Unusual job on the bench today

Discussion

Blackpuddin said:

evoivboy said:

What a contrast in attitudes between the money-grubbing world of top-level football and the old boy liquidating his wife's jewellery for the benefit of a local childrens' charity. Well, he is alive and well..... just. Apparently his kids came over from Australia for Christmas and they all brought flu with them. The daughter went down on the 24th, the son on the 25th and Roy went down on the 26th. By his account he is lucky to be here after suffering a severe chest infection, a heart issue caused by the flu and chest, and a few days not of this earth due to fever and exhaustion. The guy likes his challenges!! (had polio as a child and was bed bound for 2 years, rescued his late wife from an awful childhood, went to Oz with less than nothing and pretty much single handedly built the textile and fabric industry that Australia and much of the world enjoys today).

Bit of a legend and I'm happy to say he's back on the childrens charity train as we speak.

ecain63 said:

evoivboy said:

ecain63 said:

I think maybe guilty by association?

yes maybe, shame as it's a work of artWhen she gets it does that mean she can't post pics on faceache etc?

(Haven't got a clue as to the item itself though.)

mikeveal said:

ecain63 said:

evoivboy said:

ecain63 said:

I think maybe guilty by association?

yes maybe, shame as it's a work of artWhen she gets it does that mean she can't post pics on faceache etc?

(Haven't got a clue as to the item itself though.)

As promised, the platinum 3 stone crossover that I made last week. The customer had her own stones from an existing yellow and white gold ring that just wasn't getting any air time. For those who might guess, the shank is an oversized cast item that I can modify to suit. Makes more sense sometimes than making my own. The rest of it (undersetting and claws) is all my own graft

Eddie

With the shank already formed for me i start by making the undersetting. This is constructed using a double tapered piece of platinum plate that matches the widths of the graduated stones:

With the stones in position (roughly) the shank is filed to the correct shape and taper as well being sized:

Stones secured:

Claws are then placed between each corner to stop the stones knocking together and chipping:

The claws are trimmed and rounded:

Old vs new:

Some polising later and it's done:

Eddie

With the shank already formed for me i start by making the undersetting. This is constructed using a double tapered piece of platinum plate that matches the widths of the graduated stones:

With the stones in position (roughly) the shank is filed to the correct shape and taper as well being sized:

Stones secured:

Claws are then placed between each corner to stop the stones knocking together and chipping:

The claws are trimmed and rounded:

Old vs new:

Some polising later and it's done:

As it's a watch forum........

2 watch refurbs we had in this week. The first is an 18ct and steel Omega Constellation. Just needed a spruce up. The Constellation case is an easy one to take apart so this part is a very quick job. The bracelet can be fully disassembled but with the right tools I can achieve a good two-tone finish with the links still pinned together. :

Stripped and ready for some TLC. You can see how heavily worn the bracelet is....

Now fully stripped and cleaned before the work begins:

Without revealing my secrets the parts are refinished and then washed and dried:

And reassembled:

The second watch is a ladies Steel and Diamond DateJust. As well as a refurb it also needs a diamond set in the bezel where one has fallen out:

With the bracelet removed I set the diamond and then polished the sides of the case. With that done the bracelet is fully polished and the two-tone finish applied:

Eddie

2 watch refurbs we had in this week. The first is an 18ct and steel Omega Constellation. Just needed a spruce up. The Constellation case is an easy one to take apart so this part is a very quick job. The bracelet can be fully disassembled but with the right tools I can achieve a good two-tone finish with the links still pinned together. :

Stripped and ready for some TLC. You can see how heavily worn the bracelet is....

Now fully stripped and cleaned before the work begins:

Without revealing my secrets the parts are refinished and then washed and dried:

And reassembled:

The second watch is a ladies Steel and Diamond DateJust. As well as a refurb it also needs a diamond set in the bezel where one has fallen out:

With the bracelet removed I set the diamond and then polished the sides of the case. With that done the bracelet is fully polished and the two-tone finish applied:

Eddie

Blackpuddin said:

The old watch is lovely.

Of all the metals, which is your favourite to work with?

In manufacturing I'd say platinum. You can work it hard and get away with intense heat without too much aggro. You have to be cautious when working with stone set items but in general it's a very compliant material..... but you can't easily melt it to reuse scrap. That's the only bad point.Of all the metals, which is your favourite to work with?

In repairs I'd say 18ct gold (all colours). Withstands a bit of heat without overheating and risking harder stones, is easily worked and easily polished.

Worst metals: silver is cheap and it's is low quality in nearly every way. Not my favourite and very difficult to earn money from.

Palladium is a trash metal and an absolute rip off. A pain to work with and embarrassing to talk about with customers who've been duped into buying it from the big highstreet stores.

9ct white. Cheap and poorly produced. Always gives unexpected problems when using heat.

NDA said:

How are those very small stones held in - such as on the bezel of a watch? They don't have claws (as far as I can see) and I doubt they're glued in. I guess they must be reasonably secure.

They are indeed held by claws. The type of claws are known as grains and are little nodules of metal that protrude from the main body and are pressed over the 4 corner edges of the stone. The stone is recessed into the bezel so that the grains can remain flush enough not to catch or look unsightly.ecain63 said:

In manufacturing I'd say platinum. You can work it hard and get away with intense heat without too much aggro. You have to be cautious when working with stone set items but in general it's a very compliant material..... but you can't easily melt it to reuse scrap. That's the only bad point.

My wife has a pair of platinum earings that she never wears - there's a lot of platinum in them (think Pirates)Is there no way they can be reworked into something more useable? (eg a ring or a pendant)

ecain63 said:

NDA said:

How are those very small stones held in - such as on the bezel of a watch? They don't have claws (as far as I can see) and I doubt they're glued in. I guess they must be reasonably secure.

They are indeed held by claws. The type of claws are known as grains and are little nodules of metal that protrude from the main body and are pressed over the 4 corner edges of the stone. The stone is recessed into the bezel so that the grains can remain flush enough not to catch or look unsightly.So you have eyes like a hawk then?

NDA said:

ecain63 said:

NDA said:

How are those very small stones held in - such as on the bezel of a watch? They don't have claws (as far as I can see) and I doubt they're glued in. I guess they must be reasonably secure.

They are indeed held by claws. The type of claws are known as grains and are little nodules of metal that protrude from the main body and are pressed over the 4 corner edges of the stone. The stone is recessed into the bezel so that the grains can remain flush enough not to catch or look unsightly.So you have eyes like a hawk then?

Good evening again....

One for a PH client this time. The couple came in with a single stone diamond ring (18ct with a 2.01ct diamond) that they wanted to be redesigned and remodelled to incorporate a pair of high quality sapphires. They came prepared with a clutch of drawings and I had ready 3 pairs of light to mid blue, AAA quality stones between 5mm and 5.5mm. They chose the lighter of the stones (5.5mm) and after some negotiation we decided upon a final design.

Here's how it went:

The 18ct white gold head / setting is separated from the 18ct yellow shank.

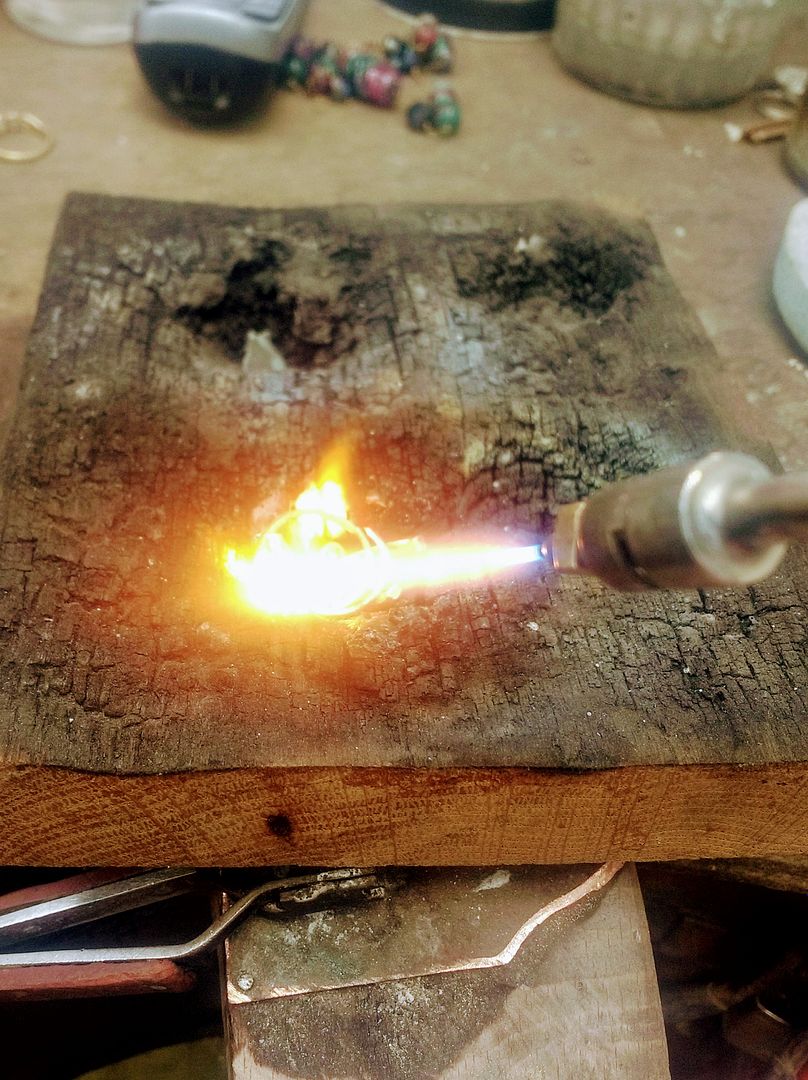

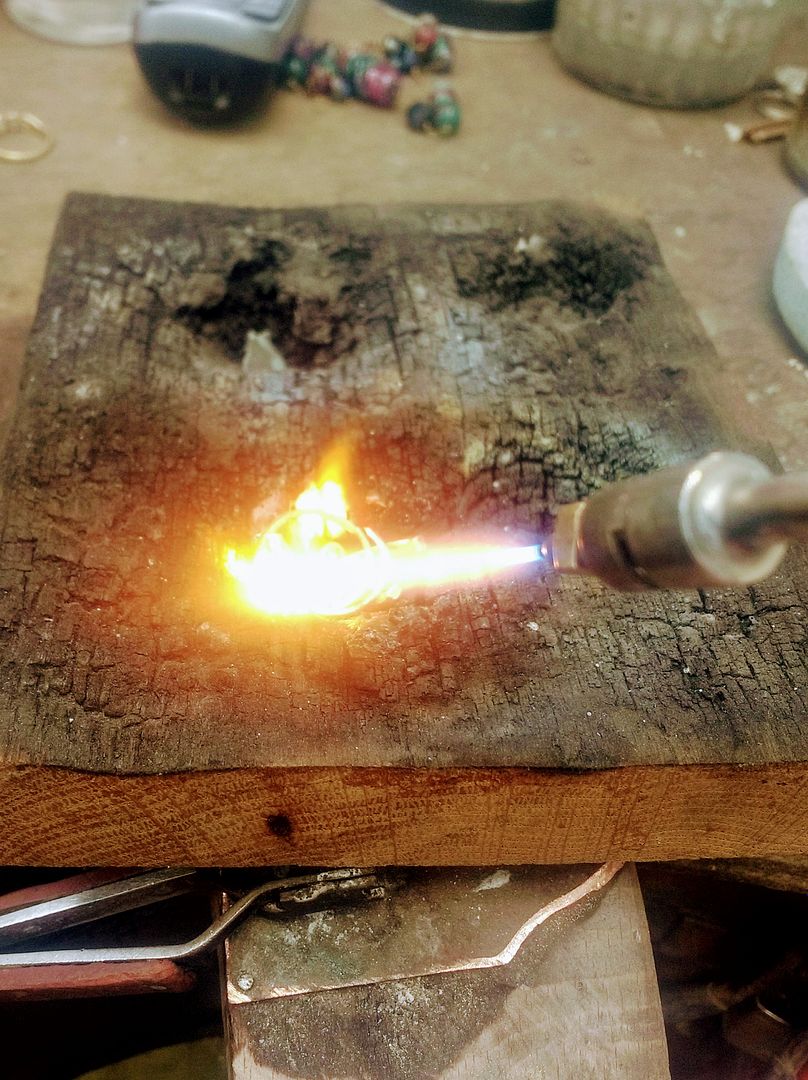

They wish the original shank to be used in the new mount so it is melted in with some 18ct yellow bullion to allow an excess during build.

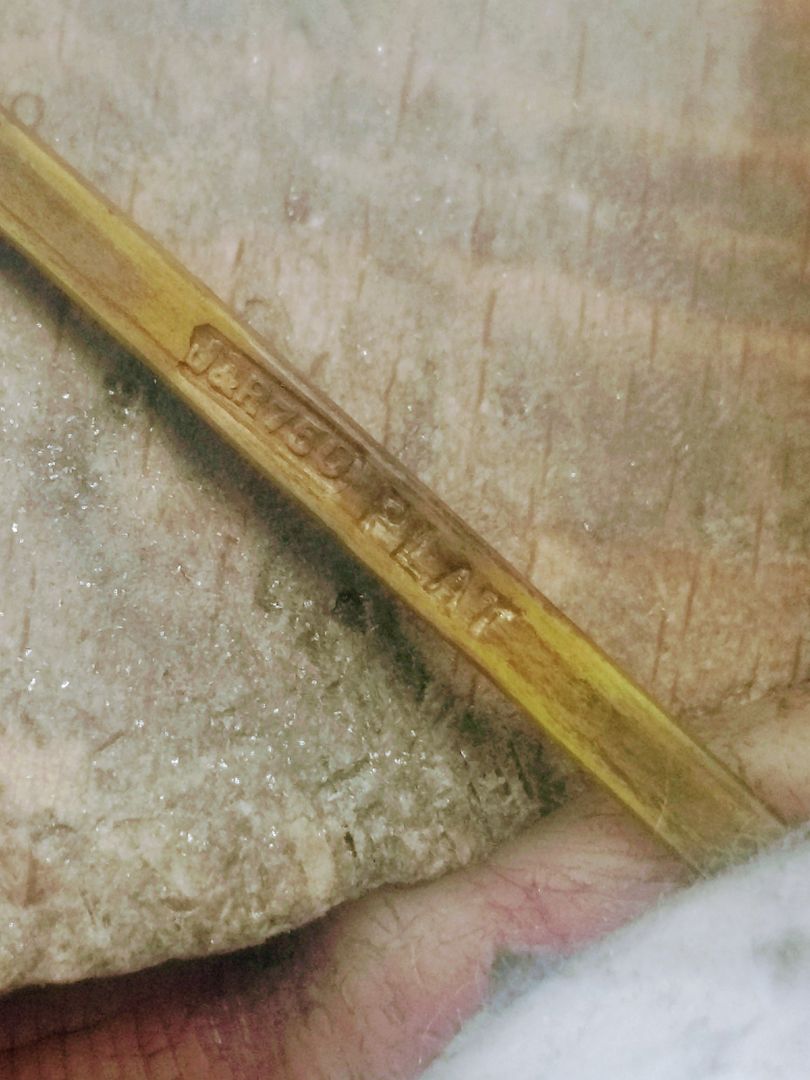

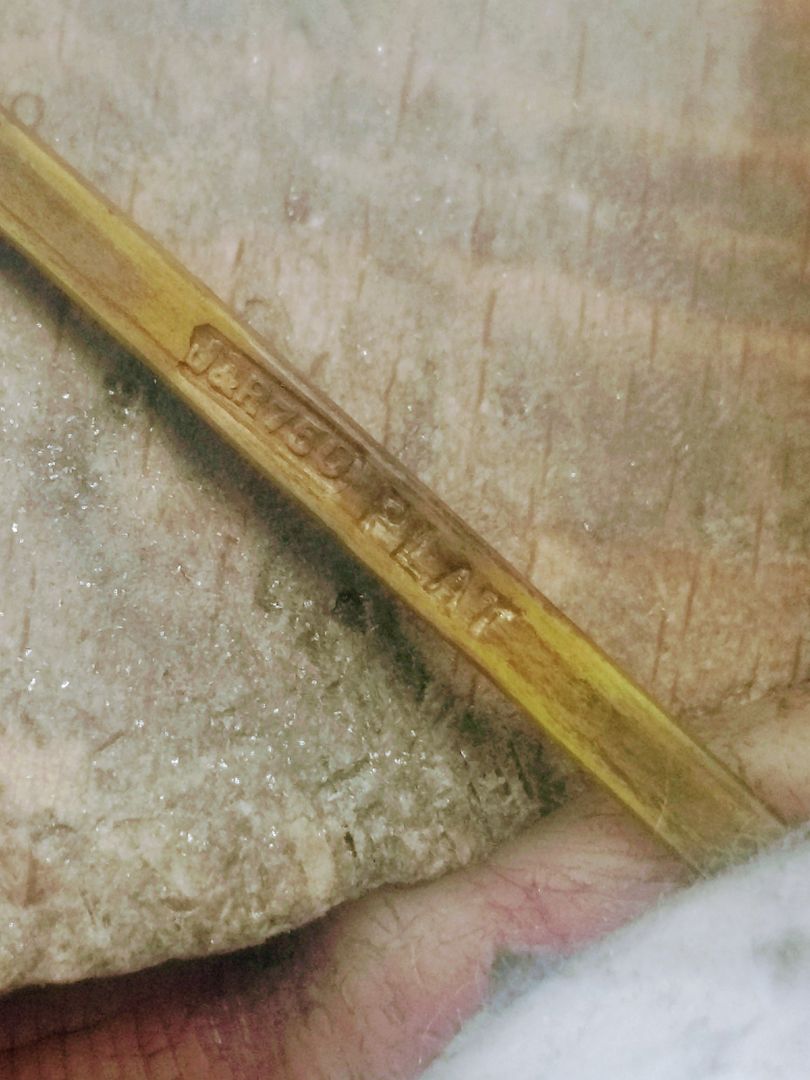

The new bar is rolled to 2.08mm square and then to 2.3mm x 1.75mm D-shape to form the new shank. This is then stamped at one end with the 18ct marking and a PLAT mark to show the material used for the top of the setting:

The top setting is a modified version of a ready made cast item. I could make this part from scratch but as it's on the shelf it pays to adjust what's readily available:

The customer wants an 18ct yellow undersetting that flowed in line with the shank. To start I have remelted an amount of the shank material and rolled it to a suitable width:

This is then turned to a shape that suits a size L finger:

The top setting is then soldered on with 18ct solder:

The undersetting is then shaped to suit. The stones are pretty big so the step from the wide setting to the narrower shank needs to be managed:

The setting is drilled........ and you can see it taking shape:

Now i make the shank. The required length is turned to match the size L head:

To make the split shoulders the ends are turned up and the underside of the shank is notched to fit the setting:

I've also made more of a flute in the end of the undersetting to allow it to marry up with the shank:

The parts are then cleaned in the 'pickle' before being soldered together with 18ct solder:

The mount is then tidied ready for a light polish. I'll do the setting work tomorrow, but the pics that follow give a rough idea of what it will look like:

More tomorrow I hope

One for a PH client this time. The couple came in with a single stone diamond ring (18ct with a 2.01ct diamond) that they wanted to be redesigned and remodelled to incorporate a pair of high quality sapphires. They came prepared with a clutch of drawings and I had ready 3 pairs of light to mid blue, AAA quality stones between 5mm and 5.5mm. They chose the lighter of the stones (5.5mm) and after some negotiation we decided upon a final design.

Here's how it went:

The 18ct white gold head / setting is separated from the 18ct yellow shank.

They wish the original shank to be used in the new mount so it is melted in with some 18ct yellow bullion to allow an excess during build.

The new bar is rolled to 2.08mm square and then to 2.3mm x 1.75mm D-shape to form the new shank. This is then stamped at one end with the 18ct marking and a PLAT mark to show the material used for the top of the setting:

The top setting is a modified version of a ready made cast item. I could make this part from scratch but as it's on the shelf it pays to adjust what's readily available:

The customer wants an 18ct yellow undersetting that flowed in line with the shank. To start I have remelted an amount of the shank material and rolled it to a suitable width:

This is then turned to a shape that suits a size L finger:

The top setting is then soldered on with 18ct solder:

The undersetting is then shaped to suit. The stones are pretty big so the step from the wide setting to the narrower shank needs to be managed:

The setting is drilled........ and you can see it taking shape:

Now i make the shank. The required length is turned to match the size L head:

To make the split shoulders the ends are turned up and the underside of the shank is notched to fit the setting:

I've also made more of a flute in the end of the undersetting to allow it to marry up with the shank:

The parts are then cleaned in the 'pickle' before being soldered together with 18ct solder:

The mount is then tidied ready for a light polish. I'll do the setting work tomorrow, but the pics that follow give a rough idea of what it will look like:

More tomorrow I hope

desolate said:

My wife has a pair of platinum earings that she never wears - there's a lot of platinum in them (think Pirates)

Is there no way they can be reworked into something more useable? (eg a ring or a pendant)

Sorry, didn't see this. It is possible, but depends on the metal after melting. It's not an easy material to recycle and takes a monumental amount of heat to convert to liquid form. Sometimes it's malleable enough to reform but often it becomes hard and brittle. Totally depends on what the metal has been mixed with and if any solder exists. Is there no way they can be reworked into something more useable? (eg a ring or a pendant)

ecain63 said:

Sorry, didn't see this. It is possible, but depends on the metal after melting. It's not an easy material to recycle and takes a monumental amount of heat to convert to liquid form. Sometimes it's malleable enough to reform but often it becomes hard and brittle. Totally depends on what the metal has been mixed with and if any solder exists.

Thanks.Sounds like it is high risk and one could end up with nothing.

However there's currently a few k of earing that hasn't seen the light of day for many a year.

NDA said:

Have you thought about being a hand model?

Assuming you haven't finished that ring, could you show how the claws are bent in such a way so that the stones are undamaged (by the bending) and tight in the setting?

I'll do a sequence of drawings later to show how it's done. You might not be able to see it in the job but on paper will be easy to understand and see.

Assuming you haven't finished that ring, could you show how the claws are bent in such a way so that the stones are undamaged (by the bending) and tight in the setting?

Gassing Station | Watches | Top of Page | What's New | My Stuff