Unusual job on the bench today

Discussion

Morning....

2 things........

1st thing: Scan results. Despite a little scare with my CT showing something on my liver again the MRI found it to be nothing more than scarring / fibrosis from the chemo. So, I'm all good and signed off until next year

2nd thing: My nurse specialist loved the SuperWoman badge I made her and now proudly sports it on her uniform. Happy days!

Back to the thread...... (edited to add comentary )

)

9ct rose gold heart pendent set with pink and yellow sapphires (and a diamond top and bottom) on a 9ct rose gold spiga chain. All to the customers spec.

So, we took a bar of 2.5mm d-shaped wire...

And bent one curved piece to make one half of a heart.

With that half we turned it back to front to make a mirrored version of the first.... and hey presto!

Which we then soldered.

The heart was then cleaned up and made ready for the next phase...

The off-cuts from the heart are remelted and from that we make some flat bar to use as a bail...

The bar is turned to the required profile and cut to length....

And filed to a V shape...

The manufacturers mark and carat weight are produced from the same piece of bar and this is shaped and then soldered to the rear of the heart...

The off-cuts are melted again and some fine wire is made to be used as a jump ring for the bail and a pin to secure it.

The heart then goes in for finishing and polishing with its mates

The stones to be set are mainly pink and yellow sapphires with the addition of a small diamond to match at the top and bottom.

With the stones set the heart goes onto its chain and all is complete. Hopefully one happy customer

2 things........

1st thing: Scan results. Despite a little scare with my CT showing something on my liver again the MRI found it to be nothing more than scarring / fibrosis from the chemo. So, I'm all good and signed off until next year

2nd thing: My nurse specialist loved the SuperWoman badge I made her and now proudly sports it on her uniform. Happy days!

Back to the thread...... (edited to add comentary

)

)9ct rose gold heart pendent set with pink and yellow sapphires (and a diamond top and bottom) on a 9ct rose gold spiga chain. All to the customers spec.

So, we took a bar of 2.5mm d-shaped wire...

And bent one curved piece to make one half of a heart.

With that half we turned it back to front to make a mirrored version of the first.... and hey presto!

Which we then soldered.

The heart was then cleaned up and made ready for the next phase...

The off-cuts from the heart are remelted and from that we make some flat bar to use as a bail...

The bar is turned to the required profile and cut to length....

And filed to a V shape...

The manufacturers mark and carat weight are produced from the same piece of bar and this is shaped and then soldered to the rear of the heart...

The off-cuts are melted again and some fine wire is made to be used as a jump ring for the bail and a pin to secure it.

The heart then goes in for finishing and polishing with its mates

The stones to be set are mainly pink and yellow sapphires with the addition of a small diamond to match at the top and bottom.

With the stones set the heart goes onto its chain and all is complete. Hopefully one happy customer

Edited by ecain63 on Wednesday 15th August 16:18

Great news on the scan results, Eddie. Despite never having met you, I’m chuffed to bits things continue to go well for you on that front. I’m sure the rest of us here feel the same too.

And another great post showing stuff getting made. I wouldn’t choose it for me (obviously!) or my GF, the same with some other stuff, but I never tire of seeing the actual process.

Apologies if it’s been asked before, but do you sketch stuff befor you make it, or is it all in your head? I know some customers may well turn up with a sketch or picture themselves, or you might sketch stuff out when at the unutial “design stage” with a customer, but do you ever make stuff from scratch without drawn/written plans?

And another great post showing stuff getting made. I wouldn’t choose it for me (obviously!) or my GF, the same with some other stuff, but I never tire of seeing the actual process.

Apologies if it’s been asked before, but do you sketch stuff befor you make it, or is it all in your head? I know some customers may well turn up with a sketch or picture themselves, or you might sketch stuff out when at the unutial “design stage” with a customer, but do you ever make stuff from scratch without drawn/written plans?

Good god man, I need commentary with these pictures, you cant expect us all to remember the names of the processes and what is going on in these pictures, even if we have seen them 10s of times previously.

Seriously, lovely work as ever. Keep at it, it really is one of the more pleasant threads on this site.

Wonderful news on the scans. Stay healthy

Seriously, lovely work as ever. Keep at it, it really is one of the more pleasant threads on this site.

Wonderful news on the scans. Stay healthy

Dibble said:

Great news on the scan results, Eddie. Despite never having met you, I’m chuffed to bits things continue to go well for you on that front. I’m sure the rest of us here feel the same too.

And another great post showing stuff getting made. I wouldn’t choose it for me (obviously!) or my GF, the same with some other stuff, but I never tire of seeing the actual process.

Apologies if it’s been asked before, but do you sketch stuff befor you make it, or is it all in your head? I know some customers may well turn up with a sketch or picture themselves, or you might sketch stuff out when at the unutial “design stage” with a customer, but do you ever make stuff from scratch without drawn/written plans?

All the time. I very rarely draw or sketch what I'm making because for me the job should be individual and with the materials you often find you're adjusting as you go. I've done so many now that I can pretty much do it all by eye or memory. The only things I measure are the gauges of wire or sheet to make sure the job can be completed without stones being too big or too small, or to make sure I've budgeted correctly.And another great post showing stuff getting made. I wouldn’t choose it for me (obviously!) or my GF, the same with some other stuff, but I never tire of seeing the actual process.

Apologies if it’s been asked before, but do you sketch stuff befor you make it, or is it all in your head? I know some customers may well turn up with a sketch or picture themselves, or you might sketch stuff out when at the unutial “design stage” with a customer, but do you ever make stuff from scratch without drawn/written plans?

I've said to many customers over the years..... sometimes to their dismay but usually sparking a curiosity, "I'm crap at designing jewellery but awesome at fixing my mistakes and making it up as I go along".

ecain63 said:

Morning....

2 things........

1st thing: Scan results. Despite a little scare with my CT showing something on my liver again the MRI found it to be nothing more than scarring / fibrosis from the chemo. So, I'm all good and signed off until next year

2nd thing: My nurse specialist loved the SuperWoman badge I made her and now proudly sports it on her uniform. Happy days!

Brilliant news Eddie, on both fronts.2 things........

1st thing: Scan results. Despite a little scare with my CT showing something on my liver again the MRI found it to be nothing more than scarring / fibrosis from the chemo. So, I'm all good and signed off until next year

2nd thing: My nurse specialist loved the SuperWoman badge I made her and now proudly sports it on her uniform. Happy days!

Good morning PHers  What's news?

What's news?

It continues to be busy here at 'the bench' and there are plenty of ongoing and future projects to keep myself and my colleagues entertained. It's been a funny old year in the trade and we continue to fight the growing tide that is modern consumer demand and expectations. They are modern day business perks I know, but I feel more than ever that there will come a time when my tolerance runs out and I go looking for new and less emotionally demanding employment. That's a whole other topic so I will just crack on with the latest 'stuff' to leave the workshop.......

Job number 1 has been popping in and out of my sight for a while and is a result of a customers unhappiness with another outlet. He bought what was a 9ct white gold and diamond (only just) engagement ring and as expected it's not lasted long and they've gone around the houses to recover the money that was spent at sale. In a nutshell the cheap and cheerful thing came and bit them. So, where do I come in? I wrote the report that secured the refund and as a reward they have instructed me to produce a new one, in platinum. The budget was tight coming out of a 9ct ring so I suggested that to achieve a near replica of the old ring we needed to buy an off-the-shelf mount and modify it to suit.

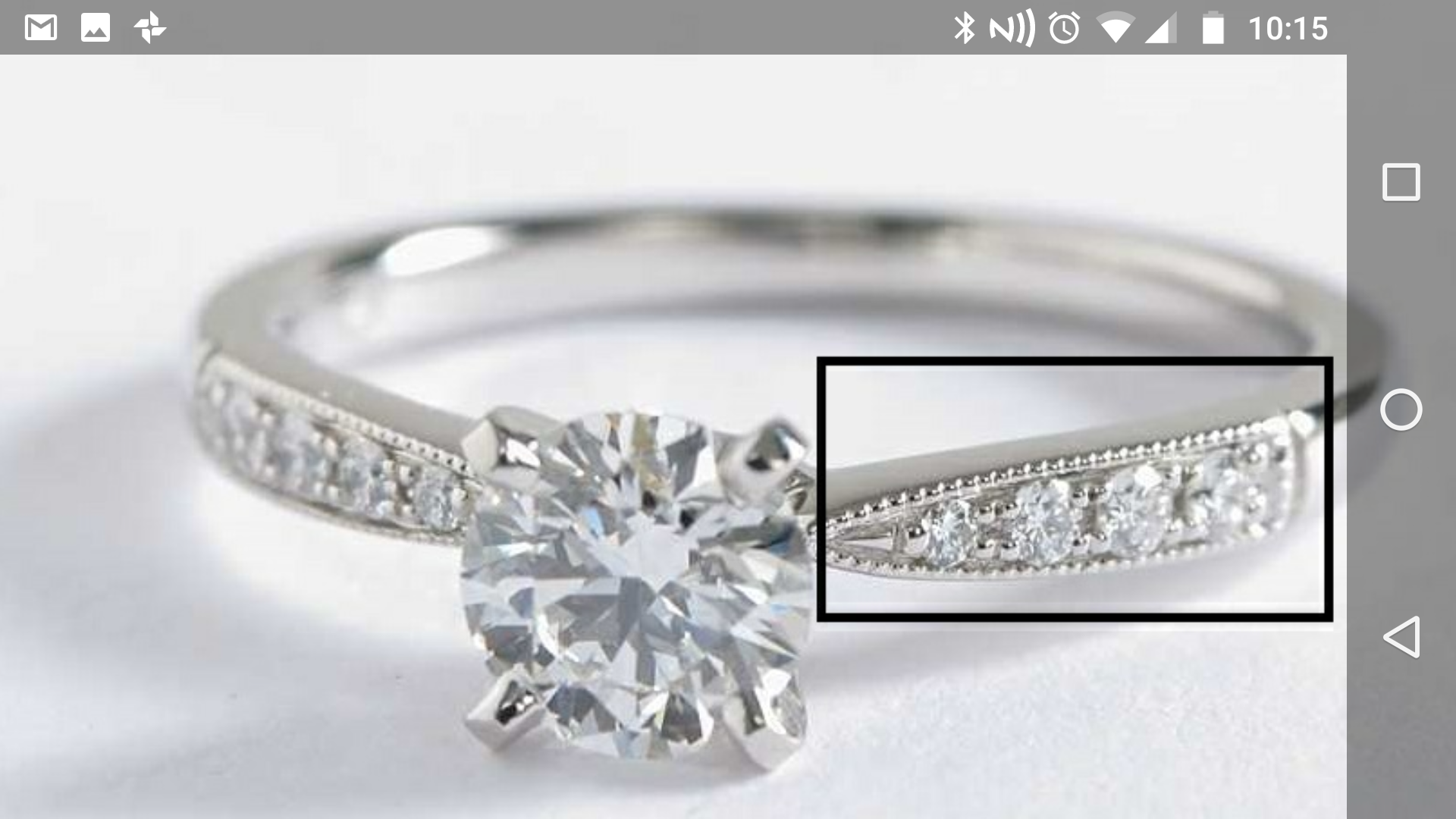

Here's the original item:

She was really keen to keep the heart details on the sides so we set to work. I got hold of a pre set mount (diamonds already in the shoulders) and rolled some platinum wire. This is shaped and tacked into place to begin the makings of a new setting:

A few more light welds and the wires are in place:

A piece of 2.5mm platinum tube is then cut and notched at the 4 corners before being slipped into the middle of the 4 wires and soldered in place. This is the middle rim of the setting.

With a bore I shape this inner rim and you see the heart appear.

Some filing and grinding later (and soldering to fill joints and gaps) the sides are profiled to suit.

