Exige S1 over-winter Refresh

Discussion

Cheers Capo.... indeed that's the explanation I've had from many people so I'll definitely be keeping that in mind.

The S1 Exige runs an external oil cooler (air to air) at the front of the car. It's non-thermostatically controlled. Given the large size of the lubrication circuit, it can take AAAGES for the oil to heat up to operating temperature. My guess is that it's been driven hard before the oil's had a chance to get up to full temp in its past 7 years and it's gradually degraded. First thing I'll be putting in the car with the new engine is a datalogging oil temp/pressure sensing system so I can see exactly what's going on and then if high oil pressure IS a problem, then take appropriate steps to rectify it.

The S1 Exige runs an external oil cooler (air to air) at the front of the car. It's non-thermostatically controlled. Given the large size of the lubrication circuit, it can take AAAGES for the oil to heat up to operating temperature. My guess is that it's been driven hard before the oil's had a chance to get up to full temp in its past 7 years and it's gradually degraded. First thing I'll be putting in the car with the new engine is a datalogging oil temp/pressure sensing system so I can see exactly what's going on and then if high oil pressure IS a problem, then take appropriate steps to rectify it.

Scuffers said:

there are later material ones avalable now that don't do this (can't remeber the name off the top of my head, a quick main to DVA would answer that one though).

Cheers Simon, already on top of that one.... DVA will be supplying me the new improved bearings for the rebuild... I'm picking that it's just a case of standard bearings not being up to track abuse at 8000RPM.PROGRESS!!!! ... ok well no, not really... but I felt I should update y'all to let you know where I'm at with things

As I've mentioned before, the VHPD is going to be rebuilt. After weighing up several options, I've decided to go "the whole hog" and build the engine with a decent budget doing everything right, rather than just slapping it back together as a standard VHPD. Everything's been pulled apart and inspected and I'm hopefully going to soon pack up the complete cylinder head, crankshaft, flywheel, clutch cover, pulleys and oil pump to send back to the UK.

The plan is to order new rods and pistons in the UK and have them meet my bottom-end components at Vibration Free so that I can follow what Steve Butts/Skeggsy have done with their Ks and do the full on high-tolerance balance and tungsten crankshaft insertion. While this is going on, my head will go on to DVAPower and get the magic DVA tough with porting and will be rebuilt with all new fresh bits and pieces and all the good bits to make the head able to make more use of a freer bottom end. I'm currently just trying to find out when Dave's got some free time to do the job but other than that it's all go!

The other hold up has been (as some of you might have seen from my other thread on SELOC) that I discovered some corrosion in the lower rear firewall. This was discovered as a small 4mm diameter hole in the bulkhead when I was reinstalling the fuel tank. Subsequent stripping of the firewall heatshield has shown that moisture has gotten in behind this and has caused an identical crevice corrosion problem as to what occurs with the OEM rubber floor mats.

The images I below show the state of the engine bay with the corrosion being clear in the fourth picture. There's a few other small pits on other locations along the firewall.

I have been in contact with Lotus over this issue and they have been very helpful to date. They are interested in learning more about this as they've not been aware of this area being a problem on the chassis before. My chassis is under the 8 year corrosion guarantee and they are currently formulating a fix and are going to send me a repair kit (and new engine bay heat shield) free of charge once they determine the best cause of action to affect a repair and prevent any further corrosion spread.

If any of you are contemplating a strip down and rebuild at any stage in the future, or doing an engine-out job, it would certainly be a worthwhile exercise to strip back the firewall to see if there's any corrosion damage lurking underneath.

Alternatively you can simply drop out the fuel tank and look at the bulkhead from this side to see if there are any holes that have gone through, although this may not show any corrosion that's still in its infancy. I'm certainly very lucky that I bothered to check as I've caught this at a reasonably early stage and can now hopefully arrive at a permanent fix so it'll never need doing again.

All this has put a large pause on proceedings and what was initially meant to be an over-winter refresh (as the thread title suggests) is now turning into something altogether rather more comprehensive. I'm hoping to have the car back together in the NZ Autumn in time for the last of the nice weather before I have to put my toys away again for winter '09.

Rest assured, when she's all done, it's going to be SIGNIFICANTLY better than it was before.

Jobs coming up in the next couple of weeks will be to finish cleaning up the engine bay and to re-hang the rear subframe. Once this is done, I'll then install bushes and balljoints in all the wishbones and set about hanging them back on the car. I'm hoping to get the car rolling again by early/mid December as this'll give me a chance to clean up the garage a bit and also to wheel the car in/out so I can work on it in the sun when the weather's nice as the garage is a little dingy, even in daylight.

f**k me, I don't do things by halves do I?

As I've mentioned before, the VHPD is going to be rebuilt. After weighing up several options, I've decided to go "the whole hog" and build the engine with a decent budget doing everything right, rather than just slapping it back together as a standard VHPD. Everything's been pulled apart and inspected and I'm hopefully going to soon pack up the complete cylinder head, crankshaft, flywheel, clutch cover, pulleys and oil pump to send back to the UK.

The plan is to order new rods and pistons in the UK and have them meet my bottom-end components at Vibration Free so that I can follow what Steve Butts/Skeggsy have done with their Ks and do the full on high-tolerance balance and tungsten crankshaft insertion. While this is going on, my head will go on to DVAPower and get the magic DVA tough with porting and will be rebuilt with all new fresh bits and pieces and all the good bits to make the head able to make more use of a freer bottom end. I'm currently just trying to find out when Dave's got some free time to do the job but other than that it's all go!

The other hold up has been (as some of you might have seen from my other thread on SELOC) that I discovered some corrosion in the lower rear firewall. This was discovered as a small 4mm diameter hole in the bulkhead when I was reinstalling the fuel tank. Subsequent stripping of the firewall heatshield has shown that moisture has gotten in behind this and has caused an identical crevice corrosion problem as to what occurs with the OEM rubber floor mats.

The images I below show the state of the engine bay with the corrosion being clear in the fourth picture. There's a few other small pits on other locations along the firewall.

I have been in contact with Lotus over this issue and they have been very helpful to date. They are interested in learning more about this as they've not been aware of this area being a problem on the chassis before. My chassis is under the 8 year corrosion guarantee and they are currently formulating a fix and are going to send me a repair kit (and new engine bay heat shield) free of charge once they determine the best cause of action to affect a repair and prevent any further corrosion spread.

If any of you are contemplating a strip down and rebuild at any stage in the future, or doing an engine-out job, it would certainly be a worthwhile exercise to strip back the firewall to see if there's any corrosion damage lurking underneath.

Alternatively you can simply drop out the fuel tank and look at the bulkhead from this side to see if there are any holes that have gone through, although this may not show any corrosion that's still in its infancy. I'm certainly very lucky that I bothered to check as I've caught this at a reasonably early stage and can now hopefully arrive at a permanent fix so it'll never need doing again.

All this has put a large pause on proceedings and what was initially meant to be an over-winter refresh (as the thread title suggests) is now turning into something altogether rather more comprehensive. I'm hoping to have the car back together in the NZ Autumn in time for the last of the nice weather before I have to put my toys away again for winter '09.

Rest assured, when she's all done, it's going to be SIGNIFICANTLY better than it was before.

Jobs coming up in the next couple of weeks will be to finish cleaning up the engine bay and to re-hang the rear subframe. Once this is done, I'll then install bushes and balljoints in all the wishbones and set about hanging them back on the car. I'm hoping to get the car rolling again by early/mid December as this'll give me a chance to clean up the garage a bit and also to wheel the car in/out so I can work on it in the sun when the weather's nice as the garage is a little dingy, even in daylight.

f**k me, I don't do things by halves do I?

Edited by Esprit on Sunday 7th December 12:25

Kiwi XTR2 said:

I get scared to look at this thread for fear of what the next update is.

At least having it rolling again will be a significant milestone in having it finished.

Yeah well once it's rolling there'll be a big wait while I get the engine components back from the UK and begin the engine reassembly. I'll then have some minor bits and pieces to do around the chassis like fabricating up a carbonfibre battery mount for my new lightweight battery (yet to purchase) and wiring in the Emerald ECU ready for the new engine, but the biggest hurdle by far will be getting the engine back in one piece and ready to run again.At least having it rolling again will be a significant milestone in having it finished.

tricky 100 said:

Are you going to respray the body ?

Possibly eventually, although not as part of this winter. After I get the car built up I'll have to cut spending on it for a few months to rebuild my battered savings. The paint's in pretty good condition but I'll respray it in a year or two and put some armourfend on the nose and sills to stop the thing stonechipping quite so badly.And thanks Tim

I'm sure I'm doing the right thing

I'm sure I'm doing the right thing

TonyHetherington said:

Absolutely.

You're making a superb job of it also, and I'm very jealous that you have the time, the inclanation, the ability and the desire to do it.

Bloody well done, it looks like a credit to you and I cannot WAIT to see the finished result. Bravo

Not quite sure I have the time (he says sitting at his work desk at 5 minutes to midnight... again)... but yes, it's a case of knowing that I'll not be satisfied if it's not done right. I want the car to be in a state I can enjoy for the next 10 years or more without having to worry about hidden niggles. I'll know that everything's been done right and the car's effective age has been reset to zero. That way, I know its history intimately and that if I look after her, she'll look after me.... which is important when you're at Pukekohe turning into Jennian at almost 200km/h You're making a superb job of it also, and I'm very jealous that you have the time, the inclanation, the ability and the desire to do it.

Bloody well done, it looks like a credit to you and I cannot WAIT to see the finished result. Bravo

Thanks one and all for the kind comments.... I know I need not worry because if I get stuck I've got such a great community behind me to call on should I need

Edited by Esprit on Monday 3rd November 10:57

Well a little bit more progress today.... aside from the engine dramas that is, but I got my wishbones preassembled today including the suspension bushes and ball joints.

Fingers crossed, I'll be hanging these off the car sometime in the next week or two as I work towards getting the car back on its wheels and rolling so that it's a little more easy to work on.

Tomorrow's job is the rear subframe detailing.

But for now, wishbones...

Fingers crossed, I'll be hanging these off the car sometime in the next week or two as I work towards getting the car back on its wheels and rolling so that it's a little more easy to work on.

Tomorrow's job is the rear subframe detailing.

But for now, wishbones...

Edited by Esprit on Sunday 7th December 12:26

The last week or two has been painfully slow going... I've been slowly cleaning up the chassis corners so that the suspension can be bolted back on. Getting rid of 8 years worth of grime and accumulated crap that had sunk into the anodising has proven tricky.... the only way to clean it is by rubbing down with a solvent first to remove most of the stuck-on stuff then going over and cleaning the resultant with Autosol.

This has to be done by hand as you don't want to machine buff it and go through the anodising....just rubbing down by hand with the Autosol is quite safe on the anodising (so long as you don't go nuts) and it cleans it up well, albeit slowly. I've done the front corners and also the front underchassis (see pic showing in-progress cleaning). I've also done one of the rear corners and also much of the engine bay. Another 5-6 hours elbow grease and this will be done. I'll also do the full underfloor as well but this will wait until after the car is back on its wheels again as I've more pressing matters. I'll also give the undertrays and fuel tank shear panel the same treatment to get it looking presentable before this whole shabang is finished.

I've also started making up my fastener list. Done the front and some of the rear suspension for starters, will complete this this week as I want to order fasteners shortly. Still to go are all the clam fixing fasteners and other miscellaneous ones from around the car. The list probably won't be 100% complete on its first iteration as I'm bound to miss a few, but it'll post a link to the Excel spreadsheet up on SELOC when done for those who want to look. It's pretty specific to my build but it should include MOST of the external fasteners on the car that suffer from weathering should anyone want to replicate what I've done.

Other big news is that I've also now finalised the engine spec and now plans are actually underway to get it rebuilt. Rough spec as follows:

New Stock Rover crankshaft custom tungsten inserted by Vibration Free

New Steel H-Beam rods from Arrow Precision

New Omega Pistons / rings (machined by DVAPower for larger valves)

Bottom end will be balanced as an assembly with my existing flywheel/clutch cover and pulleys

VHPD head will be sent to DVAPower to receive his porting magic. Head will then be rebuilt with:

Larger valves

Dual valve springs

Colisbro guides

Piper 1444 Cams

Piper Vernier cam pulleys

Engine will then be rebuilt here in NZ with all new consumables (seals, gaskets, fasteners, liners etc). Whole setup will be run from a new Emerald ECU which will be mapped locally.

Ideally the goal is to build a reliable road/trackday engine that spits out enough power to keep a Honda-powered car at least semi-honest on track. Theoretically, anything up to about 240bhp should be possible in this spec but in the interest of longevity I will be trying to tune it to produce some solid torque without raising the VHPD redline... down the track I can investigate if I want to up the RPM envelope to chase more power. I'm hoping for about 220bhp in a semi-reliable package... something that should be possible.

So yeah, that's it in a nutshell... things should start moving in the next couple of weeks, engine bits being ordered this week and I'll be freighting off my stuff to the UK shortly thereafter. Meanwhile, I've a chassis to finish cleaning up and fasteners to order and still a VERY long list of things to do before the engine comes back together sometime late February..... can't say I don't keep myself busy!

This has to be done by hand as you don't want to machine buff it and go through the anodising....just rubbing down by hand with the Autosol is quite safe on the anodising (so long as you don't go nuts) and it cleans it up well, albeit slowly. I've done the front corners and also the front underchassis (see pic showing in-progress cleaning). I've also done one of the rear corners and also much of the engine bay. Another 5-6 hours elbow grease and this will be done. I'll also do the full underfloor as well but this will wait until after the car is back on its wheels again as I've more pressing matters. I'll also give the undertrays and fuel tank shear panel the same treatment to get it looking presentable before this whole shabang is finished.

I've also started making up my fastener list. Done the front and some of the rear suspension for starters, will complete this this week as I want to order fasteners shortly. Still to go are all the clam fixing fasteners and other miscellaneous ones from around the car. The list probably won't be 100% complete on its first iteration as I'm bound to miss a few, but it'll post a link to the Excel spreadsheet up on SELOC when done for those who want to look. It's pretty specific to my build but it should include MOST of the external fasteners on the car that suffer from weathering should anyone want to replicate what I've done.

Other big news is that I've also now finalised the engine spec and now plans are actually underway to get it rebuilt. Rough spec as follows:

New Stock Rover crankshaft custom tungsten inserted by Vibration Free

New Steel H-Beam rods from Arrow Precision

New Omega Pistons / rings (machined by DVAPower for larger valves)

Bottom end will be balanced as an assembly with my existing flywheel/clutch cover and pulleys

VHPD head will be sent to DVAPower to receive his porting magic. Head will then be rebuilt with:

Larger valves

Dual valve springs

Colisbro guides

Piper 1444 Cams

Piper Vernier cam pulleys

Engine will then be rebuilt here in NZ with all new consumables (seals, gaskets, fasteners, liners etc). Whole setup will be run from a new Emerald ECU which will be mapped locally.

Ideally the goal is to build a reliable road/trackday engine that spits out enough power to keep a Honda-powered car at least semi-honest on track. Theoretically, anything up to about 240bhp should be possible in this spec but in the interest of longevity I will be trying to tune it to produce some solid torque without raising the VHPD redline... down the track I can investigate if I want to up the RPM envelope to chase more power. I'm hoping for about 220bhp in a semi-reliable package... something that should be possible.

So yeah, that's it in a nutshell... things should start moving in the next couple of weeks, engine bits being ordered this week and I'll be freighting off my stuff to the UK shortly thereafter. Meanwhile, I've a chassis to finish cleaning up and fasteners to order and still a VERY long list of things to do before the engine comes back together sometime late February..... can't say I don't keep myself busy!

Edited by Esprit on Sunday 23 November 12:21

SimJen said:

Nice job, hope you're not too scared to give it a good thrashing once complete.....

I would have probably just stuck a S/C Honda motor in it, but then I do love the sound of a tuned Vtec!

But its good you are keeping it as it should be

Look forward to more updates once you get the motor back.

Won't be afraid to give it a good thrashing at all... car will see about a 70/30 split of road time and track time... certainly it'll never be used as a commuter/daily drive and it'll probably almost never see another rainy day in its life butother than that it'll be used as Colin Chapman would have wanted I would have probably just stuck a S/C Honda motor in it, but then I do love the sound of a tuned Vtec!

But its good you are keeping it as it should be

Look forward to more updates once you get the motor back.

Progress on the Chassis...

The fastener list is coming along and will be placing an order this week.

I've been working this weekend on the firewall. Lotus have specified me a fix which involves bonding on a reinforcement plate with epoxy over the worst of the corrosion as well as treating with ACF50 before reapplying the heat shield. They have ascertained that in my case there is no loss of structural integrity (in the scheme of things the corrosion damage is very very minor) but they are rather alarmed at the corrosion in this area as they've not seen it before, mainly due to the fact that very few cars have actually had their heat-shields removed for a look-see. Certainly if you're ever pulling the engine out of your Elise/Exige, I'd be stripping the heat-shield off for a good check-over as it could potentially end up in a VERY bad state if left unchecked.

Given the lack of structural damage and my desire to completely stop/prevent corrosion in this area I've basically done the same fix I did on my floorpans. I could go ahead with the Lotus fix, but I think my fix will be more comprehensive at solving the issue in my case.

I've scrubbed the firewall and wire-brushed / ground (with a dremel) out all of the corrosion/pitting from the firewall. The one through-hole I've drilled out with a 10mm drill (to remove all the active corrosion) and will be filling the hole with a blanking grommet. Given that the fuel lines exit just above this as well as another large blanking grommet (unused penetration) then this should look tidy when done.

I then went through the full three-step POR15 treatment (in silver) to clean, etch and coat/seal the firewall. The result has come out absolutely fantastic and I'm very pleased with it. As with the floorpans you can still see the pitting evident beneath the POR15 but I decided not to try filling these as I wanted the the POR to be in direct contact with the metal, providing the best corrosion protection. With filling there's always a risk that moisture can get trapped between the metal and the filler, allowing crevice corrosion to continue beneath the coating. Either way it looks ace and it'll be hidden anyway once the new heat-shield is affixed in place.

Firewall masked up with pitting and corrosion-affected areas scrubbed free from corrosion:

Completed firewall:

As you can see, the POR15 finish looks very aluminium-like anyway, so I'm very very happy with the repair.

Next job will be to get the fuel lines and fuel tank back in hopefully later this week.... stay tuned

The fastener list is coming along and will be placing an order this week.

I've been working this weekend on the firewall. Lotus have specified me a fix which involves bonding on a reinforcement plate with epoxy over the worst of the corrosion as well as treating with ACF50 before reapplying the heat shield. They have ascertained that in my case there is no loss of structural integrity (in the scheme of things the corrosion damage is very very minor) but they are rather alarmed at the corrosion in this area as they've not seen it before, mainly due to the fact that very few cars have actually had their heat-shields removed for a look-see. Certainly if you're ever pulling the engine out of your Elise/Exige, I'd be stripping the heat-shield off for a good check-over as it could potentially end up in a VERY bad state if left unchecked.

Given the lack of structural damage and my desire to completely stop/prevent corrosion in this area I've basically done the same fix I did on my floorpans. I could go ahead with the Lotus fix, but I think my fix will be more comprehensive at solving the issue in my case.

I've scrubbed the firewall and wire-brushed / ground (with a dremel) out all of the corrosion/pitting from the firewall. The one through-hole I've drilled out with a 10mm drill (to remove all the active corrosion) and will be filling the hole with a blanking grommet. Given that the fuel lines exit just above this as well as another large blanking grommet (unused penetration) then this should look tidy when done.

I then went through the full three-step POR15 treatment (in silver) to clean, etch and coat/seal the firewall. The result has come out absolutely fantastic and I'm very pleased with it. As with the floorpans you can still see the pitting evident beneath the POR15 but I decided not to try filling these as I wanted the the POR to be in direct contact with the metal, providing the best corrosion protection. With filling there's always a risk that moisture can get trapped between the metal and the filler, allowing crevice corrosion to continue beneath the coating. Either way it looks ace and it'll be hidden anyway once the new heat-shield is affixed in place.

Firewall masked up with pitting and corrosion-affected areas scrubbed free from corrosion:

Completed firewall:

As you can see, the POR15 finish looks very aluminium-like anyway, so I'm very very happy with the repair.

Next job will be to get the fuel lines and fuel tank back in hopefully later this week.... stay tuned

Edited by Esprit on Sunday 7th December 12:43

Simon,

Wow, so it really does look like a common issue then. I'm surprised it's not more well-known (amongst the Lotus community, not necessarily with Lotus themselves). Certainly people like Chris Randall and yourself who have stripped a fair few chassis for racing have seen it a fair bit, but it's not really one of those things that people check.

All I know is that in future when buying an Elise (if I planned on keeping it for any length of time), at some stage I'd drop the engine and do the POR15 thing again because it's one of those things you want to sort out before it becomes too bad. Fingers crossed that threads like this one help raise awareness and propose viable solutions

Wow, so it really does look like a common issue then. I'm surprised it's not more well-known (amongst the Lotus community, not necessarily with Lotus themselves). Certainly people like Chris Randall and yourself who have stripped a fair few chassis for racing have seen it a fair bit, but it's not really one of those things that people check.

All I know is that in future when buying an Elise (if I planned on keeping it for any length of time), at some stage I'd drop the engine and do the POR15 thing again because it's one of those things you want to sort out before it becomes too bad. Fingers crossed that threads like this one help raise awareness and propose viable solutions

collieek said:

Not sure if I should have started reading this. I planned to refresh the suspension this year and then the engine next winter.

What make of paint is the POR 15 you are using it looks to do a good job. On one of the other threads someone asked for the preparation details did you post them?

Cheers

Paul

As Graham said, it's available from Frosts. It's made by a company called PPC over in Oz... it really is top stuff. The prep is fairly involved with the metal first needing a degrease/clean with their alkaline cleaner "marine clean" followed by an acid/phosphate etch with their "metal ready" To give you an idea, to clean, scrub, prep, etch , mask and double-coat the firewall was a full day's work to make a really good job of it... could do it much quicker but I'm not about cutting corners (as you might have guessed).What make of paint is the POR 15 you are using it looks to do a good job. On one of the other threads someone asked for the preparation details did you post them?

Cheers

Paul

All info (including instruction sheets on POR15) is available here: http://www.ppc.au.com/

The difference with POR15 compared with other paints/coatings is that it's 100% non-porous and moisture cure so it dries by sucking moisture out of the air and out of the metal's surface. This means that so long as it's not WET when you paint it on, once it's dry and sealed over with the POR15, no moisture can exist beneath the coating, even in the pores in sites of existing corrosion (which is why you can often paint over corrosion only to have it bubble the paint again in a year's time.

It's not as nice a coating (decorative wise) as a proper top-coat but if that's of concern to you you can treat POR15 like an undercoat and then paint over the top... but for chassis work like I'm using it before, the POR15 MORE than does the trick

Oh and Paul, please don't let this thread put you off doing a bit of a refresh yourself... just because I've decided to go to the nth degree on everything, doesn't mean that's what you'll need to do... I'm a near-perfectionist and it's a curse sometimes, much of the stuff I've done is WELL above and beyond what's necessary, but I do get some kind of perverse enjoyment out of it... doesn't stop me wanting it bloody finished though!

Edited by Esprit on Tuesday 9th December 03:20

Well another week, another update!

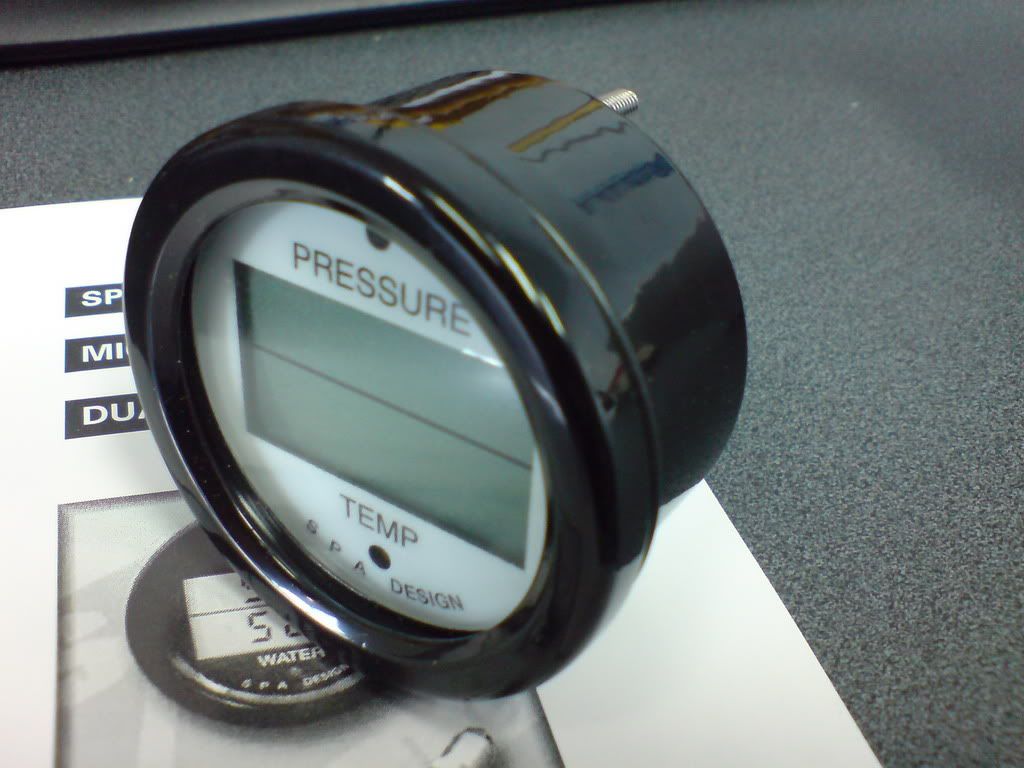

Decided this week to press on with a few other things and I've ordered a new oil pressure/temperature gauge. I've gone for the SPADesign dual temperature/pressure gauge as it seemed to be the pick of the bunch for quality and functionality in a single gauge. Part of me wanted to stick with an analogue gauge, but the SPA I was able to get external triggering and two-gauges-in-one functionality, so it won out.

She'll be like this one but with a white face to match the STACK dash cluster:

I will be mounting the gauge where the radio usually goes (I don't run a radio in the Exige) and I shall be making up a glassfibre replacement for the OEM blanking plate (in blue alcantara). Once this is made up I'll be upholstering it in the original alcantara so hopefully it'll all look like a factory-fitment when it's done.

This is where it all gets a bit crazy though. I was reading through the gauge specs and looking at the external warning triggering and I got to thinking about how I could best use this in the car. I sat down and made a plan of what I ideally wanted and how I wanted it to work. I wanted something that I could rely on on track (or on the road) to draw my attention as we all know gauges are only useful when you notice them! I decided on the following:

- Super-bright LED lights for both oil overtemperature and oil underpressure (Red for overtemp, White for underpress)

- Loud audible warning for both (constant-on for underpressure, 0.5s on, 4.5s off for overtemp)

- Audible warning to be latching (as in it'll stay on even if the oil pressure/temperature only briefly gets out-of-range)

- Audible warning to be silencable (much like a "snooze" button on a clock radio)

- All external warnings to be switchable (as in a toggle-switch overrride for all the external gubbins leaving only the gauge functioning)

- A little bit of intelligence built into the audible warning (so that the alarm doesn't go off as soon as you switch the key on before cranking the car as this would get annoying!)

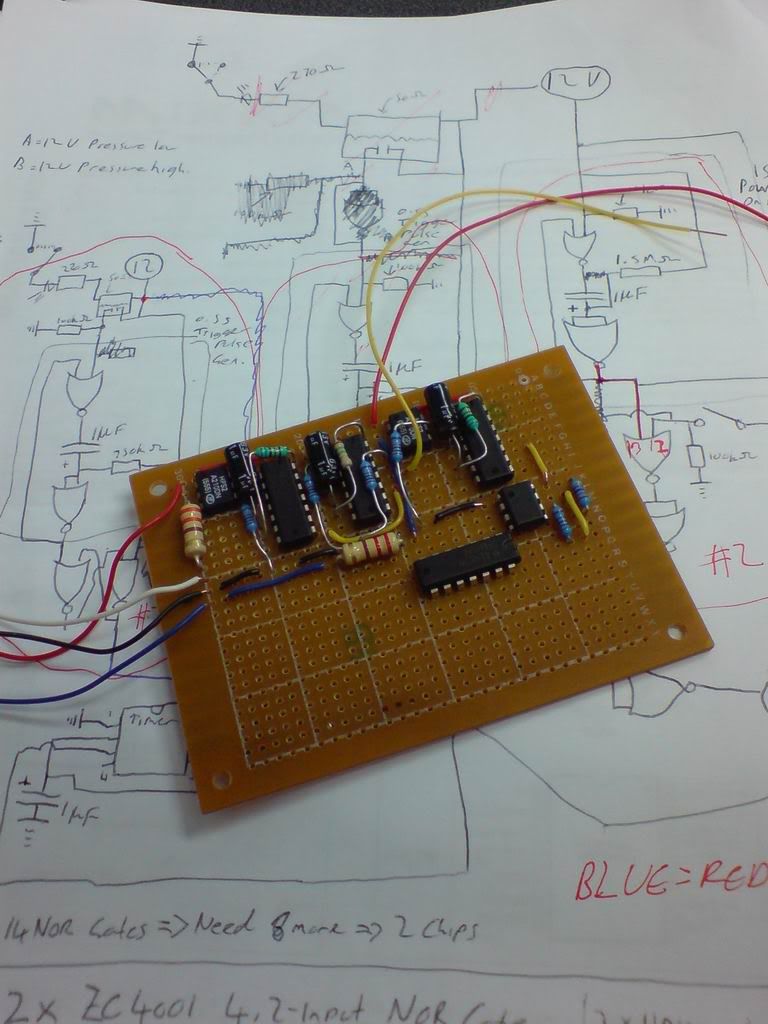

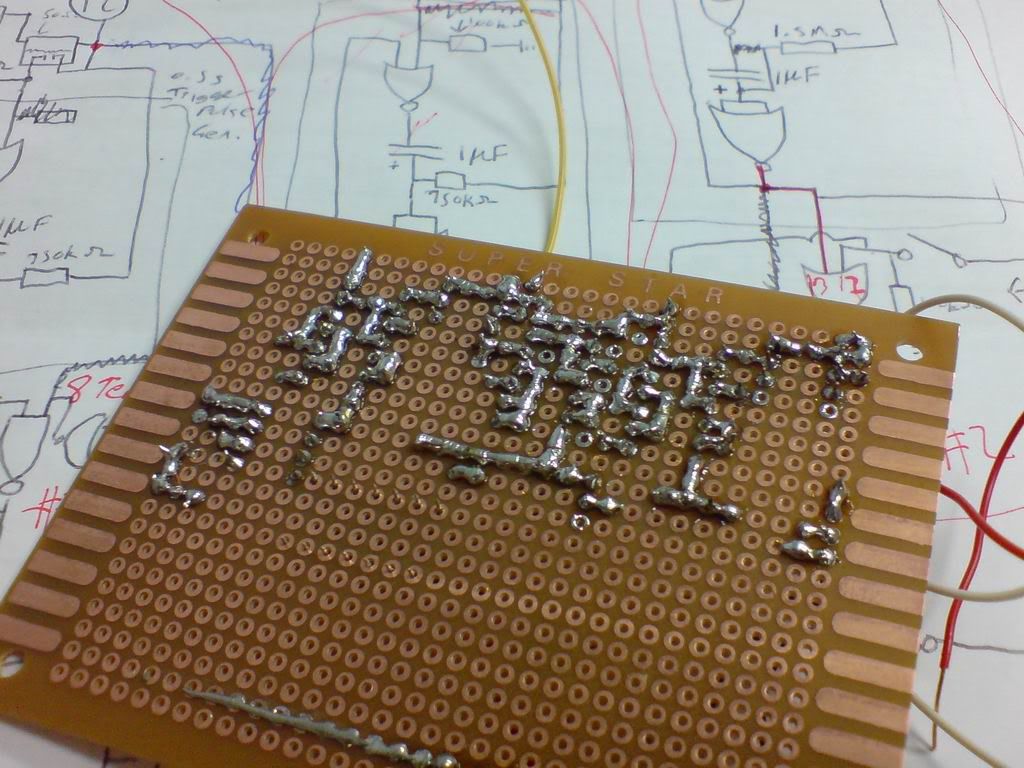

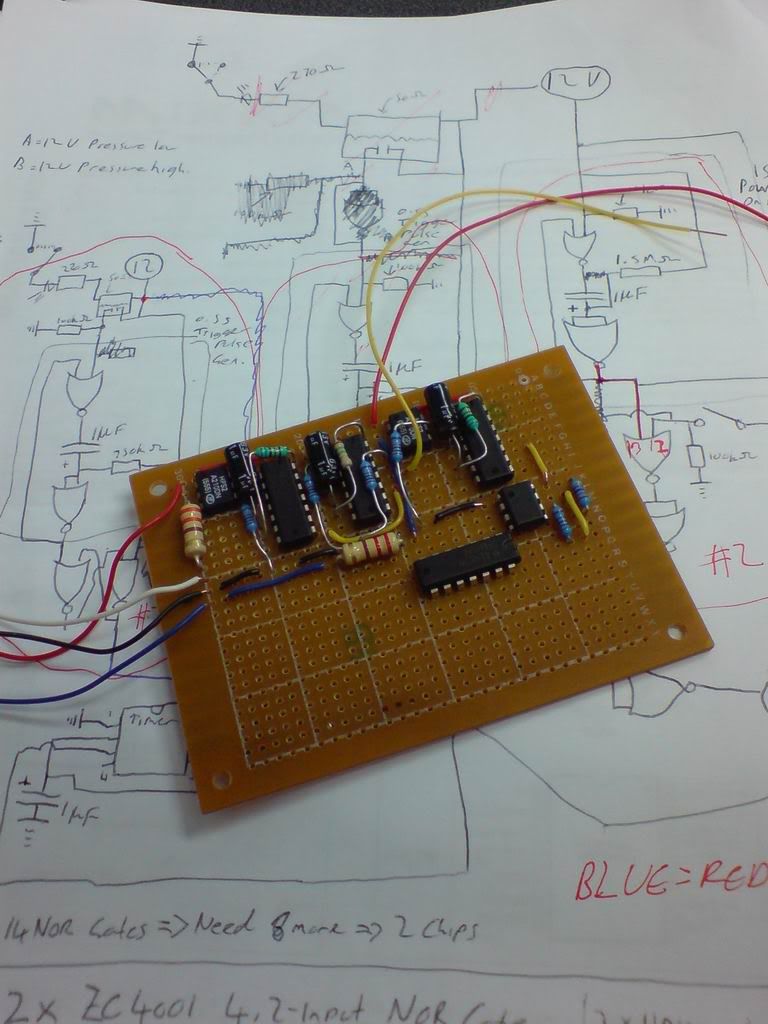

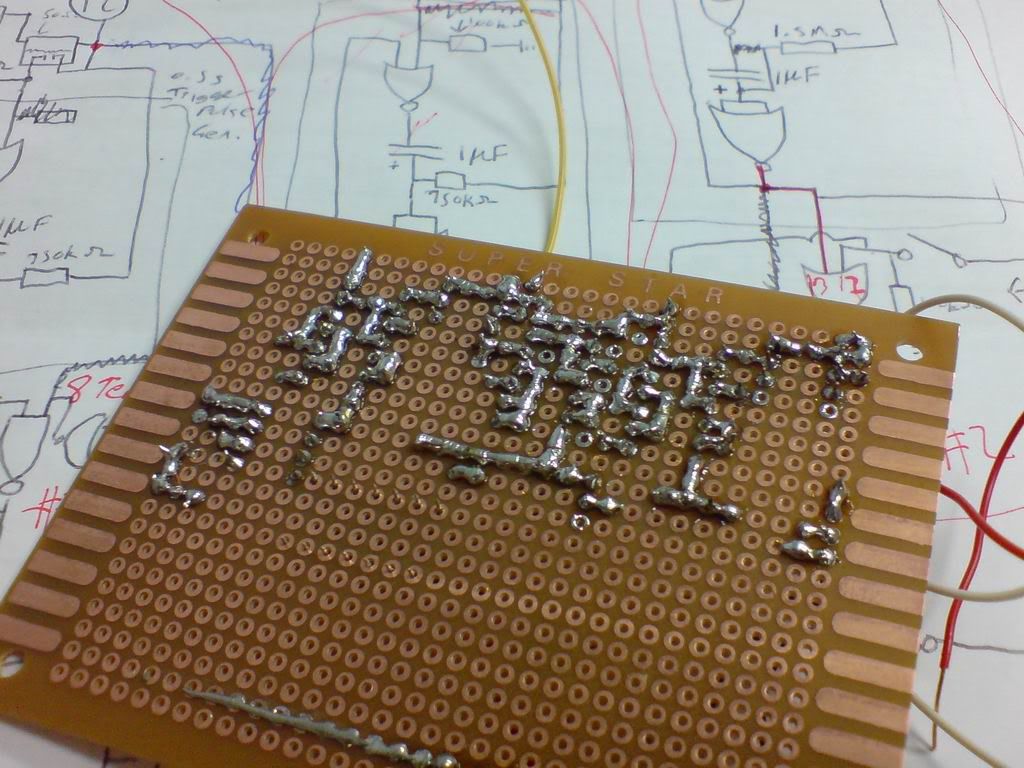

I then set about thinking about how to achieve all this and I thought back to my old varsity days and computer science papers and started to draw up a logic circuit using logic-gates. A couple of late evenings head-scratching got me a circuit that I was pretty happy with. A bit of binary mathematics showed that it should take care of every case I wanted to achieve so I then set about laying out an electrical diagram. This took another evening to get right, so the next day I went into Jaycar (electrical retailer over here in NZ) and bought up a bunch of circuit componentry.

I spent all afternoon with the soldering iron this evening and the circuit is now about 80% complete. I've tested subsections of this and so far, everything checks out well... impressive for a colour-blind, complete novice when it comes to electronics! Couple of photos that show the circuit in progress and also the fag-packet sketches I used to figure out what the hell I was doing! My soldering skills still leave a little to be desired though

Another evening I should have it done and tested.... it'll then be shelved for a bit while I make up the mounting panel (will begin in January). I just wanted to get the circuitry out of the way so that I knew it could be done (or more that I could do it, I'm sure anyone with half a brain when it comes to electronics could do it easier and far more elegantly than I've done). I've got all the push-buttons, LEDs and switches too and I forked out for high quality ones. I figured it'd be on-show, front-and-centre so I'd best try to make it look and feel as quality as I could get it!

And now for something a bit more special (but still very much relevant to the subject of the thread). Last night some friends and I all met up around Ian Wilson's (PHer iwilson) place for a BBQ and poker evening. Ian's always a great host and it's always fantastic to catch up with friends (most of them petrolheads!) in that environment, especially when I seem to spend all of my time either at work, in the gym or working on the car!

Anyway, during the evening I was called into the lounge whereupon I was sprung with what can only be described as one of the most fantastic surprises I've ever had in my life.

My friend Graham (PHer "Kiwi XTR2") had organised for Kylie (another PHer "Kylie") to paint a picture of SEXIGE. Kylie is a highly accomplished landscape artist (one of her many talents as she's pretty handy behind the wheel of her Esprit Sport350 too!) and has recently turned her hand to airbrushing. Graham had set it all up (so I understand) and between the two of them they'd seen it through to what can only be described as an utterly amazing conclusion. I suspected nothing and they sprung me good and proper... I was totally speechless and very, VERY humbled.

It seems that Graham had grown tired of all my moaning about how long this project was taking and about how it had ballooned out of all sensible proportion... all I can say is what a fantastic way to shut me up! The picture is about a metre across by about 700mm high so it's a big-un! I'll be hanging it after Christmas as a reminder and an inspiration as to what I'm toiling towards. Apologies for the photo quality as I've not had a chance to photograph it in good light yet but it gives an idea. The detail Kylie has reproduced is stunning and it captures the attitude of the car brilliantly. Compare with the original photo in the first post in the thread and you'll agree she's made a wonderful, wonderful job of it.

Right, I'll stop rambling on now as that's enough for one night I think. But I'll just finish off by saying that quite apart from the tangible pleasures that Lotus ownership brings, the friends I've made over the last 3.5 years of ownership (both Lotus owners and otherwise, through trackdays with owners of many different marques) is WELL worth the price of admission on its own. I live and breathe these little glued-together cars from Norfolk and many of my friends share this passion with their own cars (whatever the badge) and it's my experience that surrounding yourself with these kinds of people truly enriches one's life.

So to all of you who I've met; either online here or in person, whether we've known each other for years or we've spoken just once, to each and every one of you I thank you from the bottom of my heart for making me a very happy person... I'm one lucky sonofab h!

h!

And to Graham and Kylie, again I thank you... I shall never forget this!

Decided this week to press on with a few other things and I've ordered a new oil pressure/temperature gauge. I've gone for the SPADesign dual temperature/pressure gauge as it seemed to be the pick of the bunch for quality and functionality in a single gauge. Part of me wanted to stick with an analogue gauge, but the SPA I was able to get external triggering and two-gauges-in-one functionality, so it won out.

She'll be like this one but with a white face to match the STACK dash cluster:

I will be mounting the gauge where the radio usually goes (I don't run a radio in the Exige) and I shall be making up a glassfibre replacement for the OEM blanking plate (in blue alcantara). Once this is made up I'll be upholstering it in the original alcantara so hopefully it'll all look like a factory-fitment when it's done.

This is where it all gets a bit crazy though. I was reading through the gauge specs and looking at the external warning triggering and I got to thinking about how I could best use this in the car. I sat down and made a plan of what I ideally wanted and how I wanted it to work. I wanted something that I could rely on on track (or on the road) to draw my attention as we all know gauges are only useful when you notice them! I decided on the following:

- Super-bright LED lights for both oil overtemperature and oil underpressure (Red for overtemp, White for underpress)

- Loud audible warning for both (constant-on for underpressure, 0.5s on, 4.5s off for overtemp)

- Audible warning to be latching (as in it'll stay on even if the oil pressure/temperature only briefly gets out-of-range)

- Audible warning to be silencable (much like a "snooze" button on a clock radio)

- All external warnings to be switchable (as in a toggle-switch overrride for all the external gubbins leaving only the gauge functioning)

- A little bit of intelligence built into the audible warning (so that the alarm doesn't go off as soon as you switch the key on before cranking the car as this would get annoying!)

I then set about thinking about how to achieve all this and I thought back to my old varsity days and computer science papers and started to draw up a logic circuit using logic-gates. A couple of late evenings head-scratching got me a circuit that I was pretty happy with. A bit of binary mathematics showed that it should take care of every case I wanted to achieve so I then set about laying out an electrical diagram. This took another evening to get right, so the next day I went into Jaycar (electrical retailer over here in NZ) and bought up a bunch of circuit componentry.

I spent all afternoon with the soldering iron this evening and the circuit is now about 80% complete. I've tested subsections of this and so far, everything checks out well... impressive for a colour-blind, complete novice when it comes to electronics! Couple of photos that show the circuit in progress and also the fag-packet sketches I used to figure out what the hell I was doing! My soldering skills still leave a little to be desired though

Another evening I should have it done and tested.... it'll then be shelved for a bit while I make up the mounting panel (will begin in January). I just wanted to get the circuitry out of the way so that I knew it could be done (or more that I could do it, I'm sure anyone with half a brain when it comes to electronics could do it easier and far more elegantly than I've done). I've got all the push-buttons, LEDs and switches too and I forked out for high quality ones. I figured it'd be on-show, front-and-centre so I'd best try to make it look and feel as quality as I could get it!

And now for something a bit more special (but still very much relevant to the subject of the thread). Last night some friends and I all met up around Ian Wilson's (PHer iwilson) place for a BBQ and poker evening. Ian's always a great host and it's always fantastic to catch up with friends (most of them petrolheads!) in that environment, especially when I seem to spend all of my time either at work, in the gym or working on the car!

Anyway, during the evening I was called into the lounge whereupon I was sprung with what can only be described as one of the most fantastic surprises I've ever had in my life.

My friend Graham (PHer "Kiwi XTR2") had organised for Kylie (another PHer "Kylie") to paint a picture of SEXIGE. Kylie is a highly accomplished landscape artist (one of her many talents as she's pretty handy behind the wheel of her Esprit Sport350 too!) and has recently turned her hand to airbrushing. Graham had set it all up (so I understand) and between the two of them they'd seen it through to what can only be described as an utterly amazing conclusion. I suspected nothing and they sprung me good and proper... I was totally speechless and very, VERY humbled.

It seems that Graham had grown tired of all my moaning about how long this project was taking and about how it had ballooned out of all sensible proportion... all I can say is what a fantastic way to shut me up! The picture is about a metre across by about 700mm high so it's a big-un! I'll be hanging it after Christmas as a reminder and an inspiration as to what I'm toiling towards. Apologies for the photo quality as I've not had a chance to photograph it in good light yet but it gives an idea. The detail Kylie has reproduced is stunning and it captures the attitude of the car brilliantly. Compare with the original photo in the first post in the thread and you'll agree she's made a wonderful, wonderful job of it.

Right, I'll stop rambling on now as that's enough for one night I think. But I'll just finish off by saying that quite apart from the tangible pleasures that Lotus ownership brings, the friends I've made over the last 3.5 years of ownership (both Lotus owners and otherwise, through trackdays with owners of many different marques) is WELL worth the price of admission on its own. I live and breathe these little glued-together cars from Norfolk and many of my friends share this passion with their own cars (whatever the badge) and it's my experience that surrounding yourself with these kinds of people truly enriches one's life.

So to all of you who I've met; either online here or in person, whether we've known each other for years or we've spoken just once, to each and every one of you I thank you from the bottom of my heart for making me a very happy person... I'm one lucky sonofab

h!

h!And to Graham and Kylie, again I thank you... I shall never forget this!

Edited by Esprit on Sunday 14th December 12:11

bencollins said:

If i might make a suggestion, the blanking panel could be cardboard if you are covering it with Alcantara. Messing about with GRP is just that, messy. Have worked on full cardboard chassis (model) builds which held the engine ok (statically!), so if you perforate/slit it, fold it, pin it and glue it right, it is very strong, you can even make furniture with card etc. The gauge looks spot on.

Thanks Ben, I'll bear it in mind. I'll certainly be making the initial template in cardboard anyway if nothing else.I've not moulded parts in GRP since my uni days so I really should to get my eye back in. I should also be able to build a lot of stiffness into the shape as well so I should be able to use a pretty thin laminate.

SimJen said:

lucky man!

thats one nice picture, Kylie is very talented by the look of that.

not sure my missus would let me hang a painting of the Seven in the house though, would clash with her decor!!

did Kylie happen to mention how much she would charge for such a painting?

Thankfully I'm still flatting then and have no missus thats one nice picture, Kylie is very talented by the look of that.

not sure my missus would let me hang a painting of the Seven in the house though, would clash with her decor!!

did Kylie happen to mention how much she would charge for such a painting?

Kylie I'm sure would be most welcome to discuss costs etc. She's on here (Username = Kylie, funnily enough) and she's a bigger petrolhead than most blokes I know put together so she's always up for a bit of Lotus chat

Well, another update:

Not a whoole lot of progress of late as I've actually been rather sick this last week or two. I've had a stomach bug that this week turned into a killer virus from 'nam meaning I couldn't eat or drink much and you could have fried eggs on my forehead with the fevers I've been getting. Still, the show must go on and I'm happy to report some very minor progress.

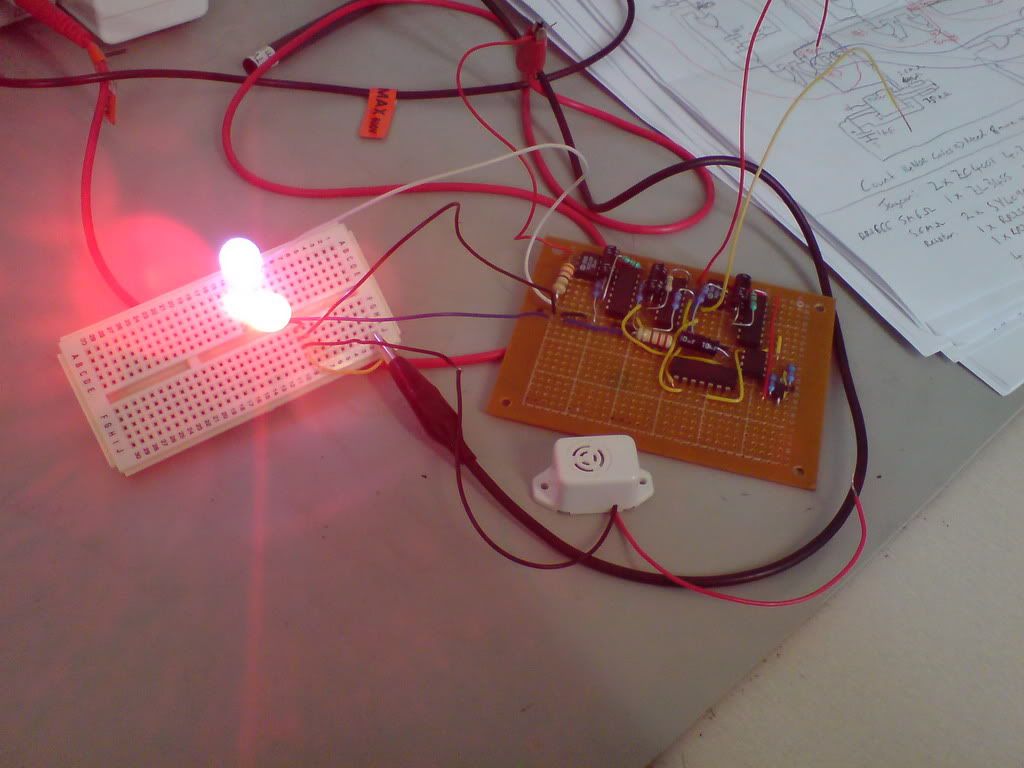

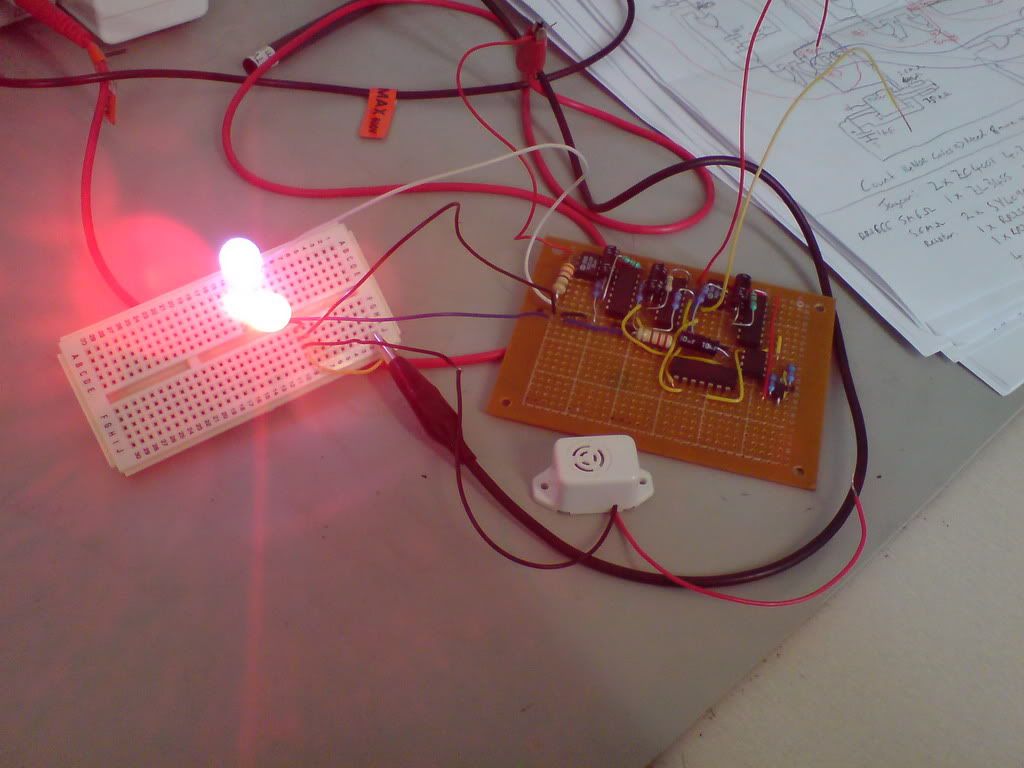

After a LOT of faffing about, I've finally completed my oil temp/press warning circuit. I've no pictures as of yet but the circuit board is now looking a lot more messy but basically the same. It's taken me MUCH more work than I'd originally anticipated (doesn't it always?!?!)... not helped by manufacturers putting misprints in their datasheets causing me to have to do stuff three times, only to find they STILL don't work before questioning the datasheets and finding that they're wrong. Good news is that I managed to get to the bottom of it in the end and after about 4 trips back to Jaycar to get bits and pieces to modify the circuit, I'm happy to report it works EXACTLY as I'd laid out in last week's update!

I'm very proud/happy with this since I'm a complete and utter novice when it comes to electronics (at least I can claim to be a spirited amateur on the mechanical side of things!) and just through using my head and doing some study, I've built a pretty comprehensive little digital logic circuit to control everything... it's pretty simple in the global scheme of things but for something like this it's actually got a fair bit of smarts to it

I've also picked up my nicely ground flywheel ready to pack up and ship off to the UK with my pulleys, clutch cover, head etc. This now looks really pretty and will mean that when the new clutch is put in prior to the engine going back in, it'll have the best possible surface to bed into meaning the slippage issues I had with my last clutch shouldn't re-emerge, even if it is dealing with another 30-40bhp than it was before.

Good times.

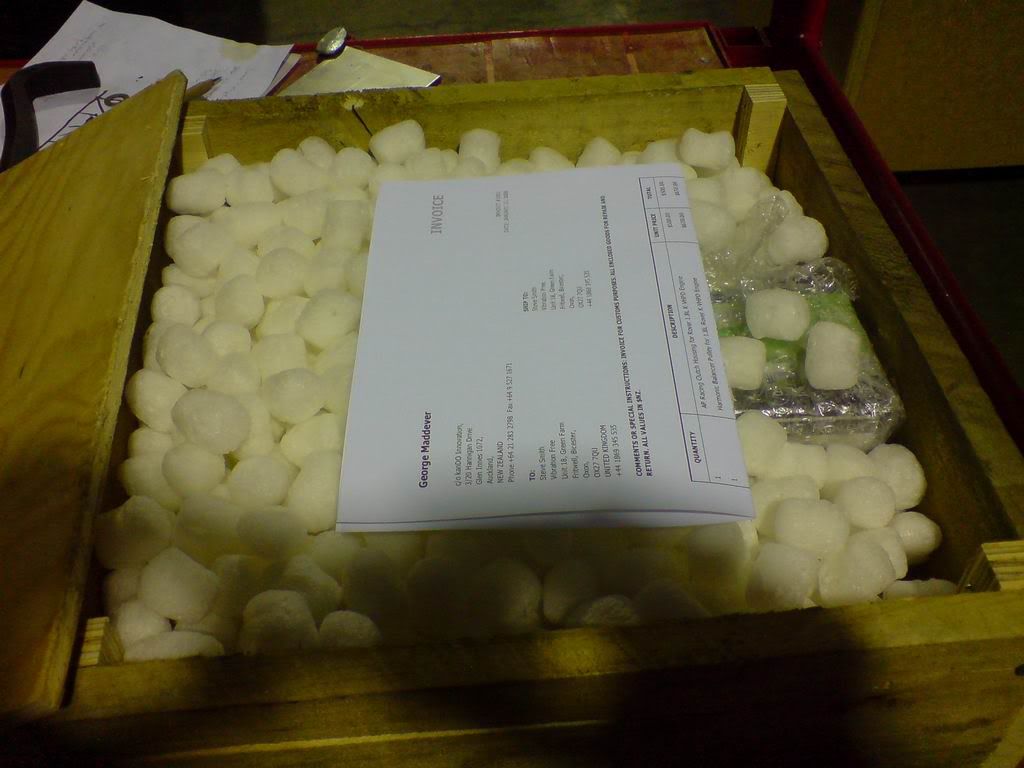

This week I'm just crating my stuff up to send back to the UK and will be taking a break for a week or two over Christmas down-country so there won't be much action. I am going to take some work away with me though and am going to set to work making up the wooden "plug" for making the fibreglass mould for my dashboard gauge-pod. This should keep me busy and allow me to start glassing early in January. I'll also contact the Lotus Trim Shop and see if they can't track me down some of the original Blue alcantara so that when the time comes, I can upholster the gauge pod and make it look just like it came from the factory!

Onwards and upwards (hopefully with less viral infestations!)

Not a whoole lot of progress of late as I've actually been rather sick this last week or two. I've had a stomach bug that this week turned into a killer virus from 'nam meaning I couldn't eat or drink much and you could have fried eggs on my forehead with the fevers I've been getting. Still, the show must go on and I'm happy to report some very minor progress.

After a LOT of faffing about, I've finally completed my oil temp/press warning circuit. I've no pictures as of yet but the circuit board is now looking a lot more messy but basically the same. It's taken me MUCH more work than I'd originally anticipated (doesn't it always?!?!)... not helped by manufacturers putting misprints in their datasheets causing me to have to do stuff three times, only to find they STILL don't work before questioning the datasheets and finding that they're wrong. Good news is that I managed to get to the bottom of it in the end and after about 4 trips back to Jaycar to get bits and pieces to modify the circuit, I'm happy to report it works EXACTLY as I'd laid out in last week's update!

I'm very proud/happy with this since I'm a complete and utter novice when it comes to electronics (at least I can claim to be a spirited amateur on the mechanical side of things!) and just through using my head and doing some study, I've built a pretty comprehensive little digital logic circuit to control everything... it's pretty simple in the global scheme of things but for something like this it's actually got a fair bit of smarts to it

I've also picked up my nicely ground flywheel ready to pack up and ship off to the UK with my pulleys, clutch cover, head etc. This now looks really pretty and will mean that when the new clutch is put in prior to the engine going back in, it'll have the best possible surface to bed into meaning the slippage issues I had with my last clutch shouldn't re-emerge, even if it is dealing with another 30-40bhp than it was before.

Good times.

This week I'm just crating my stuff up to send back to the UK and will be taking a break for a week or two over Christmas down-country so there won't be much action. I am going to take some work away with me though and am going to set to work making up the wooden "plug" for making the fibreglass mould for my dashboard gauge-pod. This should keep me busy and allow me to start glassing early in January. I'll also contact the Lotus Trim Shop and see if they can't track me down some of the original Blue alcantara so that when the time comes, I can upholster the gauge pod and make it look just like it came from the factory!

Onwards and upwards (hopefully with less viral infestations!)

Edited by Esprit on Sunday 21st December 12:28

Here's a pic showing the finished circuit on benchtest. The two LEDs are both illuminated. One is white and the other red but they are so bright they overexpose the camera here so they both look white. You can also see the buzzer. I may opt for a louder unit but will trial this one in the car and see how I get on, it's an easy retrofit. The circuit borard will be trimmed of its excess and then mounted on the back of the gauge mounting plinth. It'll then be wired into the switches/LEDs.

Also here's my flywheel/clutch cover/front pulleys ready to set flight to the UK for balancing at Vibration Free. Flywheel's been ground and I've also machined off the redundant front pulley boss off the alternator pulley/harmonic balancer. The elastomeric balancer will be retained. I've given the pulley a coat of black POR15 to make it look not quite so crap once it's bolted back on the engine

Also here's my flywheel/clutch cover/front pulleys ready to set flight to the UK for balancing at Vibration Free. Flywheel's been ground and I've also machined off the redundant front pulley boss off the alternator pulley/harmonic balancer. The elastomeric balancer will be retained. I've given the pulley a coat of black POR15 to make it look not quite so crap once it's bolted back on the engine

Not a WHOOOLE lot has gone on of late, I've been busy organising stuff.

Late last week I bought my nice shiny new Arrow rods and these are about to be shipped for balancing... works of art they are (pic stolen from mikelr because I've obviously not got them with me!

(pic stolen from mikelr because I've obviously not got them with me!  )

)

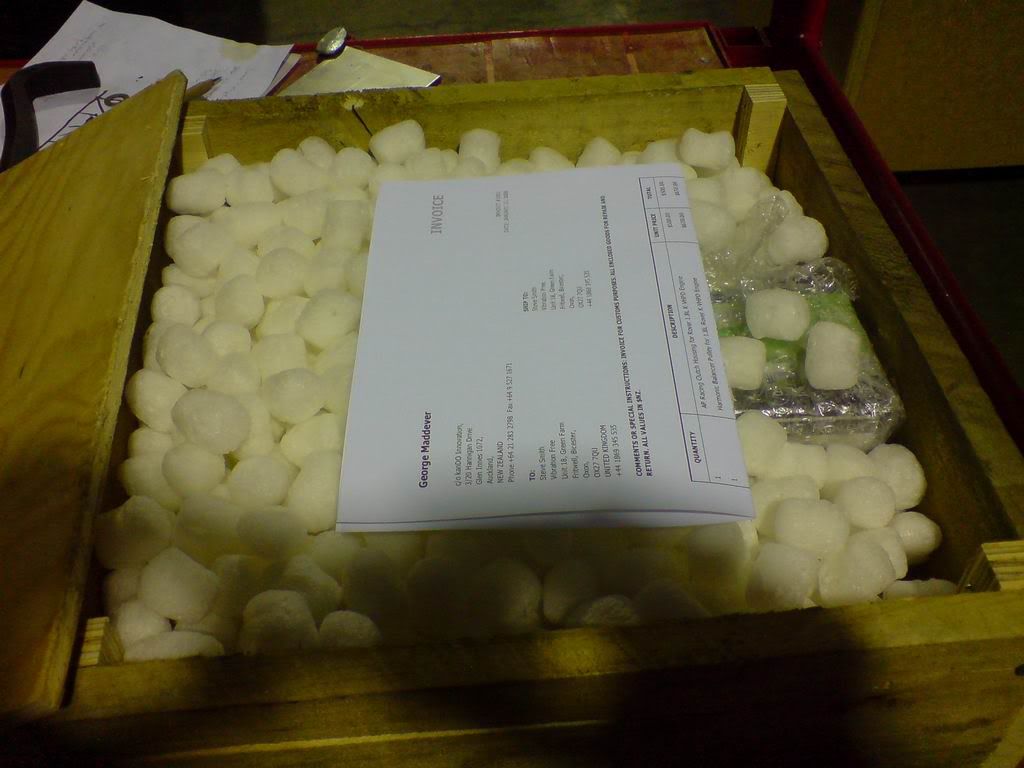

I've just tonight finished crating up my clutch cover, flywheel and pulleys to go to Vibration Free for balancing with my crank, as well as mycylinder head to get some nice DVAPower loving God speed my little mechanical componenty friends!

God speed my little mechanical componenty friends!

Late last week I bought my nice shiny new Arrow rods and these are about to be shipped for balancing... works of art they are

(pic stolen from mikelr because I've obviously not got them with me!

(pic stolen from mikelr because I've obviously not got them with me!  )

)

I've just tonight finished crating up my clutch cover, flywheel and pulleys to go to Vibration Free for balancing with my crank, as well as mycylinder head to get some nice DVAPower loving

God speed my little mechanical componenty friends!

God speed my little mechanical componenty friends!

Another small but significant step today... my alcantara for the dashboard gauge pod arrived today. I can now start doing the work to mould this piece up secure in the knowledge I can upholster it when done and get it looking nice  In the ziplok bag is also a couple of fresh snubber washers for my front suspension

In the ziplok bag is also a couple of fresh snubber washers for my front suspension

In the ziplok bag is also a couple of fresh snubber washers for my front suspension

In the ziplok bag is also a couple of fresh snubber washers for my front suspension

Gassing Station | Elise/Exige/Europa/340R | Top of Page | What's New | My Stuff