'67 Camaro RS/SS - saved from the scrapman

Discussion

TL:DR - guy buys a completely stripped '67 Camaro to save it from going for scrap, stores it in a couple of garages for twenty years, the second one increasingly damp. Shocked into action when realises how bad it is becoming, gets finger out and starts a build thread.

The long version...

I first came across this '67 Camaro RS/SS in the late 1990's when it was purchased by the brother-in-law of a friend.

As purchased, it was a complete running car in slightly dog-eared condition but was good enough to pass an MOT with minor work. Sadly, I don't have any pictures from this time, but it looked very much like this - just nowhere near as tidy, with an incorrect cowl induction hood (they didn't become a production option until '69).

The then owner then decided to carry out a nut and bolt restoration, building himself a rotisserie and fully stripping the car down to the bare monocoque and mounting it up. The separate front chassis section and the entire underside of the bodyshell were sandblasted, the front floorpans replaced and the underside was painted.

It was around this time that his marriage failed, and he went of sailing around the world to escape from it all. I lost touch for a couple of years and then received a call from him out of the blue - his ex-wife had taken ownership of the house and given him a week to remove the Camaro and all its associated bits, or it would all be scrapped.

Did I want to take it on? The car would be free, just pay him for the approx. £1,500 of new parts that he had ordered from the US that would come with it...

What could I do? Well obviously, buy it! Despite having neither space, time or the money to fully restore it back then, a van and trailer were hired, and a very long day spent removing the shell from the rotisserie and bolting enough back onto it to make it roll. Plus attempting to corral all the boxes and loose bits that were spread throughout his house, garage and sheds.

The car was rolled into a hastily hired lockup near home, and the boxes, loose bits and tools were all dumped in there too for the evening and the hire trailer and van returned in a hurry, just before closing time.

The next day I returned to the lockup to find the doors ajar and half hanging off. It had been broken into overnight and my toolboxes had gone. Fortunately, the car hadn't been vandalised, but clearly my confidence in storing anything of value in the lockup was shattered.

After some discussions a kindly elderly neighbour offered her empty garage for my long-term use, and I gratefully accepted. The car was pushed (fortunately it rolled easily) the short distance to her house and stashed away.

At this point life sort of got in the way. Years passed and the Camaro was put on the back burner. Plans were made, a little work even carried out now and then when the guilt kicked in, but not very much.

After a nearly a decade the elderly neighbour moved house and the Camaro was moved to my parent's garage where it remained. During this time a few things changed. Firstly, values started rising significantly, making the expenditure needed more justifiable. Secondly, my disposable income also increased, putting me in a position to do the car justice and thirdly, unbeknown to me, the garage roof started to leak, not hugely, but enough to make the garage constantly damp.

I hadn't been checking on the car with any regularity, so when I finally did, I was horrified - rampant surface rust everywhere, even on surfaces that had previously been cleaned, treated and painted. Not good. I needed to rescue the car immediately, get my finger out and get working on it.

To that effect, I collected it a couple of weeks ago.

The plan is simple - my '66 El Camino is going to beshipped off to get the rest of the body prep and respray carried out professionally sold. This frees up a slot in the dehumidified garage for the Camaro where I can stabilise its condition and treat the rust before moving on to the mechanical side of things.

To give an idea of what I am up against...

Despite appearances, the car has very "good bones" and is rock solid underneath. The rear screen area will need a patch panel, and the upper scuttle and dash area will be replaced (I already have the large 1-piece section for that) due to rust in the scuttle and the dash having been badly hacked around previously.

The aim is to build a comfortable daily driver that can also be used for touring, using relatively modern running gear and upgrading the steering and suspension with the aftermarket improvements in setup and geometry that have been developed over the last 54 years.

Interior and exterior will remain largely faithful to the car's original appearance.

The long version...

I first came across this '67 Camaro RS/SS in the late 1990's when it was purchased by the brother-in-law of a friend.

As purchased, it was a complete running car in slightly dog-eared condition but was good enough to pass an MOT with minor work. Sadly, I don't have any pictures from this time, but it looked very much like this - just nowhere near as tidy, with an incorrect cowl induction hood (they didn't become a production option until '69).

The then owner then decided to carry out a nut and bolt restoration, building himself a rotisserie and fully stripping the car down to the bare monocoque and mounting it up. The separate front chassis section and the entire underside of the bodyshell were sandblasted, the front floorpans replaced and the underside was painted.

It was around this time that his marriage failed, and he went of sailing around the world to escape from it all. I lost touch for a couple of years and then received a call from him out of the blue - his ex-wife had taken ownership of the house and given him a week to remove the Camaro and all its associated bits, or it would all be scrapped.

Did I want to take it on? The car would be free, just pay him for the approx. £1,500 of new parts that he had ordered from the US that would come with it...

What could I do? Well obviously, buy it! Despite having neither space, time or the money to fully restore it back then, a van and trailer were hired, and a very long day spent removing the shell from the rotisserie and bolting enough back onto it to make it roll. Plus attempting to corral all the boxes and loose bits that were spread throughout his house, garage and sheds.

The car was rolled into a hastily hired lockup near home, and the boxes, loose bits and tools were all dumped in there too for the evening and the hire trailer and van returned in a hurry, just before closing time.

The next day I returned to the lockup to find the doors ajar and half hanging off. It had been broken into overnight and my toolboxes had gone. Fortunately, the car hadn't been vandalised, but clearly my confidence in storing anything of value in the lockup was shattered.

After some discussions a kindly elderly neighbour offered her empty garage for my long-term use, and I gratefully accepted. The car was pushed (fortunately it rolled easily) the short distance to her house and stashed away.

At this point life sort of got in the way. Years passed and the Camaro was put on the back burner. Plans were made, a little work even carried out now and then when the guilt kicked in, but not very much.

After a nearly a decade the elderly neighbour moved house and the Camaro was moved to my parent's garage where it remained. During this time a few things changed. Firstly, values started rising significantly, making the expenditure needed more justifiable. Secondly, my disposable income also increased, putting me in a position to do the car justice and thirdly, unbeknown to me, the garage roof started to leak, not hugely, but enough to make the garage constantly damp.

I hadn't been checking on the car with any regularity, so when I finally did, I was horrified - rampant surface rust everywhere, even on surfaces that had previously been cleaned, treated and painted. Not good. I needed to rescue the car immediately, get my finger out and get working on it.

To that effect, I collected it a couple of weeks ago.

The plan is simple - my '66 El Camino is going to be

To give an idea of what I am up against...

Despite appearances, the car has very "good bones" and is rock solid underneath. The rear screen area will need a patch panel, and the upper scuttle and dash area will be replaced (I already have the large 1-piece section for that) due to rust in the scuttle and the dash having been badly hacked around previously.

The aim is to build a comfortable daily driver that can also be used for touring, using relatively modern running gear and upgrading the steering and suspension with the aftermarket improvements in setup and geometry that have been developed over the last 54 years.

Interior and exterior will remain largely faithful to the car's original appearance.

Edited by 99t on Wednesday 20th September 21:13

gregs656 said:

This one will be good.

I can see why the surface rust shocked you. Looks quite deep in places?

Some of it is quite deep, however a little bit of exploratory grinding at some of the worst looking bits has failed to produce any holes before getting back to clean metal - I suspect the thickness of the body panels may be what saves themI can see why the surface rust shocked you. Looks quite deep in places?

.

.Thanks for all the comments, will aim to update quite regularly.

I'll certainly need to purchase a different sump and oil pickup plus headers, modified fuel system, revised belt setup to raise the aircon compressor and alternator, hydraulic clutch pedal mod plus much, much more...

It's early days, let's hope it doesn't come to that!

It's early days, let's hope it doesn't come to that!

Retro_Jim said:

Excellent work on firstly saving the Camaro, I think the plan is solid. Building something you can use is definitely the way to go, are you looking at an LS swap?

Yes, I have a complete running and driving Monaro CV8 that I am going to pull the running gear from. Plenty of LS swap kits available these days, however having looked at pictures of engine and gearbox mounts, I reckon they are within my fabrication abilities.I'll certainly need to purchase a different sump and oil pickup plus headers, modified fuel system, revised belt setup to raise the aircon compressor and alternator, hydraulic clutch pedal mod plus much, much more...

RC1807 said:

RRR's team have saved worse (from my view) in Dallas. How easy are these to get parts for - shipping usually needed from the US and A?

Yes a lot of stuff will come from the US - shipping costs will basically double the restoration cost, fortunately a lot of parts are quite reasonably priced and my time costs nothing so that sort of balances the costs out a bit!P5BNij said:

Fantastic, another one saved - this will definitely be one to watch and compare to Leigh W’s similar Camaro over in the yanks thread

I wondered how I had missed that, but after going looking, his is the Pontiac Firebird variety F-Body so very similar but with some styling changes (love the front end treatment on a first gen Firebird, probably prefer it to the Camaro but nobody offered me a Firebird to save!!)

RicksAlfas said:

I can recommend a fantastic media blaster near Halifax if that's any help to you.

He did my Alfa bodyshell last year.

Cheers, I do have a relation who is a media blaster as it happens, however I'm a bit reluctant to have the body blasted, seen it go wrong too many times but may well have the floors and boot and any bits too big for my blast cabinet done by him.He did my Alfa bodyshell last year.

Volvolover said:

Commenting purely to get updates but i must say I approve MASSIVELY of the towing vehicle here :-)

Thanks, it has its own little thread here https://www.pistonheads.com/gassing/topic.asp?h=0&...steveo3002 said:

get your mrs to write to car sos and tell em you have some lurgy , get it done up in no time

It's early days, let's hope it doesn't come to that!

It's early days, let's hope it doesn't come to that!CAPP0 said:

I always like reading your threads 99t, I used to have a Monaro and I have an itch for an Elk which will have to be scratched one day. On top of that a close friend is muttering about a truck like yours which means I'll get to play with that too!

What's the story with the Monaro becoming the donor - rust too far gone now?

Cheers, appreciate the kind words.What's the story with the Monaro becoming the donor - rust too far gone now?

When I bought the Monaro, it was always with an eye towards being a drivetrain donor at some point, albeit one that could provide plenty of entertainment along the way.

For that reason I bought the cheapest roadworthy one in the country and then steadfastly refused to spend money on anything that wasn't related to maintaining drivetrain health or general safety.

The net effect of this is that whilst it still runs perfectly, after eight and half years of neglect, almost everything else on the car has deteriorated to the point where it is no longer enjoyable to drive.

The final nail in the coffin was after passing the MOT in 2020, yet another power steering line rotted through in a fairly inaccessible place and I just couldn't find the will to fix it, so it has been parked up, fizzing gently, ever since...

Blue 7 said:

... I don’t know if you’re into motorsport, but by strange coincidence I’m mid way through Mark Donohue’s book ‘The unfair advantage’. It has plenty of ‘in period’ Camaro content & is entertainingly written. Well worth a look if you’re ever in need of a little inspiration.

Good luck with the build, I look forward to the updates!

Funny enough I'm sitting here looking at a rather lovely 1/18 GMP model of his '67 racecar! I'll have to look for a copy of the book, cheers. Good luck with the build, I look forward to the updates!

Slowly collecting parts that will be needed.

The rear "deck" filler panel (between rear screen and bootlid) arrived in perfect condition and looks a superb pressing from AMD, lovely tight radii on the folds. Nice and heavy gauge too.

Of course for every piece of good fortune encountered, a little pestilence must be endured - I give you today's delivery, courtesy of Herpes...

It is only the thin, pressed stainless trim for around the front screen, I'm sure it'll be fine...

The rear "deck" filler panel (between rear screen and bootlid) arrived in perfect condition and looks a superb pressing from AMD, lovely tight radii on the folds. Nice and heavy gauge too.

Of course for every piece of good fortune encountered, a little pestilence must be endured - I give you today's delivery, courtesy of Herpes...

It is only the thin, pressed stainless trim for around the front screen, I'm sure it'll be fine...

Somehow, and I'm not sure how, four out of five pieces in the box were undamaged!

The other one has a small dent which I duly photographed and sent to ebay along with pictures of the boxes - 24 hours later, a full refund (from ebay, not the seller under their Global Shipping Programme guarantee) and keep the parts!

The other one has a small dent which I duly photographed and sent to ebay along with pictures of the boxes - 24 hours later, a full refund (from ebay, not the seller under their Global Shipping Programme guarantee) and keep the parts!

Thanks all, I will try to keep up a steady rate of progress on this one, although initially updates may be few and far between since I'm sure there can only be so much interest in "here is a piece of rusty metal looking less rusty, just like the one I posted yesterday"...

So far so good though, I'm doing something in the garage almost every day which is an improvement on my usual (lack of) winter productivity.

@Getragdogleg - one of the benefits of owing something / procrastinating for so long is that I've had plenty of time to do my homework on what I actually have here.

For those unfamiliar, a '67 Camaro like this should have two metal plates attached to the body - a vin tag in the door jamb with the chassis number and other details on, and a "cowl tag" from Fisher Autobody, who built the shells for GM, with a build sequence number on, and in 1967 only, various option codes.

The car, as collected, came with a cowl tag but no vin plate - the friend that I purchased it from, assured me that he had removed it to keep safe "somewhere" and would let me have it - well it never materialized.

Due to the somewhat frantic nature of the cars initial collection, doing due diligence wasn't high on my list of priorities since I knew the vendor and he had previously talked long and loudly about how he had researched the car prior to purchase and confirmed its provenance and originality.

Unfortunately it was all bulls t, one of a number of reasons why we are no longer in contact.

t, one of a number of reasons why we are no longer in contact.

Other than on the vin tag, the chassis number is stamped in two places on the cowl / firewall. Neither are easily read when the car is fully assembled. The chassis number and cowl tag body sequence number won't be the same, they aren't meant to be, BUT they should be similar. A gap of a few hundred is fine, a thousand or so isn't unheard of. But they should be in the same ballpark.

On my car, there is a gap of seventeen thousand between them. The stamped chassis numbers do not appear to have been tampered with, so the only logical conclusion is that the cowl tag is not original to the car.

This is a shame, and will impact the ultimate value of the car, but since I'm building it to drive not to sell it is unlikely to be an issue any time soon. Plus it removes any guilt I might feel about building it "my way" rather than being a stickler for originality.

The car has been registered in the UK since around 1970, using the numbers that still appear on the car, so I don't anticipate any issues in that respect.

For what it is worth then, the cowl tag decodes as follows:

12E - assembled last week of December '66

NOR - Norwood plant - most were.

67-12437 - Chevrolet Camaro V8 coupe '67

760-Y - standard bucket seats with optional headrest (long gone)

Y-Y - Butternut Yellow paint

(2)LG - four speed floor shift and centre console (both long gone although the car has a clutch pedal and the location of the speedo cable hole suggests a Muncie 4-speed box).

(3)L - Rally Sport package (present)

(4)P - Traction bar, 12 bolt rear end = SuperSport in conjunction with the evidence of Muncie box (traction bar gone but mounting plate remains, axle is a 12-bolt but non original, some SS trim remains e.g. gas cap

(5)C - shoulder harnesses (not present)

In summary, '67 RS/SS 4-speed manual.

So far so good though, I'm doing something in the garage almost every day which is an improvement on my usual (lack of) winter productivity.

@Getragdogleg - one of the benefits of owing something / procrastinating for so long is that I've had plenty of time to do my homework on what I actually have here.

For those unfamiliar, a '67 Camaro like this should have two metal plates attached to the body - a vin tag in the door jamb with the chassis number and other details on, and a "cowl tag" from Fisher Autobody, who built the shells for GM, with a build sequence number on, and in 1967 only, various option codes.

The car, as collected, came with a cowl tag but no vin plate - the friend that I purchased it from, assured me that he had removed it to keep safe "somewhere" and would let me have it - well it never materialized.

Due to the somewhat frantic nature of the cars initial collection, doing due diligence wasn't high on my list of priorities since I knew the vendor and he had previously talked long and loudly about how he had researched the car prior to purchase and confirmed its provenance and originality.

Unfortunately it was all bulls

t, one of a number of reasons why we are no longer in contact.

t, one of a number of reasons why we are no longer in contact.Other than on the vin tag, the chassis number is stamped in two places on the cowl / firewall. Neither are easily read when the car is fully assembled. The chassis number and cowl tag body sequence number won't be the same, they aren't meant to be, BUT they should be similar. A gap of a few hundred is fine, a thousand or so isn't unheard of. But they should be in the same ballpark.

On my car, there is a gap of seventeen thousand between them. The stamped chassis numbers do not appear to have been tampered with, so the only logical conclusion is that the cowl tag is not original to the car.

This is a shame, and will impact the ultimate value of the car, but since I'm building it to drive not to sell it is unlikely to be an issue any time soon. Plus it removes any guilt I might feel about building it "my way" rather than being a stickler for originality.

The car has been registered in the UK since around 1970, using the numbers that still appear on the car, so I don't anticipate any issues in that respect.

For what it is worth then, the cowl tag decodes as follows:

12E - assembled last week of December '66

NOR - Norwood plant - most were.

67-12437 - Chevrolet Camaro V8 coupe '67

760-Y - standard bucket seats with optional headrest (long gone)

Y-Y - Butternut Yellow paint

(2)LG - four speed floor shift and centre console (both long gone although the car has a clutch pedal and the location of the speedo cable hole suggests a Muncie 4-speed box).

(3)L - Rally Sport package (present)

(4)P - Traction bar, 12 bolt rear end = SuperSport in conjunction with the evidence of Muncie box (traction bar gone but mounting plate remains, axle is a 12-bolt but non original, some SS trim remains e.g. gas cap

(5)C - shoulder harnesses (not present)

In summary, '67 RS/SS 4-speed manual.

I said:

I'm sure there can only be so much interest in "here is a piece of rusty metal looking less rusty, just like the one I posted yesterday"

So here is a piece of rusty metal looking less rusty...

Since this was taken I have worked my way forward, de-rusting the rear pillar and outer 12" or so of the roof on both sides. Although I have removed some deep pitting, only one spot about 2mm across turned into a pinhole so far. Easy enough to weld up.

I've still got the centre section of the roof to treat, but quite confident now that the roof panel is worth saving.

The rear screen channels are another matter though, the closer I look at them, the worse they get! The upper section (top of the rear window) is ok but the offside needs 90% replacing and the nearside perhaps 30-40%.

On the offside, splitting the rusted upper layer away from the structure below is complicated because there are many places where previous rust has been "repaired" by filling the rust holes with mig until they are covered, those welds have, of course, stuck to the layer I want to keep.