The metal is tidied up and then checked for anything that might cause issues later on:

A nice G VS quality 0.25ct brilliant cut diamond will finish off the piece and is the biggest upgrade over the original stone. They were sold a J SI3 in the 9ct ring. When I started the job 11 years ago I don't think there even was an SI3, that's how much the market has changed. Diamonds of such quality were termed as PK or industrial grade, the same goes for the now fashionable chocolate diamonds. They used to be the crap nobody wanted,

We had her wedding ring to size with the job so once the engagement ring was set and complete the 2 rings were polished and given a good rhodium plating to show them off to their fullest:

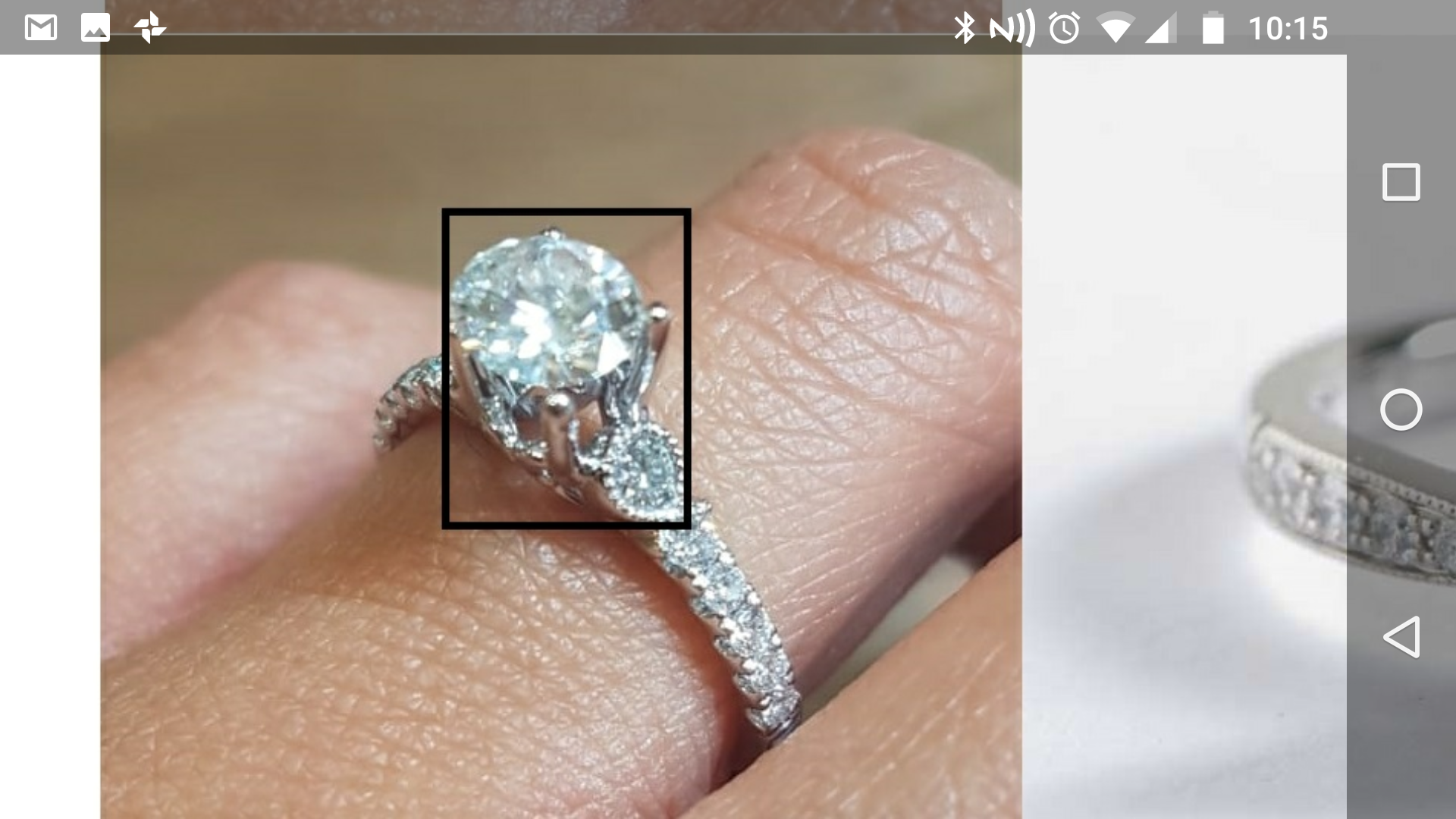

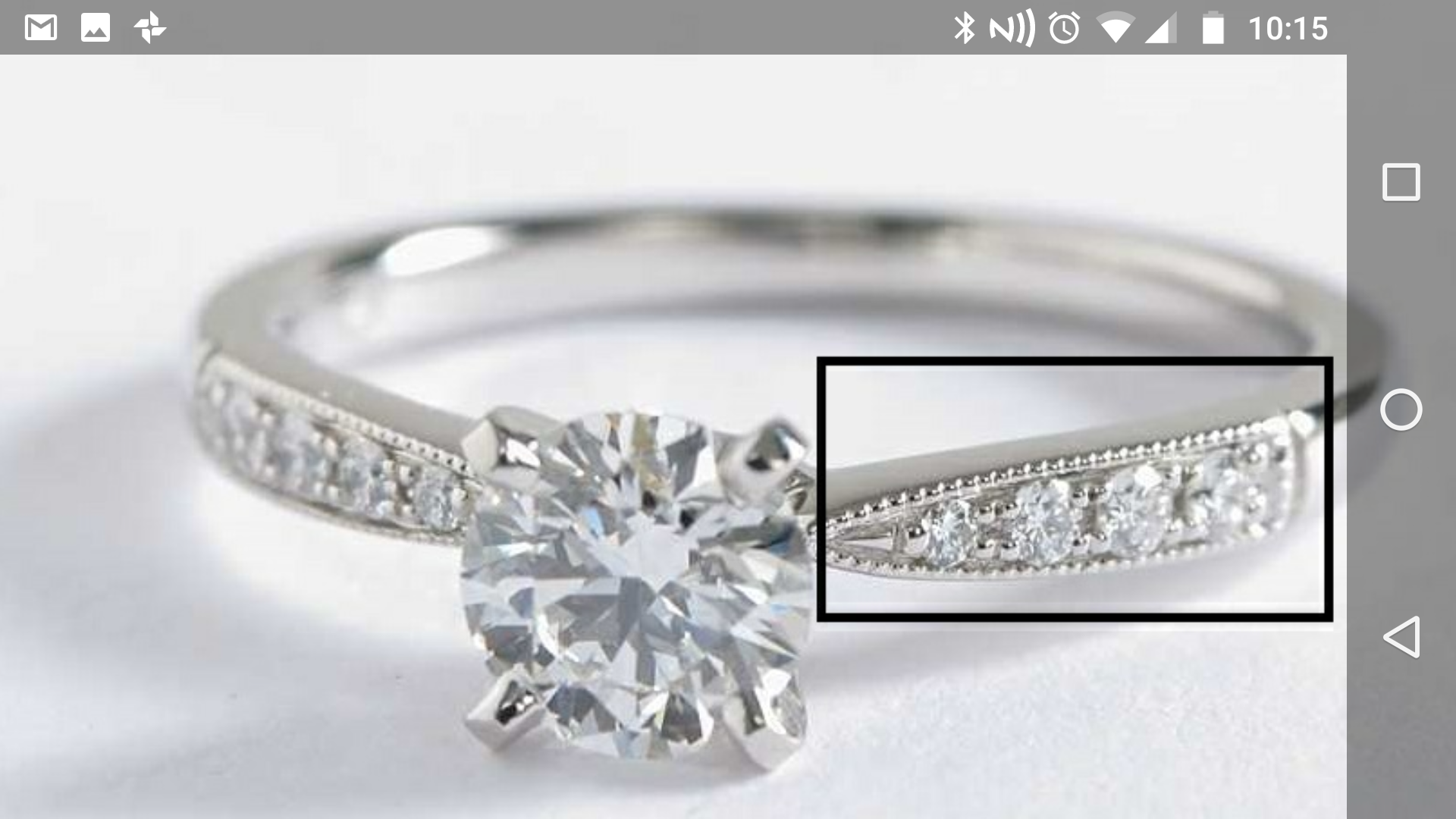

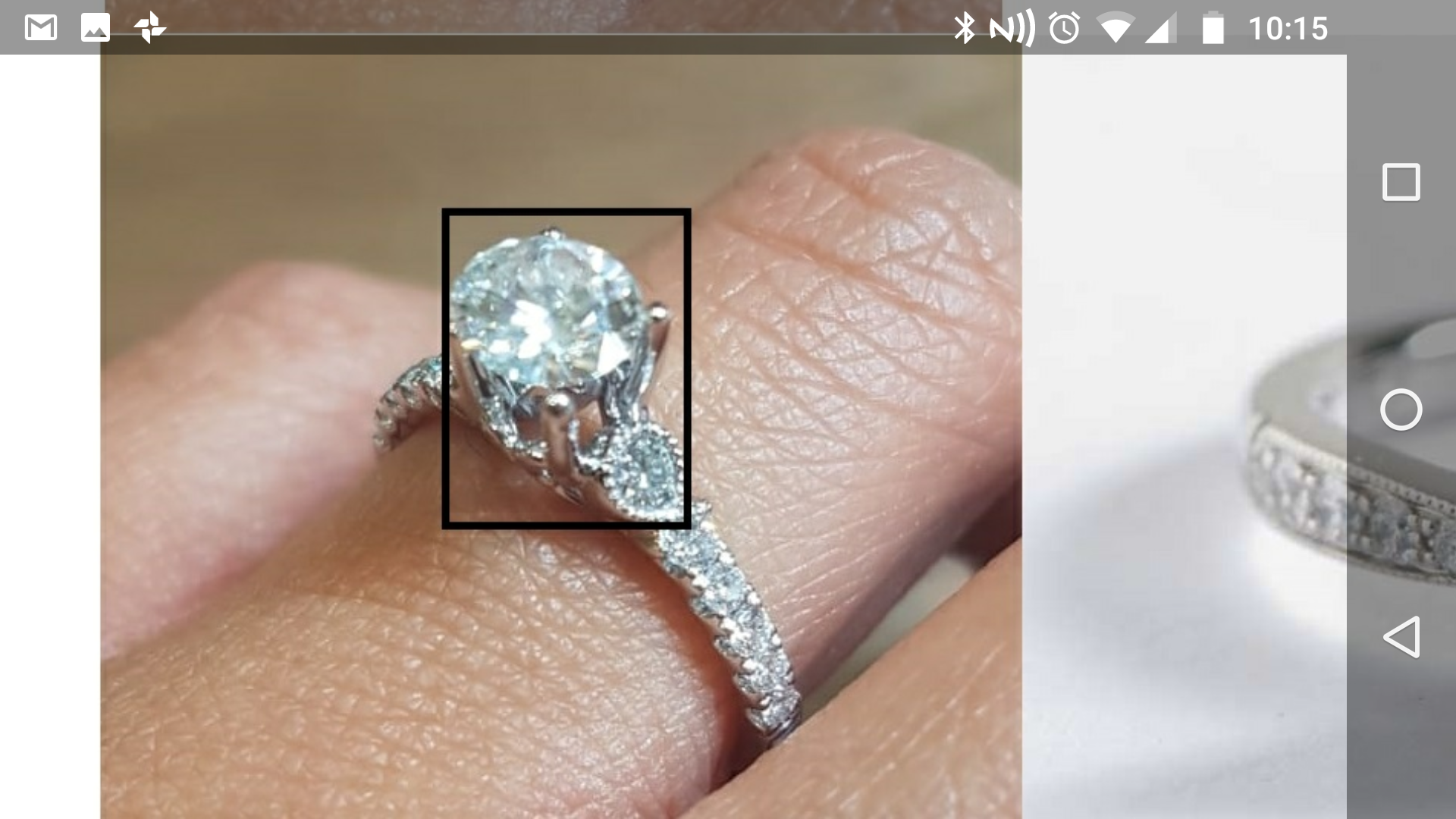

Job 2 is of a similar style. The customer wants something different to the norm but is too similar to an existing style to warrant spending large sums on a custom scratch build. Here is the spec: Regular tapered diamond set shoulder but with a round setting at the top and millgrained edges.

Here's what I did:

The customer had spent a while with us and had chosen a nice 0.70ct old cut diamond. It's got a good spread and is lovely and white with a characterful 'eye' in the middle. A platinum mount was ordered and some 2.5mm platinum tubing:

The shoulder is cut at the setting and the ends rounded off (concave) to accept the tube. The tube is then soldered in place:

The tube is cut down to length and the other piece soldered in exactly the same way:

This is then tidied up and the ring sized for the customers finger:

A pair of 2mm diamonds are set in the round settings and I get on with the millgrain finish (personally not a fan): The tool I use is literlly just a graining tool, which is a hollow tipped pointer thing that we use for setting small stones. It makes nice round marks

The centre stone is set (you can see the eye in this pic) and then the ring is finished by polishing and rhodium plating:

Ok, that's the rings done. Here is the bruiser bangle.

Remember the huge, 50g+ solid 9ct heart I made last year for the lady who already had the really heavy chain?

This year she's getting a bangle:

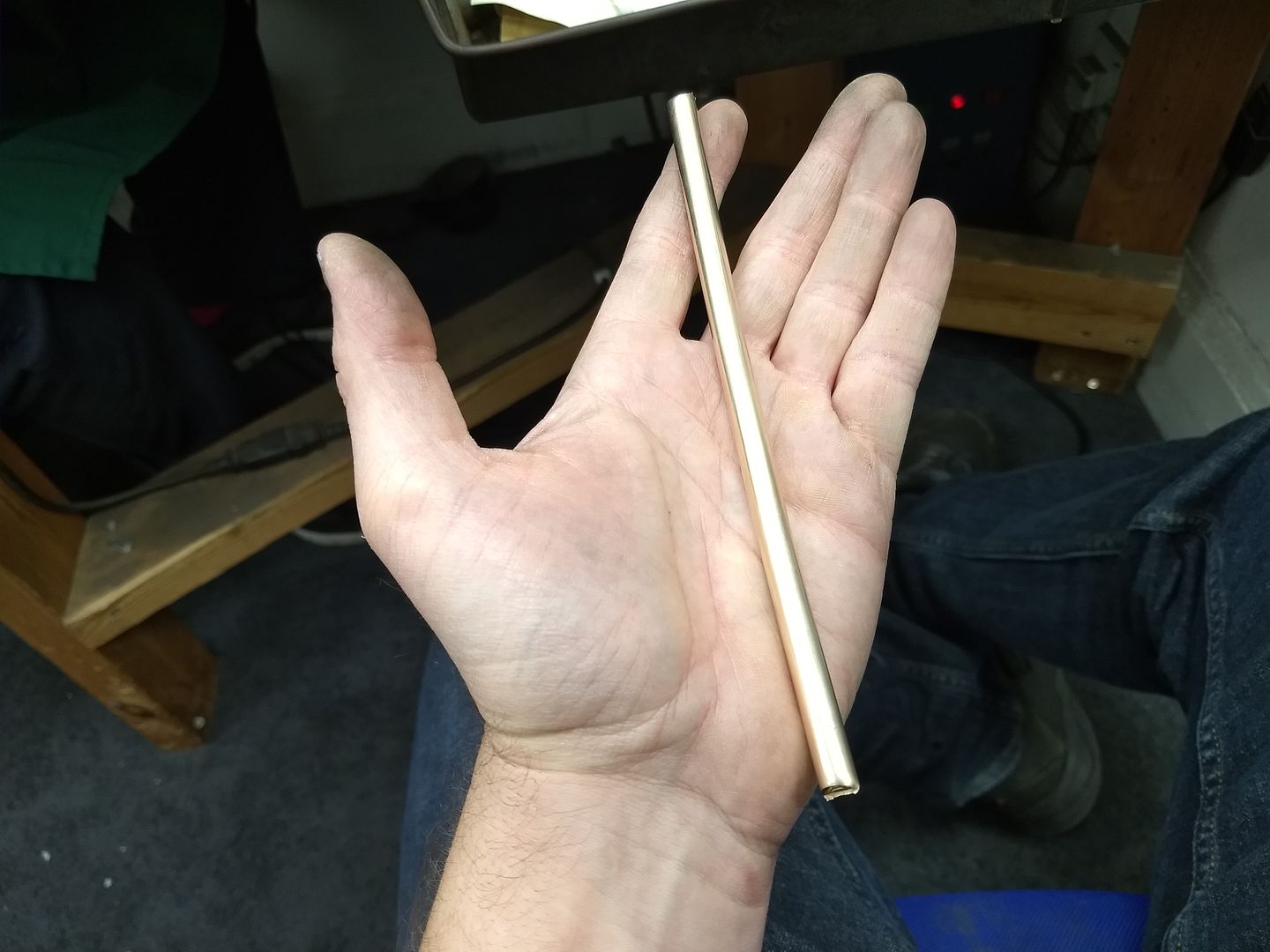

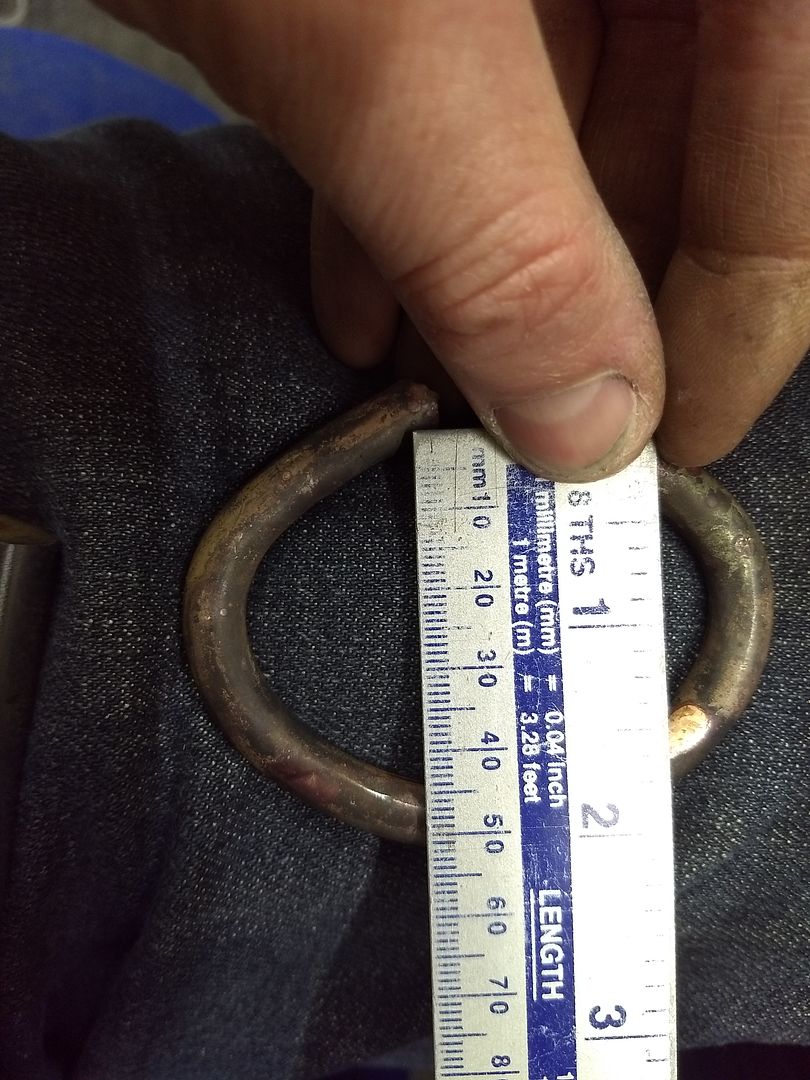

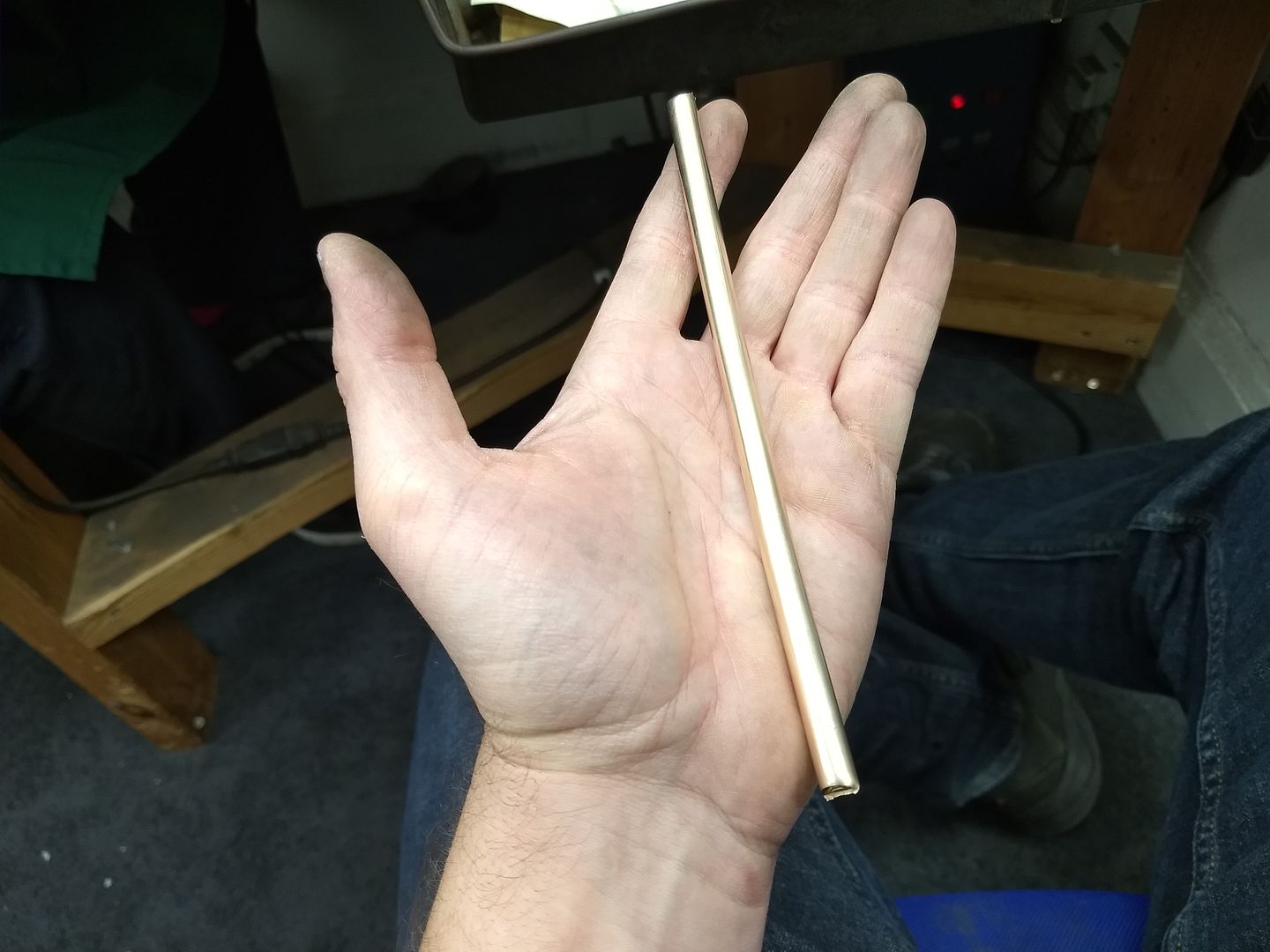

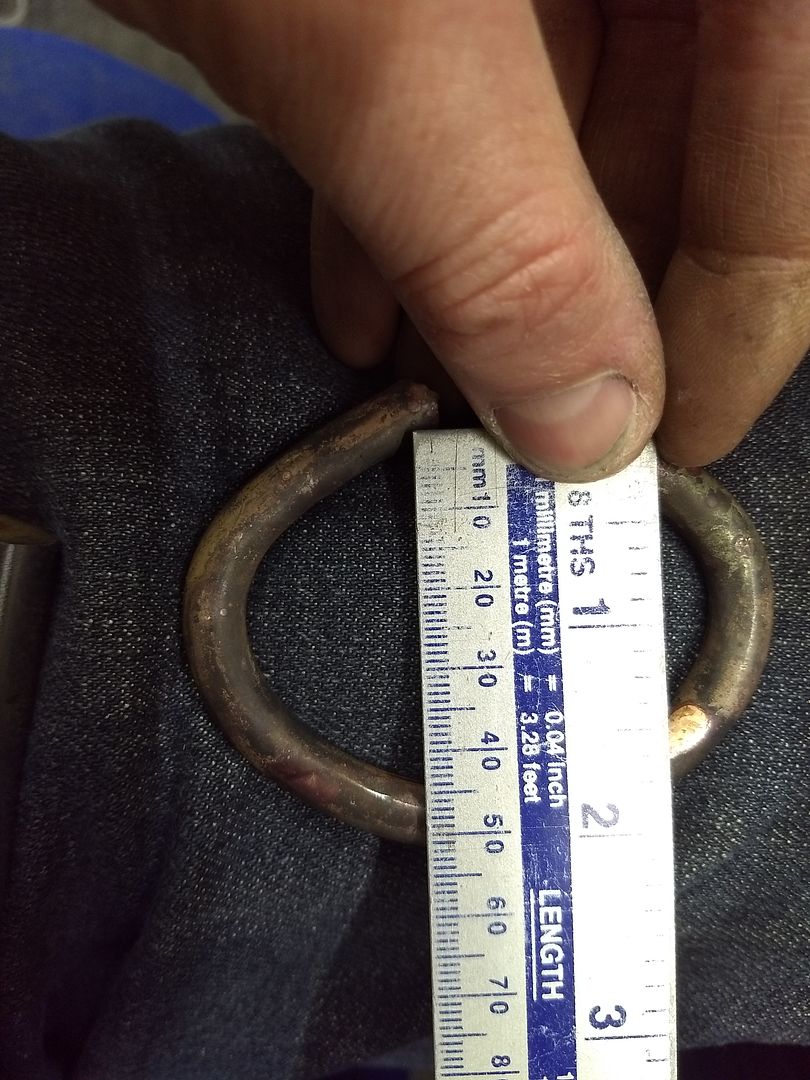

Take 1 x 8mm round wire bar. All 102g of it:

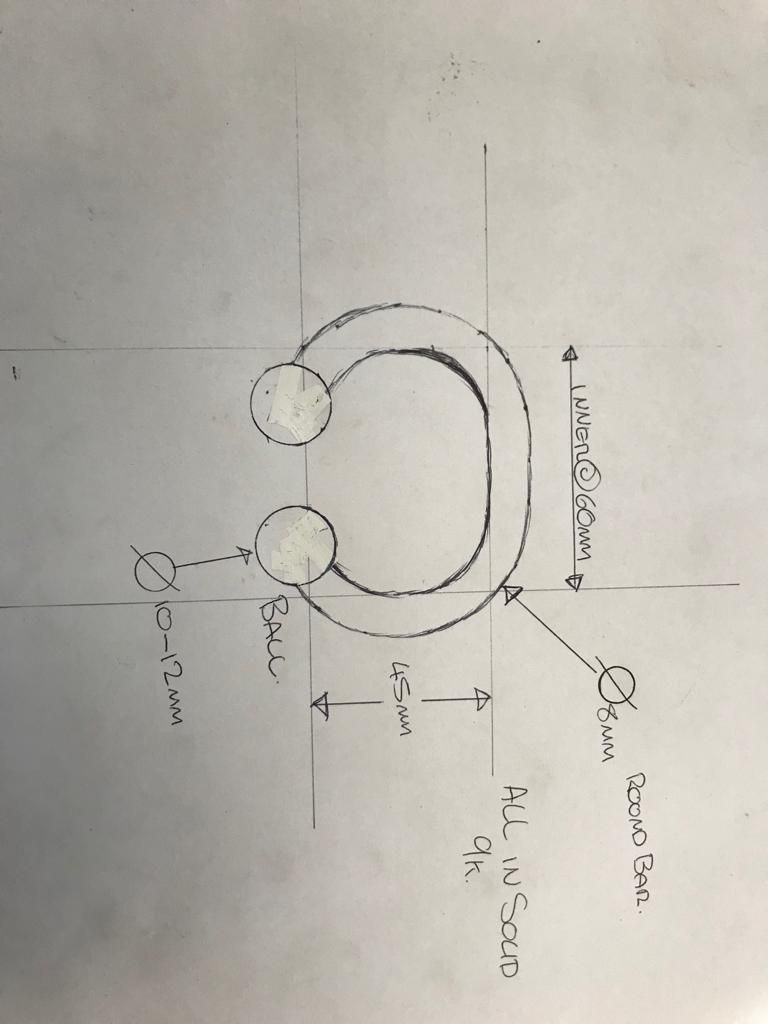

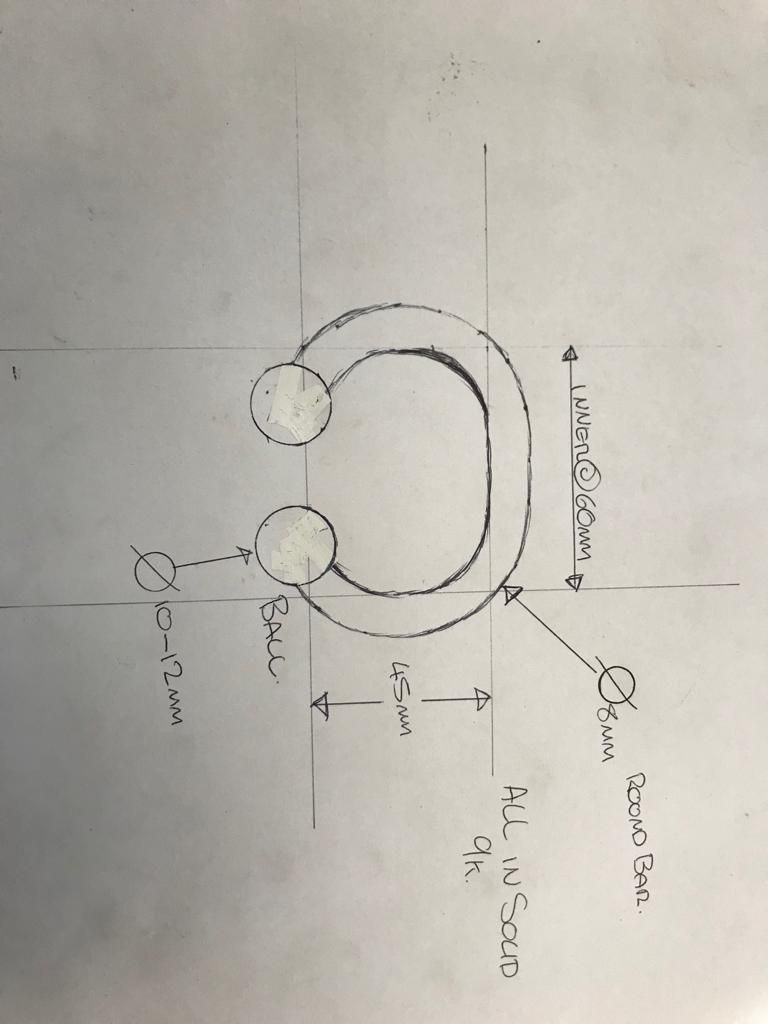

And the idea:

9ct gold is bloody hard even with heating so I had to employ the vice for the bending:

The excess length is removed and these will be used to produce the balls on the ends:

Out comes the casting clay and with a 12mm ball I turn the 2 x 10g cut offs into 2 x 10g casts:

The balls are filed to a rough shape and size and the excess / sprue removed:

Once the balls are the required shape and size I flatted and then hollow out one end so the joint will be solid when it comes to soldering:

Soldered and cleaned:

I'll buff it to remove any dents or marks from manufacture. You ideally want to do as little of this as possible so you don't lose weight. Of the 102g in the original bar the finished item weighed in at 93g and there was 3.5g in the 2 bits left over from the balls. That's pretty decent considering the filing, sawing and polishing that went on.

The bangle is then polished and it's job done for that little beauty. I'm half tempted to make a platinum one for stock

Eddie

What's news?

What's news? It continues to be busy here at 'the bench' and there are plenty of ongoing and future projects to keep myself and my colleagues entertained. It's been a funny old year in the trade and we continue to fight the growing tide that is modern consumer demand and expectations. They are modern day business perks I know, but I feel more than ever that there will come a time when my tolerance runs out and I go looking for new and less emotionally demanding employment. That's a whole other topic so I will just crack on with the latest 'stuff' to leave the workshop.......

Job number 1 has been popping in and out of my sight for a while and is a result of a customers unhappiness with another outlet. He bought what was a 9ct white gold and diamond (only just) engagement ring and as expected it's not lasted long and they've gone around the houses to recover the money that was spent at sale. In a nutshell the cheap and cheerful thing came and bit them. So, where do I come in? I wrote the report that secured the refund and as a reward they have instructed me to produce a new one, in platinum. The budget was tight coming out of a 9ct ring so I suggested that to achieve a near replica of the old ring we needed to buy an off-the-shelf mount and modify it to suit.

Here's the original item:

She was really keen to keep the heart details on the sides so we set to work. I got hold of a pre set mount (diamonds already in the shoulders) and rolled some platinum wire. This is shaped and tacked into place to begin the makings of a new setting:

A few more light welds and the wires are in place:

A piece of 2.5mm platinum tube is then cut and notched at the 4 corners before being slipped into the middle of the 4 wires and soldered in place. This is the middle rim of the setting.

With a bore I shape this inner rim and you see the heart appear.

Some filing and grinding later (and soldering to fill joints and gaps) the sides are profiled to suit.

The metal is tidied up and then checked for anything that might cause issues later on:

A nice G VS quality 0.25ct brilliant cut diamond will finish off the piece and is the biggest upgrade over the original stone. They were sold a J SI3 in the 9ct ring. When I started the job 11 years ago I don't think there even was an SI3, that's how much the market has changed. Diamonds of such quality were termed as PK or industrial grade, the same goes for the now fashionable chocolate diamonds. They used to be the crap nobody wanted,

We had her wedding ring to size with the job so once the engagement ring was set and complete the 2 rings were polished and given a good rhodium plating to show them off to their fullest:

Job 2 is of a similar style. The customer wants something different to the norm but is too similar to an existing style to warrant spending large sums on a custom scratch build. Here is the spec: Regular tapered diamond set shoulder but with a round setting at the top and millgrained edges.

Here's what I did:

The customer had spent a while with us and had chosen a nice 0.70ct old cut diamond. It's got a good spread and is lovely and white with a characterful 'eye' in the middle. A platinum mount was ordered and some 2.5mm platinum tubing:

The shoulder is cut at the setting and the ends rounded off (concave) to accept the tube. The tube is then soldered in place:

The tube is cut down to length and the other piece soldered in exactly the same way:

This is then tidied up and the ring sized for the customers finger:

A pair of 2mm diamonds are set in the round settings and I get on with the millgrain finish (personally not a fan): The tool I use is literlly just a graining tool, which is a hollow tipped pointer thing that we use for setting small stones. It makes nice round marks

The centre stone is set (you can see the eye in this pic) and then the ring is finished by polishing and rhodium plating:

Ok, that's the rings done. Here is the bruiser bangle.

Remember the huge, 50g+ solid 9ct heart I made last year for the lady who already had the really heavy chain?

This year she's getting a bangle:

Take 1 x 8mm round wire bar. All 102g of it:

And the idea:

9ct gold is bloody hard even with heating so I had to employ the vice for the bending:

The excess length is removed and these will be used to produce the balls on the ends:

Out comes the casting clay and with a 12mm ball I turn the 2 x 10g cut offs into 2 x 10g casts:

The balls are filed to a rough shape and size and the excess / sprue removed:

Once the balls are the required shape and size I flatted and then hollow out one end so the joint will be solid when it comes to soldering:

Soldered and cleaned:

I'll buff it to remove any dents or marks from manufacture. You ideally want to do as little of this as possible so you don't lose weight. Of the 102g in the original bar the finished item weighed in at 93g and there was 3.5g in the 2 bits left over from the balls. That's pretty decent considering the filing, sawing and polishing that went on.

The bangle is then polished and it's job done for that little beauty. I'm half tempted to make a platinum one for stock

Eddie

pincher said:

Lovely work as always Eddie

Do you always document the ‘build’ with photos, or only if the client requests it? And how much notice do you need to make something custom - weeks or months?

It depends what it is really. If it's an interesting or unusual job then i may take a few pics for our facebook page or for the customer to use as a reference. But it's not a given with every item. Obviously if the customer asks at the beginning then I'll do a full set.

Do you always document the ‘build’ with photos, or only if the client requests it? And how much notice do you need to make something custom - weeks or months?

Turnaround times are also job and material dependant. If it's easy then a few days will sometimes do, occasionally quicker. For engagement rings and other projects that require building or designing then anything from a couple of weeks to a couple of months with a bit of notice needed initially to get diamonds in for viewing or a customer visit. I have been known to do jobs very quickly if the circumstances dictate, but that's always a price vs family life negotiation as I value my time at home given it's so limited these days.

Gassing Station | Watches | Top of Page | What's New | My Stuff