The cursed Rallye

Discussion

Here you go: http://www.ebay.co.uk/ulk/itm/281783986268

I did one of these belts on an 807 a while back, not fun. Even with the correct flywheel tool you still need to grind it down to fit. If this applies to your car I can lend you a pre ground tool. (Postage on the full kit wouldn't make a loan worthwhile).

I did one of these belts on an 807 a while back, not fun. Even with the correct flywheel tool you still need to grind it down to fit. If this applies to your car I can lend you a pre ground tool. (Postage on the full kit wouldn't make a loan worthwhile).

Where are you based?

I'd just get a quote from Carl Chambers. He's done so many, got such a good reputation, could probably do it with his eyes closed and one arm behind his back! I wrote my GTi6 off long before needing to pick the phone up to Carl, sadly! There's no peace of mind like knowing someone has done it who is more than just a little familiar with the job...

I'd just get a quote from Carl Chambers. He's done so many, got such a good reputation, could probably do it with his eyes closed and one arm behind his back! I wrote my GTi6 off long before needing to pick the phone up to Carl, sadly! There's no peace of mind like knowing someone has done it who is more than just a little familiar with the job...

You really should change the belt at 36k/3 years, ive owned 3 GTI 6's and had my phase 1 when Peugeot decreed that it should be reduced from 72k to 36k.

There are horror stories about these failing just after 36k miles, most had been on there far longer than 3 years though, bad maintenance practice tbh.

Heater matrix is common on 306's, it was just a bad quality velo part, had to have a couple replaced on the... 6 306's ive owned (with a decent after market alloy part)

There are horror stories about these failing just after 36k miles, most had been on there far longer than 3 years though, bad maintenance practice tbh.

Heater matrix is common on 306's, it was just a bad quality velo part, had to have a couple replaced on the... 6 306's ive owned (with a decent after market alloy part)

Don't worry all. It'll get done. Soon. Ish.

Locking the pulleys together with a wedge type device is probably OK for belt removal, but probably not for refitting. The whole idea of this approach is that all legs of the belt will be at the same tension and the cam timing will be spot-on. A reason that was not at all clear to me before I read the official Peugeot procedure...

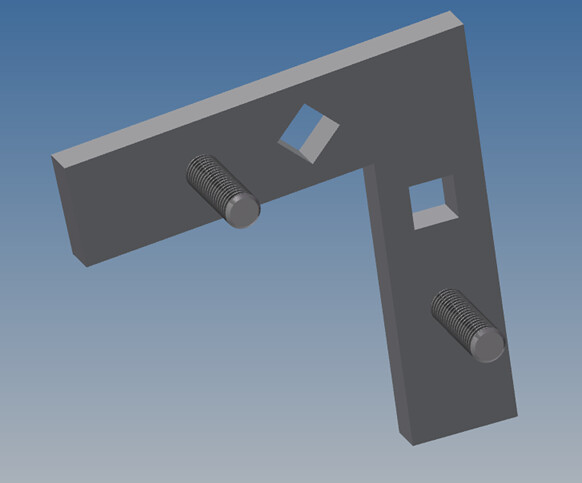

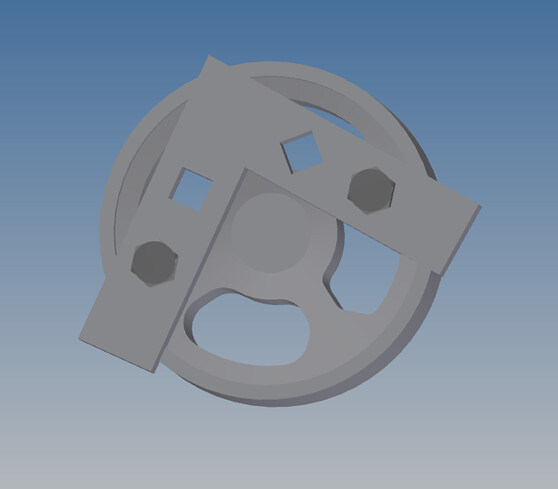

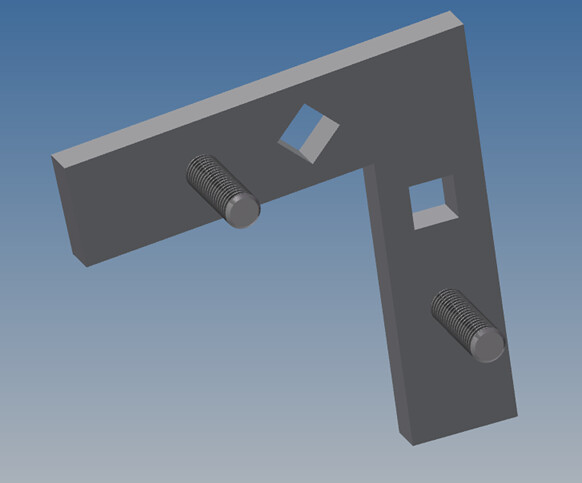

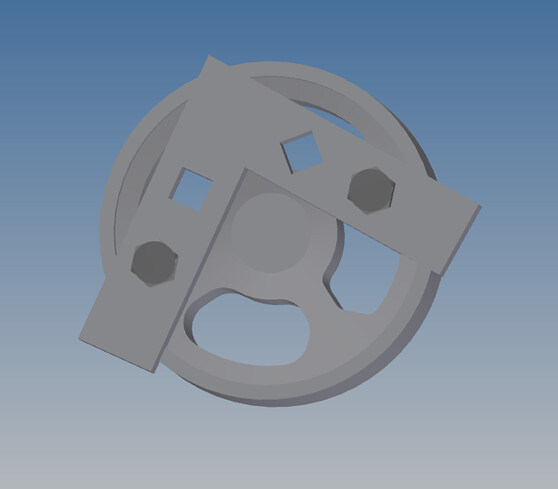

That in mind, I designed this:

Note the 2off 1/2" square drive holes, offset at 45deg. There are y-shaped tools available off the shelf, but I'm fairly sure that one with a fixed handle won't easily fit on both pulleys.

I'd overlooked locking the crank though, so would be really interested in seeing pics of the tool you used if possible. Last time I just got an assistant to stand on the brakes with it in 6th when I loosened/tightened the crank pulley bolt.

helix402 said:

Here you go: http://www.ebay.co.uk/ulk/itm/281783986268

I did one of these belts on an 807 a while back, not fun. Even with the correct flywheel tool you still need to grind it down to fit. If this applies to your car I can lend you a pre ground tool. (Postage on the full kit wouldn't make a loan worthwhile).

It's not so much the timing pins I need (although I'm not sure what happened to my special cut down 6mm drill bit...), more a device for holding the cam pulley still while I do up the big bolt in the end of the camshaft. The pulleys aren't keyed onto the end of the driveshaft, but a tab washer behind them is. When taking the belt off, the first step is to get the pins in the two tab washers and the crank pulley to get everything in a safe position. Then loosen off the big bolts that hold the pulley on without - and this is the important bit - putting any strain on the timing pin(s) or the belt. Tricky. As ever, refitting is the reverse of removal with slightly higher stakes: stretch the belt or get the timing out a bit and you'll be looking down the barrel of a premature belt failure or a piston/valve mashup.I did one of these belts on an 807 a while back, not fun. Even with the correct flywheel tool you still need to grind it down to fit. If this applies to your car I can lend you a pre ground tool. (Postage on the full kit wouldn't make a loan worthwhile).

Locking the pulleys together with a wedge type device is probably OK for belt removal, but probably not for refitting. The whole idea of this approach is that all legs of the belt will be at the same tension and the cam timing will be spot-on. A reason that was not at all clear to me before I read the official Peugeot procedure...

That in mind, I designed this:

Note the 2off 1/2" square drive holes, offset at 45deg. There are y-shaped tools available off the shelf, but I'm fairly sure that one with a fixed handle won't easily fit on both pulleys.

I'd overlooked locking the crank though, so would be really interested in seeing pics of the tool you used if possible. Last time I just got an assistant to stand on the brakes with it in 6th when I loosened/tightened the crank pulley bolt.

C.A.R. said:

Where are you based?

I'd just get a quote from Carl Chambers. He's done so many, got such a good reputation, could probably do it with his eyes closed and one arm behind his back! I wrote my GTi6 off long before needing to pick the phone up to Carl, sadly! There's no peace of mind like knowing someone has done it who is more than just a little familiar with the job...

Bristol. I think I got my replacement bumper off Carl (he's in Leicester right?). Seemed like a good chap, and no doubt knows his XUs, but a) it's a bit of a trek and b) I like working on my car.I'd just get a quote from Carl Chambers. He's done so many, got such a good reputation, could probably do it with his eyes closed and one arm behind his back! I wrote my GTi6 off long before needing to pick the phone up to Carl, sadly! There's no peace of mind like knowing someone has done it who is more than just a little familiar with the job...

Just looked jphim up.

Carl Grimsley I believe. User name c. Grimsley on here.

http://www.cgcarsleicester.co.uk

I used him and would use him again if I had a gti6

Carl Grimsley I believe. User name c. Grimsley on here.

http://www.cgcarsleicester.co.uk

I used him and would use him again if I had a gti6

I almost swapped my RS Turbo for a 306 GTi6 in Diablo Red back in the early 2000s... I'm both glad and sad that I didn't do the deal after reading this thread, haha. I still think a Ph2 306 is a good looking car, but the tough time you've had with yours is exactly what I was afraid of experiencing myself all those years ago.

That said, you'll surely be coming to the end of the 'known' weak areas by now?? Therefore, getting that bit closer to trouble free times.

Cheers,

Grant

That said, you'll surely be coming to the end of the 'known' weak areas by now?? Therefore, getting that bit closer to trouble free times.

Cheers,

Grant

RS Grant said:

I almost swapped my RS Turbo for a 306 GTi6 in Diablo Red back in the early 2000s... I'm both glad and sad that I didn't do the deal after reading this thread, haha. I still think a Ph2 306 is a good looking car, but the tough time you've had with yours is exactly what I was afraid of experiencing myself all those years ago.

That said, you'll surely be coming to the end of the 'known' weak areas by now?? Therefore, getting that bit closer to trouble free times.

Cheers,

Grant

Yeh, all the major bits have been done. Save the rear beam, which I can do slow-time now I've got the spare on.That said, you'll surely be coming to the end of the 'known' weak areas by now?? Therefore, getting that bit closer to trouble free times.

Cheers,

Grant

Though this thread may make it seem like a bit of a nightmare (and to a certain extent, buying any car with a failing head gasket *is* a nightmare), it's actually been pretty good. I've never been stranded anywhere and have no issue with setting off on any journey here or abroad. I'm sure that if I had to pay a mechanic to do all the work I'd be questioning whether it was worth it. Fortunately I really enjoy working on cars, and get a buzz out of keeping them up together, so something like this suits me well.

Quick update.

Old tyres gone

New wheels on

Shiny bolts on

New MOT. First clean one with this car!

MOT tester recognised the car. Comment as he handed over the car was "perfect, as usual". Didn't have the heart to tell him he gave it 4 advisories last year...

(It also had some ABS sensors at the rear and a quick brake caliper fettle to stop the rear brakes binding for the MOT. Caliper rebuild kits will be on order soon, even though one caliper is less than 3 yrs old. )

)

Old tyres gone

New wheels on

Shiny bolts on

New MOT. First clean one with this car!

MOT tester recognised the car. Comment as he handed over the car was "perfect, as usual". Didn't have the heart to tell him he gave it 4 advisories last year...

(It also had some ABS sensors at the rear and a quick brake caliper fettle to stop the rear brakes binding for the MOT. Caliper rebuild kits will be on order soon, even though one caliper is less than 3 yrs old.

)

)What a superb thread! Really enjoying the read and your experience of pattern parts vs originals.

My one piece of advice when doing something like the cam belts and it being a more major job - if you've got to take the block to a point where you can access most other things, swallow the pain and replace those accessible bits. Trust me, once you've got it all out, you'll never want to repeat the procedure any time soon.

My one piece of advice when doing something like the cam belts and it being a more major job - if you've got to take the block to a point where you can access most other things, swallow the pain and replace those accessible bits. Trust me, once you've got it all out, you'll never want to repeat the procedure any time soon.

helix402 said:

Here's the crank pin;

This was used on an 807, can't remember if it a was a 2.0 or 2.2. You're welcome to borrow it if you want (if it's needed on your car), if you're doing the belt yourself.

Thanks for the offer. Very kind. Unfortunately I don't know where that would fit. Like what you've done with the grinder though! (I've managed to source a leccy rattle gun to borrow, so that should sort it anyway)

This was used on an 807, can't remember if it a was a 2.0 or 2.2. You're welcome to borrow it if you want (if it's needed on your car), if you're doing the belt yourself.

@mattsrallye: Will have a poke around for some more pics. While I wasn't keen at first, I'm getting to like the look. It seems to have made the 50 profile tyres look more like they're supposed to be there

Got the timing belt done this weekend.

The old one looked fine, but the tensioner and idler bearings had both lost a bit of grease past their outer seals, so maybe they weren't far away from end of life. Must've been all that time up at 7200rpm The old water pump was identical to the new one in all respects bar the date mark, casting mark, and logo on the box it came in. Even if the old one was First Line, it came out of the same factory as the SKF one.

The old water pump was identical to the new one in all respects bar the date mark, casting mark, and logo on the box it came in. Even if the old one was First Line, it came out of the same factory as the SKF one.

So yeh, maybe I could've stretched it a bit more, but I managed to do some timely rust treatment on the O/S chassis leg, and the coolant needed renewing, so I guess it wasn't entirely wasted.

This time it was much easier than I remembered. I put this down to:

The mega camshaft spanner thingy is as in the CAD images above (or as close as I can make it in the farm workshop...) Filing out the 1/2" squares didn't take as long as I expected.

Offset spanners were so useful. Only just bought a set, partly to help brother with his top mounts on his 205, and partly because I knew I'd need a 18mm one for the camshaft pulleys. Turns out the whole set has been mega useful, especially for doing the tensioner/idler bolts. And the aux belt adjuster bolts. And the undertray bolts. And basically everywhere. Recommended! Didn't get a ratchet out until I had to take the spark plugs out...

So about that. Needless to say something had to go wrong. As soon as i'd dropped the coolant, taken the upper cam cover off, arch liner out and tried to time up the engine before locking the crank, it became very clear the crank pulley had done its old slippy roundy bit. The crank timing hole was a good 30 deg out (f king stupid design). By this stage I was committed. This was my last free weekend till September. So knowing the cams were roughly right, I went by their marks and locked it all up. Belt off, pump out, new pump in, tensioner/idler on all as normal. Then belt on. Easy. Still a little puckering though. What if something had slipped? Did I feel the crank move when I tool the pulley off? Nah... Maybe... Nah... Brew, bed. Think on it.

king stupid design). By this stage I was committed. This was my last free weekend till September. So knowing the cams were roughly right, I went by their marks and locked it all up. Belt off, pump out, new pump in, tensioner/idler on all as normal. Then belt on. Easy. Still a little puckering though. What if something had slipped? Did I feel the crank move when I tool the pulley off? Nah... Maybe... Nah... Brew, bed. Think on it.

The old one looked fine, but the tensioner and idler bearings had both lost a bit of grease past their outer seals, so maybe they weren't far away from end of life. Must've been all that time up at 7200rpm

The old water pump was identical to the new one in all respects bar the date mark, casting mark, and logo on the box it came in. Even if the old one was First Line, it came out of the same factory as the SKF one.

The old water pump was identical to the new one in all respects bar the date mark, casting mark, and logo on the box it came in. Even if the old one was First Line, it came out of the same factory as the SKF one.So yeh, maybe I could've stretched it a bit more, but I managed to do some timely rust treatment on the O/S chassis leg, and the coolant needed renewing, so I guess it wasn't entirely wasted.

This time it was much easier than I remembered. I put this down to:

- Modified crankshaft locking tool (like no. 2 in helix402's img above, but with bits cut off)

- Homebrew mega camshaft spanner thingy

- Offset ring spanners

The mega camshaft spanner thingy is as in the CAD images above (or as close as I can make it in the farm workshop...) Filing out the 1/2" squares didn't take as long as I expected.

Offset spanners were so useful. Only just bought a set, partly to help brother with his top mounts on his 205, and partly because I knew I'd need a 18mm one for the camshaft pulleys. Turns out the whole set has been mega useful, especially for doing the tensioner/idler bolts. And the aux belt adjuster bolts. And the undertray bolts. And basically everywhere. Recommended! Didn't get a ratchet out until I had to take the spark plugs out...

So about that. Needless to say something had to go wrong. As soon as i'd dropped the coolant, taken the upper cam cover off, arch liner out and tried to time up the engine before locking the crank, it became very clear the crank pulley had done its old slippy roundy bit. The crank timing hole was a good 30 deg out (f

king stupid design). By this stage I was committed. This was my last free weekend till September. So knowing the cams were roughly right, I went by their marks and locked it all up. Belt off, pump out, new pump in, tensioner/idler on all as normal. Then belt on. Easy. Still a little puckering though. What if something had slipped? Did I feel the crank move when I tool the pulley off? Nah... Maybe... Nah... Brew, bed. Think on it.

king stupid design). By this stage I was committed. This was my last free weekend till September. So knowing the cams were roughly right, I went by their marks and locked it all up. Belt off, pump out, new pump in, tensioner/idler on all as normal. Then belt on. Easy. Still a little puckering though. What if something had slipped? Did I feel the crank move when I tool the pulley off? Nah... Maybe... Nah... Brew, bed. Think on it.The thing I remembered from last time was that with the timing pins in, the valves were at risk, but the pistons were safe, being at the same position in all bores. This nugget in mind...

0745 Sun AM, back out in the workshop cutting up a bit of rod in my new vice on my new bench (obligatory 'best garage on PH shot', woodwork may no longer be this clean):

Anyway. Bit of rod, in through sparkling plug hole on the top of piston 4 (or 1 in 'normal'), with a straight edge across between cam covers. Mark it, move it to cyl 3 and compare. It was a bit unclear so I filed some notches at exactly 1 mm intervals. Pretty close to identical, but not perfect. Little tweak on the crank pulley, lock up the cam pulleys, unlock crank and give it the old 720deg turn. Nothign banged. Camshaft pins not perfect, so went through the process again. Second time lucky, bashed it all back together fired it up and off I went into the sunset.

Not quite. Did a quick gearbox oil change and popped the coolant back in, then off I went into the sunset. Well, it was dark by then, but the old girl is in fine fettle.

Top tip for gearbox oil:

In other news:

I have run into a bit of a brake binding issue over the last few months. Economy taking a 20% hit for a month, rear end sinking under acceleration. You know how it is. Culprit: AlOx all over the place on my O/S R caliper. Now scotchbrited back to life. Zero cost fix. But the piston was a bit pitted. It's only a couple of years old... Fecking non-gen parts.

Also had to replace the only wearing part I know of on an exhaust system, the braided seal thingy between manifold and cat section. I actually bought one about 6 mths ago because I'd not replaced one in the time I've had the car, so it was probably about due... (old on top, new on bottom, both on brand new shiny rough planed oak workbench )

)

I'm also slowly getting on with refurbing the beam that came off last year. It's a bit fooked:

Caught it just in time though. Bearing race has a hole in, but beam tube is just about unmarked...

I'm also fairly sure the cat has collapsed and the shocks could do with replacing. She's a good old girl, but not without issue.

0745 Sun AM, back out in the workshop cutting up a bit of rod in my new vice on my new bench (obligatory 'best garage on PH shot', woodwork may no longer be this clean):

Anyway. Bit of rod, in through sparkling plug hole on the top of piston 4 (or 1 in 'normal'), with a straight edge across between cam covers. Mark it, move it to cyl 3 and compare. It was a bit unclear so I filed some notches at exactly 1 mm intervals. Pretty close to identical, but not perfect. Little tweak on the crank pulley, lock up the cam pulleys, unlock crank and give it the old 720deg turn. Nothign banged. Camshaft pins not perfect, so went through the process again. Second time lucky, bashed it all back together fired it up and off I went into the sunset.

Not quite. Did a quick gearbox oil change and popped the coolant back in, then off I went into the sunset. Well, it was dark by then, but the old girl is in fine fettle.

Top tip for gearbox oil:

- Preheat the bottles on a radiator for an hour beforehand - it pours like water.

- Ickle funnel in a bent bit of 20 mm elec conduit with the end cut on the slant works a treat. Pop it in through the breather and away you go.

In other news:

I have run into a bit of a brake binding issue over the last few months. Economy taking a 20% hit for a month, rear end sinking under acceleration. You know how it is. Culprit: AlOx all over the place on my O/S R caliper. Now scotchbrited back to life. Zero cost fix. But the piston was a bit pitted. It's only a couple of years old... Fecking non-gen parts.

Also had to replace the only wearing part I know of on an exhaust system, the braided seal thingy between manifold and cat section. I actually bought one about 6 mths ago because I'd not replaced one in the time I've had the car, so it was probably about due... (old on top, new on bottom, both on brand new shiny rough planed oak workbench

)

)

I'm also slowly getting on with refurbing the beam that came off last year. It's a bit fooked:

Caught it just in time though. Bearing race has a hole in, but beam tube is just about unmarked...

I'm also fairly sure the cat has collapsed and the shocks could do with replacing. She's a good old girl, but not without issue.

Edited by bitwrx on Monday 18th April 22:32

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff