Unusual job on the bench today

Discussion

I bought an old pocket watch on eBay which was said to have been sat in a drawer for 30 years.

I took it apart, cleaned the parts, re-oiled it and simply refitted them, and sure enough the thing started working again. I felt like some sort of technological genius and began thinking about what I could use my new-found powers for.

And then I open this thread and see all of the genuinely amazing things E63 does. f k.

k.

I took it apart, cleaned the parts, re-oiled it and simply refitted them, and sure enough the thing started working again. I felt like some sort of technological genius and began thinking about what I could use my new-found powers for.

And then I open this thread and see all of the genuinely amazing things E63 does. f

k.

k. Sycamore said:

I bought an old pocket watch on eBay which was said to have been sat in a drawer for 30 years.

I took it apart, cleaned the parts, re-oiled it and simply refitted them, and sure enough the thing started working again. I felt like some sort of technological genius and began thinking about what I could use my new-found powers for.

And then I open this thread and see all of the genuinely amazing things E63 does. f k.

k.

Thank you for the compliment. Genuinely, thank you I took it apart, cleaned the parts, re-oiled it and simply refitted them, and sure enough the thing started working again. I felt like some sort of technological genius and began thinking about what I could use my new-found powers for.

And then I open this thread and see all of the genuinely amazing things E63 does. f

k.

k.

In all fairness, I'd not dare to dismantle the movement of a watch or clock for fear of cocking it up. To have managed to strip, clean, oil and reassemble a pocket watch that wasn't working for 30 years and then see it fire up in front of your eyes is something to be proud of. Especially with no training or experience. You really should have documented it for us to see. I'd have read it with great interest.

As above, today I finally got the bloody thing finished. Of all the jobs I've done i'd definitely say that this is one of my most technically challenging. 5 weeks on and off from start to finish.

Here's how it ended.....

The first link was at 90% complete the other day / yesterday. Today we start by putting the stones in the second link. It's not a straight forward job because the stones are all different shapes. The inner stone is a princess cut and the outer are a mix of rounds and baguettes. At 1.75mm they are not that big either so getting them to do what you want is pretty much impossible (especially after a bottle of beer because you've had another clear scan). The second link:

As the stones are set I also have to add solder or bits of gold to fill gaps. If the drill slips and makes the hole too big I can correct with the stone in place. Here we are in between setting and repairing. The woes of handmaking

And more soldering to adjust:

Finally all the stones are in. The claws get tidied up and the links are VERY CAREFULLY polished. After that the whole thing is rhodium plated:

I'm going to enjoy being paid for that one.

Here's how it ended.....

The first link was at 90% complete the other day / yesterday. Today we start by putting the stones in the second link. It's not a straight forward job because the stones are all different shapes. The inner stone is a princess cut and the outer are a mix of rounds and baguettes. At 1.75mm they are not that big either so getting them to do what you want is pretty much impossible (especially after a bottle of beer because you've had another clear scan). The second link:

As the stones are set I also have to add solder or bits of gold to fill gaps. If the drill slips and makes the hole too big I can correct with the stone in place. Here we are in between setting and repairing. The woes of handmaking

And more soldering to adjust:

Finally all the stones are in. The claws get tidied up and the links are VERY CAREFULLY polished. After that the whole thing is rhodium plated:

I'm going to enjoy being paid for that one.

Edited by ecain63 on Wednesday 16th August 18:05

ecain63 said:

As above, today I finally got the bloody thing finished. Of all the jobs I've done i'd definitely say that this is one of my most technically challenging. 5 weeks on and off from start to finish.

Here's how it ended.....

....(especially after a bottle of beer because you've had another clear scan)...

Firstly, many congratulations on the scan. I can only begin to imagine the mental anguish that comes with such a situation. Secondly, do you see such a job like the one above as more of a challenge or a chore? It sounds like you price it accordingly, which is entirely fair enough considering the outstanding quality of your work!Here's how it ended.....

....(especially after a bottle of beer because you've had another clear scan)...

CardShark said:

Firstly, many congratulations on the scan. I can only begin to imagine the mental anguish that comes with such a situation. Secondly, do you see such a job like the one above as more of a challenge or a chore? It sounds like you price it accordingly, which is entirely fair enough considering the outstanding quality of your work!

The challenge or chore thing comes down to how busy I am at the time. Unfortunately with this job it was taken in when I was particularly snowed under. We do 50+ smaller jobs per day anyway but of late I've had an abundance of commission pieces to do as well. No complaints, the new shop is doing well. As with any busy business, there are days when you're just have too much on and you have to either delay or turn down work. I did try to turn this one down but the customer was willing to pay whatever was necessary to get it done. No compromise! The bill is £1000 for this which is actually really not enough for the time taken, material and skills needed to complete to the standard the customer would expect. Ripping people off because I don't want to do a job is not where I put myself in the market.

Did I enjoy doing it? Not really. Did I enjoy the feeling of seeing it take shape and finally getting it done? Yes.

I do a lot of jobs like this, where the payment is in the satisfaction of completion rather than the doing.

Another little build today. Made this for one of the retailers I do repairs, alterations and creations for:

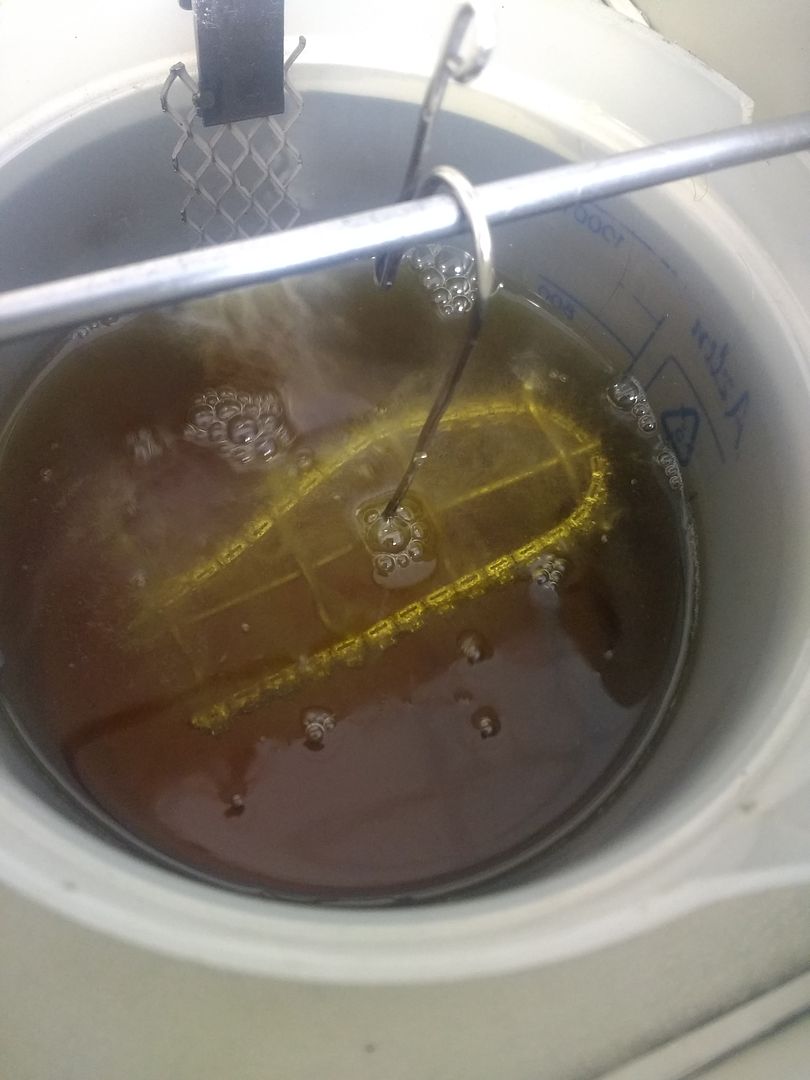

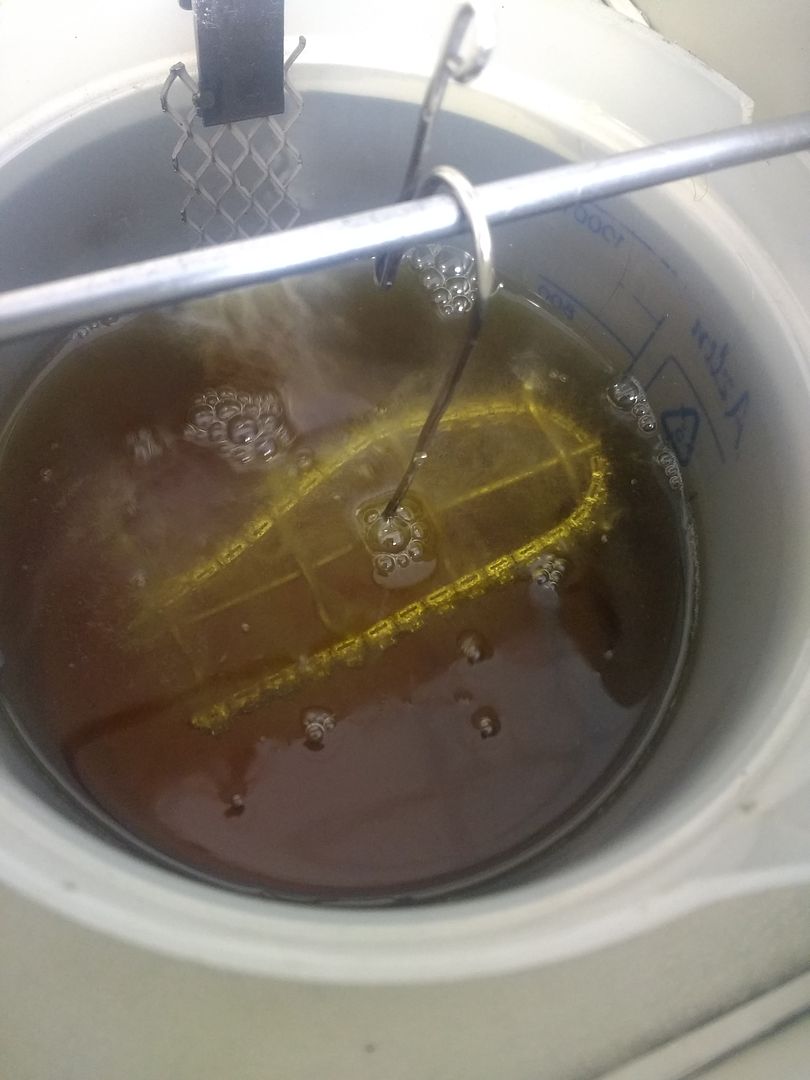

Customers own gold to be melted and a single 0.26ct diamond. We supplied the settings, 2 x 0.14ct diamonds and 3 x 0.9ct diamonds. The gold was a mix of 9ct yellow, 18ct yellow, 22ct yellow and a little bit of 9ct white. It all went together ok in the pot.

After the gold was melted I rolled and drew it down to a 2.25mm round wire.

With this I turned 3 x size T bands:

Making the settings is pretty easy. Using 9ct yellow gold tube of varying sizes we can make the correct settings for the stones. This is the tube for the 0.26ct diamond. The round groove cut in is for the band to be soldered into:

It's then cut down:

And the sides cut to accept the next band:

The same is then done for the 3.2mm 0.14ct stone settings:

And then the 2.9mm 0.9ct stone settings:

Here are the diamonds:

And then the setting:

With the stones set the metalwork is tidied up and readied for polishing. Once polished the rings are cleaned and hey presto:

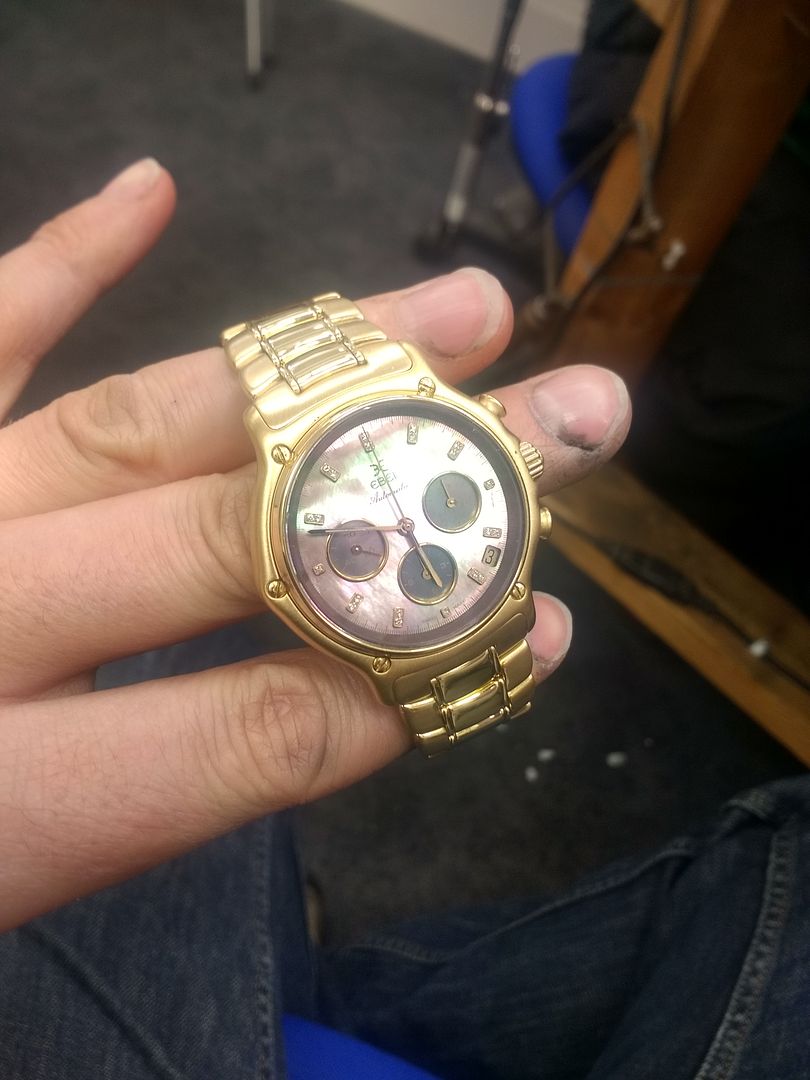

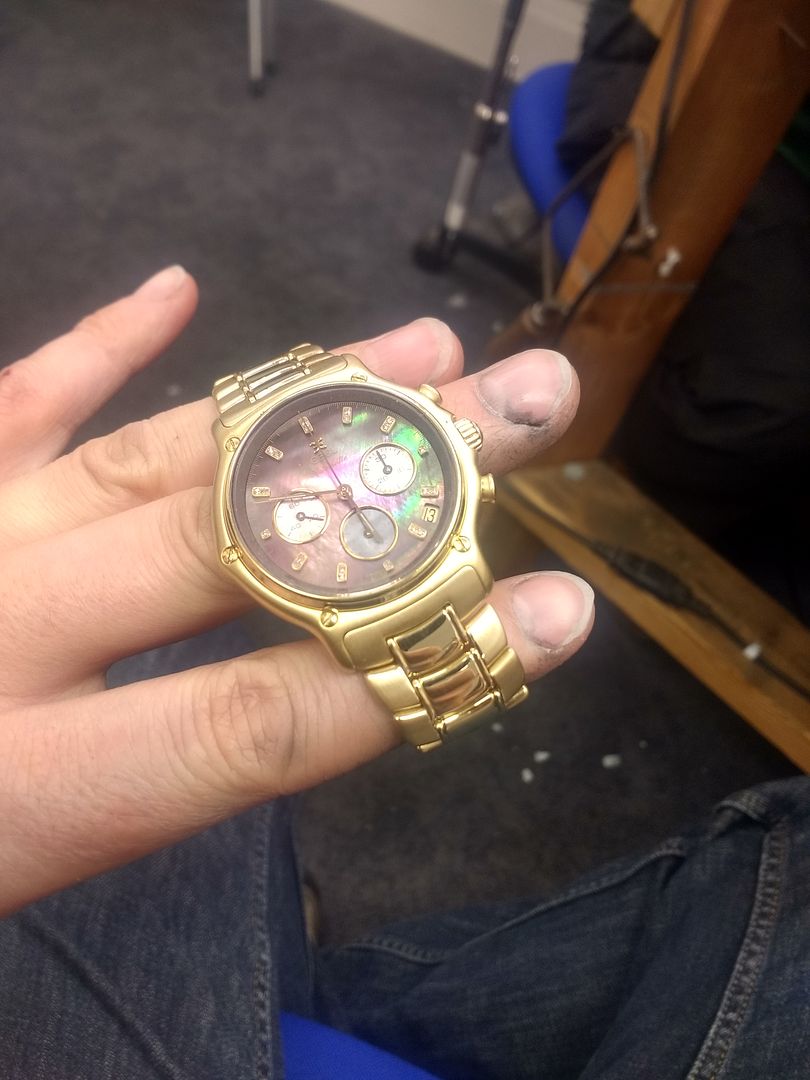

We've also had a couple of watches in for refurb:

Customers own gold to be melted and a single 0.26ct diamond. We supplied the settings, 2 x 0.14ct diamonds and 3 x 0.9ct diamonds. The gold was a mix of 9ct yellow, 18ct yellow, 22ct yellow and a little bit of 9ct white. It all went together ok in the pot.

After the gold was melted I rolled and drew it down to a 2.25mm round wire.

With this I turned 3 x size T bands:

Making the settings is pretty easy. Using 9ct yellow gold tube of varying sizes we can make the correct settings for the stones. This is the tube for the 0.26ct diamond. The round groove cut in is for the band to be soldered into:

It's then cut down:

And the sides cut to accept the next band:

The same is then done for the 3.2mm 0.14ct stone settings:

And then the 2.9mm 0.9ct stone settings:

Here are the diamonds:

And then the setting:

With the stones set the metalwork is tidied up and readied for polishing. Once polished the rings are cleaned and hey presto:

We've also had a couple of watches in for refurb:

Gassing Station | Watches | Top of Page | What's New | My Stuff