Unusual job on the bench today

Discussion

Oh you lucky people. 2 updates in a week

So, what do we have this time? A job that I enjoyed for a change, and one that I feel proud of and am sure the owner will appreciate. It's for the better half of a fellow PHer btw. As was mentioned before they came in to see me with children and crisps. The good lady had some white gold and diamond rings and wanted to melt them down to make something new. This was the (rough-ish) guide:

And here are the deconstructed rings we'll use:

The gold was melted and turned into a bar. I'm always a little wary melting white gold to use in a new item as it doesn't always produce a usable material. Often its brittle or porous, but in this case it melted fine and was only a little hard if anything:

The bar was rolled out a bit more and after bending it I cut it to roughly the length needed for the job. I'll mention now that this is one of my 'measure nothing' jobs and it's all done off the cuff, by eye:

This is where I make my one solitary solder on this job. The band is joined and then made round and to the correct size:

The ring will effectively be filed out of the solid band. It's not something I usually do but seeing as it's playing ball for now I would rather not be soldering this white metal too much. Also, any off cuts / filings will go against the cost of the job so the customer isn't out of pocket as a result. The filing begins with the shank:

Which progresses to making a rough head section:

With that done I mark out the centre and where the main diamond will sit. This will be the guide for everything around it:

The positioning of the adjacent stones is then marked and drilled:

These stones are slightly smaller.... so have smaller holes:

The ring was originally to have 3 main stones but the excess I left was too perfect to not incorporate another 2 to make 5. She agreed and hey presto:

Nice little test fit:

The mount is cleaned up ready for the next phase (at this point I'm thinking "s t, this might actually be quite good"):

t, this might actually be quite good"):

The next bit is to set the main diamonds. Middle first and then so on:

The shoulders are the next area to get stuck into. 12 small diamonds measuring 1.65mm each have either been selected from the stones in the pile or swapped with stones from the pile to make sure they all match: The total carat weight of all the stones is 0.80ct:

The spacing is marked out with a fine saw at 2.2mm approx:

And then with a 1mm drill I make the pilot holes. First one side then the next:

The holes are bored out to 1.5mm at half depth with another drill and then 1.6mm to the desired depth with a setters drill. I also cut the settings across the middle to make the claws:

Now it's time to start setting. Using a couple of graining tools the claws are pressed over the edges of the stones. 1.65mm stones are a snug fit in the 1.6mm holes but as gold is soft they go in with a light push:

Check size again:

And all set:

The sides are given a light file to bring the width in and the settings some definition:

With that done the ring is polished, cleaned in the ultrasonic and then rhodium plated. In my opinion it's one of the best jobs I've had this year and I really hope Rachael loves it:

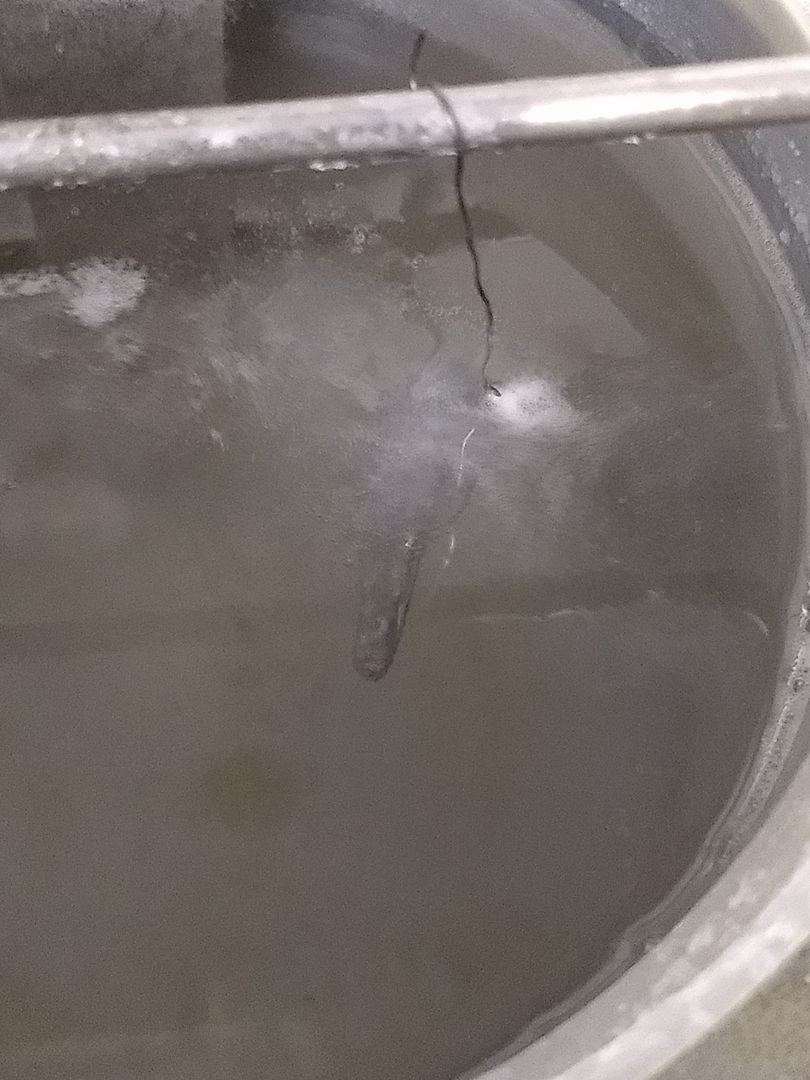

(salt cleaning bath)

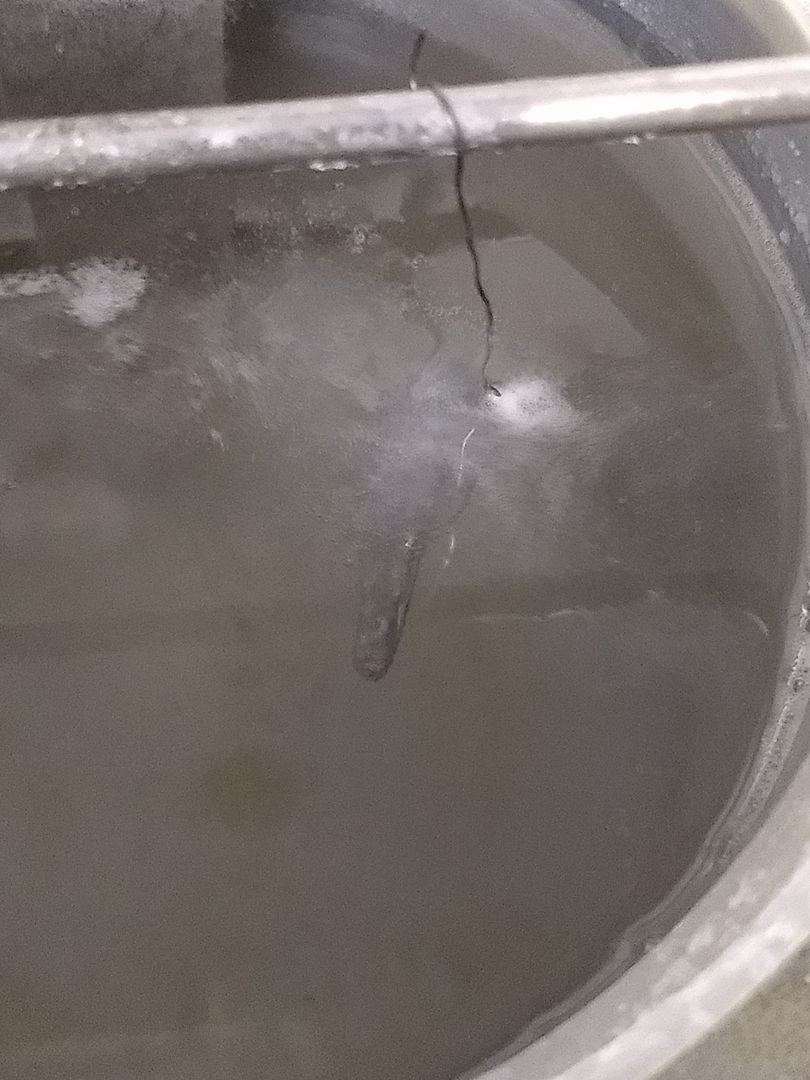

(rhodium plating bath)

So, what do we have this time? A job that I enjoyed for a change, and one that I feel proud of and am sure the owner will appreciate. It's for the better half of a fellow PHer btw. As was mentioned before they came in to see me with children and crisps. The good lady had some white gold and diamond rings and wanted to melt them down to make something new. This was the (rough-ish) guide:

And here are the deconstructed rings we'll use:

The gold was melted and turned into a bar. I'm always a little wary melting white gold to use in a new item as it doesn't always produce a usable material. Often its brittle or porous, but in this case it melted fine and was only a little hard if anything:

The bar was rolled out a bit more and after bending it I cut it to roughly the length needed for the job. I'll mention now that this is one of my 'measure nothing' jobs and it's all done off the cuff, by eye:

This is where I make my one solitary solder on this job. The band is joined and then made round and to the correct size:

The ring will effectively be filed out of the solid band. It's not something I usually do but seeing as it's playing ball for now I would rather not be soldering this white metal too much. Also, any off cuts / filings will go against the cost of the job so the customer isn't out of pocket as a result. The filing begins with the shank:

Which progresses to making a rough head section:

With that done I mark out the centre and where the main diamond will sit. This will be the guide for everything around it:

The positioning of the adjacent stones is then marked and drilled:

These stones are slightly smaller.... so have smaller holes:

The ring was originally to have 3 main stones but the excess I left was too perfect to not incorporate another 2 to make 5. She agreed and hey presto:

Nice little test fit:

The mount is cleaned up ready for the next phase (at this point I'm thinking "s

t, this might actually be quite good"):

t, this might actually be quite good"):

The next bit is to set the main diamonds. Middle first and then so on:

The shoulders are the next area to get stuck into. 12 small diamonds measuring 1.65mm each have either been selected from the stones in the pile or swapped with stones from the pile to make sure they all match: The total carat weight of all the stones is 0.80ct:

The spacing is marked out with a fine saw at 2.2mm approx:

And then with a 1mm drill I make the pilot holes. First one side then the next:

The holes are bored out to 1.5mm at half depth with another drill and then 1.6mm to the desired depth with a setters drill. I also cut the settings across the middle to make the claws:

Now it's time to start setting. Using a couple of graining tools the claws are pressed over the edges of the stones. 1.65mm stones are a snug fit in the 1.6mm holes but as gold is soft they go in with a light push:

Check size again:

And all set:

The sides are given a light file to bring the width in and the settings some definition:

With that done the ring is polished, cleaned in the ultrasonic and then rhodium plated. In my opinion it's one of the best jobs I've had this year and I really hope Rachael loves it:

(salt cleaning bath)

(rhodium plating bath)

NDA said:

Looks great....

I always love how your work seems, to the casual observer, to come together at the last minute!

Scrap

Scrap

Scrap with scratches

Scrap with scratches and holes...

POW!

Beautiful ring!

Amazing - I just don't have the dexterity and patience you have. Lovely stuff.

Possibly the best description of my job ever I always love how your work seems, to the casual observer, to come together at the last minute!

Scrap

Scrap

Scrap with scratches

Scrap with scratches and holes...

POW!

Beautiful ring!

Amazing - I just don't have the dexterity and patience you have. Lovely stuff.

ecain63 said:

Howdy

Just waved off the happy couple after making this shaped platinum band for them this morning (and supplying a gents platinum band)

Any questions on the processes just ask

As you can see, in the pic you have 3 items. The original engagement ring top left which I made last year. Top right is a new 5mm court shaped blank in platinum. Bottom is a 3mm square bar of platinum, which is what we'll spend most of our time on here,

Just have to say a massive thanks to Eddie. As those who have met him will know, not only is he massively skilled, but he also just the most lovely bloke. The now Mrs morgs (as of just over a week!) adores both her rings, so mission accomplished!

Just waved off the happy couple after making this shaped platinum band for them this morning (and supplying a gents platinum band)

Any questions on the processes just ask

As you can see, in the pic you have 3 items. The original engagement ring top left which I made last year. Top right is a new 5mm court shaped blank in platinum. Bottom is a 3mm square bar of platinum, which is what we'll spend most of our time on here,

It was a few hours journey (twice!) to see Eddie after some phone and email contact, but I can't overstate how worthwhile it is to make that journey if you're thinking about getting something made.

Cheers Eddie!

I've been following this thread for a while and I'm fascinated by the craftsmanship and skill on display.

Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

QuickQuack said:

I've been following this thread for a while and I'm fascinated by the craftsmanship and skill on display.

Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

Howdy. PM on here if you can. I'll get the email and then respond when I get 5 minutes Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

ecain63 said:

QuickQuack said:

I've been following this thread for a while and I'm fascinated by the craftsmanship and skill on display.

Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

Howdy. PM on here if you can. I'll get the email and then respond when I get 5 minutes Now that it's my turn to need a special item (for Mrs. QQ for a significant age birthday...), Eddie, is it best to email you on the address in your profile or send a pm via the forum?

I just wanted to thank all on PH for their support in 2018 and especially to all those who have put their faith in me and what I do. Have a great Christmas and a fantastic New Year. I'll be hard at it in the office over the weekend but will most likely update the thread in January. Regards,

Eddie

Eddie

Gassing Station | Watches | Top of Page | What's New | My Stuff