The nearside is less bodged and the metal is far too thin to clean up - in some places I started drilling out the spot welds to separate the upper layer from the structure underneath, and after a few minutes ended up using pliers to roll the upper skin back like opening a tin of corned beef, so thin was the metal that it just ripped around the welds.

I had initially hoped not to have to replace the "deck panel" between the rear screen and boot lid as it is mostly ok, however on closer inspection the lower screen channel is utterly shot - unsurprising as this is where water must sit the longest.

Replacement presents a problem though - I'm fairly certain that when the shell was built, the deck panel was welded into place before the rear quarters were fitted, and the majority of restorers would probably remove the rear quarters if rebuilding to the point of replacing the deck panel. However I don't intend to remove them as they are in very good shape.

Long story short, with the rear quarters in place, access to at least 60% of the side flanges is somewhere between nightmarish and non-existent.

From inside the boot you can sort of see what I mean - the flange runs the length of the oval highlight. The boot hinge structure also supports the inner body structure at the rear - removing those both sides might give better access, but the body would need bracing to ensure it didn't flex.

Since I didn't fancy the idea of hacking away large parts of the internal structure, I came up with a Plan B (for bodge!)

Namely, remove the deck panel, except for the outer edges, leaving the factory flange welds in place and trimming the replacement panel to butt weld to the remains of the old panel (which is in good, solid condition)

In theory this should be fine, the welds are close to the panel edge so shouldn't cause distortion, there is access from underneath the welds to allow them to be dressed and sealed, and none of the above prevents me from replacing the bits that are shot.

With this plan in mind, I started slowly and carefully cutting away the deck panel, leaving the outer couple of centimeters intact.

Found some more interesting repairs to the lower channel as I cut it away!

Getting there. Will do final trimming to the ends when I've cut the new panel enough to lay it over the top. And of course, plenty of rust treatment needed on the previously hidden metal too...

Hopefully when fitted, the factory seams will still be mostly intact and there will be minimal evidence that the panel has been replaced...

Slow but steady progress on the rear screen area, been trying to do an hour every night with about an 80% success rate I would estimate.

De-rusting the inner rear deck section before fitting the new deck panel - it doesn't need to be perfect as hidden when complete and was clearly bare metal from the factory, so anything I do must improve it!

My usual process, small section at a time, mechanical cleaning to remove the worst, soak and agitate in dilute phosphoric for an hour or so. Dry off and apply Hydrate 80 followed by Electrox.

Also completed fine trimming the new panel to fit

Bearing in mind this is only clamped at the bottom and just resting in place otherwise, I think it should be ok

Inner deck panel fully de-rusted

Including into the corners and nooks and crannies that will never be more accessible than they are now

Trimmed the screen channel repair section to fit

And then did a full dry assembly before welding properly. Amazing how a piece of glass makes it look more like a car, albeit briefly!

Made sure that the gaps between glass and body were all nice and even

Then welded in the screen channel repair sections, ground back the welds and primed

Rear deck panel fitting next...

De-rusting the inner rear deck section before fitting the new deck panel - it doesn't need to be perfect as hidden when complete and was clearly bare metal from the factory, so anything I do must improve it!

My usual process, small section at a time, mechanical cleaning to remove the worst, soak and agitate in dilute phosphoric for an hour or so. Dry off and apply Hydrate 80 followed by Electrox.

Also completed fine trimming the new panel to fit

Bearing in mind this is only clamped at the bottom and just resting in place otherwise, I think it should be ok

Inner deck panel fully de-rusted

Including into the corners and nooks and crannies that will never be more accessible than they are now

Trimmed the screen channel repair section to fit

And then did a full dry assembly before welding properly. Amazing how a piece of glass makes it look more like a car, albeit briefly!

Made sure that the gaps between glass and body were all nice and even

Then welded in the screen channel repair sections, ground back the welds and primed

Rear deck panel fitting next...

Oneball said:

Looks a really tidy job, you’ll be thinking about what colour to paint it soon

at the thought, and absolutely no idea on colour!

at the thought, and absolutely no idea on colour!Bit of progress over the long weekend.

Glued and welded the rear deck panel into place.

Welds look messy because they were built up as a series of small "spot" welds alternating between areas to prevent heat build up. They'll flat back ok.

Alignment of new panel to original factory seams looks good - I'm looking at the seam running up the picture, above and below where my series of welds meets it.

Overview

I'll crack on with grinding back the welds soon enough, but wanted to get stuck into the other major panel replacement needed - the dash and scuttle panel.

This grotty looking section is where the lower edge of the windscreen bonds, and although appearing in similar condition to much of the rest of the car, I already knew that this one was coming through from inside rather than being pure surface rust.

A fairly gentle poke with a screwdriver confirmed what I already knew

Ground back a couple of stitch welds at the ends and then started unpicking the spot welds along the length

Pretty much as expected, but the top of the firewall and cowl section exposed is thick metal and solid despite appearances. Confident it will clean up and treat with minimal, if any, patching.

With the spot welds across the front removed, it was a simple matter of chopping through an under-dash bracket or three - there are five but the welds on two had already failed! Obviously I checked what came with the new dash panel before hacking away! I'll remove the remains of the old brackets as necessary now access in much better.

Old vs new (top view)

Old vs new (dash view) Note the additional face level vents on the new dash - I ordered an A/C dash rather than non-A/C as this is an upgrade I will definitely be making.

Finally, the inside of the firewall in "not too bad" condition. I'll clean, treat and paint it all whilst access is as good as it will ever get!

Oilchange said:

Cool thread mate.

Thanks.

Thanks.I said:

Confident it will clean up and treat with minimal, if any, patching

I shouldn't have been quite so confident, although most of it looks like it will clean up ok, upon closer inspection it does need at least one small patch before the new panel goes on.Passenger side cleaned up ok as below

But the end section highlighted above, but on the driver's side, was much frillier and had to go. Should be a straightforward patch though and 100% hidden when the new dash / cowl section is fitted.

The surface rust under the cutout is the outer top of the firewall. I'll give the bit I can see a bit of a clean up now as, being very narrow, it'll be hard to access later, most of the rest of it can be reached through the larger openings to the left.

Oneball said:

Still no nasty surprises, everywhere else in the world has a better climate!

My C10 and El Camino are both California imports whereas this has been in the UK since 1970. Certainly this has more rust than they do (it has had front floors for example, whilst theirs are minty fresh) but the window channel areas that I'm replacing are a weak spot on most US vehicles of this era almost regardless of climate.That said, one of the tales that came attached to the Camaro, is that one of the reasons it survived 50+ years in the UK climate so well (relatively at least) is because it spent much of the 1980's garaged, because its then owner was "shooting tigers"...

Apocryphal? Quite possibly but it would help explain how the sills, rear arches and rear quarters survived in such good order. It would also go some way to explaining why the non-original small block that came with the car has had its engine number ground off...

Patched and painted that little upper cowl section.

I was actually pleased to do that bit of welding as otherwise de-rusting continues at a steady if somewhat tedious pace. I've just started on the inner surfaces which are easily accessible with the dash removed. Not aiming for utterly pristine metal on inner / hidden surfaces, they've lasted 55 years already, a good clean up and treat should preserve them beyond my remaining lifetime!

My daily routine is "choose a small section / grind off paint and heaviest rust with surface cleaning disc / use finger sander on remaining rust patches / use Dremel with a diamond bit on pitted areas / apply acid and work into remaining pits / dry / apply Hydrate 80 / apply Electrox" Repeat ad nauseam.

I'm viewing this stage as my penance for letting it rot in a damp garage for too many years, a chore that must be completed before I can get to the more interesting parts of the build.

Inevitably whilst doing so the mind wanders and recently my musings have related to the car's original colour. Having established conclusively that the trim tag is not original to the car, it means the original colour was not necessarily Butternut Yellow as per the tag. So what was it?

I remembered that I had run a vehicle check on the car prior to purchase, perhaps that would show the colour at import?

No such luck. Plenty of previous keepers and colour changes recorded though, and they're just the ones recorded...

Much of the car has been in bare metal before, quite possibly more than once, so clues must be sought in areas that haven't been touched during previous paint jobs - of which there are a few, since the car has never been as fully stripped down as it is now.

Looking at the pile of panels removed from the car, the bootlid shows signs of red where the most recent respray, in black, has flaked off. One of the doors and the cowl panel also show signs of red - the cowl panel being the most convincing as to possibly being a factory finish rather than previous paint overspray.

That said the other door shows signs of blue inside it, although rubbing down the door jamb area (beside producing a pretty pattern ) suggests that this may be the remains of the most recent colour before black

) suggests that this may be the remains of the most recent colour before black

Based on the rings, it appears to have had two resprays in black, one in a very spangly blue, then possibly a coat of sealant (brown) and maybe a yellow - which could be a high build layer but looks a bit bright for that? Under that is white and then the very thin coats are what I believe to be factory applied rust proofing coats.

So on that basis, white? I removed a door striker (one of the last things still bolted to the shell) and the result would suggest so.

Likewise the rear light openings, inner sill areas and patches under where the boot seal used to be. In all cases, removing the white reveals only a very thin coat of "red oxide" type coating which I believe is factory.

No evidence of red though. The cowl in particular looks a very factory finish on the underside, but the lack of red traces anywhere on the monocoque section suggests that the panel may simply be from another car...?

Who knows, it's all guesswork at this stage. Keeps a bored mind amused anyway

I was actually pleased to do that bit of welding as otherwise de-rusting continues at a steady if somewhat tedious pace. I've just started on the inner surfaces which are easily accessible with the dash removed. Not aiming for utterly pristine metal on inner / hidden surfaces, they've lasted 55 years already, a good clean up and treat should preserve them beyond my remaining lifetime!

My daily routine is "choose a small section / grind off paint and heaviest rust with surface cleaning disc / use finger sander on remaining rust patches / use Dremel with a diamond bit on pitted areas / apply acid and work into remaining pits / dry / apply Hydrate 80 / apply Electrox" Repeat ad nauseam.

I'm viewing this stage as my penance for letting it rot in a damp garage for too many years, a chore that must be completed before I can get to the more interesting parts of the build.

Inevitably whilst doing so the mind wanders and recently my musings have related to the car's original colour. Having established conclusively that the trim tag is not original to the car, it means the original colour was not necessarily Butternut Yellow as per the tag. So what was it?

I remembered that I had run a vehicle check on the car prior to purchase, perhaps that would show the colour at import?

No such luck. Plenty of previous keepers and colour changes recorded though, and they're just the ones recorded...

Much of the car has been in bare metal before, quite possibly more than once, so clues must be sought in areas that haven't been touched during previous paint jobs - of which there are a few, since the car has never been as fully stripped down as it is now.

Looking at the pile of panels removed from the car, the bootlid shows signs of red where the most recent respray, in black, has flaked off. One of the doors and the cowl panel also show signs of red - the cowl panel being the most convincing as to possibly being a factory finish rather than previous paint overspray.

That said the other door shows signs of blue inside it, although rubbing down the door jamb area (beside producing a pretty pattern

) suggests that this may be the remains of the most recent colour before black

) suggests that this may be the remains of the most recent colour before black

Based on the rings, it appears to have had two resprays in black, one in a very spangly blue, then possibly a coat of sealant (brown) and maybe a yellow - which could be a high build layer but looks a bit bright for that? Under that is white and then the very thin coats are what I believe to be factory applied rust proofing coats.

So on that basis, white? I removed a door striker (one of the last things still bolted to the shell) and the result would suggest so.

Likewise the rear light openings, inner sill areas and patches under where the boot seal used to be. In all cases, removing the white reveals only a very thin coat of "red oxide" type coating which I believe is factory.

No evidence of red though. The cowl in particular looks a very factory finish on the underside, but the lack of red traces anywhere on the monocoque section suggests that the panel may simply be from another car...?

Who knows, it's all guesswork at this stage. Keeps a bored mind amused anyway

Getragdogleg said:

Has it still got the trim tag on the cowl by the wiper motor ?

It does have "a" trim tag, but it cannot be original to the car - there is too much of a gap between the tag and chassis numbers, over a month in terms of time based on CRG build numbers, and the gap is the wrong way round.What I mean by this - the trim tag dates the final assembly to late December '66, whilst the chassis number and various marking on some parts suggest the parts were only manufactured towards the end of January '67 - e.g. the rear quarters are stamped H4 which decodes as week 4 of the calendar year. Which ties up nicely with things like this on the headlamp mechanism.

There was a strike at the Norwood plant around January '67, so some build numbers are a bit screwy from that period, however the car simply cannot have been assembled before the parts were made!!

Getragdogleg said:

Interesting, does it have access holes to get to the bumper iron bolts in the front frame rails or are they clip in nuts?

Mine has a hole in one side and a clip nut the other which puts it as a late 66 car as they switched to clip nuts.

It has the later style access holes on both sides. Mine has a hole in one side and a clip nut the other which puts it as a late 66 car as they switched to clip nuts.

Also has mid-style "full telephone" indentation (plus five smaller indentations) in the door jamb areas, which again loosely date it between December and March '67.

Apologies to all other than Getragdogleg for the excessive Camaro beardage!!

Getragdogleg said:

Having said that... Does it have steel seat backs and any shiny inner roof rail trims ? does it have rocker spears on the outer sills ?

Sadly it had lost its original interior and much of the external trim long before I took it on. I'm not sure about the inner roof rail trims, I don't recollect seeing them in any of the boxes of bits though.Rather overdue update...

To be honest, much of what I've been doing isn't very updateworthy - slow and steady de-rusting, treating and sealing the main bodyshell, inside and out, visible or otherwise.

Bits that start off looking like this (the black) are then stripped to reveal surface rust under the paint.

After mechanical cleaning followed by phosphoric it ends up looking like this, prior to being sealed and primed.

When I become bored doing that, I have started selecting random parts to refurb from the many, many boxes that contain the rest of the car.

The clutch and brake pedal assembly, for example, started off looking like this

And closer, like this

Started cleaning and painting some bits of it by hand...

...but it was taking hours and hours to do, and combined with the amount of parts needing attention it felt like an overwhelming task. The solution was to find a space for the blast cabinet I had bought a while back but had never assembled due to lack of room.

Having found a suitable spot outside the end of the garage, I built a basic but waterproof enclosure to house the cabinet, with two opening sides to allow access to the loading door, and gloves/screen. Sorry no pic of the cabinet itself but it is a decent size.

This meant the large main pressing of the pedal assembly could be transformed in minutes rather than hours.

Between last Autumn and early Summer, progress really halted as the construction of a house extension becoming all consuming so far as free time was concerned.

However in what little free time I had, I did start ordering some parts to assist the mechanical side in due course.

Holley LS1 into 67-69 F-body sump kit

Holley Blackheart mounting kit for the same application.

Hopefully using the same "brand" for both will reduce the likelihood of clearance issues as they state that they are designed to work together. We'll see...

This week the driveline donor returned home, running well and sounding healthy. Don't let the picture fool you, other than the engine and box, pretty much everything else on this old girl is well worn, rusting away or just plain knackered!

The first job is to drain most of the fuel, since I brimmed the tank before putting it into storage. Obviously as the fuel is over three years old, I'll be selective what I use it in, but since the Monaro still seems to run happily enough on it, I'm sure it'll be fine in the mower and C10, both of which are sufficiently unstressed to run on almost anything vaguely flammable!

