Anyone interested in home-built sailing dinghies?

Discussion

B'stard Child said:

Lovely skills to have

I still splice ropes for household/garden stuff - we have a sail in the garden as a sunshade and the ropes are spliced into eyelets in the corners

I kinda wish I'd done this sooner, but better late than never!I still splice ropes for household/garden stuff - we have a sail in the garden as a sunshade and the ropes are spliced into eyelets in the corners

Now having a rough idea of the going rates for new sails by the square metre and average hourly rates for sail maker labour I'm glad I did this before paying someone to make mine. The trick, I think, will be to keep our hands in often enough to remain fresh on certain aspects of it. As you've highlighted, the possibilities to use these skills in a more abstract way are extensive

I had a few pressing things to do, but this weekend I started modifying the inexpensive used combi trailer.

I started by getting the bow up where I wanted it. The Apple 16 is a rather different shape compared to the GP14 which I think was on this trailer before.

That's better. Not finished, but going in the right direction.

It sits on its keel in the centre, but the GP14 was gunwale hung. I want to use these for stablity and to share some of the weight.

I cut and rewelded those supports to sit under the iroko rubbing strips

This will basically work.

I will weld on a post at the front of the trailer for a winch, and I will add two further supports from steel plate covered with carpet to sit under a pair of chines. This will ease getting on and off the trailer, and offload what's likely a fairly high stress on the keel from that point load. It's plenty strong enough to sit there like this, and I've taken it out for 2 miles at low speed but I don't think bouncing over a pothole at ~50mph will do the hull any long term good.

I'm confident this is going to work out just fine though.

I started by getting the bow up where I wanted it. The Apple 16 is a rather different shape compared to the GP14 which I think was on this trailer before.

That's better. Not finished, but going in the right direction.

It sits on its keel in the centre, but the GP14 was gunwale hung. I want to use these for stablity and to share some of the weight.

I cut and rewelded those supports to sit under the iroko rubbing strips

This will basically work.

I will weld on a post at the front of the trailer for a winch, and I will add two further supports from steel plate covered with carpet to sit under a pair of chines. This will ease getting on and off the trailer, and offload what's likely a fairly high stress on the keel from that point load. It's plenty strong enough to sit there like this, and I've taken it out for 2 miles at low speed but I don't think bouncing over a pothole at ~50mph will do the hull any long term good.

I'm confident this is going to work out just fine though.

Allegro_Snapon said:

Brilliant Jamie. Make sure you get to Orkney again it is my favourite place in the UK. Sail up from Aberdeen in your boat?

How life has changed since putting "CAT" badges on Ford Cougars - I met you briefly at Cougarfest in Northants - 2003 I think?

Hi, my first time at Cougarfest was 2006 I think, or possibly 2005. Changing things on other peoples' cars certainly sounds like me. For about 3 years running someone handed me a box of lowering springs, their car keys and a bottle of beer. Tony Langston from round Huntingdon sort of way would usually help. Having a car in bits seemed to act as a focal point for people to gather round How life has changed since putting "CAT" badges on Ford Cougars - I met you briefly at Cougarfest in Northants - 2003 I think?

In fact, here's me lying on the ground.

It was either lying on the floor under a car in bits which was very much my preference, or end up like this guy lying on the floor with his car inexplicably parked inside the marquee in the morning.

What was your username?

Edited by jamieduff1981 on Monday 15th May 14:56

I was sitting in bed at 0700 on Sunday morning drinking coffee and scrolling through phones with my wife. She held her phone over to me and asked if I'd like a non-working wood lathe and a big pile of chisels for £50, whilst showing me a Facebook Marketplace listing from our nearest big-ish town 20 minutes away. I messaged the seller who said "the sooner the better" so we agreed to arrive there by 0800. I gave them £50 and loaded the stuff into the back of the car.

I had breakfast when we got back, and by 1000hrs the lathe was working properly. Luckily for me, the seller was not good with electrical things and it was just really bad wiring. Other than watching some wood turners on Youtube once in a blue moon, my only previous experience with wood turning was a quick go on a lathe once at school - one of those lessons where the class lines up for a quick attempt before the next kid tries it. For really basic stuff it doesn't seem too difficult though. By 1100hrs on Sunday morning I had made myself a fid.

There's definitely room for improvement but for my first attempt at turning something myself I'm fairly happy with it.

So much so that I made another

I am going to order the thimbles to go into the rope cringles of my staysail and gaff mainsail. Once they arrive, I shall make a split fid to aid installing them, as well as another for the man who ran the sail making course we're on to suit dimensions he's going to send me for the thimbles if he wants to use.

I had breakfast when we got back, and by 1000hrs the lathe was working properly. Luckily for me, the seller was not good with electrical things and it was just really bad wiring. Other than watching some wood turners on Youtube once in a blue moon, my only previous experience with wood turning was a quick go on a lathe once at school - one of those lessons where the class lines up for a quick attempt before the next kid tries it. For really basic stuff it doesn't seem too difficult though. By 1100hrs on Sunday morning I had made myself a fid.

There's definitely room for improvement but for my first attempt at turning something myself I'm fairly happy with it.

So much so that I made another

I am going to order the thimbles to go into the rope cringles of my staysail and gaff mainsail. Once they arrive, I shall make a split fid to aid installing them, as well as another for the man who ran the sail making course we're on to suit dimensions he's going to send me for the thimbles if he wants to use.

I'm almost certain I'll find uses for this along the way. I'm not exactly sure what yet, but for £50 it seemed like the obvious thing to do was to buy it! My wife observed that turning wood is considered by many to be a hobby in its own right. I think for me it'll just be a tool though. I have a thickness planer and a hydraulic press, but I doubt my hobbies will ever be "thinning down wood" or "crushing things".

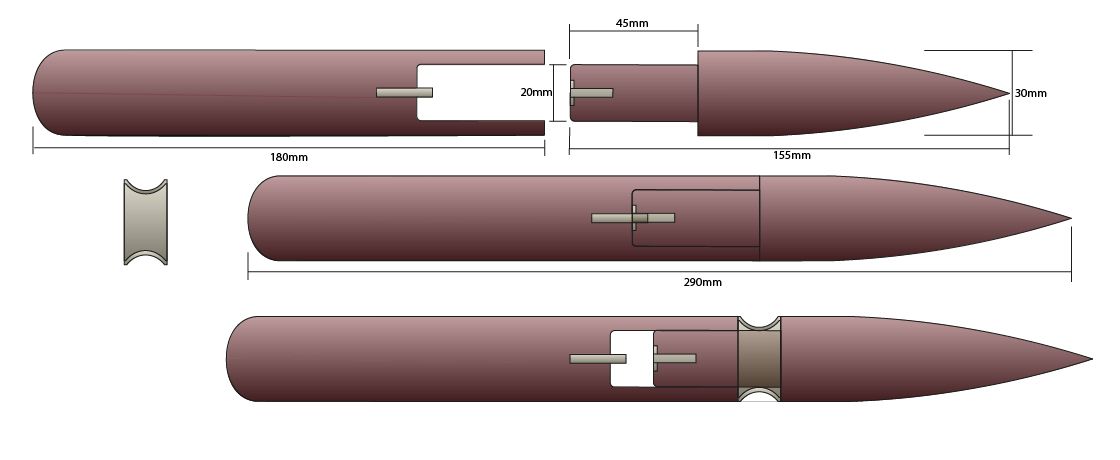

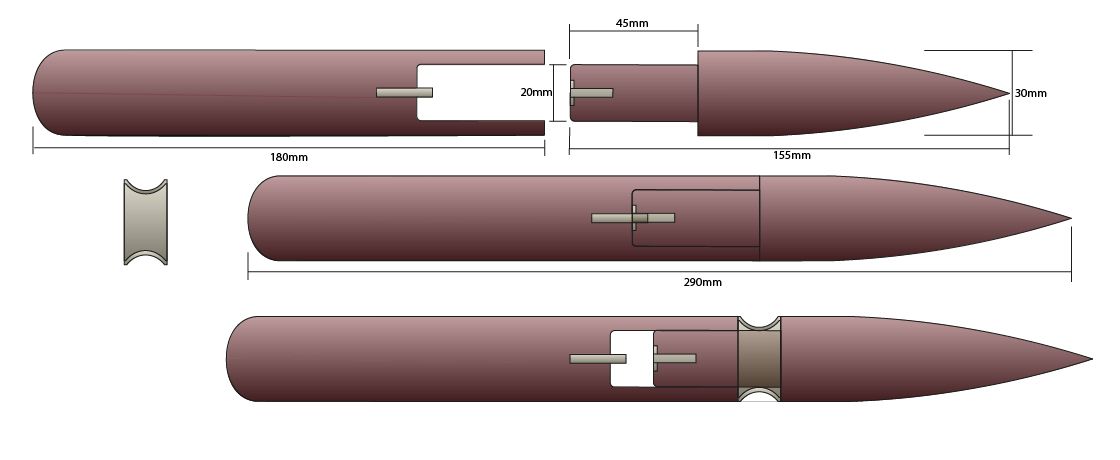

I have sketched up a split fid which started much shorter. There has been a bit of back and forth with the sail maker / course instructor Mark about how he'd want to use it so I drew it longer like this so he could clamp it between his knees and press the rope cringle down over it. It does end up more like a vampire stake though and perhaps a bit hard to stow so I'm shortening the base of it about 40mm from this sketch's proportions and I will lose some of the excess untapered length from the front to shorten by about 60mm overall. It'll screw together using a snooker cue brass connector thingie.

As our staysail and gaff main are getting rope cringles and brass thimbles too, I'm going to make one for myself first which can be a little shonky and hopefully apply any learnings to the one I make for Mark...

I have sketched up a split fid which started much shorter. There has been a bit of back and forth with the sail maker / course instructor Mark about how he'd want to use it so I drew it longer like this so he could clamp it between his knees and press the rope cringle down over it. It does end up more like a vampire stake though and perhaps a bit hard to stow so I'm shortening the base of it about 40mm from this sketch's proportions and I will lose some of the excess untapered length from the front to shorten by about 60mm overall. It'll screw together using a snooker cue brass connector thingie.

As our staysail and gaff main are getting rope cringles and brass thimbles too, I'm going to make one for myself first which can be a little shonky and hopefully apply any learnings to the one I make for Mark...

That's been a fairly intensive weekend, and some dinghy happened along the way. Unfortunately my photographic record captures everything half-done.

I glued up the internal timbers in the bow on Friday.

On Saturday these were all trimmed and excess epoxy dealt with and now it looks quite tidy.

Then, we temporarily bolted up the chainplates to the hull and made both shrouds and one of the forestays. These have a loop at the top swaged in place and are swaged to a turnbuckle at the bottom finally attached to the hull fittings with a quickly removable pin. Luckily being interested in cars but not interested in paying for third parties to keep the things I like running, I bought a 20 tonne hydraulic press around 10 years ago. It has paid for itself many times over in garage bills avoided, and served again in swaging the cables nicely. I'm very glad I have it!

When the loops at the top were done the 3 stays were cut about 150mm / 6 inches over and the mast was stepped and angles checked before the actual length was measured leaving me plenty adjustment either way on the turnbuckles.

The turnbuckle fittings were then swaged to the bottom end of each cable. In my childish glee at seeing my very first dinghy with the mast in and standing rigging in and snugged up (not too tight) I took a short video but neglected to take a still photograph with it all in place properly...

Today I "dry" fitted the rudder. Whilst the gudgeons are almost certainly fine and it's hard to imagine hurting the 8mm diameter pins themselves, the Allen pintles are maybe a bit weedy. It feels fine, but I acknowledge that rudders and their hardware can get quite a bit of punishment. I think I'll keep the pins but fabricate some heavier bands to fix to the headstock.

I glued up the internal timbers in the bow on Friday.

On Saturday these were all trimmed and excess epoxy dealt with and now it looks quite tidy.

Then, we temporarily bolted up the chainplates to the hull and made both shrouds and one of the forestays. These have a loop at the top swaged in place and are swaged to a turnbuckle at the bottom finally attached to the hull fittings with a quickly removable pin. Luckily being interested in cars but not interested in paying for third parties to keep the things I like running, I bought a 20 tonne hydraulic press around 10 years ago. It has paid for itself many times over in garage bills avoided, and served again in swaging the cables nicely. I'm very glad I have it!

When the loops at the top were done the 3 stays were cut about 150mm / 6 inches over and the mast was stepped and angles checked before the actual length was measured leaving me plenty adjustment either way on the turnbuckles.

The turnbuckle fittings were then swaged to the bottom end of each cable. In my childish glee at seeing my very first dinghy with the mast in and standing rigging in and snugged up (not too tight) I took a short video but neglected to take a still photograph with it all in place properly...

Today I "dry" fitted the rudder. Whilst the gudgeons are almost certainly fine and it's hard to imagine hurting the 8mm diameter pins themselves, the Allen pintles are maybe a bit weedy. It feels fine, but I acknowledge that rudders and their hardware can get quite a bit of punishment. I think I'll keep the pins but fabricate some heavier bands to fix to the headstock.

Hi folks,

It's been a busy summer so far, and not in the good way!

The foredeck isn't glued down yet but the bits fit reasonably nicely now:

I've decided though that it's getting high time I finished the outside of the hull, so I ordered up hard wearing paint products suitable for marine use from a supplier I know very well and trust.

Other than the varnish for my spars of course, they are all white but they are chemically compatible with the liquid colourants I use in my little model paint business so I am able to make the exact shade I want for the hull above the rubbing strips on my paint mixing machine

With the goal of getting the hull dressed up in mind I relocated it out into the garden and flipped it over again. I still had two hardwood strips to glue on either side of the daggerboard slot, which I did.

I've then become a bit fussier than I originally intended and have been using a baton and a pencil to mark out areas that will annoy me and dealing with them ahead of paint, and rollering on additional coats of epoxy in the process.

Overall I think it'll be ok and I'm trying not to be too hard on myself. With the benefit of hindsight I should have spent more time on the original scarph joints of the plywood as there have been little humps at the joints. They are not deep under the batons, but if the paint finish is glossy I'll see the unfairness in the reflections so there are big wide skims of epoxy and microballoon filler to fair this out. If I get to build a second boat, I'll do things differently. I still fully intend to finish this dinghy and enjoy it though, so want to avoid the trap I so easily fall into which is finding something less than perfect and abandoning the project because of it.

It's been a busy summer so far, and not in the good way!

The foredeck isn't glued down yet but the bits fit reasonably nicely now:

I've decided though that it's getting high time I finished the outside of the hull, so I ordered up hard wearing paint products suitable for marine use from a supplier I know very well and trust.

Other than the varnish for my spars of course, they are all white but they are chemically compatible with the liquid colourants I use in my little model paint business so I am able to make the exact shade I want for the hull above the rubbing strips on my paint mixing machine

With the goal of getting the hull dressed up in mind I relocated it out into the garden and flipped it over again. I still had two hardwood strips to glue on either side of the daggerboard slot, which I did.

I've then become a bit fussier than I originally intended and have been using a baton and a pencil to mark out areas that will annoy me and dealing with them ahead of paint, and rollering on additional coats of epoxy in the process.

Overall I think it'll be ok and I'm trying not to be too hard on myself. With the benefit of hindsight I should have spent more time on the original scarph joints of the plywood as there have been little humps at the joints. They are not deep under the batons, but if the paint finish is glossy I'll see the unfairness in the reflections so there are big wide skims of epoxy and microballoon filler to fair this out. If I get to build a second boat, I'll do things differently. I still fully intend to finish this dinghy and enjoy it though, so want to avoid the trap I so easily fall into which is finding something less than perfect and abandoning the project because of it.

The two pack stuff is hard wearing stuff with normally a high gloss finish like glass

I painted a firefly hull with it in duck egg blue and then sanded it all over with 1500 W&D to get it to a really smooth matt finish (because I read that a matt finish was better for laminar flow and because I was racing in it)

It looked like really old paint in good condition - no idea if it made the firefly quicker or not

I painted a firefly hull with it in duck egg blue and then sanded it all over with 1500 W&D to get it to a really smooth matt finish (because I read that a matt finish was better for laminar flow and because I was racing in it)

It looked like really old paint in good condition - no idea if it made the firefly quicker or not

I've been painting a 2-pack polyurethane undercoat on the hull lately, and I have one more coat to go. The finish isn't going to be what I imagined when I started, but it will be serviceable. The whole boat isn't what I imagined at the start, but it'll be serviceable. I can always build another boat later and employ what I've learned along the way.

I made a fitting for the end of the bowsprit on Saturday.

I was supposed to do some more paint yesterday but instead decided that the best thing to do in the hot weather was metalwork. I think I've now made all the custom fabrications apart from however I attach the bobstay at the stem.

Still, that meant I was able to attach the bowsprit (almost) properly, therefore the second forestay could be made, but not properly tensioned just yet. Using some cheap string as a halyard, I found running the jib up irressistable.

We then did some garden sailing to check the rough positions for the sheet fairleads although I'll revisit that once the bobstay plus proper cord for the halyards allow me to get the luff tension somewhere sensible.

Lastly, we dismantled and flipped her back over before some rain came in...

I made a fitting for the end of the bowsprit on Saturday.

I was supposed to do some more paint yesterday but instead decided that the best thing to do in the hot weather was metalwork. I think I've now made all the custom fabrications apart from however I attach the bobstay at the stem.

Still, that meant I was able to attach the bowsprit (almost) properly, therefore the second forestay could be made, but not properly tensioned just yet. Using some cheap string as a halyard, I found running the jib up irressistable.

We then did some garden sailing to check the rough positions for the sheet fairleads although I'll revisit that once the bobstay plus proper cord for the halyards allow me to get the luff tension somewhere sensible.

Lastly, we dismantled and flipped her back over before some rain came in...

On Saturday my friend helped me machine down unwieldy lengths of Douglas Fir and glued two of them together. Yesterday morning my daughters helped me glue the other two together, then machine yesterday's to final dimensions, mark out the taper, cut the taper, plane and sand the corners off and last night I've fettled the gooseneck fitting. The whole thing is now ready for a final smooth sanding and varnishing.

If anyone's unsure what this is, then a re-familiarisation with renowned classical poet Baldrick's masterpiece "The German Guns" should give you the inspiration you need.

That just leaves the shorter gaff to make from yesterday morning's glue up, although that needs hardwood jaws made before tapering and shaping.

If anyone's unsure what this is, then a re-familiarisation with renowned classical poet Baldrick's masterpiece "The German Guns" should give you the inspiration you need.

That just leaves the shorter gaff to make from yesterday morning's glue up, although that needs hardwood jaws made before tapering and shaping.

I've been making the jaws for the gaff from Iroko. There is still work to be done - they're too wide for a start, but that was intentional to ensure I didn't do a me and make them too narrow!

I'll round over the corners of the jaws themselves before gluing them to the Douglas Fir spar, and I'll cut the various tapers on the spar itself before gluing on the jaws. I also will plane down the corners of the spar but leave final rounding until the jaws are permanently attached.

I'll round over the corners of the jaws themselves before gluing them to the Douglas Fir spar, and I'll cut the various tapers on the spar itself before gluing on the jaws. I also will plane down the corners of the spar but leave final rounding until the jaws are permanently attached.

I haven't shared any updates for a while - work was taking a toll on me. I did make some improvements to the hull where the white basecoat showed it was needed. I could have carried on forever with that but my wife is quite pragmatic and told me to just stop and that nobody who matters to me is going to care. In the interests of finishing the boat and getting on the water therefore, I have applied the polyurethane white topcoat over the weekend. Is it perfect? Absolutely not. Is it even good? No, not really. It's serviceable though.

Next I think I will mix the colour for the upper part of the hull above the rubbing strip (which I have not done a good job of in finding a fair line towards the aft end - if I did this again I'd mark screw holes on the plank while it was still flat on the floor to ensure I had the mid-point of the plank pre-drilled all the way from stem to stern), mask below (above??) the rubbing strip and get it painted up to (down to?) the shear line.

I'm about to order stainless steel strip to screw to the false keels as per plans which provides some wear protection, then I don't think I will need the hull upside down again for the rest of the build.

Next I think I will mix the colour for the upper part of the hull above the rubbing strip (which I have not done a good job of in finding a fair line towards the aft end - if I did this again I'd mark screw holes on the plank while it was still flat on the floor to ensure I had the mid-point of the plank pre-drilled all the way from stem to stern), mask below (above??) the rubbing strip and get it painted up to (down to?) the shear line.

I'm about to order stainless steel strip to screw to the false keels as per plans which provides some wear protection, then I don't think I will need the hull upside down again for the rest of the build.

Gassing Station | Boats, Planes & Trains | Top of Page | What's New | My Stuff