head gasket failure prompts winter rebuild

Discussion

TuxMan said:

Thanks for the input James , very strange that Mike could not map the car successfully , will have to bow down to Mr Yellowshed for a reason as to why , wonder if anyone else has had the same issues ???

I take it Mike covered the extra cost of Trevor remapping your car ??

To my dismay, as with all of the issues i have had post build, no additional costs have been offered yet!I take it Mike covered the extra cost of Trevor remapping your car ??

I am taking matters further so i'd rather not comment on any more detail here. sure you understand.

James

Here are pics of the only markings i can find on the gaskets which were fitted to my car.

the black one here only has a barcode on which i'm guessing would mean something to Ford...

the blue on has these markings on and a symbol which i think stands for Ford Motor Company:

2S7E-6083-CC

C3HO3

Anyone recognise them?

cheers

the black one here only has a barcode on which i'm guessing would mean something to Ford...

the blue on has these markings on and a symbol which i think stands for Ford Motor Company:

2S7E-6083-CC

C3HO3

Anyone recognise them?

cheers

Had a phone call today from AW Tracksport who are cleaning up the pistons and checking the heads. one of my pistons needs to be replaced unfortunately.

the strip of material between the two piston rings had cracked and fell off while the piston was being cleaned. guess that's an excuse to upgrade....

am i the first big power car to find the limit of the standard pistons...

cheers

James

Trevor (yellowshed) knew the build of the car and advised a cap at 450ftlbs torque. Which equated to 530bhp at whatever revs (can't remember exactly).

Perhaps the extra power and torque was enough to tip it over the edge but I suspect it would have failed even if id have had the same stats as Tux! It's not as though the car had done many miles on the new set up!

Cheers

Perhaps the extra power and torque was enough to tip it over the edge but I suspect it would have failed even if id have had the same stats as Tux! It's not as though the car had done many miles on the new set up!

Cheers

hey guys,

here's a little update on the winter rebuild. sorry i've been so quiet, busy times.

spent the last month or so cleaning up the various engine parts ready for the rebuild. in between xmas and new year i took a little trip to Jetstream to pick up all the gaskets and gear linkage parts.

I've also started to cut the tunnel ready for the Jetstream gear linkage upgrade and wiring in my data logger.

I was planning on getting the original pistons cleaned up and ceramic coated but when tracksport were cleaning the ring grooves one of the pistons broke apart. this explains the pressure that was getting into the sump when i was at Silverstone.

here's a pic of the bit that broke off. it was the only piston which was damaged

the heads are back from the engine builder. They were leak tested and checked for flatness and all ok :-). the valves were ground in and the valve seals were replaced.

the exhaust has just come back from CamCoat and looks the business.

Andy from Tracksport travelled up yesterday to help me get the engine back together. We honed the bores and put the new Mountune forged pistons, arrow conrods and uprated new bearing shells together.

we then hit a bit of a snag. we fitted a couple of the pistons to the block and turned the engine by hand to make sure everything was ok and when the pistons got to the bottom of the stroke the engine would not turn further. on further inspection we could see the bottom of the new pistons was contacting the counter weight on the crank (on both pistons we had fitted).

We then compared the new pistons to the original Noble ones and the original ones are cast pistons but then someone has machined away material around the gudgeon pin to prevent this clash. Frustrating as that stopped work for the day. I've had a chat with Jetstream and we will be looking into it next week so interested to see how that progresses.

here are some pics of what i'm talking about...

of course the Arrow conrods are shorter than the original ford parts to lower the compression ratio for the turbos so the piston would sit lower in the cylinder which would explain why Noble would have needed to machine the pistons here.

The mountune pistons have about 1mm of extra material than the Noble pistons so it is not far off.

The Mountune pistons are designed for the normally aspirated engine so they would not be expecting the shorter conrods so i think i need to get the pistons machined in a similar way but as i say, we are looking into it and will let you lot know what we find out.

cheers

James

here's a little update on the winter rebuild. sorry i've been so quiet, busy times.

spent the last month or so cleaning up the various engine parts ready for the rebuild. in between xmas and new year i took a little trip to Jetstream to pick up all the gaskets and gear linkage parts.

I've also started to cut the tunnel ready for the Jetstream gear linkage upgrade and wiring in my data logger.

I was planning on getting the original pistons cleaned up and ceramic coated but when tracksport were cleaning the ring grooves one of the pistons broke apart. this explains the pressure that was getting into the sump when i was at Silverstone.

here's a pic of the bit that broke off. it was the only piston which was damaged

the heads are back from the engine builder. They were leak tested and checked for flatness and all ok :-). the valves were ground in and the valve seals were replaced.

the exhaust has just come back from CamCoat and looks the business.

Andy from Tracksport travelled up yesterday to help me get the engine back together. We honed the bores and put the new Mountune forged pistons, arrow conrods and uprated new bearing shells together.

we then hit a bit of a snag. we fitted a couple of the pistons to the block and turned the engine by hand to make sure everything was ok and when the pistons got to the bottom of the stroke the engine would not turn further. on further inspection we could see the bottom of the new pistons was contacting the counter weight on the crank (on both pistons we had fitted).

We then compared the new pistons to the original Noble ones and the original ones are cast pistons but then someone has machined away material around the gudgeon pin to prevent this clash. Frustrating as that stopped work for the day. I've had a chat with Jetstream and we will be looking into it next week so interested to see how that progresses.

here are some pics of what i'm talking about...

of course the Arrow conrods are shorter than the original ford parts to lower the compression ratio for the turbos so the piston would sit lower in the cylinder which would explain why Noble would have needed to machine the pistons here.

The mountune pistons have about 1mm of extra material than the Noble pistons so it is not far off.

The Mountune pistons are designed for the normally aspirated engine so they would not be expecting the shorter conrods so i think i need to get the pistons machined in a similar way but as i say, we are looking into it and will let you lot know what we find out.

cheers

James

been speaking to Dave at Jetstream today, very helpful.

he's spoken to Mountune and they don't think they have every machined pistons but we doubt that. Dave has another set of pistons, rods and a crank and his has the same clash.

we both plan to machine the back of the pistons to remove the clash. will put some pics up soon. it only needs a small area reducing by just over 1mm.

here are some pics of my sexy black ceramic coated exhasut. the exhaust was bead blasted prior to coating and has come up really well.

he's spoken to Mountune and they don't think they have every machined pistons but we doubt that. Dave has another set of pistons, rods and a crank and his has the same clash.

we both plan to machine the back of the pistons to remove the clash. will put some pics up soon. it only needs a small area reducing by just over 1mm.

here are some pics of my sexy black ceramic coated exhasut. the exhaust was bead blasted prior to coating and has come up really well.

daddysumo said:

James,

1) Are you using the Noble Arrow rods or Mountune Arrow rods.

2) Are you uing M400 type pistons or Mountune spec pistons.

Keep up the good work.. looking good !

hey Steve,1) Are you using the Noble Arrow rods or Mountune Arrow rods.

2) Are you uing M400 type pistons or Mountune spec pistons.

Keep up the good work.. looking good !

just seen your post. Noble Arrow rods and i'm 99% sure the pistons are Mountune spec as the M400 ones don't fit the Arrow rods (from what i understand).

On another note, the pro alloy header tank arrived today from Jetstream and it looks bloody good, well made bit of kit.

Also, the Pistons have been sent back to Jetstream where they will be machined. thanks to them for sorting a fix and picking up the cost of modifying them.

Planning on rebuilding the engine on Sat 4th of Feb as away for the next two weekends.

cheers

James

had a great day yesterday...

rebuilt the engine with Andy from AW Tracksport keeping a careful eye on my workmanship. went smoothly.

going to pop in the garage for a couple of hours this afternoon and pop the turbos on and get the exhaust fitted one night this week. all getting exciting now. no reason why i shouldn't be done by my target, end of Feb :-). the Spa/Ring trip in April is looking more likely...

couple of black head gaskets ;-)

cheers

rebuilt the engine with Andy from AW Tracksport keeping a careful eye on my workmanship. went smoothly.

going to pop in the garage for a couple of hours this afternoon and pop the turbos on and get the exhaust fitted one night this week. all getting exciting now. no reason why i shouldn't be done by my target, end of Feb :-). the Spa/Ring trip in April is looking more likely...

couple of black head gaskets ;-)

cheers

a few more pics uploaded...

made a bit more progress on Monday night after work :-)

a pic of when i was first stripping the car apart... all over the drive

look what some kind garage left in the car!!!! no word of a lie, when i routing some cables for the data logger i pulled away the aircon pipes and found a ratchet spanner behind them!!! thanks to whichever garage donated that to me...

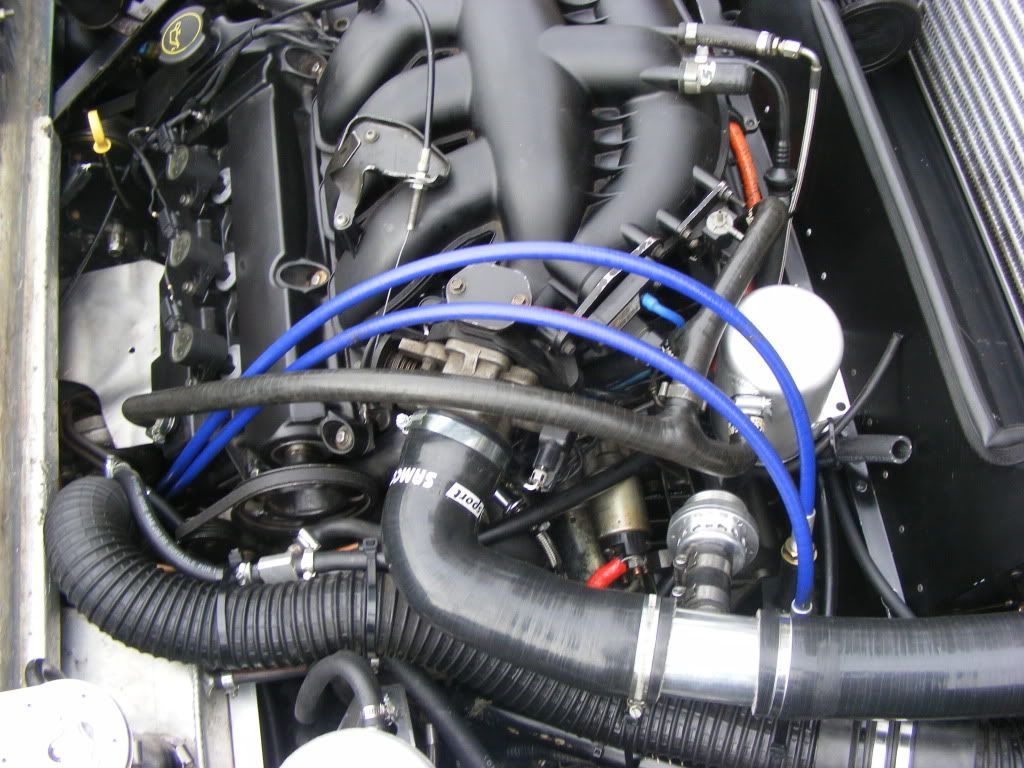

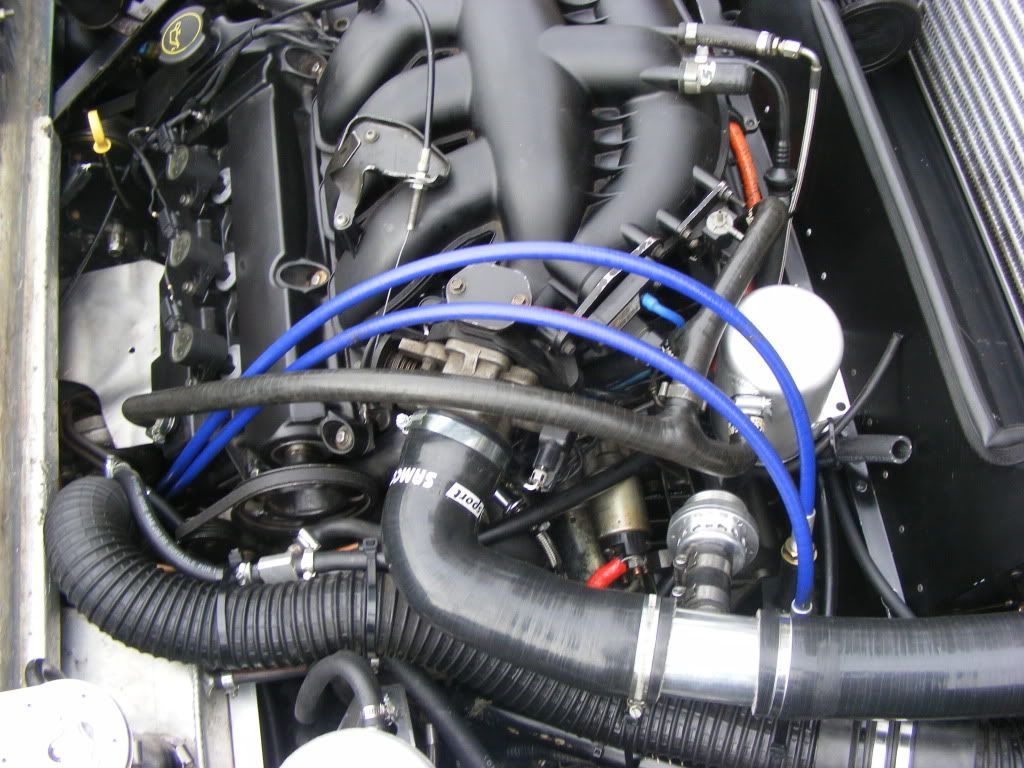

front turbo in place with ceramic coated header and down pipe/cat

front head shield and dip stick in place...

getting there. started looking at routings of harnesses etc.

hoping to finish all bar the finishing touches off this weekend. will take some pics of the upgraded gear linkage as well. i have it all bolted in place and it changes well. i still need to do a little bit of adjustment and then make the cover for the tunnel...

celebrated the progress last weekend by booking onto the trackday on Sat 17th March (Silverstone GP) and Spa on 2nd April :-)

cheers

James

made a bit more progress on Monday night after work :-)

a pic of when i was first stripping the car apart... all over the drive

look what some kind garage left in the car!!!! no word of a lie, when i routing some cables for the data logger i pulled away the aircon pipes and found a ratchet spanner behind them!!! thanks to whichever garage donated that to me...

front turbo in place with ceramic coated header and down pipe/cat

front head shield and dip stick in place...

getting there. started looking at routings of harnesses etc.

hoping to finish all bar the finishing touches off this weekend. will take some pics of the upgraded gear linkage as well. i have it all bolted in place and it changes well. i still need to do a little bit of adjustment and then make the cover for the tunnel...

celebrated the progress last weekend by booking onto the trackday on Sat 17th March (Silverstone GP) and Spa on 2nd April :-)

cheers

James

You're making me jealous, all this talk of snow holidays :-(.

I should have been in chamomix this week but I can't afford to use the holiday days cause I need them all for racing commitments. Been to the 3 valleys the last few years and love it

Also, would quite fancy a blast up to Glenshee this weekend but I'm determined to finish most of the Noble off. Have a good time up there.

I should have been in chamomix this week but I can't afford to use the holiday days cause I need them all for racing commitments. Been to the 3 valleys the last few years and love it

Also, would quite fancy a blast up to Glenshee this weekend but I'm determined to finish most of the Noble off. Have a good time up there.

i think i need to rename this thread to "head gasket failure prompts everyone to rub it in that they have been skiing/boarding and i haven't" ;-).

I really wanted to go this year as well.

anyways, exhaust back on the car last night. Hoping to pick up some hose tomorrow and there's no reason why i can't get it started by the end of the weekend :-)

I really wanted to go this year as well.

anyways, exhaust back on the car last night. Hoping to pick up some hose tomorrow and there's no reason why i can't get it started by the end of the weekend :-)

Up till 1.30 in the morning last night and fired her up just now... Pics to follow

http://www.youtube.com/watch?v=oRy4143d53k&fea...

:-D

http://www.youtube.com/watch?v=oRy4143d53k&fea...

:-D

here's a few pics of progress...

great way to hold the battery up

Alfie took great care when organising the clips ha

day light for the first time in a while!

still got to finish piping in the pro alloy catch tank, finish the mount of the Jetstream gear linkage adjustment, bolt the seats back in then she'll be ready for a quick test drive around the block.

questions:

what do people think is the best way to run a new engine in?

Where do the 2 pipes on the bottom of the pro alloy catch tank go? i assume 1 is the return to the tank, the other?

Am i right in saying the 2 vacuum lines which go to the turbos join together and attach to the top of the throttle body? just i have a dump valve and it connects to one of the vacuum lines near the butterfly valve but i only have the pipe on the throttle body left and i'm sure that is the reference vacuum for the turbos :-S. will add some specific photos soon

cheers

James

great way to hold the battery up

Alfie took great care when organising the clips ha

day light for the first time in a while!

still got to finish piping in the pro alloy catch tank, finish the mount of the Jetstream gear linkage adjustment, bolt the seats back in then she'll be ready for a quick test drive around the block.

questions:

what do people think is the best way to run a new engine in?

Where do the 2 pipes on the bottom of the pro alloy catch tank go? i assume 1 is the return to the tank, the other?

Am i right in saying the 2 vacuum lines which go to the turbos join together and attach to the top of the throttle body? just i have a dump valve and it connects to one of the vacuum lines near the butterfly valve but i only have the pipe on the throttle body left and i'm sure that is the reference vacuum for the turbos :-S. will add some specific photos soon

cheers

James

TuxMan said:

Looks great James , I've been told to use a mineral running in oil for the first 500 miles before changing to a full synthetic , what does AW Motorsport recommend ?

Pretty much what AW recommend. Was interested in driving miles, eg. Run in hard, keep revs below 4k revs for 200miles etc etcCheers

Blu3R said:

Yes. In fact you can use any vacuum point that is convenient. Mine had a dump valve when I bought it and it had been tee'd into the short hose that feeds the actuator tee.

thanks for the tips mate. thought as much with the Vacuum. so should the dump valve just be connected to the vacuum, there no reason why it should be attached to anything else (unless it is tee'd in???on the breather, i take it that it is the bigger fat pipe, which comes with the kit, that vents to atmoshere?

cheers

Gassing Station | Noble | Top of Page | What's New | My Stuff

!

!