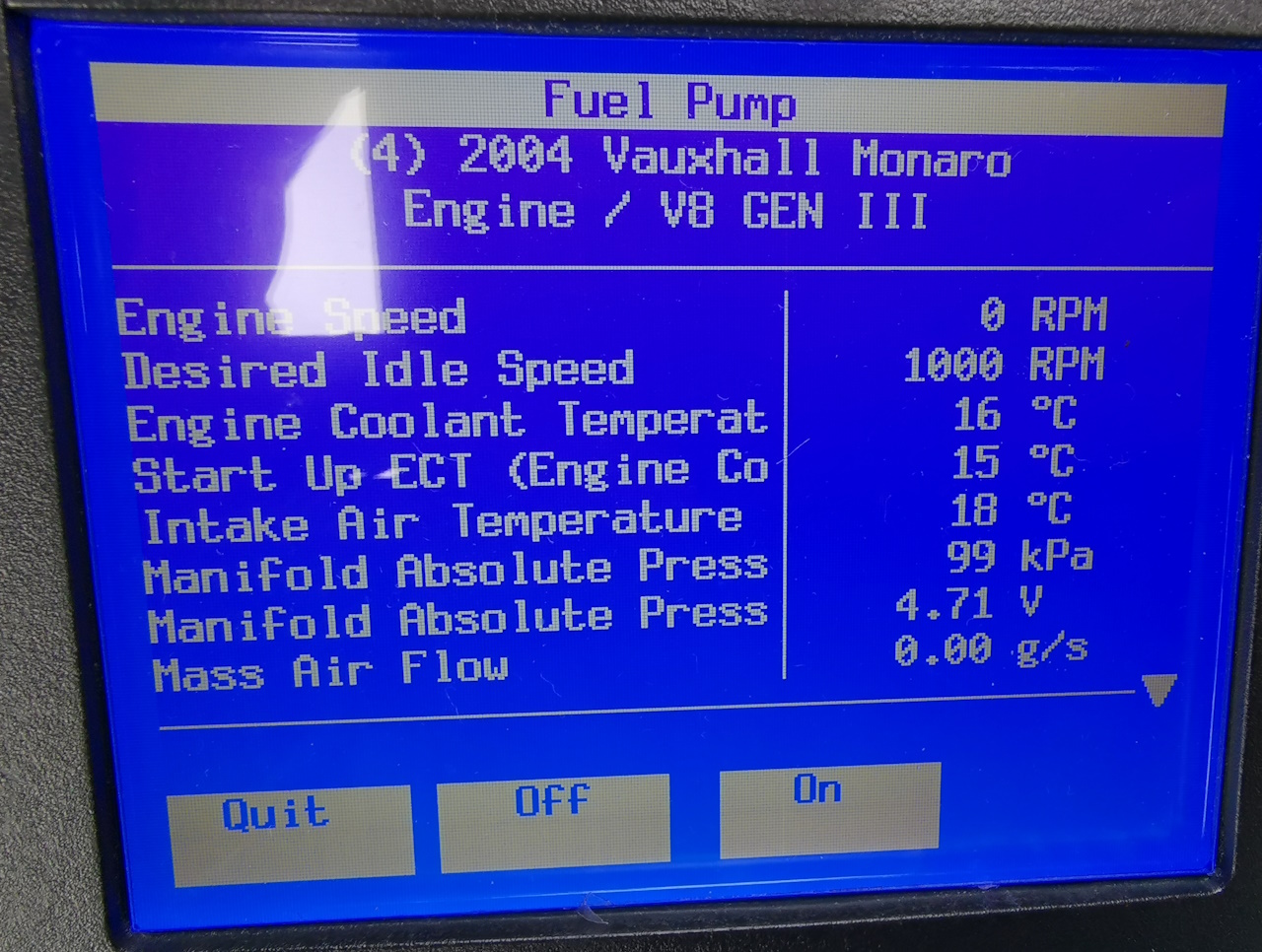

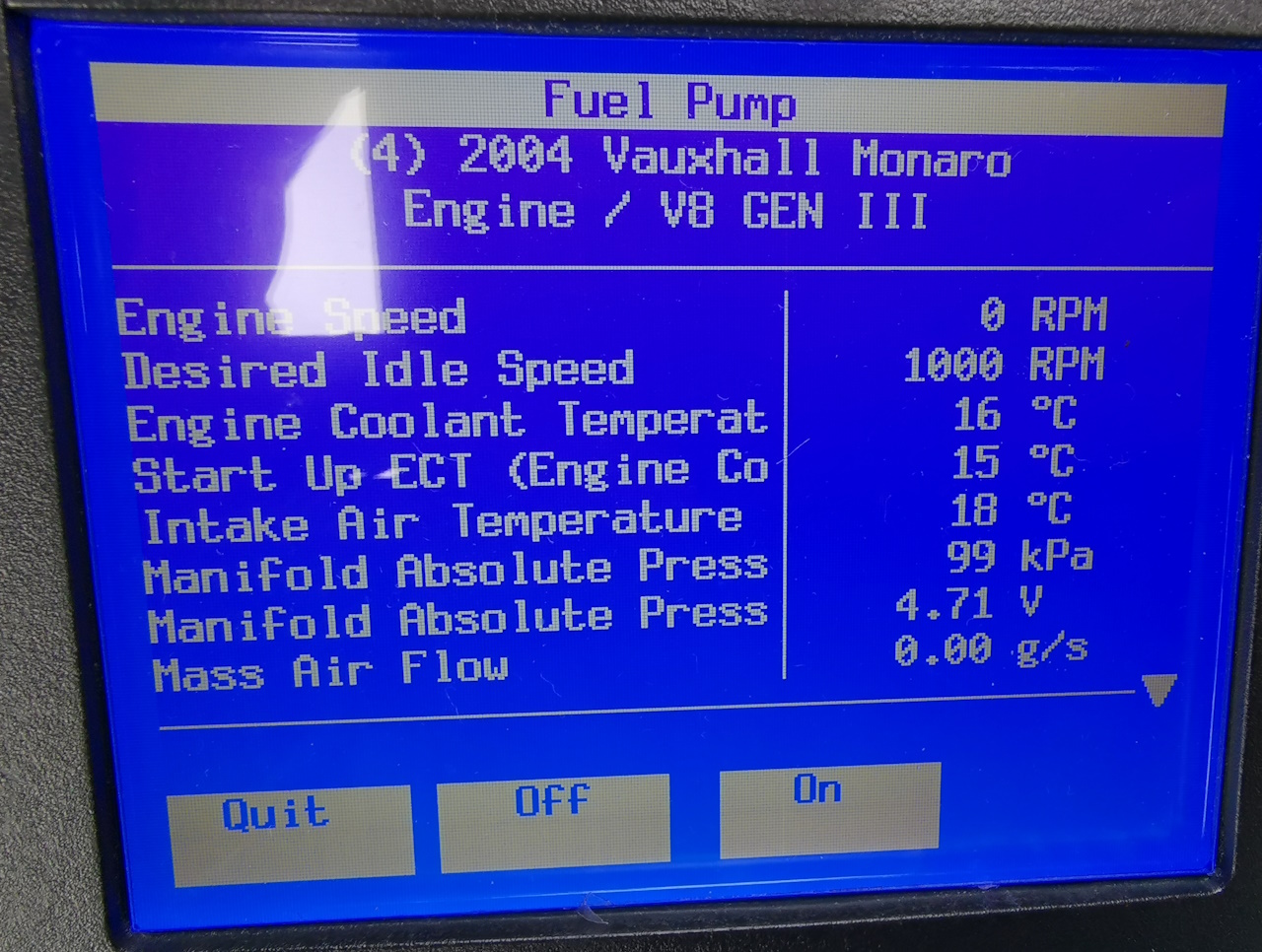

Not wishing to crawl under the car and start undoing pipes, which bitter experience tells me inevitably ends up in a petrol bath, I dug out the trusty Tech II, since I was sure I'd seen an option to "test" the fuel pump...

Sure enough

A little bit of bodgery later and I was ready to start filling fuel cans. Is it a stupid idea if it works?

I'll leave a bit of fuel in there for now because, whilst I still have a running vehicle, I want to disable the VATS anti-theft system which requires the chip-key to turn the immobiliser off.

I don't want to have to use the ugly plastic Monaro key in the Camaro, or resort to some sort of hidden key hybrid botch-up work around. At least whilst the car still runs, I can confirm the success or otherwise of my efforts - just awaiting a few bits to make a "desktop loom" to connect the PCM to...

To be honest, much of what I've been doing isn't very updateworthy - slow and steady de-rusting, treating and sealing the main bodyshell, inside and out, visible or otherwise.

Bits that start off looking like this (the black) are then stripped to reveal surface rust under the paint.

After mechanical cleaning followed by phosphoric it ends up looking like this, prior to being sealed and primed.

When I become bored doing that, I have started selecting random parts to refurb from the many, many boxes that contain the rest of the car.

The clutch and brake pedal assembly, for example, started off looking like this

And closer, like this

Started cleaning and painting some bits of it by hand...

...but it was taking hours and hours to do, and combined with the amount of parts needing attention it felt like an overwhelming task. The solution was to find a space for the blast cabinet I had bought a while back but had never assembled due to lack of room.

Having found a suitable spot outside the end of the garage, I built a basic but waterproof enclosure to house the cabinet, with two opening sides to allow access to the loading door, and gloves/screen. Sorry no pic of the cabinet itself but it is a decent size.

This meant the large main pressing of the pedal assembly could be transformed in minutes rather than hours.

Between last Autumn and early Summer, progress really halted as the construction of a house extension becoming all consuming so far as free time was concerned.

However in what little free time I had, I did start ordering some parts to assist the mechanical side in due course.

Holley LS1 into 67-69 F-body sump kit

Holley Blackheart mounting kit for the same application.

Hopefully using the same "brand" for both will reduce the likelihood of clearance issues as they state that they are designed to work together. We'll see...

This week the driveline donor returned home, running well and sounding healthy. Don't let the picture fool you, other than the engine and box, pretty much everything else on this old girl is well worn, rusting away or just plain knackered!

The first job is to drain most of the fuel, since I brimmed the tank before putting it into storage. Obviously as the fuel is over three years old, I'll be selective what I use it in, but since the Monaro still seems to run happily enough on it, I'm sure it'll be fine in the mower and C10, both of which are sufficiently unstressed to run on almost anything vaguely flammable!

Not wishing to crawl under the car and start undoing pipes, which bitter experience tells me inevitably ends up in a petrol bath, I dug out the trusty Tech II, since I was sure I'd seen an option to "test" the fuel pump...

Sure enough

A little bit of bodgery later and I was ready to start filling fuel cans. Is it a stupid idea if it works?

I'll leave a bit of fuel in there for now because, whilst I still have a running vehicle, I want to disable the VATS anti-theft system which requires the chip-key to turn the immobiliser off.

I don't want to have to use the ugly plastic Monaro key in the Camaro, or resort to some sort of hidden key hybrid botch-up work around. At least whilst the car still runs, I can confirm the success or otherwise of my efforts - just awaiting a few bits to make a "desktop loom" to connect the PCM to...

Monaro stripping is going well.

In addition to the engine and box and Powertrain Control Module (PCM), I plan to remove the entire wiring loom intact initially and then thin out the bits I want to keep. To that end, I have been concentrating on stripping the interior. However an ad on a well known action site has also resulted in a surprisingly brisk trade in parts, which has also guided and distracted my dismantling efforts in equal measure!

VATS removal - in order to use the factory PCM in the Camaro without the Monaro key, it is necessary to disable the standard security system.

There are a million tutorials on Youtube etc., some of which made it look quite straightforward. Armed with a little knowledge, on a "what's the worst that could happen?" basis, I made up a bench harness, downloaded some free software (PCM Hammer and Tuner Pro) and got it all to communicate, so far so good.

As a rank amateur at this sort of thing, I expected the service number on the PCM to match the installed software.

Umm, ok. This is important to get right since it is necessary to use the correct xdf file in Tuner Pro to interpret the PCM code into a human comprehensible format - using an incorrect version could well result in a corrupted PCM.

Logic dictated to use the xdf version being reported in the software, so that's what I did. It appeared to interpret the contents of the PCM correctly - I checked a few parameters and the reported values looked sensible although I fully appreciate there could be others that were completely wrong and I wouldn't have had a Scooby Doo...

The bit I'm interested in

Disabling it couldn't be much simpler

Back into PCM Hammer and write the calibration back into the PCM - it appeared to go without a glitch.

Time to see if I had succeeded?

Removed the security slip-ring from the ignition switch, so effectively using an uncoded key at this point. I knew that there was still further security within the Body Control Module (BCM) and so the engine wouldn't actually crank from the key, but in theory with the ignition on (and security light flashing) the engine should fire with power applied to the starter relay.

Easiest way to achieve that was simply to remove the relay cover and close the contacts manually...

One small but important step forward

In addition to the engine and box and Powertrain Control Module (PCM), I plan to remove the entire wiring loom intact initially and then thin out the bits I want to keep. To that end, I have been concentrating on stripping the interior. However an ad on a well known action site has also resulted in a surprisingly brisk trade in parts, which has also guided and distracted my dismantling efforts in equal measure!

VATS removal - in order to use the factory PCM in the Camaro without the Monaro key, it is necessary to disable the standard security system.

There are a million tutorials on Youtube etc., some of which made it look quite straightforward. Armed with a little knowledge, on a "what's the worst that could happen?" basis, I made up a bench harness, downloaded some free software (PCM Hammer and Tuner Pro) and got it all to communicate, so far so good.

As a rank amateur at this sort of thing, I expected the service number on the PCM to match the installed software.

Umm, ok. This is important to get right since it is necessary to use the correct xdf file in Tuner Pro to interpret the PCM code into a human comprehensible format - using an incorrect version could well result in a corrupted PCM.

Logic dictated to use the xdf version being reported in the software, so that's what I did. It appeared to interpret the contents of the PCM correctly - I checked a few parameters and the reported values looked sensible although I fully appreciate there could be others that were completely wrong and I wouldn't have had a Scooby Doo...

The bit I'm interested in

Disabling it couldn't be much simpler

Back into PCM Hammer and write the calibration back into the PCM - it appeared to go without a glitch.

Time to see if I had succeeded?

Removed the security slip-ring from the ignition switch, so effectively using an uncoded key at this point. I knew that there was still further security within the Body Control Module (BCM) and so the engine wouldn't actually crank from the key, but in theory with the ignition on (and security light flashing) the engine should fire with power applied to the starter relay.

Easiest way to achieve that was simply to remove the relay cover and close the contacts manually...

One small but important step forward

fred bloggs said:

The car still has the factory immobilisor as it is a signal from the body control module that allows the ecu to fire the engine. If you could find which wire sends that signal from the body control module and put 5v there you'd be rocking, No ?

As I understand the PCM cuts fuel and the BCM cuts cranking. I hope to retain the BCM to a limited degree in the Camaro as I believe things like cruise control are done through that, which I would like to retain (happy to be corrected as I'm still very much sussing this stuff out...). So I will need to physically bypass the start inhibit side of things in that moduleNow the fuel cut is bypassed in the PCM, as you say all that is needed to start is voltage to the starter relay (plus permanent +ve and ignition +ve to the fuse box as required) which can all come from the Camaro's standard ignition switch.

I don't doubt that there will be some head scratching needed at some point however!

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff