E30 M52-swapped Trackday Car

Discussion

More news - its nearly done!

Once the throttle cable was sorted, the only thing that was stopping me taking it for a quick spin around the compound was the anti-social lack of exhaust. So I remedied this by refitting the heat shield for the prop (which took much longer to figure out than it should've done) and fit my £40 exhaust. Fitting an exhaust on your own, on axle stands is not easy nor enjoyable. But I got there in the end and now the car really is starting to look presentable.

I then plumbed in the screenwash tubes for the fibreglass bonnet. An easy job requiring nothing more than some short self-tappers and some p-clips, but fitting the nozzles was another matter.

These are made of plastic and have a small stub with two tabs on it, so when you push them through the holes in the bonnet, the tabs stop it being pulled back out again. This is all well and good when you have a bonnet of 0.3 mm thick steel, but the skin of my fibreglass bonnet is somewhat thicker than that! So they didn't fit very well at all.

Enter Sugru. If you've not come across this stuff before, it's kinda like chemical metal, but the rubber version. And it bonds to stuff really well.

http://sugru.com/

One of my colleagues has made himself some custom ear buds for his headphones and I was really impressed. I thought it would be perfect for fitting my washer jets, and you know what? It was.

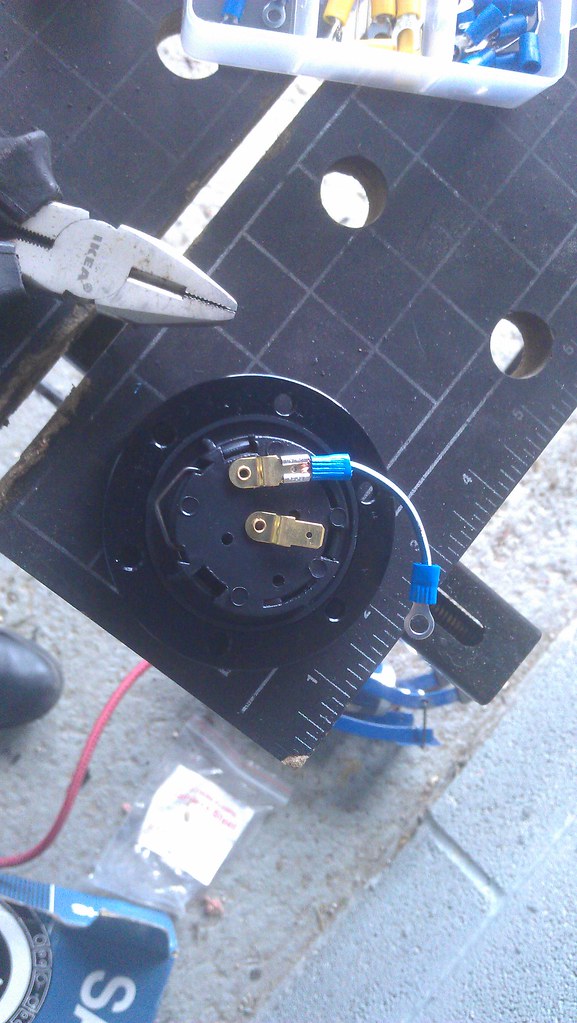

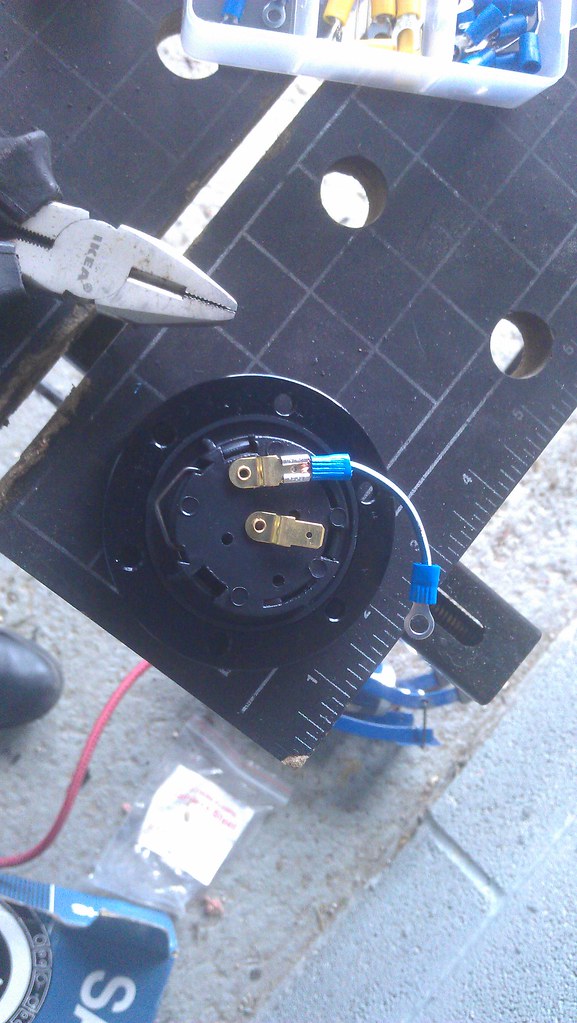

Then I addressed my issues with the standard steering wheel; namely it being too far away and being large enough to seriously impede my entry and exit from the car with my long ass legs. I got a dished 350 mm wheel and OMP boss from Rally Design, made a short wire to complete the earth circuit for the horn and all was good. The driving position is now infinitely better. And the horn works as it should.

It was at this point that I fired it up and took it for a quick spin, albeit not faster than walking pace. Unfortunately, the ECU is not secure yet and has a habit of dropping behind the clutch and/or brake pedal so until that was fixed, I wasn't going to give it any juice. Sounds well though. Very well. The non-assisted brakes felt weird at first but I quickly got the feel for them and the clutch is heavy, but smooth.

This afternoon, I skipped of work early, given the good weather and set about doing a little more work. First, I gave the inside of the rear windows, rear shelf & bench a good clean, cleaned up the passenger seat then fitted it properly, complete with harness and grip-tape in the floorpan.

I started tidying up the last of the wiring and found a place to mount the ECU securely. Albeit with a bungee cord, but a small luggage strap will do a more permanent job once I get a hold of one. Basically, it's suspended upside down underneath the dashboard and strapped solidly to the bulkhead by threading the strap through factory holes in the bulkhead.

Then I gave it the juice

I've also done a quick test of lights and electrics with a fairly good success rate, but currently I'm without electric windows and indicators, both which are a problem. Also, the fan doesn't kick in when it should so I need to figure out what's going on there.

Once I've resolved these, the only outstanding matters are figuring out what to do with the fuel tank breather, wheel alignment and (still) a few outstanding brackets I need to make for the power terminal under the bonnet, the PAS fluid reservoir and the bias bar adjuster. Then it's MOT time baby!

Once the throttle cable was sorted, the only thing that was stopping me taking it for a quick spin around the compound was the anti-social lack of exhaust. So I remedied this by refitting the heat shield for the prop (which took much longer to figure out than it should've done) and fit my £40 exhaust. Fitting an exhaust on your own, on axle stands is not easy nor enjoyable. But I got there in the end and now the car really is starting to look presentable.

I then plumbed in the screenwash tubes for the fibreglass bonnet. An easy job requiring nothing more than some short self-tappers and some p-clips, but fitting the nozzles was another matter.

These are made of plastic and have a small stub with two tabs on it, so when you push them through the holes in the bonnet, the tabs stop it being pulled back out again. This is all well and good when you have a bonnet of 0.3 mm thick steel, but the skin of my fibreglass bonnet is somewhat thicker than that! So they didn't fit very well at all.

Enter Sugru. If you've not come across this stuff before, it's kinda like chemical metal, but the rubber version. And it bonds to stuff really well.

http://sugru.com/

One of my colleagues has made himself some custom ear buds for his headphones and I was really impressed. I thought it would be perfect for fitting my washer jets, and you know what? It was.

Then I addressed my issues with the standard steering wheel; namely it being too far away and being large enough to seriously impede my entry and exit from the car with my long ass legs. I got a dished 350 mm wheel and OMP boss from Rally Design, made a short wire to complete the earth circuit for the horn and all was good. The driving position is now infinitely better. And the horn works as it should.

It was at this point that I fired it up and took it for a quick spin, albeit not faster than walking pace. Unfortunately, the ECU is not secure yet and has a habit of dropping behind the clutch and/or brake pedal so until that was fixed, I wasn't going to give it any juice. Sounds well though. Very well. The non-assisted brakes felt weird at first but I quickly got the feel for them and the clutch is heavy, but smooth.

This afternoon, I skipped of work early, given the good weather and set about doing a little more work. First, I gave the inside of the rear windows, rear shelf & bench a good clean, cleaned up the passenger seat then fitted it properly, complete with harness and grip-tape in the floorpan.

I started tidying up the last of the wiring and found a place to mount the ECU securely. Albeit with a bungee cord, but a small luggage strap will do a more permanent job once I get a hold of one. Basically, it's suspended upside down underneath the dashboard and strapped solidly to the bulkhead by threading the strap through factory holes in the bulkhead.

Then I gave it the juice

I've also done a quick test of lights and electrics with a fairly good success rate, but currently I'm without electric windows and indicators, both which are a problem. Also, the fan doesn't kick in when it should so I need to figure out what's going on there.

Once I've resolved these, the only outstanding matters are figuring out what to do with the fuel tank breather, wheel alignment and (still) a few outstanding brackets I need to make for the power terminal under the bonnet, the PAS fluid reservoir and the bias bar adjuster. Then it's MOT time baby!

So, stepping back a fortnight or so, here was my ECU suspended underneath the dashboard by a bungee cord:

This is now secured properly with some slip straps. It's not going anywhere. Under the bonnet, I had some brackets to make for the dipstick tube, the airbox and the power block.

And I also had to fit and mount my brake bias knob. I'd left the driver's side air vent free precisely for this purpose:

With regards to potential issues with the immenent MOT; I've had an ongoing problem with weeping brake fluid since I'd done the bleed of the braking system. It only weeped under pressure and it was coming from a union between a hard line and flexi pipe at the top of the offside rear trailing arm. The hardest b*stard union to get access to on the whole car. I was putting this off as I had a suspicion I might need to replace the hardline which may well have been a 'drop the heat shield & exhaust' job. As it turns out, it was just a matter of getting the right angle on it with a pair of spanners. It wasn't tight - it just felt tight because I'd assembled it dry about 14 months ago. It clicked then I got an easy half turn out of it and the weeping has stopped. I now have a fluid-tight braking system.

I also had no working indicators. At all. I had power to the hazard light switch as when that was pushed, it lit up, but there was no flashing and there were no signal lights.

On the E30, the hazard light switch is a junction box. So I started my troubleshooting by jumping various ports on the hazard light switch socket to see what reactions I got. I could get the indicators to light up, I could get them to flash, I could get them to flash via the indicator stalk, albeit only on the offside...and then the socket began to fall apart in my hands. Wires started falling out of the crimps and there was a dodgy looking connection on the power feed. I sourced a second hand socket with plenty wire attached, along with another hazard light switch for good measure, then cut out the old one and soldered in the new one. Problem solved, indicators then worked perfectly - save for the ones in the front bumper. Some testing with a multimeter narrowed this down to a poor connection between the bulb and bulb holder, so some adjustments to the spring in the holder saw these working too.

I was struggling with ideas with what to do about the fuel tank breather too, another job I'd been putting off. Pre-facelift (i.e. pre-1987) E30s just had the breather open above the fuel tank, whereas facelifted (post 1987) E30s had a pipe running from the tank to a carbon cannister under the bonnet and then into the intake manifold via a valve. I didn't particularly like either of these ideas - one being that I found it difficult to thread a pipe up and over the fuel tank due to clearances. I ended up with a sort of half-way measure using an idea I swiped from a kit car forum. I used a small universal fuel filter, opened it up and filled it with activated carbon pellets - the stuff used for fish tank filters. I closed it and attached the breather pipe to this, then left the top open up at the top of the fuel tank. This meant I had an open breather but without the stink of fuel typically associated with old cars.

Moving onto some mundane tasks; there was fitting the bonnet, fitting roll-cage padding, cleaning the car out and doing front wheel alignment (which I've slightly c*cked up, but I'll talk about that in my next post once I've remedied it). I had a bracket to make for the exhaust centre box and managed to source a front strut brace (Ultra Racing) cheap as an ex-display item.

Then, just when I thought I was about done, my engine started sounding like a sewing machine.

Poking around using a large screwdriver as a stethoscope, I sourced the noise down to the injectors - all 6 of them. Batch firing? perhaps. Nevertheless, I checked electrical connections for the cam sensor, crank sensor, lambda sensors, VANOS and fuel rail. I made sure the inlet manifold was properly torqued down and checked all breather connections. I also pulled the cam sensor, cleaned it up with a bit of fuel and replaced it. I then had a nice quiet M52, but a broken bracket on the cam sensor due to my having hands like feet. Nearly £80 for a new one! Nevertheless, problem resolved.

So tomorrow, it goes for the MOT. Fingers are crossed, hoping for the best. In the meantime, here's some photos of the (hopefully) road-worthy car. I'm not going to say it's finished as, well it's not. Quite. And probably never will be. But for now...

This is now secured properly with some slip straps. It's not going anywhere. Under the bonnet, I had some brackets to make for the dipstick tube, the airbox and the power block.

And I also had to fit and mount my brake bias knob. I'd left the driver's side air vent free precisely for this purpose:

With regards to potential issues with the immenent MOT; I've had an ongoing problem with weeping brake fluid since I'd done the bleed of the braking system. It only weeped under pressure and it was coming from a union between a hard line and flexi pipe at the top of the offside rear trailing arm. The hardest b*stard union to get access to on the whole car. I was putting this off as I had a suspicion I might need to replace the hardline which may well have been a 'drop the heat shield & exhaust' job. As it turns out, it was just a matter of getting the right angle on it with a pair of spanners. It wasn't tight - it just felt tight because I'd assembled it dry about 14 months ago. It clicked then I got an easy half turn out of it and the weeping has stopped. I now have a fluid-tight braking system.

I also had no working indicators. At all. I had power to the hazard light switch as when that was pushed, it lit up, but there was no flashing and there were no signal lights.

On the E30, the hazard light switch is a junction box. So I started my troubleshooting by jumping various ports on the hazard light switch socket to see what reactions I got. I could get the indicators to light up, I could get them to flash, I could get them to flash via the indicator stalk, albeit only on the offside...and then the socket began to fall apart in my hands. Wires started falling out of the crimps and there was a dodgy looking connection on the power feed. I sourced a second hand socket with plenty wire attached, along with another hazard light switch for good measure, then cut out the old one and soldered in the new one. Problem solved, indicators then worked perfectly - save for the ones in the front bumper. Some testing with a multimeter narrowed this down to a poor connection between the bulb and bulb holder, so some adjustments to the spring in the holder saw these working too.

I was struggling with ideas with what to do about the fuel tank breather too, another job I'd been putting off. Pre-facelift (i.e. pre-1987) E30s just had the breather open above the fuel tank, whereas facelifted (post 1987) E30s had a pipe running from the tank to a carbon cannister under the bonnet and then into the intake manifold via a valve. I didn't particularly like either of these ideas - one being that I found it difficult to thread a pipe up and over the fuel tank due to clearances. I ended up with a sort of half-way measure using an idea I swiped from a kit car forum. I used a small universal fuel filter, opened it up and filled it with activated carbon pellets - the stuff used for fish tank filters. I closed it and attached the breather pipe to this, then left the top open up at the top of the fuel tank. This meant I had an open breather but without the stink of fuel typically associated with old cars.

Moving onto some mundane tasks; there was fitting the bonnet, fitting roll-cage padding, cleaning the car out and doing front wheel alignment (which I've slightly c*cked up, but I'll talk about that in my next post once I've remedied it). I had a bracket to make for the exhaust centre box and managed to source a front strut brace (Ultra Racing) cheap as an ex-display item.

Then, just when I thought I was about done, my engine started sounding like a sewing machine.

Poking around using a large screwdriver as a stethoscope, I sourced the noise down to the injectors - all 6 of them. Batch firing? perhaps. Nevertheless, I checked electrical connections for the cam sensor, crank sensor, lambda sensors, VANOS and fuel rail. I made sure the inlet manifold was properly torqued down and checked all breather connections. I also pulled the cam sensor, cleaned it up with a bit of fuel and replaced it. I then had a nice quiet M52, but a broken bracket on the cam sensor due to my having hands like feet. Nearly £80 for a new one! Nevertheless, problem resolved.

So tomorrow, it goes for the MOT. Fingers are crossed, hoping for the best. In the meantime, here's some photos of the (hopefully) road-worthy car. I'm not going to say it's finished as, well it's not. Quite. And probably never will be. But for now...

So, it's now all road legal and above board  failed the MOT first time round on headlamp misalignment and the adjusters needed freeing up. But 2nd time pass with no advisories. I'm a happy man!

failed the MOT first time round on headlamp misalignment and the adjusters needed freeing up. But 2nd time pass with no advisories. I'm a happy man!

The drive to/from the garage did highlight a couple of issues though. Firstly, I have the rear dampers set way too soft. The exhaust hits the valence when turning/over bumps. The rear tyres scrub the arches from time to time. So first stop is the bodyshop to sort out the arches and amend the previous bodge job. Then I'll address the issues with the dampers and I should be able to give it some stick and see how it goes.

I'm also not entirely happy with my top hose arrangement, it looks a little restrictive so I'm going to sort this out. Then I have 6 litres of 5w40 fully synthetic Valvoline to go in and replace the 5w30 diesel oil that's in there now cleaning things out.

Very pleased with the way it sounds and can't wait to give it some death!

failed the MOT first time round on headlamp misalignment and the adjusters needed freeing up. But 2nd time pass with no advisories. I'm a happy man!

failed the MOT first time round on headlamp misalignment and the adjusters needed freeing up. But 2nd time pass with no advisories. I'm a happy man!The drive to/from the garage did highlight a couple of issues though. Firstly, I have the rear dampers set way too soft. The exhaust hits the valence when turning/over bumps. The rear tyres scrub the arches from time to time. So first stop is the bodyshop to sort out the arches and amend the previous bodge job. Then I'll address the issues with the dampers and I should be able to give it some stick and see how it goes.

I'm also not entirely happy with my top hose arrangement, it looks a little restrictive so I'm going to sort this out. Then I have 6 litres of 5w40 fully synthetic Valvoline to go in and replace the 5w30 diesel oil that's in there now cleaning things out.

Very pleased with the way it sounds and can't wait to give it some death!

Thanks guys

Yeah, every other weekend just doesn't cut it if you're tight for time. Takes lots of hours, only this year have I been working most weekends and occasional evenings.

e21mark - bet the E21 goes very well indeed with the M52. Out of interest, what did you feel were the shortcomings of the S50'd E30?

So, today I stiffened up the rear dampers. This is a little more involved than I would like at the moment as the Koni shocks require removal from the car to adjust. Still, it can be done on the ground and aside from being a bit fiddly for one man to do, its possible. I also made sure that the few road miles it has havn't 'unsettled' the rear subframe, diff etc so I torqued everything up again. Rear subframe nuts were surprisingly slack...but not anymore.

The front shocks were a little high too, so I dropped those by 15 mm and made sure damping pressure was even across the fronts. Then I took it for a short drive and it felt a hell of a lot better. Rear tyres still catch the arches, but a lot less severe than it was and the crashiness is gone. I changed the oil when I got back so now mechanically its almost there. I'm going to drop it off at the bodyshop tomorrow and see about getting the arches sorted and getting the rear wheel alignment done.

Yeah, every other weekend just doesn't cut it if you're tight for time. Takes lots of hours, only this year have I been working most weekends and occasional evenings.

e21mark - bet the E21 goes very well indeed with the M52. Out of interest, what did you feel were the shortcomings of the S50'd E30?

So, today I stiffened up the rear dampers. This is a little more involved than I would like at the moment as the Koni shocks require removal from the car to adjust. Still, it can be done on the ground and aside from being a bit fiddly for one man to do, its possible. I also made sure that the few road miles it has havn't 'unsettled' the rear subframe, diff etc so I torqued everything up again. Rear subframe nuts were surprisingly slack...but not anymore.

The front shocks were a little high too, so I dropped those by 15 mm and made sure damping pressure was even across the fronts. Then I took it for a short drive and it felt a hell of a lot better. Rear tyres still catch the arches, but a lot less severe than it was and the crashiness is gone. I changed the oil when I got back so now mechanically its almost there. I'm going to drop it off at the bodyshop tomorrow and see about getting the arches sorted and getting the rear wheel alignment done.

Edited by motorhole on Sunday 8th September 16:01

Well, the E30 was due for its first trackday on Friday 20th at Blyton Park, but...sadly...it didn't make it.

I got the car back from the bodyshop on Tuesday, where they had been tidying up some previously bodged arch work and trying to get extra clearance for the wheels. When I got back from the short drive through traffic, coolant was pissing out of the expansion cap and dripping from a hose that I knew was weeping and needed fixing anyway (although temperature was fine). Not good at all. I could only presume that my regular but small coolant top ups due to the weeping hose had somehow worked an airlock into the troublesome M52 coolant circuit. I hoped it wasn't a head gasket problem...

I took a long lunch hour on Wednesday to re-bleed the system from scratch but didn't manage to bleed it properly. I ended up with an airlocked system that wouldn't blow hot air from the heaters. I then decided that Thursday night was the night and I would do it properly, no rushing...and fix that damn weeping hose while I was at it.

So I drained the system, took the hose apart at the join where it was weeping, fitted slightly smaller t-bolts for a tighter fit (before the t-bolts were at their min diameter and still weren't gripping the hose correctly) and replaced it. I then took my time to refill the system correctly and replaced the expansion cap with another spare I had lying around for good measure. Done, fired up, warmed up, hot air through heaters, fan kicks in, tiny spot of air on slackening the bleed screw and nothing more, job done. Sadly, I didn't have time for the test drive and I wasn't willing to risk a 250 mile round trip and trackday on Friday in a car with questionable durability...so track duties were left to the ever reliable Fabia.

Fabias arn't built for racetracks. Too heavy and too much body roll. It was all too easy to cook the brakes, but I still had a laugh!

Nevertheless, this morning I went back to the BMW. After warming it up, I took it for a proper spin. Town driving, dual carriageway, some redline action, about 15 miles in all - and it took it with no problems. When I'd finished, I checked for air at the bleed screw and there was none. So, it appears, it's now ready for action, just one day late.

I am still suffering from rear tyre scrub though, particularly in harder left handers and under hard acceleration. I think I'm going to have to go the hard route and find some 16" wheels that'll clear the E36 M3 front brakes, in a slightly higher offset. Sad to loose money on nearly new wheels and tyres, but it will make for a better drive in the long run I think. Still, pleased to finally have it on the road and running properly

I got the car back from the bodyshop on Tuesday, where they had been tidying up some previously bodged arch work and trying to get extra clearance for the wheels. When I got back from the short drive through traffic, coolant was pissing out of the expansion cap and dripping from a hose that I knew was weeping and needed fixing anyway (although temperature was fine). Not good at all. I could only presume that my regular but small coolant top ups due to the weeping hose had somehow worked an airlock into the troublesome M52 coolant circuit. I hoped it wasn't a head gasket problem...

I took a long lunch hour on Wednesday to re-bleed the system from scratch but didn't manage to bleed it properly. I ended up with an airlocked system that wouldn't blow hot air from the heaters. I then decided that Thursday night was the night and I would do it properly, no rushing...and fix that damn weeping hose while I was at it.

So I drained the system, took the hose apart at the join where it was weeping, fitted slightly smaller t-bolts for a tighter fit (before the t-bolts were at their min diameter and still weren't gripping the hose correctly) and replaced it. I then took my time to refill the system correctly and replaced the expansion cap with another spare I had lying around for good measure. Done, fired up, warmed up, hot air through heaters, fan kicks in, tiny spot of air on slackening the bleed screw and nothing more, job done. Sadly, I didn't have time for the test drive and I wasn't willing to risk a 250 mile round trip and trackday on Friday in a car with questionable durability...so track duties were left to the ever reliable Fabia.

Fabias arn't built for racetracks. Too heavy and too much body roll. It was all too easy to cook the brakes, but I still had a laugh!

Nevertheless, this morning I went back to the BMW. After warming it up, I took it for a proper spin. Town driving, dual carriageway, some redline action, about 15 miles in all - and it took it with no problems. When I'd finished, I checked for air at the bleed screw and there was none. So, it appears, it's now ready for action, just one day late.

I am still suffering from rear tyre scrub though, particularly in harder left handers and under hard acceleration. I think I'm going to have to go the hard route and find some 16" wheels that'll clear the E36 M3 front brakes, in a slightly higher offset. Sad to loose money on nearly new wheels and tyres, but it will make for a better drive in the long run I think. Still, pleased to finally have it on the road and running properly

That's a nice looking E30! My first was an E in black too.

The wheels do look like good value but I need 5x120 fitment. My main concern with 16" wheels too is I know that not many of them will clear the E36 M3 front brakes! I THINK most of the stock BMW ones do though - the E46 wheels I had for rolling the shell around on in the early days were very tight, perhaps only a mm or so clearance, but they fit.

The wheels do look like good value but I need 5x120 fitment. My main concern with 16" wheels too is I know that not many of them will clear the E36 M3 front brakes! I THINK most of the stock BMW ones do though - the E46 wheels I had for rolling the shell around on in the early days were very tight, perhaps only a mm or so clearance, but they fit.

Footage from Blyton Park. In the absence of the BMW, I present you with some disappointingly quiet and unspectacular footage from the Fabia vRS instead.

http://www.youtube.com/watch?v=dDDjqUZ_MnU&fea...

http://www.youtube.com/watch?v=dDDjqUZ_MnU&fea...

So since the E30 ducked out of Blyton, I've taken a bit of a break, had a lovely week in Budapest with the missus then returned refreshed and determined to solve my problem! Starting with a new set of 16" wheels.

I got these BMW style 42s (16"x7J ET47) from Ebay for a bargain price - I was the only bidder and there was no reserve - taking a gamble that they would fit over the front brakes. Sold as professionally refurbished in a black powdercoat, style wise they were bang on.

When I tried to bolt them up to the car though, the caliper fouled the lip that runs around the inside of the wheel behind the spokes. Inner diameter clearance was fine though, so I ordered 4 x 15mm hubcentric spacers and a stud conversion kit for good measure.

Bolting up the wheels again, clearance looked tight. Very tight, I could just about get a credit card between the caliper and the inside of the lip. But it was true, no fouling etc.

I went ahead and got tyres fitted and valved and the wheels balanced. They balanced up just fine, but I couldn't afford another set of track-day tyres this time round. I got a set of GT Radial UHPs on the basis that they hold up to high temps well. And they were cheap. Once these are worn, I will get another set of RSRs, but until then, off with the old and on with the new:

Car drives a lot better on the 16s. Miles of clearance - I can even lower it another 10-15mm easy. No fouling anywhere. Feels a little livelier too, must be some 3kg difference per corner at least! I prefer the looks too, suit the car better. I just need a set of centre caps to finish them off.

Of course an added benefit to this setup now is that most standard E36/E46 16" wheels should fit! This opens loads of options for cheap second-hand sets of wheels if I ever want a spare set for just track use or whatever.

I've not fitted the studs yet, I've just used the longer wheel bolts that came with the spacers to test everything out. I'll fit the studs properly another weekend. Until then I'm going to enjoy the car a little bit whilst we still get the odd dry day, ironing out niggles and what not!

On a different note, this is what was left of the rear pads on the Fabia after Blyton park...

...I thought there might have been 1000 miles left in them before the trackday...or about 30 track miles it seems!

I got these BMW style 42s (16"x7J ET47) from Ebay for a bargain price - I was the only bidder and there was no reserve - taking a gamble that they would fit over the front brakes. Sold as professionally refurbished in a black powdercoat, style wise they were bang on.

When I tried to bolt them up to the car though, the caliper fouled the lip that runs around the inside of the wheel behind the spokes. Inner diameter clearance was fine though, so I ordered 4 x 15mm hubcentric spacers and a stud conversion kit for good measure.

Bolting up the wheels again, clearance looked tight. Very tight, I could just about get a credit card between the caliper and the inside of the lip. But it was true, no fouling etc.

I went ahead and got tyres fitted and valved and the wheels balanced. They balanced up just fine, but I couldn't afford another set of track-day tyres this time round. I got a set of GT Radial UHPs on the basis that they hold up to high temps well. And they were cheap. Once these are worn, I will get another set of RSRs, but until then, off with the old and on with the new:

Car drives a lot better on the 16s. Miles of clearance - I can even lower it another 10-15mm easy. No fouling anywhere. Feels a little livelier too, must be some 3kg difference per corner at least! I prefer the looks too, suit the car better. I just need a set of centre caps to finish them off.

Of course an added benefit to this setup now is that most standard E36/E46 16" wheels should fit! This opens loads of options for cheap second-hand sets of wheels if I ever want a spare set for just track use or whatever.

I've not fitted the studs yet, I've just used the longer wheel bolts that came with the spacers to test everything out. I'll fit the studs properly another weekend. Until then I'm going to enjoy the car a little bit whilst we still get the odd dry day, ironing out niggles and what not!

On a different note, this is what was left of the rear pads on the Fabia after Blyton park...

...I thought there might have been 1000 miles left in them before the trackday...or about 30 track miles it seems!

Edited by motorhole on Sunday 20th October 11:05

Thanks WSW. Been stalking your Escort build too, that's a very professional bit of work.

So this weekend I set out to solve niggling issues I've had with the cooling system from day 1. Although car never overheated, or even got close to overheating, it's not been quite right. The story went something like this.

1) Initial radiator install, filled cooling system, bled, hot air through heaters, fan comes on okay, job done. Then I noticed a small coolant leak from the radiator return hose after I'd driven it to the MOT centre. Put this on my list of things to fix once I got the car back.

2) Thought I'd managed to fix coolant leak, until I returned from the bodyshop to find coolant pissing out through the radiator expansion cap onto the floor.

3) Removed join that was cause of leak. T-bolt was slightly to big for the pipe joiner, which is why it was leaking under pressure, no matter how tight it was done up. Fitted a smaller t-bolt, leak fixed, re-bled system, job done take two.

4)...until after driving, I spotted another leak. A very slight weeping from the fan temperature switch on the side of the rad. Plus the system was over-pressurising again, causing the expansion cap to vent air. Of course, head gasket is always a possibility but I knew the engine was fine in the donor car and I had no other HG failure symptoms whatsoever. I thought I'd just best get the cooling system A1 first.

5) Scared to torque up the temp switch any more for fear of breaking the flimsy plastic, I decided I was going to remove this, use some PTFE tape and re-fit. Until I decided to do a bit of research on the Eis-branded radiator I'd bought (2nd hand, unused) and found they are generally considered to be a load of tosh. Throwing caution into the wind, I decided to stump up the £90 or so for a brand new Nissens radiator, in an effort to fix not only current issues, but to protect against any future ones. Radiator arrived next day and it only took 3 seconds to see that the quality is infinitely better than the Eis radiator. I went to fit this on Saturday morning.

6) Upon draining the system (again) and disconnecting all the hoses, I found that the temp switch was just turning in its boss, it wasn't unscrewing. Not good. I removed the rad to find the the plastic had cracked around the boss. Of course, no amount of PTFE would've fixed that. I had to cut around the plastic to remove the switch with the insert, then use a pair of grips to hold the insert whilst I unscrewed the switch. Pain in the *ss.

7) Fitted new radiator and re-filled the system once more. Ran the car up to temperature, hot air at vents, bled out a tiny amount of air then took it for a test drive. Bit of traffic, some back lanes, a fast dual carriageway blast then some more traffic before I returned.

All this drive did was confirm that nothing was right with that first rad! Before, the temp would typically sit just over halfway, dropping slightly at speed. In traffic it quickly rose to just below 3/4, when the fan would kick in and drop the temp. With the new radiator, the temp sits just below halfway and even sitting in traffic for a few minutes (after the dual carriageway), then idling it on return to the garage, it never got hot enough for the fan to have to come on at all. Checking things over afterwards revealed no leaks and no hissing expansion cap.

So now hopefully that's the end of my cooling maladies. Perfect demonstration of "buy cheap, buy twice". Now I just need to keep driving it until the next ugly issue raises its head...

So this weekend I set out to solve niggling issues I've had with the cooling system from day 1. Although car never overheated, or even got close to overheating, it's not been quite right. The story went something like this.

1) Initial radiator install, filled cooling system, bled, hot air through heaters, fan comes on okay, job done. Then I noticed a small coolant leak from the radiator return hose after I'd driven it to the MOT centre. Put this on my list of things to fix once I got the car back.

2) Thought I'd managed to fix coolant leak, until I returned from the bodyshop to find coolant pissing out through the radiator expansion cap onto the floor.

3) Removed join that was cause of leak. T-bolt was slightly to big for the pipe joiner, which is why it was leaking under pressure, no matter how tight it was done up. Fitted a smaller t-bolt, leak fixed, re-bled system, job done take two.

4)...until after driving, I spotted another leak. A very slight weeping from the fan temperature switch on the side of the rad. Plus the system was over-pressurising again, causing the expansion cap to vent air. Of course, head gasket is always a possibility but I knew the engine was fine in the donor car and I had no other HG failure symptoms whatsoever. I thought I'd just best get the cooling system A1 first.

5) Scared to torque up the temp switch any more for fear of breaking the flimsy plastic, I decided I was going to remove this, use some PTFE tape and re-fit. Until I decided to do a bit of research on the Eis-branded radiator I'd bought (2nd hand, unused) and found they are generally considered to be a load of tosh. Throwing caution into the wind, I decided to stump up the £90 or so for a brand new Nissens radiator, in an effort to fix not only current issues, but to protect against any future ones. Radiator arrived next day and it only took 3 seconds to see that the quality is infinitely better than the Eis radiator. I went to fit this on Saturday morning.

6) Upon draining the system (again) and disconnecting all the hoses, I found that the temp switch was just turning in its boss, it wasn't unscrewing. Not good. I removed the rad to find the the plastic had cracked around the boss. Of course, no amount of PTFE would've fixed that. I had to cut around the plastic to remove the switch with the insert, then use a pair of grips to hold the insert whilst I unscrewed the switch. Pain in the *ss.

7) Fitted new radiator and re-filled the system once more. Ran the car up to temperature, hot air at vents, bled out a tiny amount of air then took it for a test drive. Bit of traffic, some back lanes, a fast dual carriageway blast then some more traffic before I returned.

All this drive did was confirm that nothing was right with that first rad! Before, the temp would typically sit just over halfway, dropping slightly at speed. In traffic it quickly rose to just below 3/4, when the fan would kick in and drop the temp. With the new radiator, the temp sits just below halfway and even sitting in traffic for a few minutes (after the dual carriageway), then idling it on return to the garage, it never got hot enough for the fan to have to come on at all. Checking things over afterwards revealed no leaks and no hissing expansion cap.

So now hopefully that's the end of my cooling maladies. Perfect demonstration of "buy cheap, buy twice". Now I just need to keep driving it until the next ugly issue raises its head...

Work-Shy-Wanabe said:

Hahaa Great! Fancy a E30 project myself!

Been slobbering all over this since breakfast, http://www.ebay.co.uk/itm/BMW-E30-M3-GROUP-N-PRODU...

Good luck with the new rad!

Ha, that's just begging for a V8! Been slobbering all over this since breakfast, http://www.ebay.co.uk/itm/BMW-E30-M3-GROUP-N-PRODU...

Good luck with the new rad!

FASTaD13 said:

Hi motorhole, nice thread!

Just stumbled on it while researching an e30 track/fastroad car I'm looking to build myself. Ironically I had a literally the same 318 LUX as yours that I ended up letting go to some nice chap in a black audi IIRC... for around £800 too.. on a H plate.. In West Yorkshire!!

Can't believe you have my old car and nice to see your putting "Clifford" to good use! Would be great to see the car in action again after so If your hitting any trackdays this year please PM me as i'd love to see the car in action!

Hi FASTaD13, thanks for your comments. If this is really your old car, it's a small world!Just stumbled on it while researching an e30 track/fastroad car I'm looking to build myself. Ironically I had a literally the same 318 LUX as yours that I ended up letting go to some nice chap in a black audi IIRC... for around £800 too.. on a H plate.. In West Yorkshire!!

Can't believe you have my old car and nice to see your putting "Clifford" to good use! Would be great to see the car in action again after so If your hitting any trackdays this year please PM me as i'd love to see the car in action!

Have made a few more mods in the past few weeks. First up the heater valve died. By the looks of it, it was on its way out before I took the car off the road, so its demise was inevitable once I put 2-bar of coolant pressure (as opposed to the 1.4 bar it originally dealt with) through it. I replaced that and bled the coolant AGAIN. So far, so good.

The home-made drop links I made had to go too. Basically, the tabs on the Koni struts don't appear man enough for the thicker ARB and had bent and deformed. I got a pair of Mondeo front drop links instead - these are identical to standard E30 ones, save for a rose jointed bottom link rather than a pin and rubber bush arrangement- and used the standard wishbone pickup points instead. I dropped the front about 15 mm and it looks about there. Hopefully going to see its first action this month.

Well the BMW had its first on track outing yesterday at Oulton park. Was a mixed bag to be honest.

Track was damp starting off so not knowing/being comfortable with the car and not knowing how much grip was available, I drove very conservatively. Did 2 sessions of warmup lap, 2 fast (ish) laps, cooldown lap to break things in and those went okay. Once the track started to dry though and I started driving a little faster and braking harder, I started getting horrific vibration through the brake pedal when the brakes were hot and I was slowing from speed. Enough to frighten me!

So I pulled off the front wheels and noticed on the nearside there were signs of slight caliper-wheel contact. Filed off a mm or so from the offending extremities of the caliper and tried it again, with the same result. At this point, as braking from 'normal' speeds and when the brakes weren't stinking hot was okay, I decided to call it a day and drive home before I broke something properly. A shame, because I never really got anywhere close to figuring out the car's capabilities, but at least it got there and back under it's own steam.

So what did I learn?

1) It is fairly quick. Even driving as conservatively as I was, I could still nudge 105mph before having to brake for lodge corner.

2) I may need stiffer springs as at least once, the undertray bottomed out on the tarmac on the dip at the exit of lodge.

3) It's actually quite chuckable and grips very well - my confidence in the car in the respect has improved a lot. Never felt lairy or about to spit me off - but then I never got the opportunity to increase commitment from 5 tenths to 9.5 tenths!

4) Similarly, drivetrain and engine wise, it was bang on. Temperature never rose above halfway. No nasty noises.

I don't have time to do much work on it in the coming weeks, but when I do, I'm going to pull apart the brakes to check for uneven wear and swap out the front wheel bearings. As the wheel was only contacting the caliper on one side, when hot and under high g, there may be enough give in the bearing on the nearside for contact to occur, given the marginal clearances between caliper and wheel. Only Christ knows what the mileage was on the bearings was when I acquired the hubs. If anyone has any other ideas, do let me know

Track was damp starting off so not knowing/being comfortable with the car and not knowing how much grip was available, I drove very conservatively. Did 2 sessions of warmup lap, 2 fast (ish) laps, cooldown lap to break things in and those went okay. Once the track started to dry though and I started driving a little faster and braking harder, I started getting horrific vibration through the brake pedal when the brakes were hot and I was slowing from speed. Enough to frighten me!

So I pulled off the front wheels and noticed on the nearside there were signs of slight caliper-wheel contact. Filed off a mm or so from the offending extremities of the caliper and tried it again, with the same result. At this point, as braking from 'normal' speeds and when the brakes weren't stinking hot was okay, I decided to call it a day and drive home before I broke something properly. A shame, because I never really got anywhere close to figuring out the car's capabilities, but at least it got there and back under it's own steam.

So what did I learn?

1) It is fairly quick. Even driving as conservatively as I was, I could still nudge 105mph before having to brake for lodge corner.

2) I may need stiffer springs as at least once, the undertray bottomed out on the tarmac on the dip at the exit of lodge.

3) It's actually quite chuckable and grips very well - my confidence in the car in the respect has improved a lot. Never felt lairy or about to spit me off - but then I never got the opportunity to increase commitment from 5 tenths to 9.5 tenths!

4) Similarly, drivetrain and engine wise, it was bang on. Temperature never rose above halfway. No nasty noises.

I don't have time to do much work on it in the coming weeks, but when I do, I'm going to pull apart the brakes to check for uneven wear and swap out the front wheel bearings. As the wheel was only contacting the caliper on one side, when hot and under high g, there may be enough give in the bearing on the nearside for contact to occur, given the marginal clearances between caliper and wheel. Only Christ knows what the mileage was on the bearings was when I acquired the hubs. If anyone has any other ideas, do let me know

Thanks for the comments again guys! Must say though, the photos make the car look cleaner than it is - it's straight and solid alright, but the mismatching harnesses & bucket seats, slightly mismatching sections of paint under the bonnet where I've patched it up and whatnot do give away that it's certainly not a no-expenses spared build. With regards to rust, the areas ahead of the front arches where the front panel bolts to the inner wings are starting to look frilly - but it's not structural and it's the only real point of concern on the car now. I'll get this sorted in due course.

So here's the evidence of the braking issues:

Definite contact on inside of wheel rim! So I have the following systematic approach to remedy it:

1) I could get slightly larger wheel spacers, but I don't really want any less offset as rear wheel-inner arch clearance is already marginal under compression. So...

2)...I'm going to fit new wheel bearings on the front and take 1 mm or so off the corners of the casting ribs on the calipers with the grinder. Then try again...

3) If that doesn't fix it, I'll get a brass guide pin bushing set for the calipers, to rule out caliper movement as the culprit.

Then it'll be trackday test take 2. Probably Blyton, Donnington or Oulton Park again at end of March/April.

So here's the evidence of the braking issues:

Definite contact on inside of wheel rim! So I have the following systematic approach to remedy it:

1) I could get slightly larger wheel spacers, but I don't really want any less offset as rear wheel-inner arch clearance is already marginal under compression. So...

2)...I'm going to fit new wheel bearings on the front and take 1 mm or so off the corners of the casting ribs on the calipers with the grinder. Then try again...

3) If that doesn't fix it, I'll get a brass guide pin bushing set for the calipers, to rule out caliper movement as the culprit.

Then it'll be trackday test take 2. Probably Blyton, Donnington or Oulton Park again at end of March/April.

Okay, so today I set about Phase 1 of the brake vibration resolution project: replacing front wheel bearings.

Although it was only the nearside that was causing issues, I went about replacing both bearings anyway out of good practice and to prevent any future wheel bearing issues from arising. So I had two complete FAG wheel bearing kits to fit.

I set about the problematic nearside first and everything went exactly to plan. Hubnut freed up no problems, thanks to the world-moving leverage exerted by my 2.5m washing pole-turned-breaker bar. Bearing pulled off cleanly, as did the old dustcaps. A clean up and light grease of the spindle and the new bearing drove on nicely. The end product:

I should add that my car isn‘t suspended by that bottle jack under the lower arm, that‘s purely an auxiliary jack to stop the car (potentially) rocking around when undoing/torquing up the carrier nuts. I did the hubnuts through the wheel with the car on the ground for added safety

It turns out that this was indeed a likely culprit. I‘m not sure wheel bearings should be doing this for a start:

http://youtu.be/ddS3Q2B1Z7k

And the wheel bearings that were on the hubs were not OEM items. They‘d been replaced before and the ones that were there were of the cheap and nasty variety.

The other side was a little more problematic due to half the bearing staying on the spindle, but it still wasn‘t too much of a ballache.

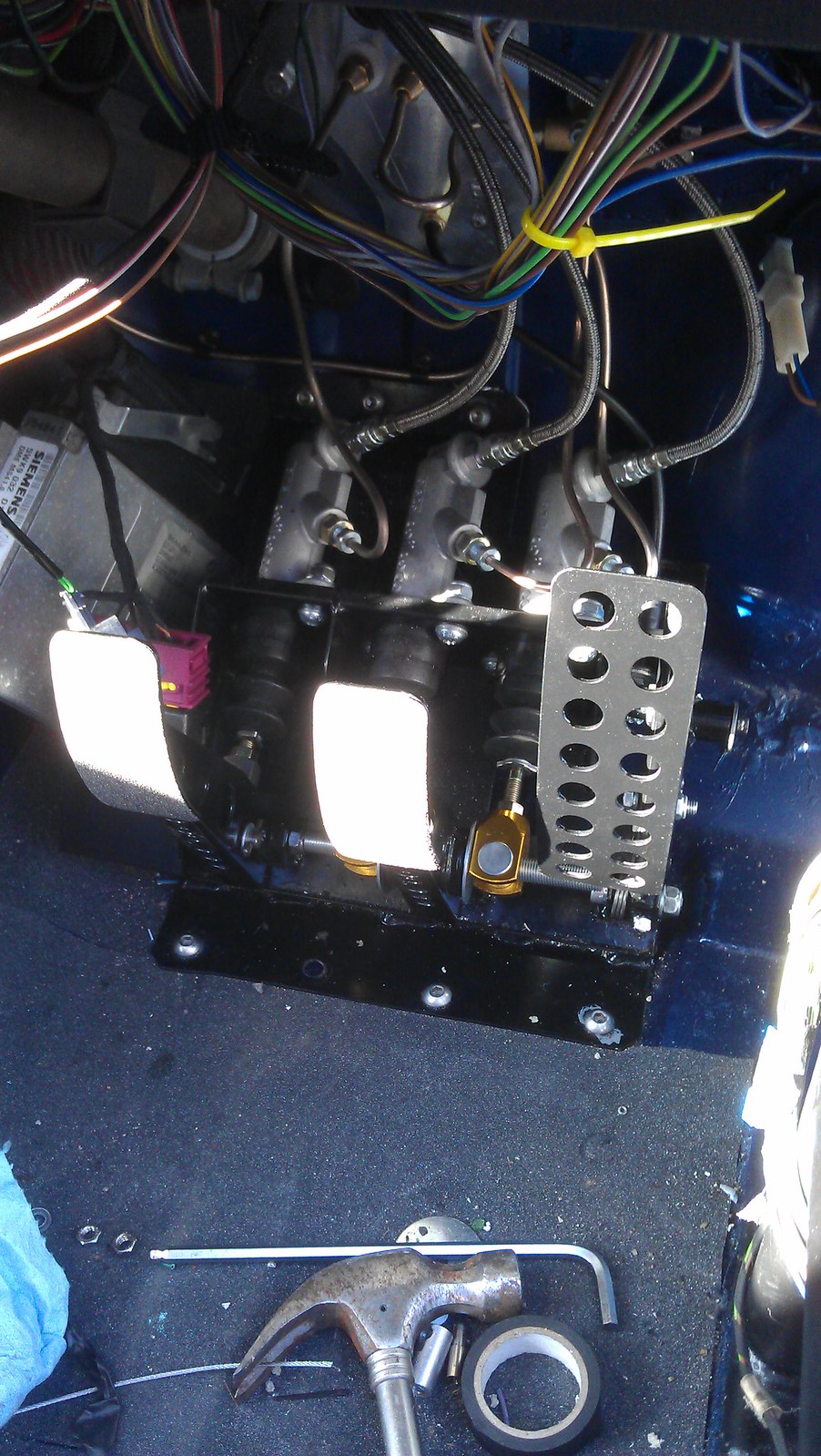

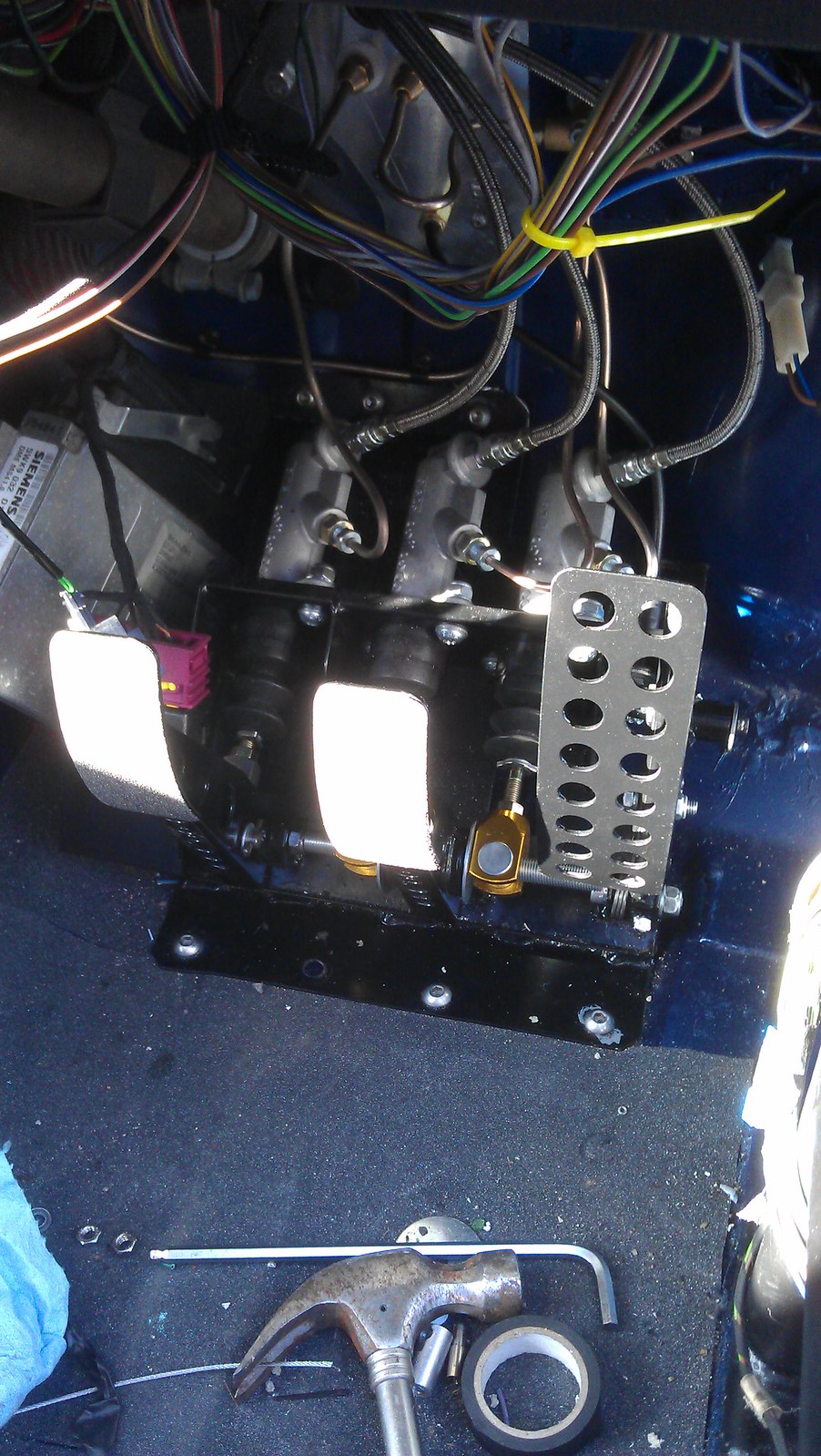

After all this I made a minor mod to the pedal box. If you‘ve been bored enough to stay with my build thread this far, you‘ll know I put a spreader plate under the floorpan for the pedal box. I wasn‘t entirely happy with this on its own though, so to spread the force a little more when really leaning on the brake pedal, I fitted some bigger skirted nuts below some thick washers. Just for added confidence Then I took the thing for a test drive.

Then I took the thing for a test drive.

Repeated hard braking from speed is difficult to do on the road safely and legally. But I did the best I could within the limits of the law and so far, so good. No nasty vibrations. But I really need another trackday to be certain. Hoping to get something for early April.

Although it was only the nearside that was causing issues, I went about replacing both bearings anyway out of good practice and to prevent any future wheel bearing issues from arising. So I had two complete FAG wheel bearing kits to fit.

I set about the problematic nearside first and everything went exactly to plan. Hubnut freed up no problems, thanks to the world-moving leverage exerted by my 2.5m washing pole-turned-breaker bar. Bearing pulled off cleanly, as did the old dustcaps. A clean up and light grease of the spindle and the new bearing drove on nicely. The end product:

I should add that my car isn‘t suspended by that bottle jack under the lower arm, that‘s purely an auxiliary jack to stop the car (potentially) rocking around when undoing/torquing up the carrier nuts. I did the hubnuts through the wheel with the car on the ground for added safety

It turns out that this was indeed a likely culprit. I‘m not sure wheel bearings should be doing this for a start:

http://youtu.be/ddS3Q2B1Z7k

And the wheel bearings that were on the hubs were not OEM items. They‘d been replaced before and the ones that were there were of the cheap and nasty variety.

The other side was a little more problematic due to half the bearing staying on the spindle, but it still wasn‘t too much of a ballache.

After all this I made a minor mod to the pedal box. If you‘ve been bored enough to stay with my build thread this far, you‘ll know I put a spreader plate under the floorpan for the pedal box. I wasn‘t entirely happy with this on its own though, so to spread the force a little more when really leaning on the brake pedal, I fitted some bigger skirted nuts below some thick washers. Just for added confidence

Then I took the thing for a test drive.

Then I took the thing for a test drive.Repeated hard braking from speed is difficult to do on the road safely and legally. But I did the best I could within the limits of the law and so far, so good. No nasty vibrations. But I really need another trackday to be certain. Hoping to get something for early April.

So last Monday, I took a long lunch from work with a few to test driving my car, prior to booking a trackday.

I turned up at the garage, rolled it out, frowned as I remembered how much it needed a wash then started checking it over. Only to find the rubber boot on the clutch master cylinder was full of brake fluid. B*ll*cks. I was especially disappointed as it was a new one too - albeit fitted over a year ago. Car went back in the garage, I didn't get my test-drive and I didn't book a trackday.

I ordered a replacement and as the weather was nice on Sunday, I set about replacing it. Drained the system, removed offending item, replaced it and did a one-man bleed using a piece of pipe and a lot of running around the car. The new m/s, despite being identical to the old one, feels different. Clutch is lighter and bite point is lower. Makes me wonder if the old one had been faulty from the off. I checked that the pushrod was entering the cylinder square and that appeared to be the case, so I can't see any other obvious reason for failure. I may take the old one apart to investigate.

I'm sure I can still hear some friction somewhere when turning right too. I've replaced the wheel bearings - so I'm ruling that out - there is now comfortable wheel/caliper clearance, but it sounds metallic so certainly not tyres on bodywork. I wonder if due to the p/s reservoir being mounted at an angle, the pump is drawing air on right hand turns? That's the next potential culprit to investigate.

One day, it will be reliable. I hope.

I turned up at the garage, rolled it out, frowned as I remembered how much it needed a wash then started checking it over. Only to find the rubber boot on the clutch master cylinder was full of brake fluid. B*ll*cks. I was especially disappointed as it was a new one too - albeit fitted over a year ago. Car went back in the garage, I didn't get my test-drive and I didn't book a trackday.

I ordered a replacement and as the weather was nice on Sunday, I set about replacing it. Drained the system, removed offending item, replaced it and did a one-man bleed using a piece of pipe and a lot of running around the car. The new m/s, despite being identical to the old one, feels different. Clutch is lighter and bite point is lower. Makes me wonder if the old one had been faulty from the off. I checked that the pushrod was entering the cylinder square and that appeared to be the case, so I can't see any other obvious reason for failure. I may take the old one apart to investigate.

I'm sure I can still hear some friction somewhere when turning right too. I've replaced the wheel bearings - so I'm ruling that out - there is now comfortable wheel/caliper clearance, but it sounds metallic so certainly not tyres on bodywork. I wonder if due to the p/s reservoir being mounted at an angle, the pump is drawing air on right hand turns? That's the next potential culprit to investigate.

One day, it will be reliable. I hope.

Well, it's been a while since I've posted but work has been progressing in small steps. I've recently has some trouble which is proving a significant setback, but - well, more on that one later.

First up: a small niggle that's been bothering me for a while, but that I've been putting off for fear of it being difficult - the passenger door lock. Basically, it opened and closed with the handles just fine, but it had to be locked individually with the key. It was essentially missing the door pin mech and the central locking wasn't working - I'd stared taking it apart because it stopped working before I took it off the road, then I'd forgotten about it.

Anyway, turned out to be a simple fix. I re-built the door pin mech, greased the lock and whatnot and made sure the central locking servo (which worked okay) was properly located. It now works perfectly.

Now, in order to stop the engine moving around under cornering - and therefore potentially leaning on my brake lines or steering linkage, I'd ordered some Poly engine & gearbox mounts from Condor Speed Shop in the states. These arrived in due course:

Then the time came round to fit them. Access to the mounts was a bit fiddly with the engine bay fully built up as it now is, but got them both loosened, before jacking the engine up once side at a time to replace each mount in turn. Torqued them up to spec, then jacked up to the car to get to the gearbox mounts. This is much easier - just support the gearbox with a bottle jack, loosen and slip out the cross-member with the old mounts on it, replace the mounts then put back in and tighten up.

Engine mounts:

Gearbox mounts:

So this is where my problems started. I jumped in the car, fired it up and immediately thought something didn't sound quite right. "No worries!" thought I, "It's probably just the mounts transmitting more noise and vibration than the old ones."

So I took it for a drive. The car sounded awful at anything over 1500rpm and had no power anywhere. The only good thing to be said about it is that it changed gear superbly!

Anyway I'm still trying to suss what I've done to c*ck things up so badly. Really annoyed at myself because whatever it is, it's me who's broken it. So far I've examined:

- Vacuum/air hoses for leaks/splits

- That the DME relay has power and is connected properly to all the fuel injectors and ICV, as it should be.

- Likewise with regards to the fuel pump relay

- That all the injector grounds are continuous at the ECU socket

- I have continuity and engine earth straps - but removed and cleaned for good measure with no effect.

- Checked fuel rail & FPR for damage

- Confirmed it's not actually misfiring (at idle) by pulling coils one at a time

So currently, I'm at a loss until I can get a diagnostics done on it. Unfortunately, my torque app and OBDII reader arn't compatible with the older BMW protocol and it can't read the ECU, so I need to source some BMW software and a laptop with a serial port. But if anybody else has any more bright ideas, I'm all ears! The most likely explanation is I've damaged something in the loom (or elsewhere) by jacking up the engine, but who knows. It just sounds like a Subaru (in a bad way - sound clip: https://www.youtube.com/watch?v=BxBJ42g-56I) and pulls like a 1.2 Corsa. Unfortunately it means I'm having to cancel my Elvington trackday as I don't really have the time to fix it between now and the 24th May.

In the meantime, here are some pictures of it cleaned up and looking good stood still at least.

First up: a small niggle that's been bothering me for a while, but that I've been putting off for fear of it being difficult - the passenger door lock. Basically, it opened and closed with the handles just fine, but it had to be locked individually with the key. It was essentially missing the door pin mech and the central locking wasn't working - I'd stared taking it apart because it stopped working before I took it off the road, then I'd forgotten about it.

Anyway, turned out to be a simple fix. I re-built the door pin mech, greased the lock and whatnot and made sure the central locking servo (which worked okay) was properly located. It now works perfectly.

Now, in order to stop the engine moving around under cornering - and therefore potentially leaning on my brake lines or steering linkage, I'd ordered some Poly engine & gearbox mounts from Condor Speed Shop in the states. These arrived in due course:

Then the time came round to fit them. Access to the mounts was a bit fiddly with the engine bay fully built up as it now is, but got them both loosened, before jacking the engine up once side at a time to replace each mount in turn. Torqued them up to spec, then jacked up to the car to get to the gearbox mounts. This is much easier - just support the gearbox with a bottle jack, loosen and slip out the cross-member with the old mounts on it, replace the mounts then put back in and tighten up.

Engine mounts:

Gearbox mounts:

So this is where my problems started. I jumped in the car, fired it up and immediately thought something didn't sound quite right. "No worries!" thought I, "It's probably just the mounts transmitting more noise and vibration than the old ones."

So I took it for a drive. The car sounded awful at anything over 1500rpm and had no power anywhere. The only good thing to be said about it is that it changed gear superbly!

Anyway I'm still trying to suss what I've done to c*ck things up so badly. Really annoyed at myself because whatever it is, it's me who's broken it. So far I've examined:

- Vacuum/air hoses for leaks/splits

- That the DME relay has power and is connected properly to all the fuel injectors and ICV, as it should be.

- Likewise with regards to the fuel pump relay

- That all the injector grounds are continuous at the ECU socket

- I have continuity and engine earth straps - but removed and cleaned for good measure with no effect.

- Checked fuel rail & FPR for damage

- Confirmed it's not actually misfiring (at idle) by pulling coils one at a time

So currently, I'm at a loss until I can get a diagnostics done on it. Unfortunately, my torque app and OBDII reader arn't compatible with the older BMW protocol and it can't read the ECU, so I need to source some BMW software and a laptop with a serial port. But if anybody else has any more bright ideas, I'm all ears! The most likely explanation is I've damaged something in the loom (or elsewhere) by jacking up the engine, but who knows. It just sounds like a Subaru (in a bad way - sound clip: https://www.youtube.com/watch?v=BxBJ42g-56I) and pulls like a 1.2 Corsa. Unfortunately it means I'm having to cancel my Elvington trackday as I don't really have the time to fix it between now and the 24th May.

In the meantime, here are some pictures of it cleaned up and looking good stood still at least.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff