Pingu's Next Project - A Flowbench

Discussion

[Mass Flow Rate Calculations]

Delta P in N/sq m = C4*9.80638

[C4 = Difference between upstream and Downstream pressure in mm H2O]

Mass Flow Rate in kg/s =C23*I15*I14*(PI()/4)*((C2/1000)^2)*(2*C5*C3)^0.5

[C2 = Orifice diameter in mm]

[C3 = Air density im kg/cu m]

[C5 = Delta P]

[C23 = Discharge Coefficient]

[I14 = Expansion Factor]

[I15 = Approach Velocity Factor]

Delta P in N/sq m = C4*9.80638

[C4 = Difference between upstream and Downstream pressure in mm H2O]

Mass Flow Rate in kg/s =C23*I15*I14*(PI()/4)*((C2/1000)^2)*(2*C5*C3)^0.5

[C2 = Orifice diameter in mm]

[C3 = Air density im kg/cu m]

[C5 = Delta P]

[C23 = Discharge Coefficient]

[I14 = Expansion Factor]

[I15 = Approach Velocity Factor]

[Final Sheet Calculations]

Test Orifice Depression in inches H2O = C3/25.4

[C3 = Test orifice depression in mm H2O]

Volume Flow Rate in CFM = (C7/C2)*2118.88

[C2 = Ambient Air Density]

[C7 = Mass Flow Rate]

Volume Flow Rate Equivalent @ 10" H2O = C6*(10/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

Volume Flow Rate Equivalent @ 25" H2O = C6*(25/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

Volume Flow Rate Equivalent @ 28" H2O = C6*(28/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

Test Orifice Depression in inches H2O = C3/25.4

[C3 = Test orifice depression in mm H2O]

Volume Flow Rate in CFM = (C7/C2)*2118.88

[C2 = Ambient Air Density]

[C7 = Mass Flow Rate]

Volume Flow Rate Equivalent @ 10" H2O = C6*(10/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

Volume Flow Rate Equivalent @ 25" H2O = C6*(25/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

Volume Flow Rate Equivalent @ 28" H2O = C6*(28/C4)^0.5

[C6 = Volume flow rate at test orifice pressure difference]

[C4 = Test orifice pressure difference]

AW111 said:

Is there a reason you're converting everything to hogsheads and roods instead of sticking to SI units?

I always convert speed into miles per hour, and fuel consumption into miles per gallon. Flow rate is much the same, I think of it in cubic feet per minute.As for the calculations inside the spreadsheet, a lot of them were reverse-engineered from the internet. As the originals were in imperial, it was easier to do the calculations in imperial.

The inputs are SI, or the most commonly used unit (mm H2O, mBar, mm, °C). What happens inside the calculation doesn't matter to the user (much like an engine).

Mignon said:

I'm not sure why you're posting all these equations. Do you want someone to check them all?

An easier question might be have you actually found any errors in my own spreadsheet? If not then yours is right when it agrees with mine.

The main reason for posting was to put them somewhere safe. At least as safe as Pistonheads An easier question might be have you actually found any errors in my own spreadsheet? If not then yours is right when it agrees with mine.

Edited by Mignon on Sunday 18th November 05:12

.

.Anyone who wants to check them, please feel free.

They will never agree exactly with your results as your equation for the discharge coefficient is based on Stolz. This one is based on Reader-Harris/Gallagher. Both spreadsheets produce the same answer to within a few decimal points of CFM on the data you posted. That should be good enough for any sensible engineer.

This set of equations assumes a D / D/2 arrangement for the taps. I think that yours assumes flange taps.

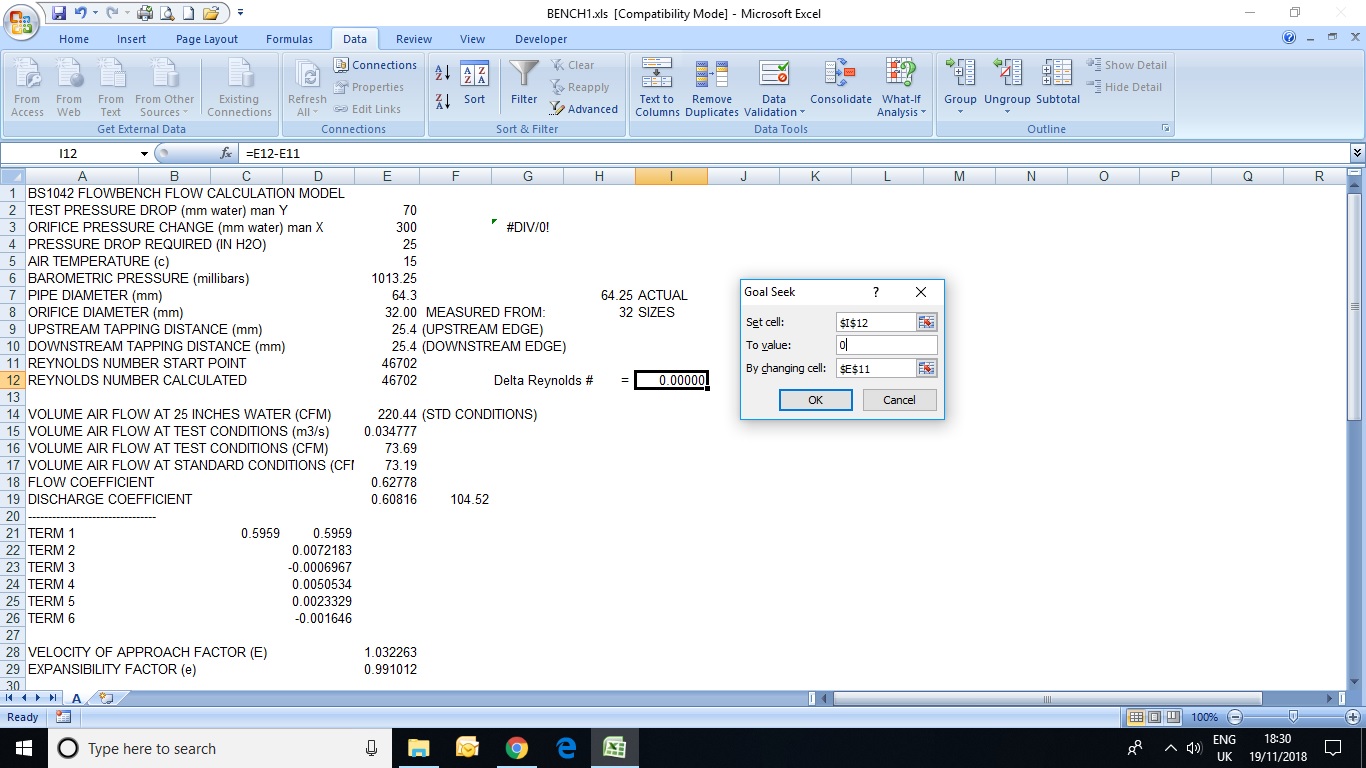

The only "fault" that I found in your spreadsheet was in how to use it. It was not a fault in the algorithms, but there was a circular reference on the Reynold's Number. The amendment that I made to your sheet was to add a cell where you manually update the Reynold's Number. This removed the circular reference. Just adjust the Reynold's Number until the updated Reynold's Number = the adjusted Reynold's Number.

Mignon said:

The circular reference was there on purpose you numpty. You just keep pressing "calc" and the Reynolds Number works itself out automatically.

A circular reference is an instant fail on every computing course I've ever done. It's not something a numpty like me was expecting to be deliberate.AW111 said:

There is a "goal seek" iterative function in excel, designed for exactly that purpose, but it's a while since I've used it.

I'm not sure what program Mignon used to write the program. Excel will allow you to load it, but it won't allow you to write it without warning you that you are creating a circular reference.I've just amended the program to use goal seek and it works.

Mignon's sheet has two Reynold's Number cells, REYNOLDS NUMBER START POINT and REYNOLDS NUMBER CALCULATED.

I've deleted the formula in REYNOLDS NUMBER START POINT. It is now just a value.

I've created a new cell that subtracts REYNOLDS NUMBER START POINT from REYNOLDS NUMBER CALCULATED.

I've used "goal seek" to change the value of REYNOLDS NUMBER START POINT until the value of the new cell equal ZERO.

The flow bench...

https://youtu.be/5G-cnCadl5c

It gives consistent results. I need to shorten the upstream pipe and I have a straightener at the ready.

https://youtu.be/5G-cnCadl5c

It gives consistent results. I need to shorten the upstream pipe and I have a straightener at the ready.

It only gets difficult if you want to build a bench that produces ABSOLUTE results that can be compared to other benches.

It's very easy to build a bench that compares RELATIVE results.

Vizard's bench is a RELATIVE test bench. He only compared his own modifications. Nothing wrong with that at all, and it's where I started - and probably should have stopped . I just found myself going down the rabbit hole of trying to make something that could produce results in SI units, rather than Pingus of pressure

. I just found myself going down the rabbit hole of trying to make something that could produce results in SI units, rather than Pingus of pressure

Good luck with your project.

It's very easy to build a bench that compares RELATIVE results.

Vizard's bench is a RELATIVE test bench. He only compared his own modifications. Nothing wrong with that at all, and it's where I started - and probably should have stopped

. I just found myself going down the rabbit hole of trying to make something that could produce results in SI units, rather than Pingus of pressure

. I just found myself going down the rabbit hole of trying to make something that could produce results in SI units, rather than Pingus of pressure

Good luck with your project.

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff