Widen mobility scooter axle

Discussion

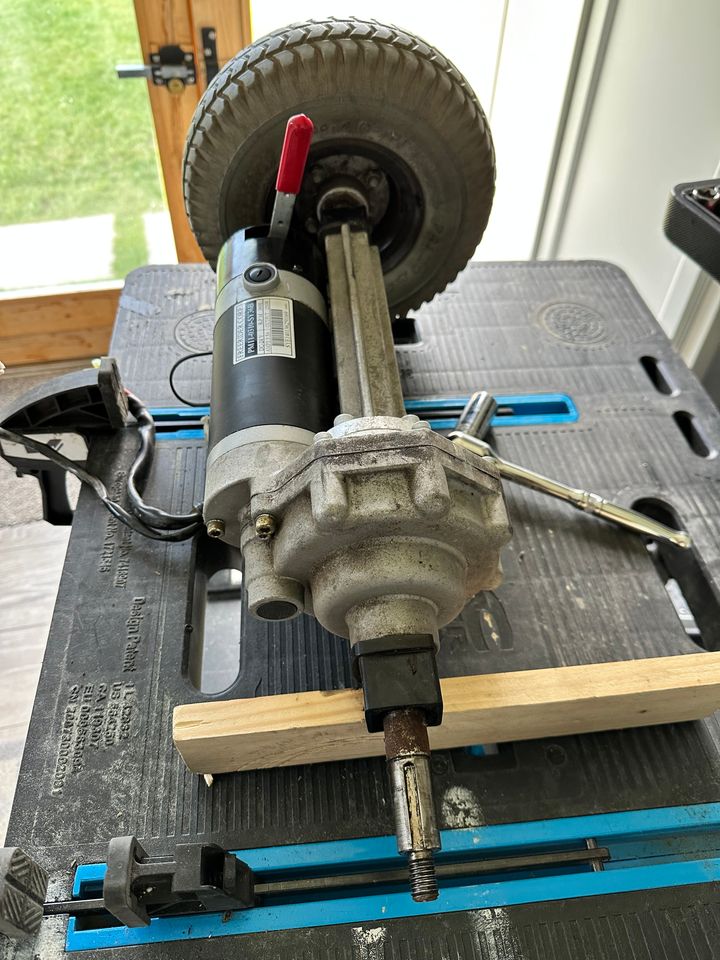

I need to try to widen the axle of a mobility scooter which is being used to make the kids a ride on car.

I’m struggling with coming up with a way to widen the rear axle by an inch either side.

Wider tyres won’t help as I won’t be able to get the nut back on to secure the new tyres, any ideas how I can do this?

I’m struggling with coming up with a way to widen the rear axle by an inch either side.

Wider tyres won’t help as I won’t be able to get the nut back on to secure the new tyres, any ideas how I can do this?

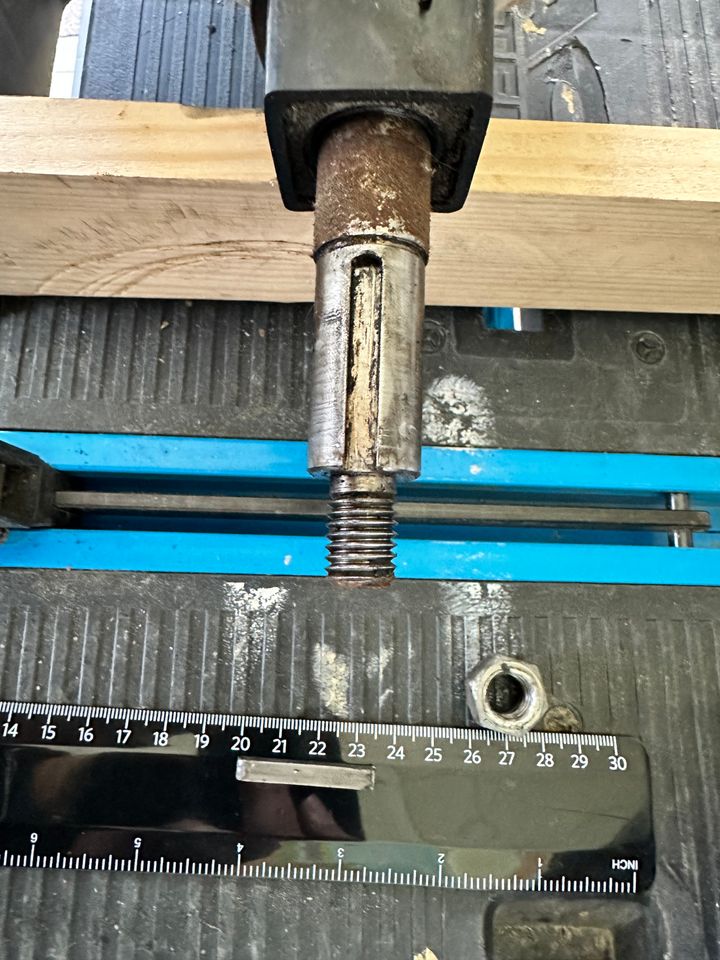

Internally threaded bar of the same diameter, attach to the existing thread, then add a piece of threaded bar into the other end to replicate what the wheel is fixed to,and I would run a bead of weld around having first chamfered a little off the edges, then weld into the gap created.

https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

J4CKO said:

Internally threaded bar of the same diameter, attach to the existing thread, then add a piece of threaded bar into the other end to replicate what the wheel is fixed to,and I would run a bead of weld around having first chamfered a little off the edges, then weld into the gap created.

https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

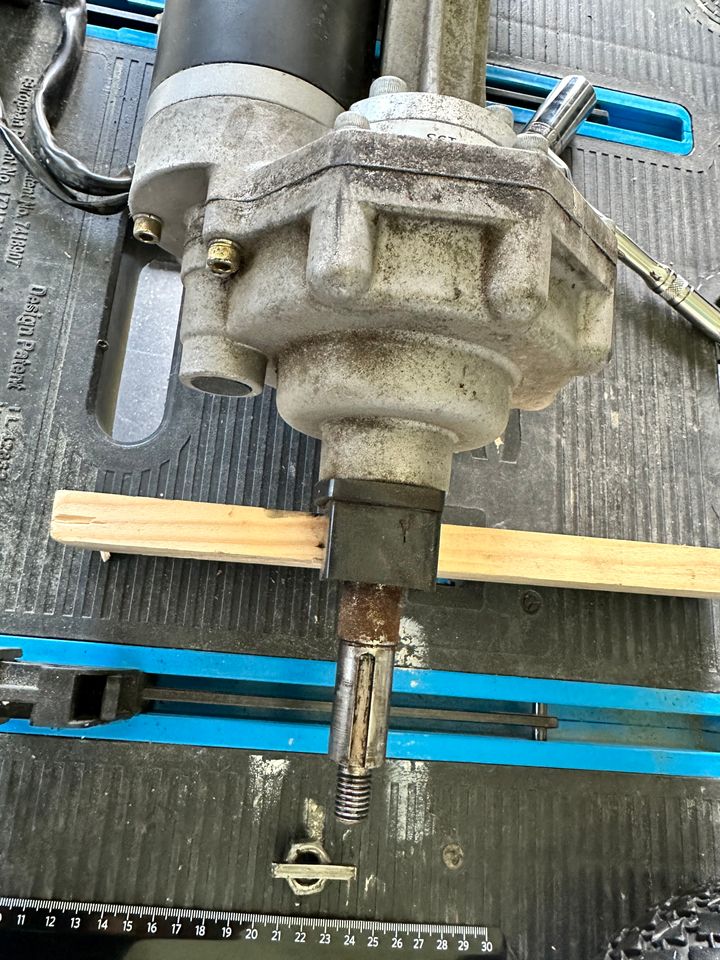

The only issue with this is that the current wheel has a slight notch cut out, almost like a key which ensure the axle spins the wheel. https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

Would have to see if I can replicate the notch onto the new piece

RZ1 said:

J4CKO said:

Internally threaded bar of the same diameter, attach to the existing thread, then add a piece of threaded bar into the other end to replicate what the wheel is fixed to,and I would run a bead of weld around having first chamfered a little off the edges, then weld into the gap created.

https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

The only issue with this is that the current wheel has a slight notch cut out, almost like a key which ensure the axle spins the wheel. https://www.ebay.co.uk/itm/111834853061?itmmeta=01...

Would have to see if I can replicate the notch onto the new piece

Would definitely need welding in that case though, good little project.

RZ1 said:

Wheel spacers won’t work as I can’t get the nut back on to secure the wheel.

Turning the wheel makes the width even narrower

If I'm reading this correctly, the wheel bolts to a hub, which fits onto the shaft, but then the bolt which secures that sub-assy to the axle bears down on the face of the wheel, not the face of the hub?Turning the wheel makes the width even narrower

Bill said:

I'd call that a 2 part split wheel and a hub. Bolt the hub to the shaft then use a spacer between the hub and wheel. Then find a suitable (or not) centre cap to cover the hole.

Looks like this could work, have managed to increase the width by 3/4 inch on one side, might need to see if I can find some slighter wider wheels as the ones I’ve got a 3 inch wide. Currently stretched them to 3 and 3/4 inch as I’ve used the spacer inside the tyre

Edited by RZ1 on Tuesday 16th April 18:02

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff