remount the TC or change shafts etc. It also has much better gearing for road use, the 6L has a hideous digger gear for first which makes it useless for UK normal road use.

Again, the issue with the 5G-tronic is that the after market TCUs cater for the slamming gear, drag race US demand as opposed to the English, want to just drive like a grown-up requirement.

In all my research, I determined that if I was going to go the LS route I would actually use an LS1 and mate it to the ZF, essentially how it was done on the Overfinch as it is the most straight forward engineering solution and the engine won't rip the box apart etc.

squirdan said:

might be of interest to me. am due to give JE the nod in next 3 weeks on a new engine for my 1980 2 door, PM me with your thoughts / further details, cheers

Dan, I've sent a batch of emails but the one with the video is reluctant to leave. I'll try and stick it on YouTube and post a link. NomduJour said:

If you buy the engine with its associated box you don't need an external controller; the adapters and mounts etc. are from a guy in California and are apparently much, much better than the Australian ones - straight bolt-in in with no driveline changes at all (with the caveat that they're designed for the NAS Defender), quite a few have been done. Will send you an email.

Please do. When I started this project it was Marks kit and no usable 6L solution. Would be extremely interesting if that's changed. Thanks. squirdan said:

DonkeyApple said:

I see that wildcat are offering this in the UK for Landies.

if it fits a defender (noting they say including older variants) does that mean it fits an RRC? thxI had the last Overfinch conversion so obviously the LS fits easily enough. My concern is that the 6L, from memory is longer than the ZF and the adaptor plate to the TC adds additional length so I'm pretty sure you'll have to mount the TC further back and running 400lbs through a shortened rear shaft but lengthened forward shaft could introduce some issues?

The other question is whether the transmission tunnel in the classic is as wide or deep as the Defender or enough to take the 6L. The 4L fitted and I don't believe the 6L is wider or taller so I can't see an issue.

My guess would be that the combo should drop in but if the 6L is longer than the ZF then you're surely going to have to remount the transfer case and get new drive shafts?

Also, with my Overfinch that had notably less power than a crate LS3 the half shafts were very much consumables.

I think I recognise that one. It looks like a car a chap called 'Zen' on the Landyzone forum built. Last time I chatted with him was a few years ago and it had a Lexus v8 engine that he'd charged and went like a rocket.

ETA: yup, it is his. I remember speaking at length with him when I was thinking of fitting 3 Series cab rio seats to mine. Very nice guy and a pretty skilled fabricator.

ETA: yup, it is his. I remember speaking at length with him when I was thinking of fitting 3 Series cab rio seats to mine. Very nice guy and a pretty skilled fabricator.

Edited by DonkeyApple on Wednesday 28th September 14:59

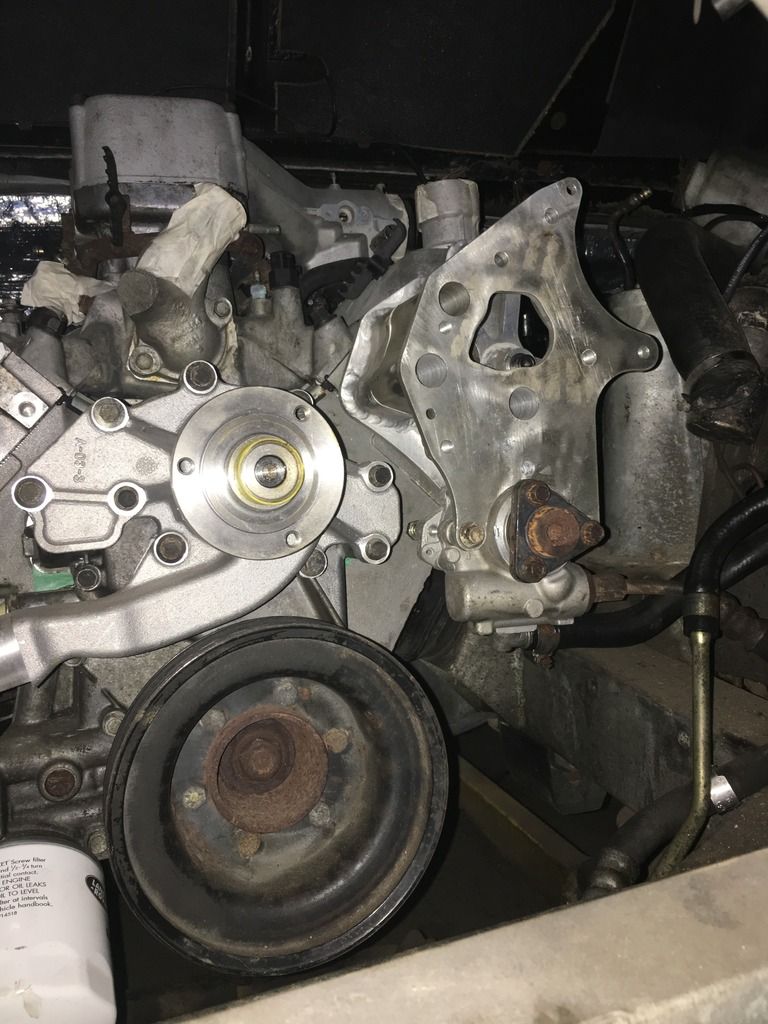

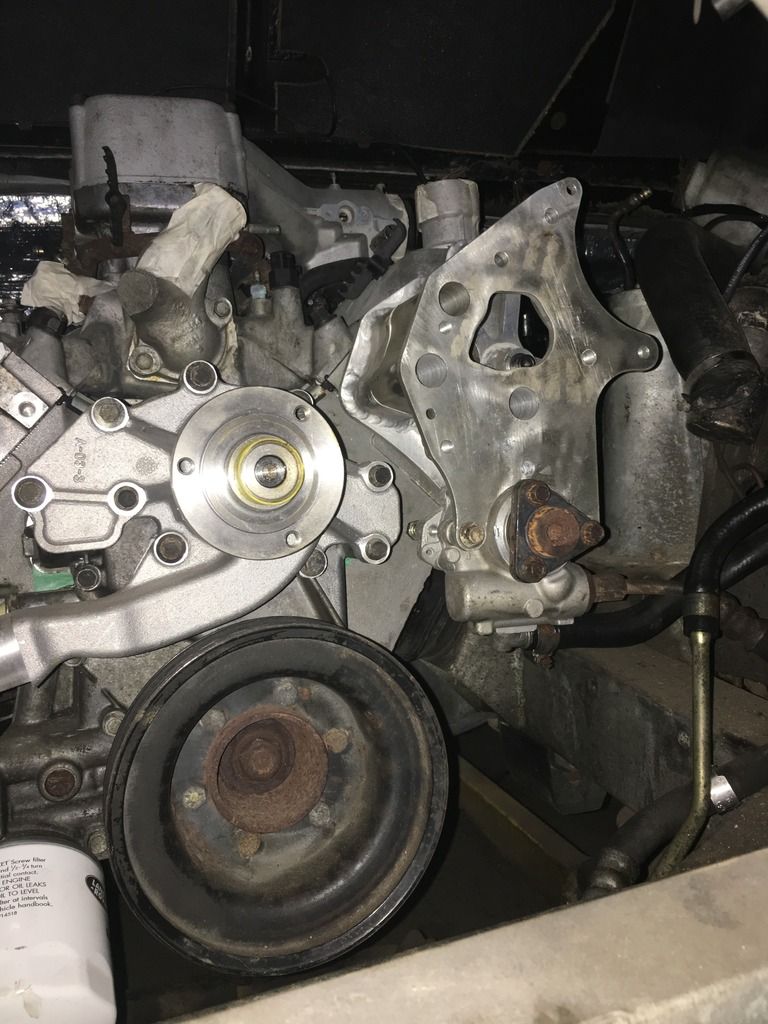

Steady progress so far.

The bracket for the Rotrex supercharger has been test fitted.

I'm using a TDi300 rad for the car as it has an integrated intercooler. There wasn't any practical way of retaining the rad and fitting a remote intercooler without quite a bit of chopping and risking the integration from being visible externally. It means the actual radiator is smaller which could have caused an issue in particularly hot weather but the TDi rad has gone away to have a deeper core fitted that will give back the same cooling area as the larger rad. A chance meeting with the chap who runs some of the special projects at JLR educated me that this is what they did in the past when building cars for the safari rallies.

We've also drilled out the block for the crank sensor that is used in later RV8 blocks so that a proper electronic ignition system can be run. So, with the intercooler and the crank sensor we should be able to get a good map for the engine with the Rotrex.

The later transmission tunnel is away being powder coated before installation and then the completion of the wiring loom and refitting of the heater matrix and air on to leave us, in theory, with a running car. And then it's into all the cosmetic work once all the sound deadening has been fitted. The underside of the trans tunnel will be fitted with lead lined deadening as will the bulkhead on the interior before a set of original LSE deadening is fitted and various areas that Land Rover never fitted deadening to are covered.

The bracket for the Rotrex supercharger has been test fitted.

I'm using a TDi300 rad for the car as it has an integrated intercooler. There wasn't any practical way of retaining the rad and fitting a remote intercooler without quite a bit of chopping and risking the integration from being visible externally. It means the actual radiator is smaller which could have caused an issue in particularly hot weather but the TDi rad has gone away to have a deeper core fitted that will give back the same cooling area as the larger rad. A chance meeting with the chap who runs some of the special projects at JLR educated me that this is what they did in the past when building cars for the safari rallies.

We've also drilled out the block for the crank sensor that is used in later RV8 blocks so that a proper electronic ignition system can be run. So, with the intercooler and the crank sensor we should be able to get a good map for the engine with the Rotrex.

The later transmission tunnel is away being powder coated before installation and then the completion of the wiring loom and refitting of the heater matrix and air on to leave us, in theory, with a running car. And then it's into all the cosmetic work once all the sound deadening has been fitted. The underside of the trans tunnel will be fitted with lead lined deadening as will the bulkhead on the interior before a set of original LSE deadening is fitted and various areas that Land Rover never fitted deadening to are covered.

It's taken the last couple of months to sort out the fuel system on the car.

It required an EFI fuel tank and pump and these later tanks sit further forward than the original ones. A bracket had to be fabricated to help locate the tank in the later position and new fuel lines had to be fabricated from scratch. In addition, only the 1984 crossover model had the new fuel tank position but older fuel filler location so had the filler pipe required. Luckily we managed to source what must be a very rare item now.

With fuelling now sorted the brake disks are in the middle of being replaced and new callipers fitted at the front.

Still mulling whether to drop the suspension an inch as this will benefit road use which is what the car is intended for.

Once the brakes are done then the car can be fired up and tested ahead of the trans tunnel being refitted and work begin on fitting out the interior.

It required an EFI fuel tank and pump and these later tanks sit further forward than the original ones. A bracket had to be fabricated to help locate the tank in the later position and new fuel lines had to be fabricated from scratch. In addition, only the 1984 crossover model had the new fuel tank position but older fuel filler location so had the filler pipe required. Luckily we managed to source what must be a very rare item now.

With fuelling now sorted the brake disks are in the middle of being replaced and new callipers fitted at the front.

Still mulling whether to drop the suspension an inch as this will benefit road use which is what the car is intended for.

Once the brakes are done then the car can be fired up and tested ahead of the trans tunnel being refitted and work begin on fitting out the interior.

I've definitely found a system for creating genuine 40 year old barn finds in under a month. The open sided barn on an arable farm has made the car look incredibly rare and valuable.

The fuel lines were fabricated from scratch. Pretty impressive job.

Once the car is back up and running and the new trans tunnel fitted then I can get on with fitting the interior out.

Might actually get the car done for the end of summer.

The fuel lines were fabricated from scratch. Pretty impressive job.

Once the car is back up and running and the new trans tunnel fitted then I can get on with fitting the interior out.

Might actually get the car done for the end of summer.

Interior plastic trim has gone to be painted to change it from the standard grey to a dark brown.

Trans tunnel underside now lined with lead sandwiched sound deadening in the hope that it cuts out some of the noise from the gearbox and transfer case.

Next step is to line rear floor and sides with 2mm Dynomat to try and reduce road noise.

Once the trans tunnel is back in then I suspect I'll also fit the 2mm sound deadening in the front foot wells and round the bulkhead before the dash goes back in.

Trans tunnel underside now lined with lead sandwiched sound deadening in the hope that it cuts out some of the noise from the gearbox and transfer case.

Next step is to line rear floor and sides with 2mm Dynomat to try and reduce road noise.

Once the trans tunnel is back in then I suspect I'll also fit the 2mm sound deadening in the front foot wells and round the bulkhead before the dash goes back in.

squirdan said:

looks good work

you will probably beat me at my current glacial progress!

using dynamat stuff myself but hoping R380 is a bit quieter anyway

cheers

It's bought the car Feb 2010 so I'm 7+ years in on the project. you will probably beat me at my current glacial progress!

using dynamat stuff myself but hoping R380 is a bit quieter anyway

cheers

I've never used anything like Dynomat before so I've no idea if it actually does anything or is just a load of hype.

I have a full set of late sound deadening for the car but it's got to be worth trying to damp down road and drivetrain noise as much as possible.

Are you going to line the whole floor of just place pads in strategic places?

NomduJour said:

Dynamat is really to deal with panel resonance, you want more mass to block sound as effectively as possible (5 kg/m or so).

It does seem to be more aimed at the stereo market but the thick matting with the lead core which I've used in the engine bay and underside of the trans tunnel is just too thick to go on the floor and still have the carpet fit. I can use it or the 5mm foam in the sides, the bulkhead and under the front seats but the 2mm stuff is all I can fit over the rear wheel arches and on the floor.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff